ISUZU TROOPER 1998 Service Repair Manual

Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1661 of 3573

ENGINE COOLING 6B Ð 7

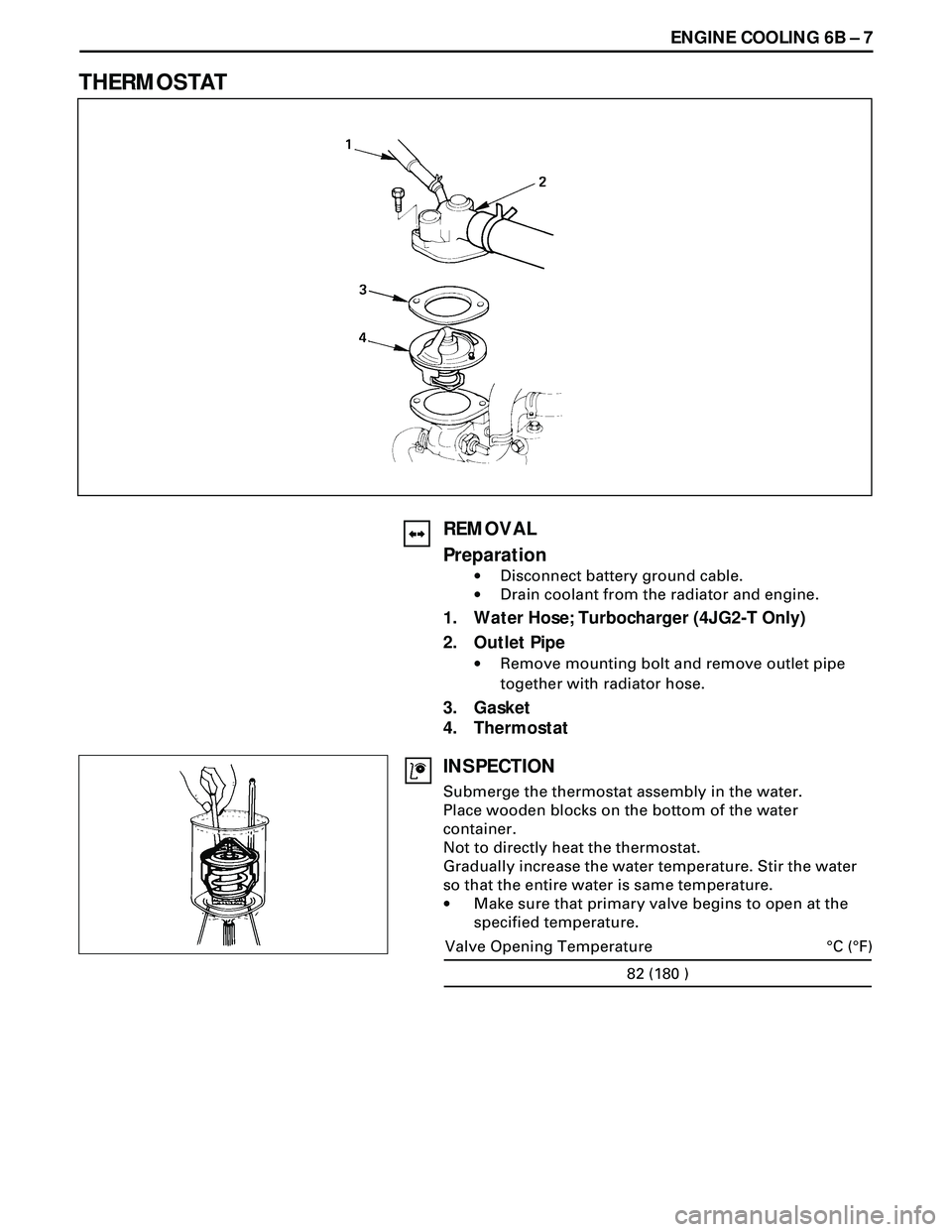

THERMOSTAT

REMOVAL

Preparation

·Disconnect battery ground cable.

·Drain coolant from the radiator and engine.

1. Water Hose; Turbocharger (4JG2-T Only)

2. Outlet Pipe

·Remove mounting bolt and remove outlet pipe

together with radiator hose.

