cooling ISUZU TROOPER 1998 Service User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 130 of 3573

1B Ð 4 AIR CONDITIONING

The refrigeration cycle includes the following four

processes as the refrigerant changes repeatedly

from liquid to gas and back to liquid while

circulating.

EVAPORATION

The refrigerant is changed from a liquid to a gas

inside the evaporator. The refrigerant mist that

enters the evaporator vaporizes readily. The liquid

refrigerant removes the required quantity of heat

(latent heat of vaporization) from the air around the

evaporator core cooling fins and rapidly vaporizes.

Removing the heat cools the air, which is then

radiated from the fins and lowers the temperature

of the air inside the vehicle.

The refrigerant liquid sent from the expansion valve

and the vaporized refrigerant gas are both present

inside the evaporator and the liquid is converted to

gas.

With this change from liquid to gas, the pressure

inside the evaporator must be kept low enough for

vaporization to occur at a lower temperature.

Because of that, the vaporized refrigerant is sucked

into the compressor.

COMPRESSION

The refrigerant is compressed by the compressor

until it is easily liquefied at normal temperature.

The vaporized refrigerant in the evaporator is

sucked into the compressor. This action maintains

the refrigerant inside the evaporator at a low

pressure so that it can easily vaporize, even at low

temperatures close to 0¡C (32¡F).

Also, the refrigerant sucked into the compressor is

compressed inside the cylinder to increase the

pressure and temperature to values such that the

refrigerant can easily liquefy at normal ambient

temperatures.

CONDENSATION

The refrigerant inside the condenser is cooled by

the outside air and changes from gas to liquid.

The high temperature, high pressure gas coming

from the compressor is cooled and liquefied by the

condenser with outside air and accumulated in the

receiver/drier. The heat radiated to the outside air

by the high temperature, high pressure gas in the

compressor is called heat of condensation. This is

the total quantity of heat (heat of vaporization) the

refrigerant removes from the vehicle interior via the

evaporator and the work (calculated as the quantity

of heat) performed for compression.

EXPANSION

The expansion valve lowers the pressure of the

refrigerant liquid so that it can easily vaporize.

The process of lowering the pressure to encourage

vaporization before the liquefied refrigerant is sent

to the evaporator is called expansion. In addition,

the expansion valve controls the flow rate of the

refrigerant liquid while decreasing the pressure.

That is, the quantity of refrigerant liquid vaporized

inside the evaporator is determined by the quantity

of heat which must be removed at a prescribed

vaporization temperature. It is important that the

quantity of refrigerant be controlled to exactly the

right value.

COMPRESSOR

The compressor performs two main functions:

It compresses low-pressure and low-temperature

refrigerant vapor from the evaporator into high-

pressure and high-temperature refrigerant vapor to

the condenser. And it pumps refrigerant and

refrigerant oil through the A/C system.

