battery ISUZU TROOPER 1998 Service User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 72 of 3573

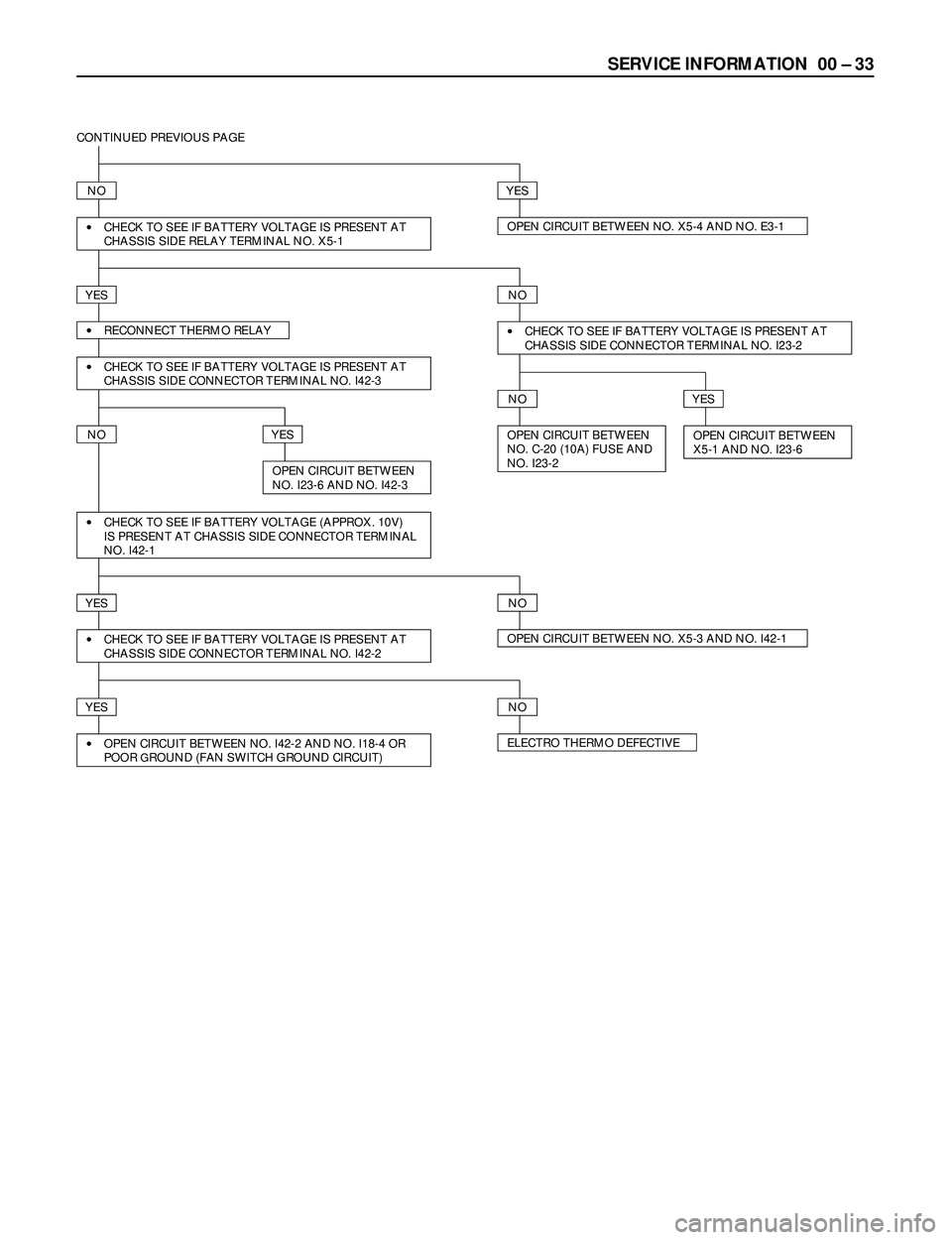

SERVICE INFORMATION 00 Ð 33

CONTINUED PREVIOUS PAGE

NOYES

·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE RELAY TERMINAL NO. X5-1OPEN CIRCUIT BETWEEN NO. X5-4 AND NO. E3-1

YESNO

·RECONNECT THERMO RELAY

·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE CONNECTOR TERMINAL NO. I42-3

·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE CONNECTOR TERMINAL NO. I23-2