3. Gasket

4. Thermostat

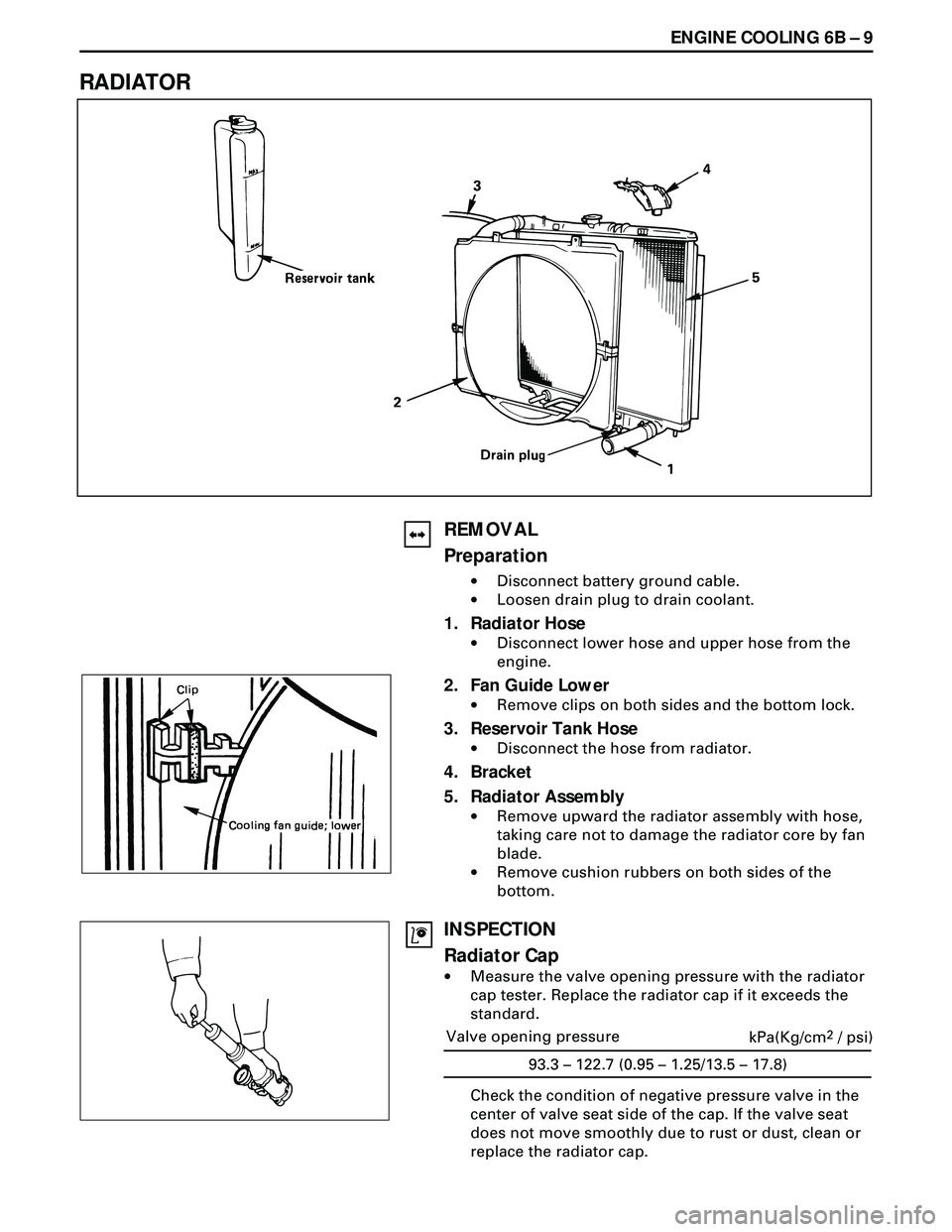

INSPECTION

Submerge the thermostat assembly in the water.

Place wooden blocks on the bottom of the water

container.

Not to directly heat the thermostat.

Gradually increase the water temperature. Stir the water

so that the entire water is same temperature.

·Make sure that primary valve begins to open at the

specified temperature.

82 (180 )

°C (°F) Valve Opening Temperature

Page 1662 of 3573

6B Ð 8 ENGINE COOLING

·Make sure that secondary valve opens fully at the

specified temperature.

Make necessary repair and parts replacement if extreme

wear or damage is found during inspection.