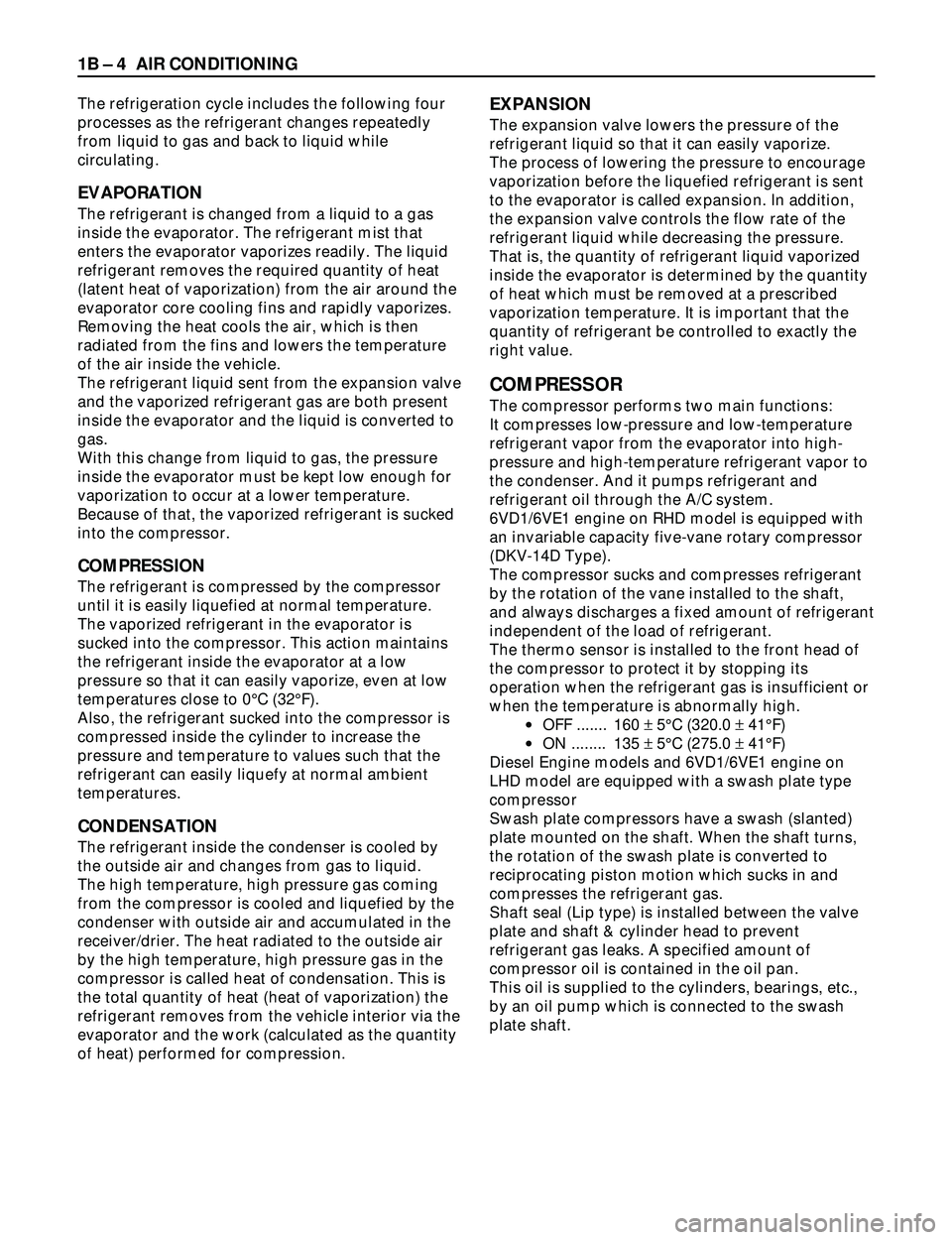

6VD1/6VE1 engine on RHD model is equipped with

an invariable capacity five-vane rotary compressor

(DKV-14D Type).

The compressor sucks and compresses refrigerant

by the rotation of the vane installed to the shaft,

and always discharges a fixed amount of refrigerant

independent of the load of refrigerant.

The thermo sensor is installed to the front head of

the compressor to protect it by stopping its

operation when the refrigerant gas is insufficient or

when the temperature is abnormally high.

·OFF ....... 160 ±5¡C (320.0 ±41¡F)

·ON ........ 135 ±5¡C (275.0 ±41¡F)

Diesel Engine models and 6VD1/6VE1 engine on

LHD model are equipped with a swash plate type

compressor

Swash plate compressors have a swash (slanted)

plate mounted on the shaft. When the shaft turns,

the rotation of the swash plate is converted to

reciprocating piston motion which sucks in and

compresses the refrigerant gas.

Shaft seal (Lip type) is installed between the valve

plate and shaft & cylinder head to prevent

refrigerant gas leaks. A specified amount of

compressor oil is contained in the oil pan.

This oil is supplied to the cylinders, bearings, etc.,

by an oil pump which is connected to the swash

plate shaft.

Page 131 of 3573

AIR CONDITIONING 1B Ð 5

With some compressors the differential between

the intake pressure and discharge pressure

generated while the compressor is operating is

used for lubrication instead of an oil pump.

The specified amount of the DKV-14D, DKS-15CH

and HD6 compressors oil is 150cc (4.2 Imp fl oz).

Also, compressor oil to be used varies according to

the compressor model. Be sure to avoid mixing

two or more different types of oil.

If the wrong oil is used, lubrication will be poor and

the compressor will seize or malfunction.

The magnetic clutch connector is a waterproof type.

MAGNETIC CLUTCH

The compressor is driven by the drive belt from the

crank pulley of the engine. If the compressor is

activated each time the engine is started, this

causes too much load to the engine. The magnetic

clutch transmits the power from the engine to the

compressor and activates it when the air

conditioning is ÒONÓ. Also, it cuts off the power

from the engine to the compressor when the air

conditioning is ÒOFFÓ. (Magnetic clutch repair

procedure can be found in Section 1D.)