NOYES

OPEN CIRCUIT BETWEEN

NO. C-20 (10A) FUSE AND

NO. I23-2OPEN CIRCUIT BETWEEN

X5-1 AND NO. I23-6NOYES

·CHECK TO SEE IF BATTERY VOLTAGE (APPROX. 10V)

IS PRESENT AT CHASSIS SIDE CONNECTOR TERMINAL

NO. I42-1

YESNO

·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE CONNECTOR TERMINAL NO. I42-2OPEN CIRCUIT BETWEEN NO. X5-3 AND NO. I42-1

YESNO

·OPEN CIRCUIT BETWEEN NO. I42-2 AND NO. I18-4 OR

POOR GROUND (FAN SWITCH GROUND CIRCUIT)ELECTRO THERMO DEFECTIVE

OPEN CIRCUIT BETWEEN

NO. I23-6 AND NO. I42-3

Page 73 of 3573

00 Ð 34 SERVICE INFORMATION

4JX1 ENGINE

123

45 6

RELAY; A/C

B-36C-20

10A

A/C FL-1

80A

MAIN

1

2

B-2

C-25

2

4

X-5

1

3

4

13

24

1

A/C SW.

FAN SW.

I-23

PRESSURE

SW.

RELAY;

THERMO

B-2

C-25I-23

BATTERY

1

E-27

MAGNETIC

CLUTCHMg

OFF

I-18

2

6

1

321123

12

34

12

213

5 46

I-18

X-5

B-1(LHD) (RHD)