INSTALLATION

4. Thermostat

3. Gasket

2. Outlet Pipe

·Connect outlet pipe and tighten bolts to the

specified torque.

19(1.9/14)

N·m (Kgm/lb·ft)

1. Water Hose: Turbocharger (4JG2-T Only)

·Install battery ground cable.

·Pour coolant,

·Start the engine and check coolant leakage.

95 (203)

°C (°F) Valve Full Open Temperature

Page 1663 of 3573

ENGINE COOLING 6B Ð 9

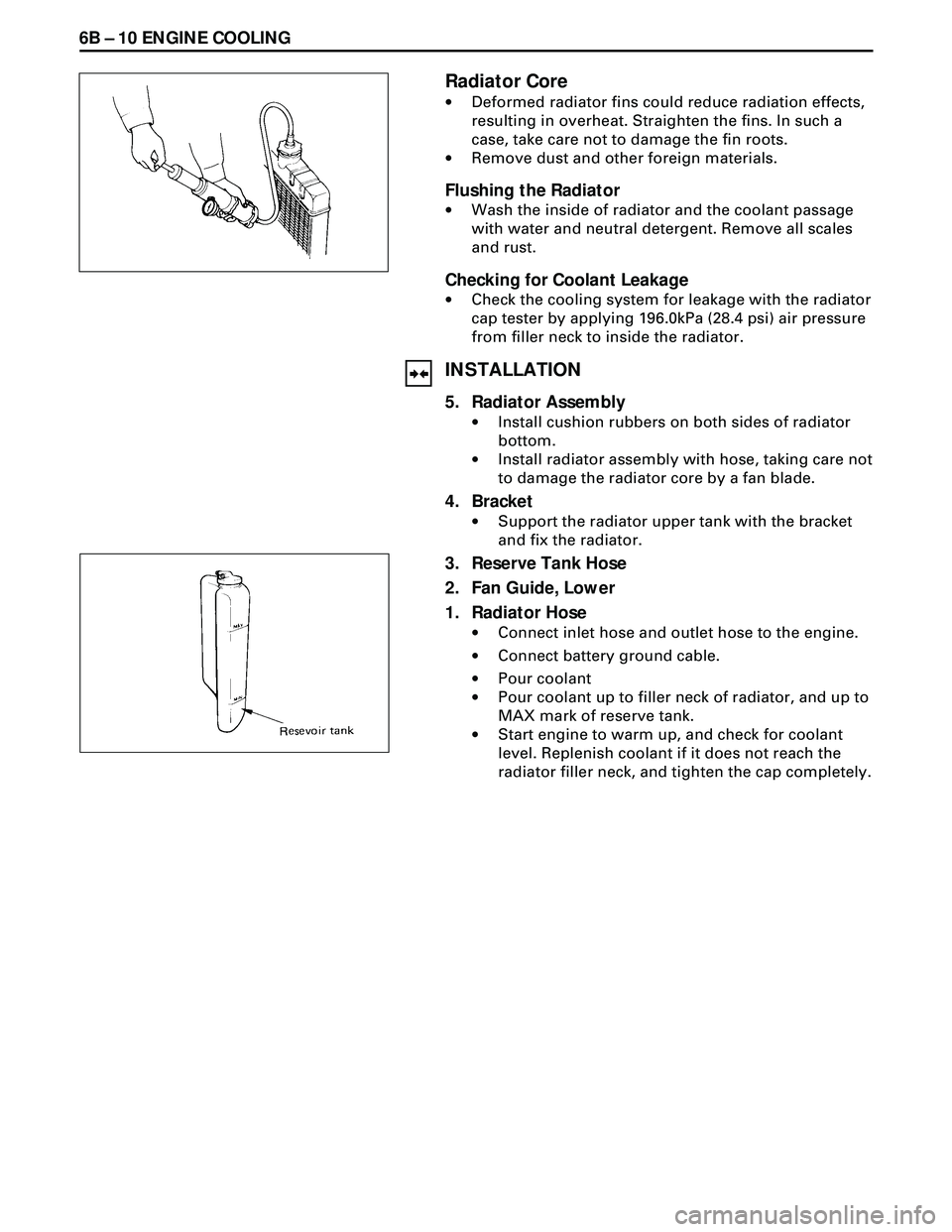

RADIATOR

REMOVAL

Preparation

·Disconnect battery ground cable.