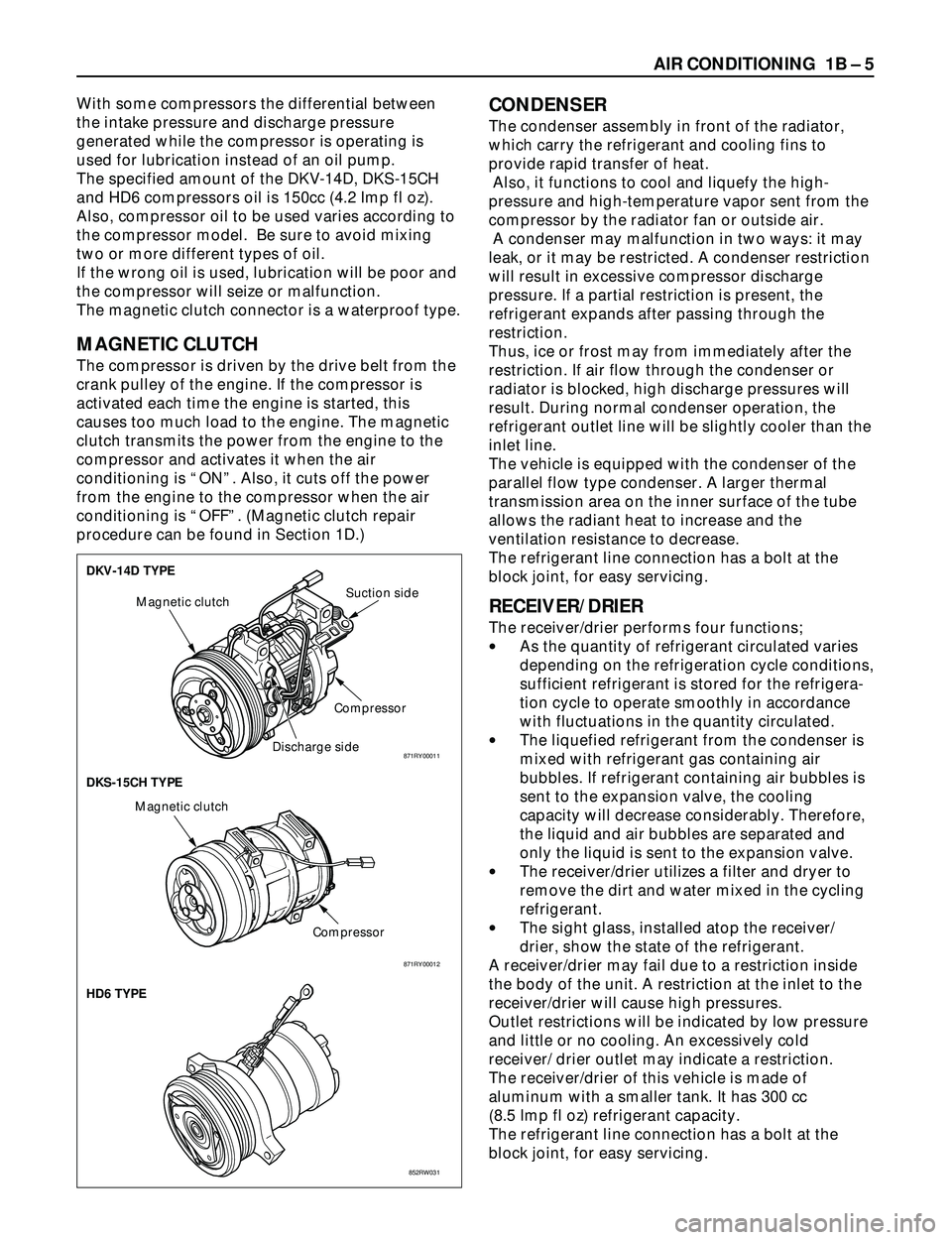

CONDENSER

The condenser assembly in front of the radiator,

which carry the refrigerant and cooling fins to

provide rapid transfer of heat.

Also, it functions to cool and liquefy the high-

pressure and high-temperature vapor sent from the

compressor by the radiator fan or outside air.

A condenser may malfunction in two ways: it may

leak, or it may be restricted. A condenser restriction

will result in excessive compressor discharge

pressure. If a partial restriction is present, the

refrigerant expands after passing through the

restriction.

Thus, ice or frost may from immediately after the

restriction. If air flow through the condenser or

radiator is blocked, high discharge pressures will

result. During normal condenser operation, the

refrigerant outlet line will be slightly cooler than the

inlet line.

The vehicle is equipped with the condenser of the

parallel flow type condenser. A larger thermal

transmission area on the inner surface of the tube

allows the radiant heat to increase and the

ventilation resistance to decrease.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

RECEIVER/DRIER

The receiver/drier performs four functions;

·As the quantity of refrigerant circulated varies

depending on the refrigeration cycle conditions,

sufficient refrigerant is stored for the refrigera-

tion cycle to operate smoothly in accordance

with fluctuations in the quantity circulated.

·The liquefied refrigerant from the condenser is

mixed with refrigerant gas containing air

bubbles. If refrigerant containing air bubbles is

sent to the expansion valve, the cooling

capacity will decrease considerably. Therefore,

the liquid and air bubbles are separated and

only the liquid is sent to the expansion valve.

·The receiver/drier utilizes a filter and dryer to

remove the dirt and water mixed in the cycling

refrigerant.

·The sight glass, installed atop the receiver/

drier, show the state of the refrigerant.

A receiver/drier may fail due to a restriction inside

the body of the unit. A restriction at the inlet to the

receiver/drier will cause high pressures.

Outlet restrictions will be indicated by low pressure

and little or no cooling. An excessively cold

receiver/ drier outlet may indicate a restriction.