3

1

2ELECTRONIC

THERMOSTAT

I-42

B-1

1

2 34

W/ CONDENSER

FAN

I-42B-36

E-27

11

D08RY00170

Page 74 of 3573

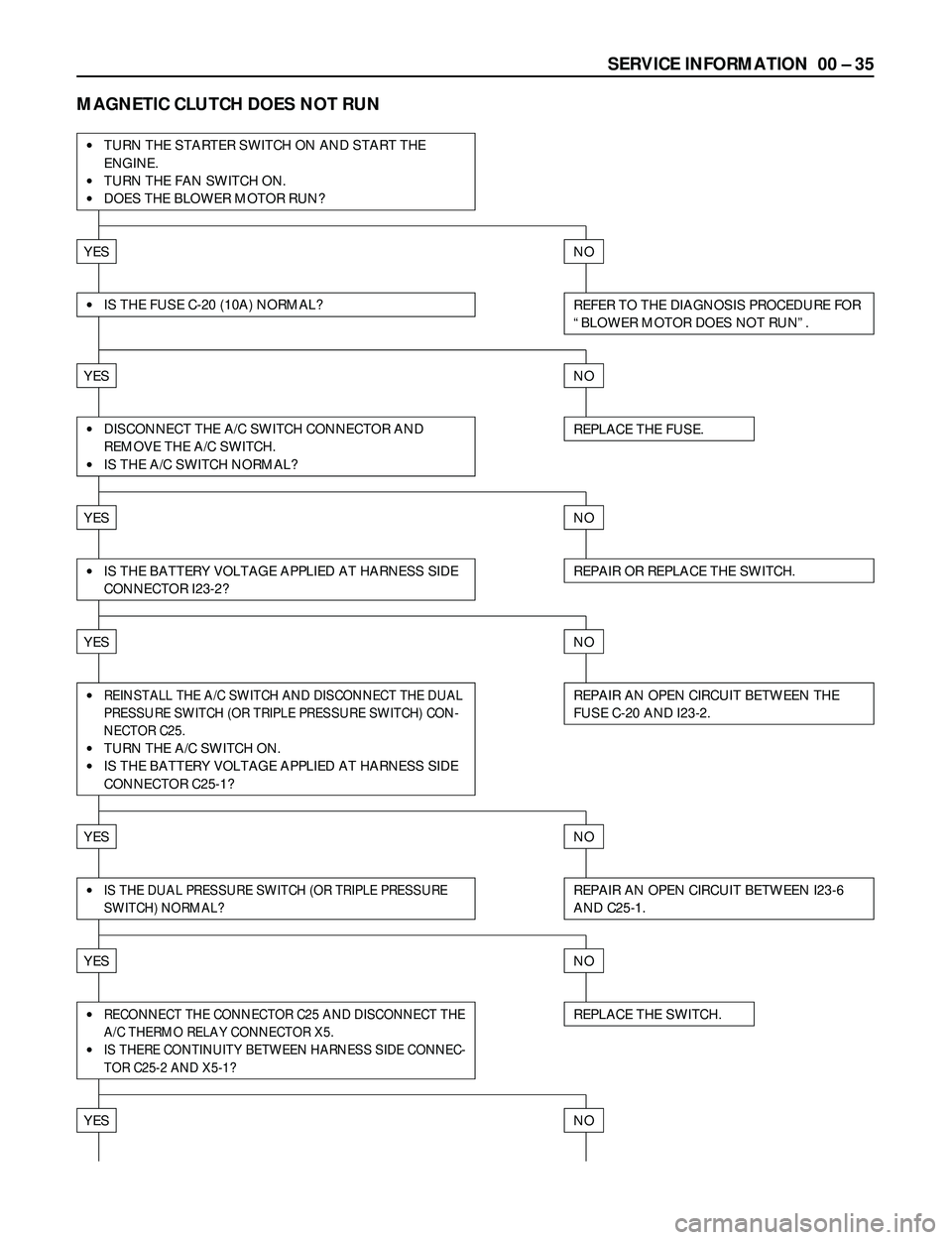

SERVICE INFORMATION 00 Ð 35

MAGNETIC CLUTCH DOES NOT RUN

·TURN THE STARTER SWITCH ON AND START THE

ENGINE.

·TURN THE FAN SWITCH ON.

·DOES THE BLOWER MOTOR RUN?

YESNO

REFER TO THE DIAGNOSIS PROCEDURE FOR

ÒBLOWER MOTOR DOES NOT RUNÓ.·IS THE FUSE C-20 (10A) NORMAL?

YESNO

REPLACE THE FUSE.·DISCONNECT THE A/C SWITCH CONNECTOR AND

REMOVE THE A/C SWITCH.

·IS THE A/C SWITCH NORMAL?

YESNO

YESNO

REPAIR AN OPEN CIRCUIT BETWEEN THE

FUSE C-20 AND I23-2.·REINSTALL THE A/C SWITCH AND DISCONNECT THE DUAL

PRESSURE SWITCH (OR TRIPLE PRESSURE SWITCH) CON-

NECTOR C25.

·TURN THE A/C SWITCH ON.

·IS THE BATTERY VOLTAGE APPLIED AT HARNESS SIDE

CONNECTOR C25-1?

YESNO

REPLACE THE SWITCH.·RECONNECT THE CONNECTOR C25 AND DISCONNECT THE

A/C THERMO RELAY CONNECTOR X5.

·IS THERE CONTINUITY BETWEEN HARNESS SIDE CONNEC-

TOR C25-2 AND X5-1?

YESNO

REPAIR AN OPEN CIRCUIT BETWEEN I23-6

AND C25-1.·IS THE DUAL PRESSURE SWITCH (OR TRIPLE PRESSURE

SWITCH) NORMAL?

YESNO

REPAIR OR REPLACE THE SWITCH.·IS THE BATTERY VOLTAGE APPLIED AT HARNESS SIDE

CONNECTOR I23-2?