·Loosen drain plug to drain coolant.

1. Radiator Hose

·Disconnect lower hose and upper hose from the

engine.

2. Fan Guide Lower

·Remove clips on both sides and the bottom lock.

3. Reservoir Tank Hose

·Disconnect the hose from radiator.

4. Bracket

5. Radiator Assembly

·Remove upward the radiator assembly with hose,

taking care not to damage the radiator core by fan

blade.

·Remove cushion rubbers on both sides of the

bottom.

INSPECTION

Radiator Cap

·Measure the valve opening pressure with the radiator

cap tester. Replace the radiator cap if it exceeds the

standard.

Check the condition of negative pressure valve in the

center of valve seat side of the cap. If the valve seat

does not move smoothly due to rust or dust, clean or

replace the radiator cap.

Valve opening pressure

93.3 – 122.7 (0.95 – 1.25/13.5 – 17.8)kPa(Kg/cm2 / psi)

Page 1664 of 3573

6B Ð 10 ENGINE COOLING

Radiator Core

·Deformed radiator fins could reduce radiation effects,

resulting in overheat. Straighten the fins. In such a

case, take care not to damage the fin roots.

·Remove dust and other foreign materials.

Flushing the Radiator

·Wash the inside of radiator and the coolant passage

with water and neutral detergent. Remove all scales

and rust.

Checking for Coolant Leakage

·Check the cooling system for leakage with the radiator

cap tester by applying 196.0kPa (28.4 psi) air pressure

from filler neck to inside the radiator.

INSTALLATION

5. Radiator Assembly

·Install cushion rubbers on both sides of radiator

bottom.

·Install radiator assembly with hose, taking care not

to damage the radiator core by a fan blade.

4. Bracket

·Support the radiator upper tank with the bracket

and fix the radiator.

3. Reserve Tank Hose

2. Fan Guide, Lower

1. Radiator Hose

·Connect inlet hose and outlet hose to the engine.

·Connect battery ground cable.

·Pour coolant

·Pour coolant up to filler neck of radiator, and up to

MAX mark of reserve tank.

·Start engine to warm up, and check for coolant

level. Replenish coolant if it does not reach the

radiator filler neck, and tighten the cap completely.