The receiver/drier of this vehicle is made of

aluminum with a smaller tank. It has 300 cc

(8.5 Imp fl oz) refrigerant capacity.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

DKV-14D TYPE

DKS-15CH TYPE

HD6 TYPE

Magnetic clutch

CompressorSuction side

Discharge side

Compressor Magnetic clutch

852RW031 871RY00012

871RY00011

Page 132 of 3573

1B Ð 6 AIR CONDITIONING

DUAL PRESSURE SWITCH

The dual pressure switch is installed on the upper

part of the receiver/drier, to detect excessively high

pressure (high pressure switch) and prevent

compressor seizure due to the refrigerant leaking

(low pressure switch), switching the compressor

ÒONÓ or ÒOFFÓ as required.

The pressure switch connector is waterproof type.

·Low-pressure control kpa (kgácm

2/ PSI)

Compressor

ON: 205.9 ± 30 (2.1 ± 0.3 / 30 ± 4)

(Except 6VD1 / 6VE1, LHD model)

186 ± 30 (1.9 ± 0.3 / 27 ± 4)

(only for 6VD1 / 6VE1, LHD model)

OFF: 176 ± 20 (1.8 ± 0.2 / 26 ± 3)

·High-pressure control

Compressor

ON: 2354 ± 196 (24.0 ± 2.0 / 341 ± 28)

OFF: 2942 ± 196 (30.0 ± 2.0 / 427 ± 28)

TRIPLE PRESSURE SWITCH

Triple pressure switch is installed atop the receiver/

drier. This switch is constructed with a unitized type

of two switches. One of them is a low and high

pressure switch (Dual pressure switch) to switch

ÒONÓ or ÒOFFÓ the magnetic clutch as a result of

irregularly high-pressure or low-pressure of the

refrigerant. The other one is a medium pressure

switch (Cycling switch) to switch ÒONÓ or ÒOFFÓ

the condenser fan sensing the condenser high side

pressure.·Low-pressure control kpa (kgácm

2/PSI)

Compressor

ON: 186 ± 30 (1.9 ± 0.3 / 27 ± 4)

OFF: 176 ± 20 (1.8 ± 0.2 / 26 ± 3)

·Medium-pressure control

Condenser fan

ON: 1471 ± 98 (15.0 ± 1.0 / 213 ± 14)

OFF: 1079 ± 98 (11.0 ± 1.0 / 156 ± 14)

·High-pressure control

Compressor

ON: 2354 ± 196 (24.0 ± 2.0 / 341 ± 28)

OFF: 2942 ± 196 (30.0 ± 2.0 / 427 ± 28)