Page 75 of 3573

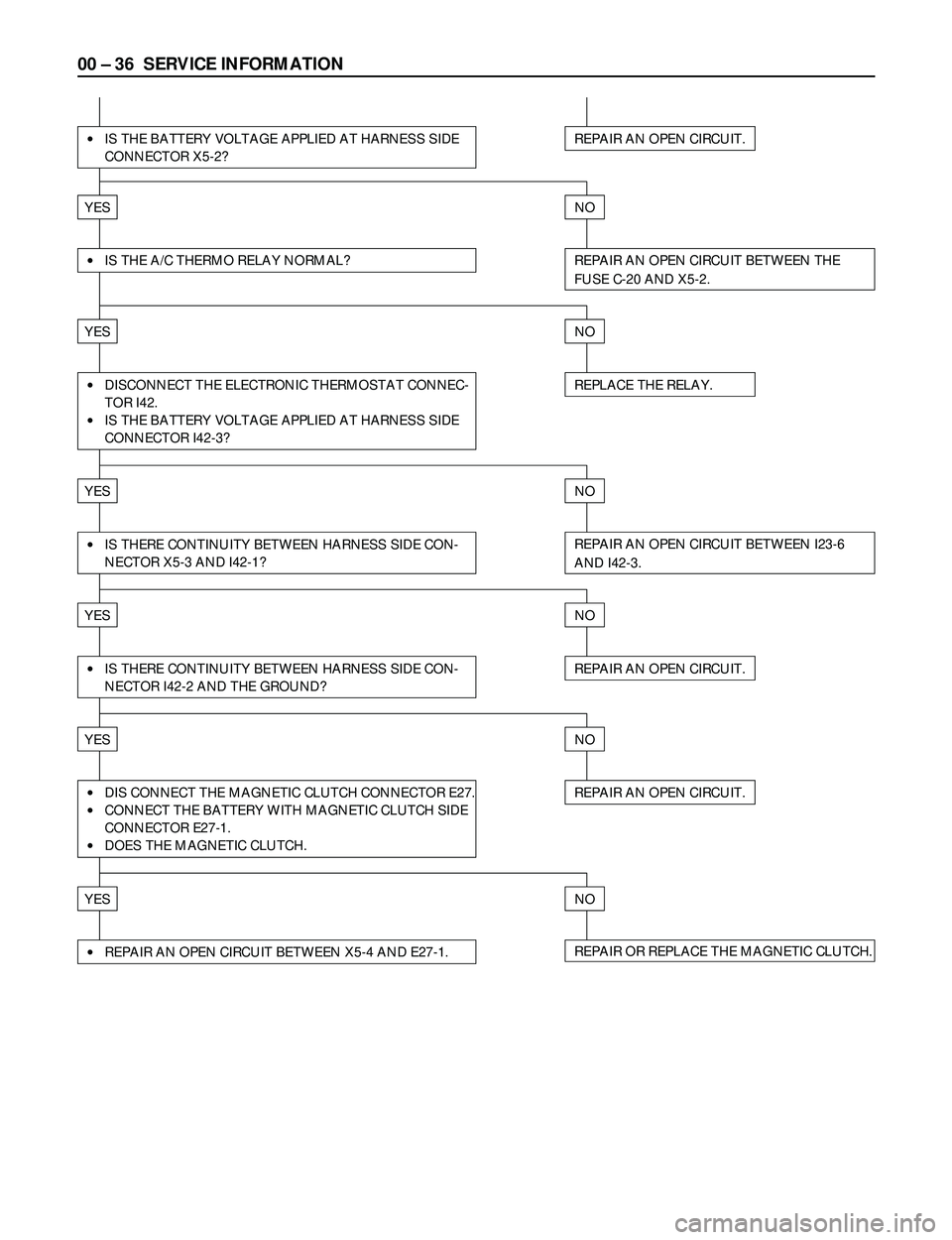

00 Ð 36 SERVICE INFORMATION

·IS THE BATTERY VOLTAGE APPLIED AT HARNESS SIDE

CONNECTOR X5-2?REPAIR AN OPEN CIRCUIT.

YESNO

·IS THE A/C THERMO RELAY NORMAL?REPAIR AN OPEN CIRCUIT BETWEEN THE

FUSE C-20 AND X5-2.

YESNO

·DISCONNECT THE ELECTRONIC THERMOSTAT CONNEC-

TOR I42.

·IS THE BATTERY VOLTAGE APPLIED AT HARNESS SIDE

CONNECTOR I42-3?

YESNO

·IS THERE CONTINUITY BETWEEN HARNESS SIDE CON-

NECTOR X5-3 AND I42-1?REPAIR AN OPEN CIRCUIT BETWEEN I23-6

AND I42-3.

YESNO

REPAIR AN OPEN CIRCUIT.

YESNO

·IS THERE CONTINUITY BETWEEN HARNESS SIDE CON-

NECTOR I42-2 AND THE GROUND?REPAIR AN OPEN CIRCUIT.

REPLACE THE RELAY.

·DIS CONNECT THE MAGNETIC CLUTCH CONNECTOR E27.

·CONNECT THE BATTERY WITH MAGNETIC CLUTCH SIDE

CONNECTOR E27-1.

·DOES THE MAGNETIC CLUTCH.

YESNO

REPAIR OR REPLACE THE MAGNETIC CLUTCH.·REPAIR AN OPEN CIRCUIT BETWEEN X5-4 AND E27-1.

Page 80 of 3573

SERVICE INFORMATION 00 Ð 41

I-18 I-23

123456126

OFF

1

FAN SW. 2

3

4

OFF

A/C SW.

ON

FAN CONTROL KNOB (FAN SWITCH) AND A/C

SWITCH

INDIVIDUAL INSPECTION

Check for continuity between fan switch and A/C switch

side connector terminals.