Page 1665 of 3573

ENGINE COOLING 6B Ð 11

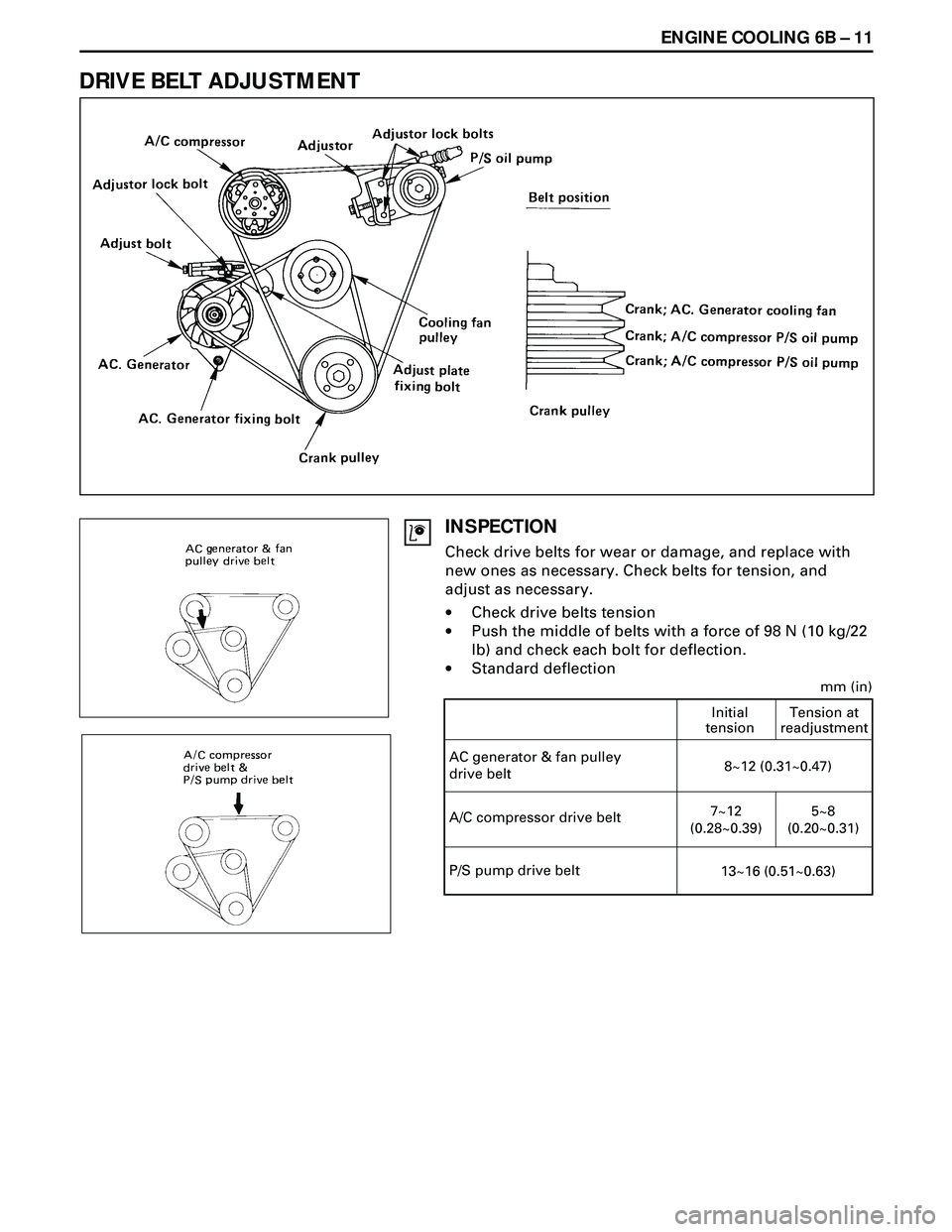

DRIVE BELT ADJUSTMENT

INSPECTION

Check drive belts for wear or damage, and replace with

new ones as necessary. Check belts for tension, and

adjust as necessary.

·Check drive belts tension

·Push the middle of belts with a force of 98 N (10 kg/22

lb) and check each bolt for deflection.

·Standard deflection

AC generator & fan pulley

drive beltInitial

tensionTension at

readjustment8~12 (0.31~0.47)

A/C compressor drive belt7~12

(0.28~0.39)5~8

(0.20~0.31)

mm (in)

P/S pump drive belt

13~16 (0.51~0.63)

Page 1666 of 3573

6B Ð 12 ENGINE COOLING

TENSION ADJUSTMENT

P/S oil pump and A/C compressor pulley belt.

·With P/S pump lock bolt loose, adjust belt tension

with adjust belt.

Cooling fan pulley belt

·With AC Generator mounting and lock bolts loose,

adjust belt tension with adjuster's adjust bolt.

AC generator fixing bolt40 (4.1/30) Torque StandardN·m(Kg·m/lb·ft)

Adjust plate fixing bolt24 (2.4/17)

Adjust plate lock bolt19 (1.9/14)

P/S oil pump adjustor lock bolt37 (3.8/27)

Page 1667 of 3573

FUEL SYSTEM 6C Ð 1

PAGE

General Description ....................................................................................................................... 6C- 1

On-Vehicle Service ......................................................................................................................... 6C- 7

Fuel Filter Assembly .................................................................................................................. 6C- 7

Fuel Filter Cartrige ..................................................................................................................... 6C- 8

Injection nozzle .......................................................................................................................... 6C- 9

Injection Pump Assembly ......................................................................................................... 6C-14

Fuel Tank .................................................................................................................................... 6C-18

Fuel Gauge Unit ......................................................................................................................... 6C-19

Fuel Filler Cap ............................................................................................................................ 6C-20

Accelerator Control ........................................................................................................................ 6C-21

Accelerator Control Cable ........................................................................................................ 6C-21

Accelerator Pedal ...................................................................................................................... 6C-23

Air Cleaner .................................................................................................................................. 6C-24

SECTION 6C

FUEL SYSTEM

CONTENTS

GENERAL DESCRIPTION

When working on the fuel system, there are several

things to keep in mind:

·Any time the fuel system is being worked on,

disconnect the negative battery cable except for

those tests where battery voltage is required.