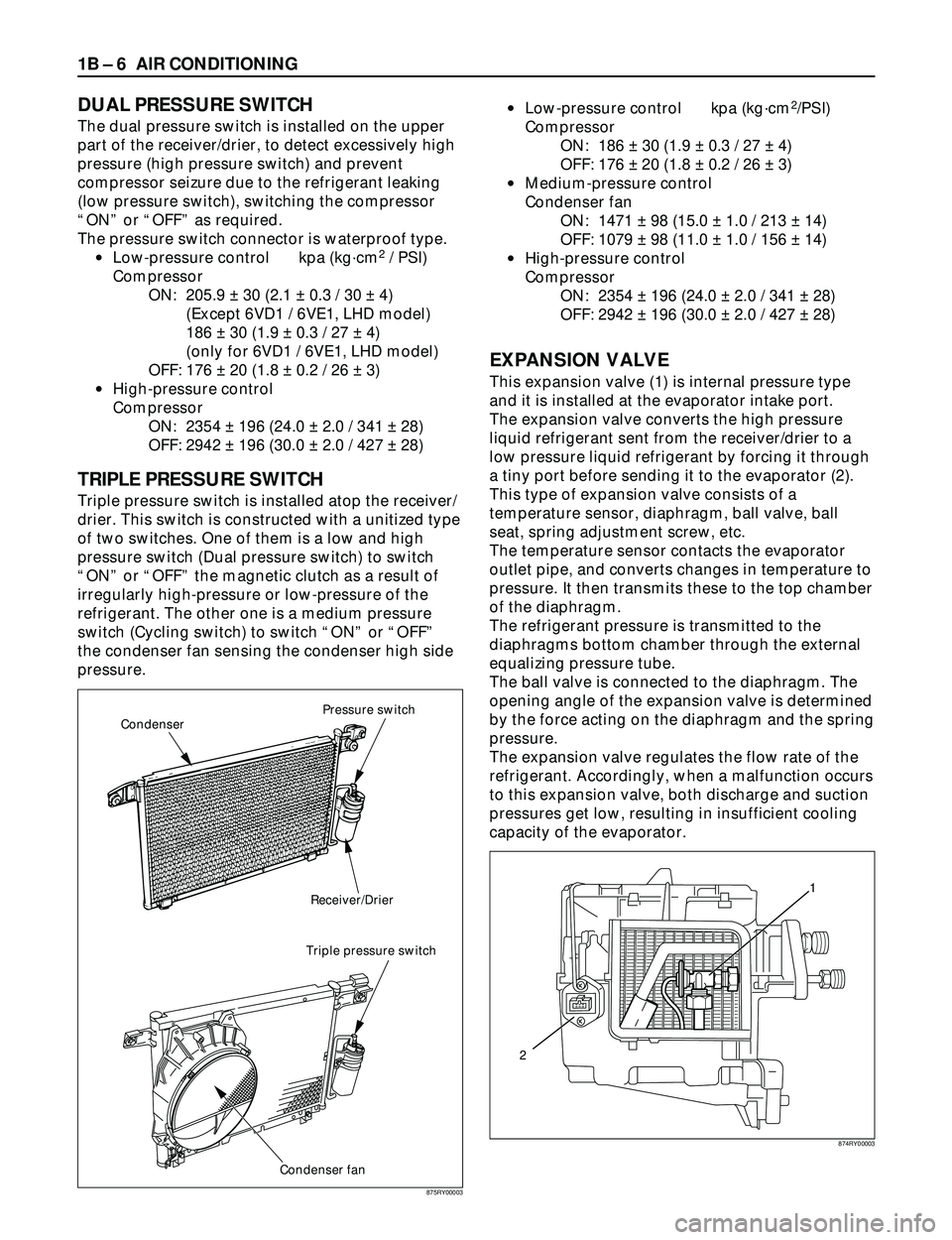

EXPANSION VALVE

This expansion valve (1) is internal pressure type

and it is installed at the evaporator intake port.

The expansion valve converts the high pressure

liquid refrigerant sent from the receiver/drier to a

low pressure liquid refrigerant by forcing it through

a tiny port before sending it to the evaporator (2).

This type of expansion valve consists of a

temperature sensor, diaphragm, ball valve, ball

seat, spring adjustment screw, etc.

The temperature sensor contacts the evaporator

outlet pipe, and converts changes in temperature to

pressure. It then transmits these to the top chamber

of the diaphragm.

The refrigerant pressure is transmitted to the

diaphragms bottom chamber through the external

equalizing pressure tube.

The ball valve is connected to the diaphragm. The

opening angle of the expansion valve is determined

by the force acting on the diaphragm and the spring

pressure.

The expansion valve regulates the flow rate of the

refrigerant. Accordingly, when a malfunction occurs

to this expansion valve, both discharge and suction

pressures get low, resulting in insufficient cooling

capacity of the evaporator.

Pressure switch

Receiver/Drier

Triple pressure switch

Condenser fan Condenser

1

2

875RY00003874RY00003

Page 133 of 3573

AIR CONDITIONING 1B Ð 7

EVAPORATOR

The evaporator cools and dehumidifies the air

before the air enters the vehicle. High-pressure

liquid refrigerant flows through the expansion valve

(1) into the low-pressure area of the evaporator (2).

The heat in the air passing through the evaporator

core is lost to the cooler surface of the core, thereby

cooling the air.

As heat is lost between the air and the evaporator

core surface, moisture in the vehicle condenses on

the outside surface of the evaporator core and is

drained off as water.

When the evaporator malfunctions, the trouble will

show up as inadequate supply of cool air. The

cause is typically a partially plugged core due to

dirt, or a malfunctioning blower motor.

The evaporator core with a laminate louver fin is a

single-sided tank type where only one tank is

provided under the core.

ELECTRONIC THERMOSTAT

The thermostat consists of the thermosensor (1)

and thermostat unit (4) which functions electrically

to reduce the noises being generated while the

system is in operation.

The electronic thermosensor (1) is mounted at the

evaporator core (2) outlet and senses the

temperature of the cool air from the evaporator (3).

Temperature signals are input to the thermostat

unit. This information is compared by the thermo

unit and the results in output to operate the A/C

Thermostat relay and turn the magnetic clutch

ÒONÓ or ÒOFFÓ to prevent evaporator freeze-up.

A characteristic of the sensor is that the resistance

decreases as the temperature increases and the

resistance increases as the temperature decreases.