2

65 4 31362

51

4

I-23I-18

I-23I-18

5

A/C SW. BEZEL

ILLUMI-

NATION

FAN SW. OFF1

2

3

4 32 6 1253641

HEATER & A/C, THERMOSTAT, COMPRESSOR,

CONDENSER FAN AND CERAMIC HEATER RELAY

Check for continuity between the relay terminals.

2Ð 4..... No continuity

(When battery voltage is applied between 1Ð 3)

2Ð 4..... Continuity

2

2

1

144

3

3

Terminal

No. SW.

position

DUAL PRESSURE SWITCH

21

Disconnect pressure switch connector and check for

continuity between pressure switch side connector

terminals.

Page 81 of 3573

00 Ð 42 SERVICE INFORMATION

TRIPLE PRESSURE SWITCH (W/CONDENSER FAN)

43

12

1) Disconnect the connector and check for continuity

between pressure switch side connector terminal.

2) Reconnect the connector to activate the A/C switch,

and check to see if there is continuity between the

chassis side connectors and the fan operates.

[A/C OFF]

[A/C ON]

Terminal No. Control Continuity

1- 2Magnetic Clutch Continuity

3- 4Condenser Fan No Continuity

Terminal

Refrigerant Pressure Continuity Fan

No.

1079±98 kPa No

OFF

(11.0±1.0 kgácm

2/ 156±14 psi) Continuity

3- 4

1471±98 kPa

Continuity ON

(15.0±1.0 kgácm

2/ 213±14 psi)

BLOWER MOTOR

1

2

1) Disconnect the blower motor (B-5) connector from

the blower motor.

2) Connect the battery positive terminal to the No. 1

(NO.2; RHD) terminal of the blower motor and

negative to the No. 2 (NO. 1; RHD).

3) Be sure to check to see if the blower motor operates

correctly.

Terminal Normal

SW. No.12346Operating

position Resistance

2.4W

0.90W

0.28W

Ð 1

2

3

4

RESISTOR

14263

2

Motor3641

432

(SW.position) (Connector

terminal)

1

1) Disconnect resistor (I-41) connector.

2) Check for continuity and resistance between the

terminals of the resistor.

Page 82 of 3573

SERVICE INFORMATION 00 Ð 43

CONDENSER FAN

1 2

THERMO SWITCH (ENGINE)

1 2

1) Disconnect the condenser fan connector (C-75).

2) Connect the battery positive terminal to the No. 1

terminal and negative to No. 2.

3) Be sure to check to see if condenser fan operates

correctly.

With the environmental temperature of the switch set to

the following conditions, check to see if there is any

continuity between the switch side connector terminals.

Ambient Terminal

Continuity

Temperature No.

Above 77 Ð 83°C

1Ð 2No Continuity

(170.6Ð181.4°F)

CERAMIC HEATER

1

2

Ceramic heater

Disconnect the ceramic heater connector and check for

continuity between ceramic heater side connector

terminals.