·Always keep a dry chemical (Class B) fire extin-

guisher near the work area.

·Replace all pipes with the same pipe and fittings

that were removed.

Clean and inspect ÒOÓ rings. Replace where

required.

·Always relieve the line pressure before servicing

any fuel system components.·Do not attempt repairs on the fuel system until

you have read the instructions and checked the

pictures relating to that repair.

Page 1668 of 3573

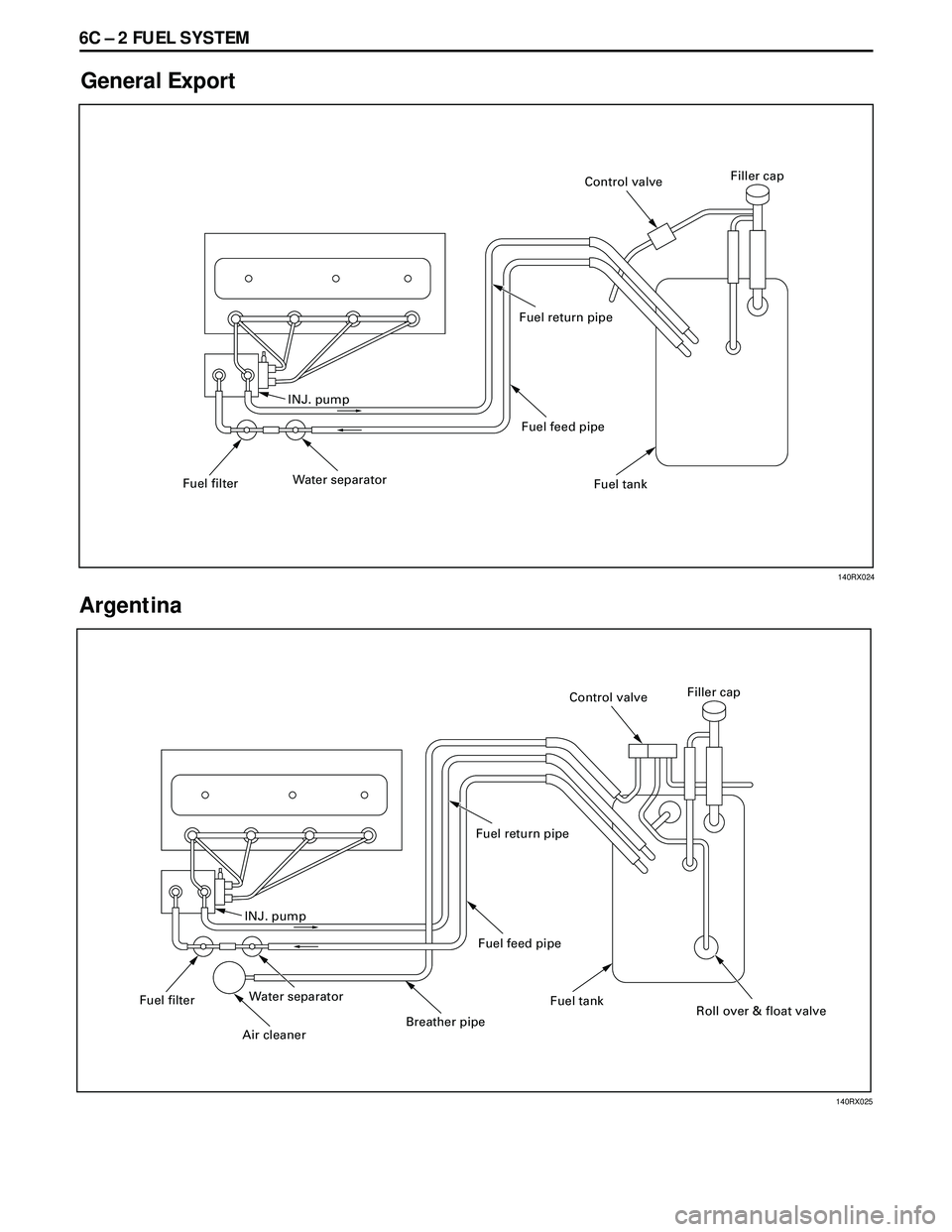

6C Ð 2 FUEL SYSTEM

General Export

Argentina