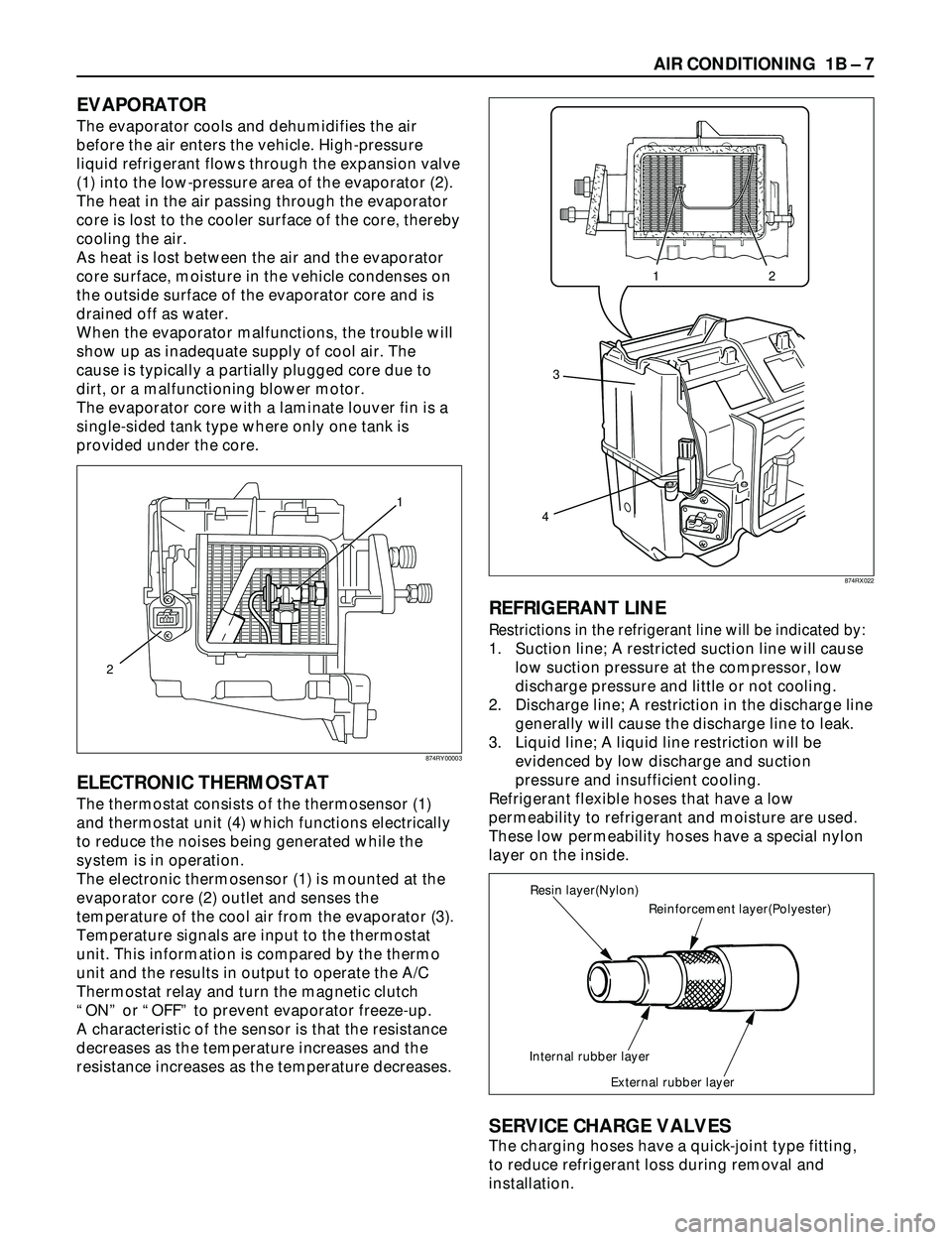

REFRIGERANT LINE

Restrictions in the refrigerant line will be indicated by:

1. Suction line; A restricted suction line will cause

low suction pressure at the compressor, low

discharge pressure and little or not cooling.

2. Discharge line; A restriction in the discharge line

generally will cause the discharge line to leak.

3. Liquid line; A liquid line restriction will be

evidenced by low discharge and suction

pressure and insufficient cooling.

Refrigerant flexible hoses that have a low

permeability to refrigerant and moisture are used.

These low permeability hoses have a special nylon

layer on the inside.

SERVICE CHARGE VALVES

The charging hoses have a quick-joint type fitting,

to reduce refrigerant loss during removal and

installation.

12

3

4

Reinforcement layer(Polyester) Resin layer(Nylon)