Connector No. B-48

Terminal 1 2

Continuity

Page 102 of 3573

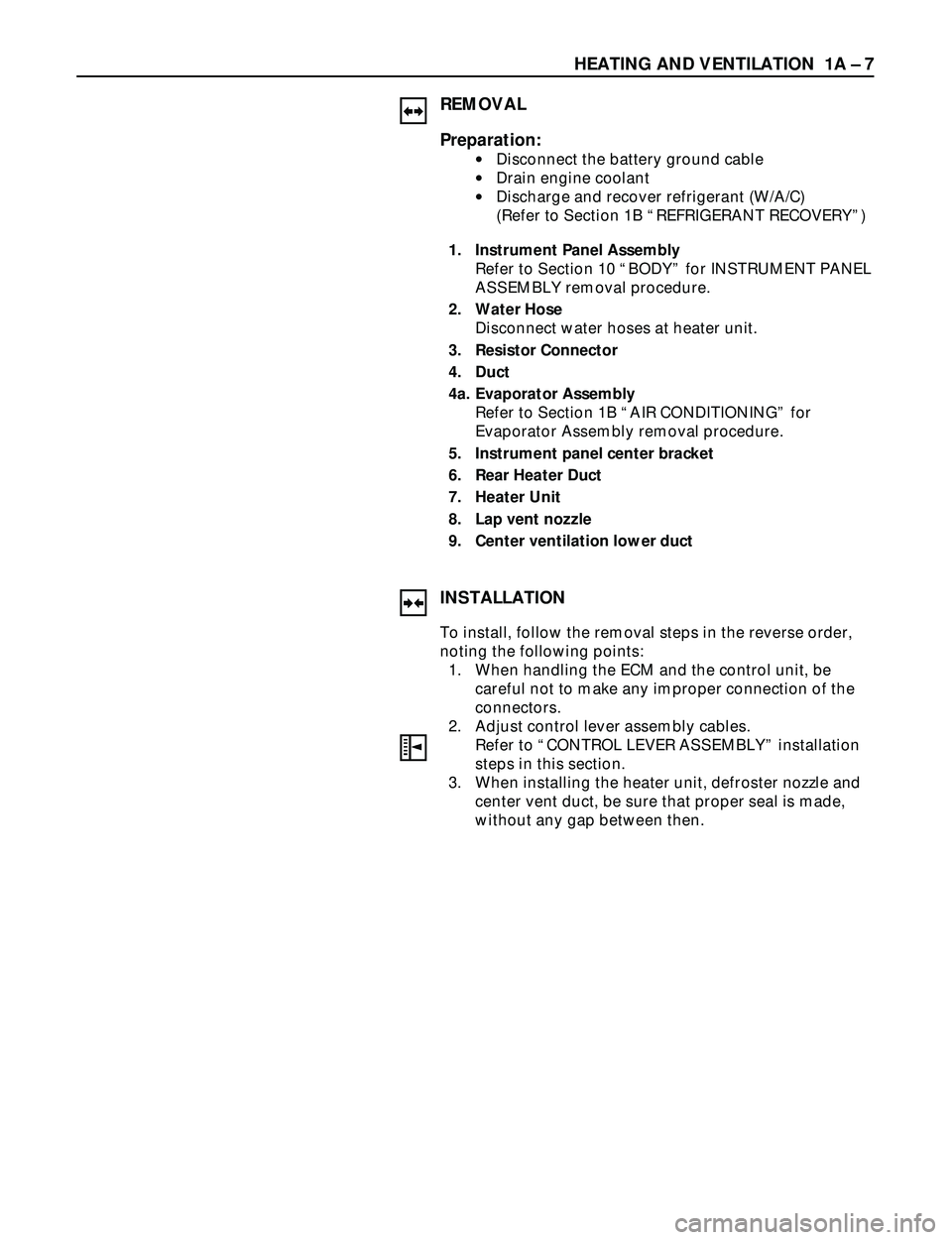

HEATING AND VENTILATION 1A Ð 7

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. When handling the ECM and the control unit, be

careful not to make any improper connection of the

connectors.

2. Adjust control lever assembly cables.

Refer to ÒCONTROL LEVER ASSEMBLYÓ installation

steps in this section.

3. When installing the heater unit, defroster nozzle and

center vent duct, be sure that proper seal is made,

without any gap between then.

REMOVAL

Preparation:

·Disconnect the battery ground cable

·Drain engine coolant

·Discharge and recover refrigerant (W/A/C)

(Refer to Section 1B ÒREFRIGERANT RECOVERYÓ)

1. Instrument Panel Assembly

Refer to Section 10 ÒBODYÓ for INSTRUMENT PANEL

ASSEMBLY removal procedure.

2. Water Hose

Disconnect water hoses at heater unit.

3. Resistor Connector

4. Duct

4a. Evaporator Assembly

Refer to Section 1B ÒAIR CONDITIONINGÓ for

Evaporator Assembly removal procedure.