INJ. pump

Fuel filterWater separatorFuel feed pipe Fuel return pipe

Fuel tankFiller cap

Control valve

INJ. pump

Fuel filterWater separator

Air cleaner

Breather pipeFuel feed pipe Fuel return pipe

Fuel tank

Roll over & float valve Filler cap

Control valve

140RX024

140RX025

Page 1669 of 3573

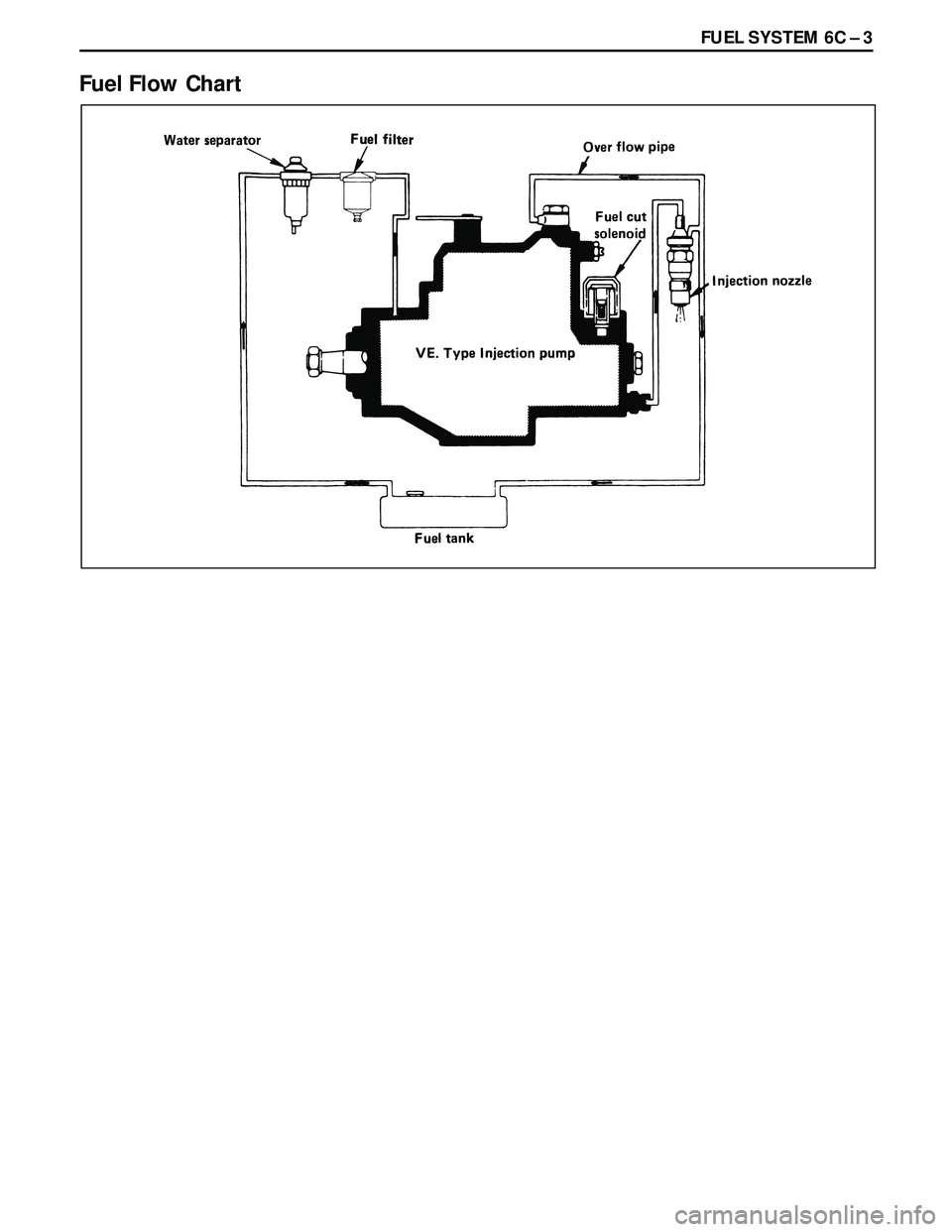

FUEL SYSTEM 6C Ð 3

Fuel Flow Chart

Page 1670 of 3573

6C Ð 4 FUEL SYSTEM

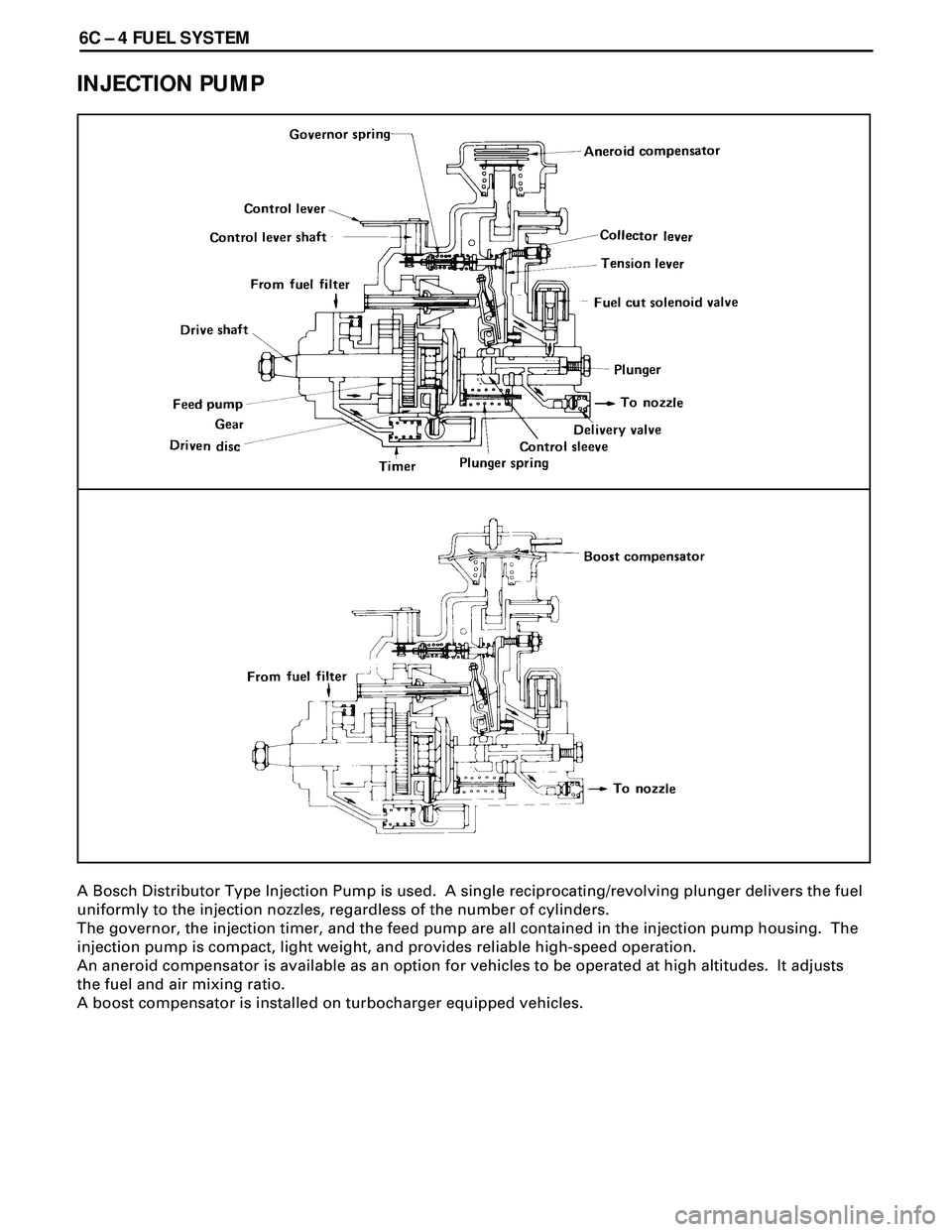

INJECTION PUMP

A Bosch Distributor Type Injection Pump is used. A single reciprocating/revolving plunger delivers the fuel

uniformly to the injection nozzles, regardless of the number of cylinders.

The governor, the injection timer, and the feed pump are all contained in the injection pump housing. The

injection pump is compact, light weight, and provides reliable high-speed operation.

An aneroid compensator is available as an option for vehicles to be operated at high altitudes. It adjusts

the fuel and air mixing ratio.

A boost compensator is installed on turbocharger equipped vehicles.