Internal rubber layer

External rubber layer

1

2

874RY00003874RX022

Page 150 of 3573

1B Ð 24 AIR CONDITIONING

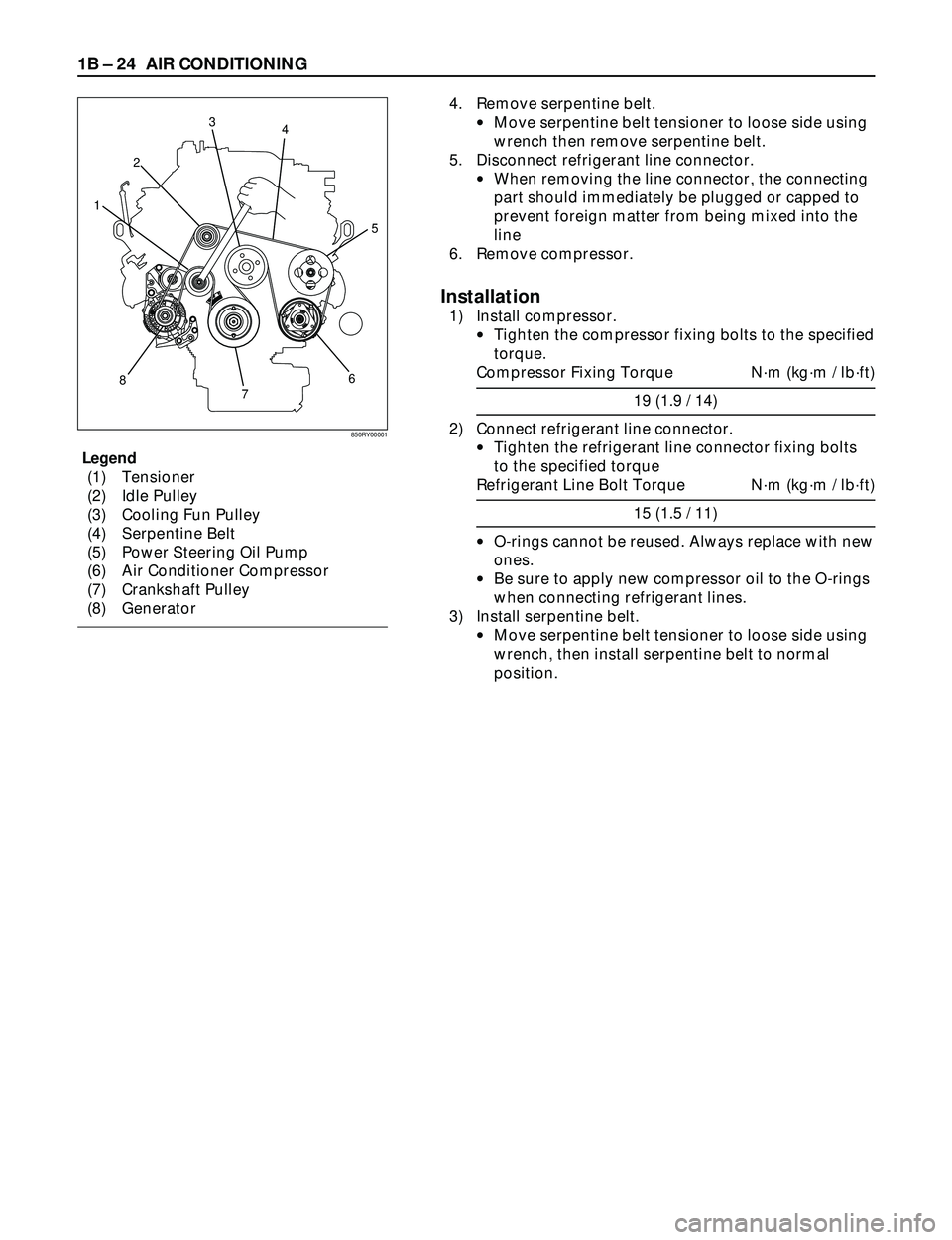

3

4

2

7 86 1

5

4. Remove serpentine belt.

·Move serpentine belt tensioner to loose side using

wrench then remove serpentine belt.

5. Disconnect refrigerant line connector.

·When removing the line connector, the connecting

part should immediately be plugged or capped to

prevent foreign matter from being mixed into the

line

6. Remove compressor.

Installation

1) Install compressor.

·Tighten the compressor fixing bolts to the specified

torque.

Compressor Fixing Torque Nám (kgám / lbáft)

19 (1.9 / 14)

2) Connect refrigerant line connector.

·Tighten the refrigerant line connector fixing bolts

to the specified torque

Refrigerant Line Bolt Torque Nám (kgám / lbáft)

15 (1.5 / 11)

·O-rings cannot be reused. Always replace with new

ones.

·Be sure to apply new compressor oil to the O-rings

when connecting refrigerant lines.

3) Install serpentine belt.

·Move serpentine belt tensioner to loose side using

wrench, then install serpentine belt to normal

position.