5. Instrument panel center bracket

6. Rear Heater Duct

7. Heater Unit

8. Lap vent nozzle

9. Center ventilation lower duct

Page 104 of 3573

HEATING AND VENTILATION 1A Ð 9

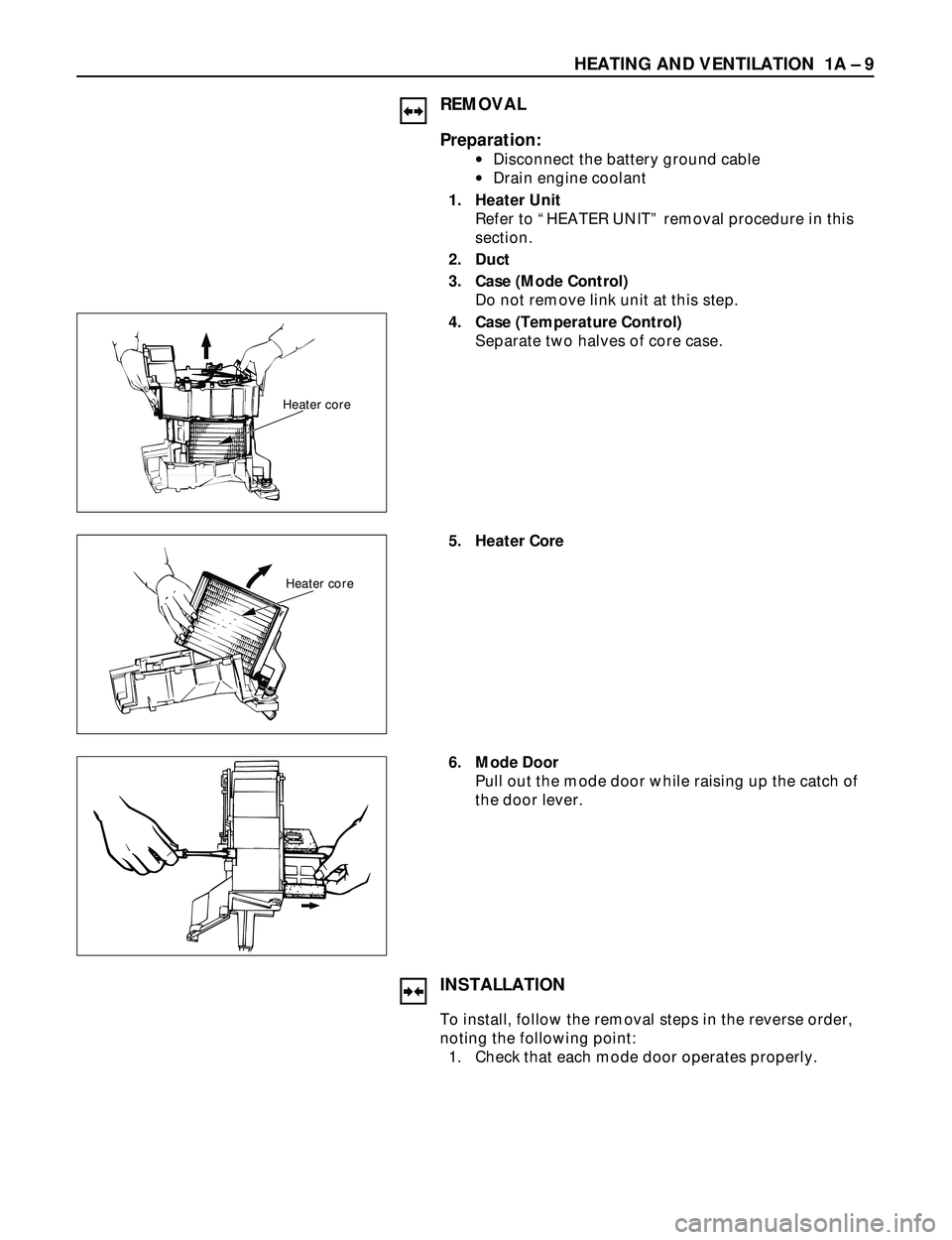

REMOVAL

Preparation:

·Disconnect the battery ground cable

·Drain engine coolant

1. Heater Unit

Refer to ÒHEATER UNITÓ removal procedure in this

section.

2. Duct

3. Case (Mode Control)

Do not remove link unit at this step.

4. Case (Temperature Control)

Separate two halves of core case.

Heater core

5. Heater Core

Heater core

6. Mode Door

Pull out the mode door while raising up the catch of

the door lever.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following point:

1. Check that each mode door operates properly.

Page 106 of 3573

HEATING AND VENTILATION 1A Ð 11

REMOVAL

Preparation:

·Disconnect the battery ground cable

·Drain engine coolant

1. Heater Unit

Refer to ÒHEATER UNITÓ removal procedure in this

section.

2. Case (Mode Control)

Remove the case (Mode control) from heater unit.

3. Washer and Mode Main Lever

4. Rod

5. Mode Sub-Lever

Press the tab of the sub-lever inward, and take out the

sub-lever.

6. Door Lever

Pull out the door lever while raising up the catch of

the door lever.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. Apply grease to mode sub-lever and to the abrasive

surface of the heater unit.

2. After installing the link unit, check to see if the link

unit operates correctly.