850RY00001

Legend

(1) Tensioner

(2) Idle Pulley

(3) Cooling Fun Pulley

(4) Serpentine Belt

(5) Power Steering Oil Pump

(6) Air Conditioner Compressor

(7) Crankshaft Pulley

(8) Generator

Page 152 of 3573

1B Ð 26 AIR CONDITIONING

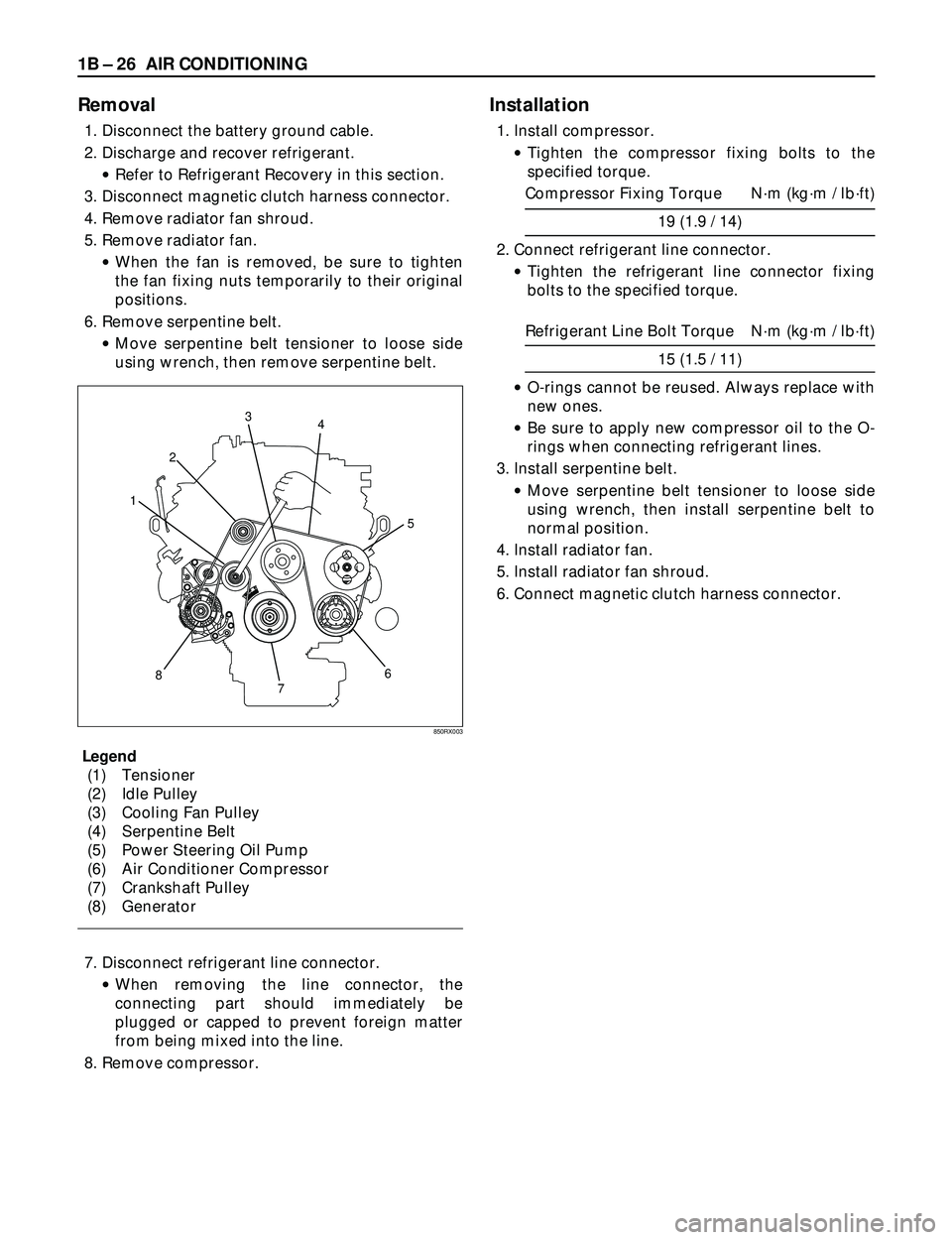

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

·Refer to Refrigerant Recovery in this section.

3. Disconnect magnetic clutch harness connector.

4. Remove radiator fan shroud.

5. Remove radiator fan.

·When the fan is removed, be sure to tighten

the fan fixing nuts temporarily to their original

positions.

6. Remove serpentine belt.

·Move serpentine belt tensioner to loose side

using wrench, then remove serpentine belt.

Legend

(1) Tensioner

(2) Idle Pulley

(3) Cooling Fan Pulley

(4) Serpentine Belt

(5) Power Steering Oil Pump

(6) Air Conditioner Compressor

(7) Crankshaft Pulley

(8) Generator

7. Disconnect refrigerant line connector.

·When removing the line connector, the

connecting part should immediately be

plugged or capped to prevent foreign matter

from being mixed into the line.

8. Remove compressor.

Installation

1. Install compressor.

·Tighten the compressor fixing bolts to the

specified torque.

Compressor Fixing Torque Nám (kgám / lbáft)

19 (1.9 / 14)

2. Connect refrigerant line connector.

·Tighten the refrigerant line connector fixing

bolts to the specified torque.

Refrigerant Line Bolt Torque Nám (kgám / lbáft)

15 (1.5 / 11)

·O-rings cannot be reused. Always replace with

new ones.

·Be sure to apply new compressor oil to the O-

rings when connecting refrigerant lines.

3. Install serpentine belt.

·Move serpentine belt tensioner to loose side

using wrench, then install serpentine belt to

normal position.

4. Install radiator fan.

5. Install radiator fan shroud.

6. Connect magnetic clutch harness connector.

3

4

2

7 86 1

5

850RX003

Page 177 of 3573

AIR CONDITIONING 1B Ð 51

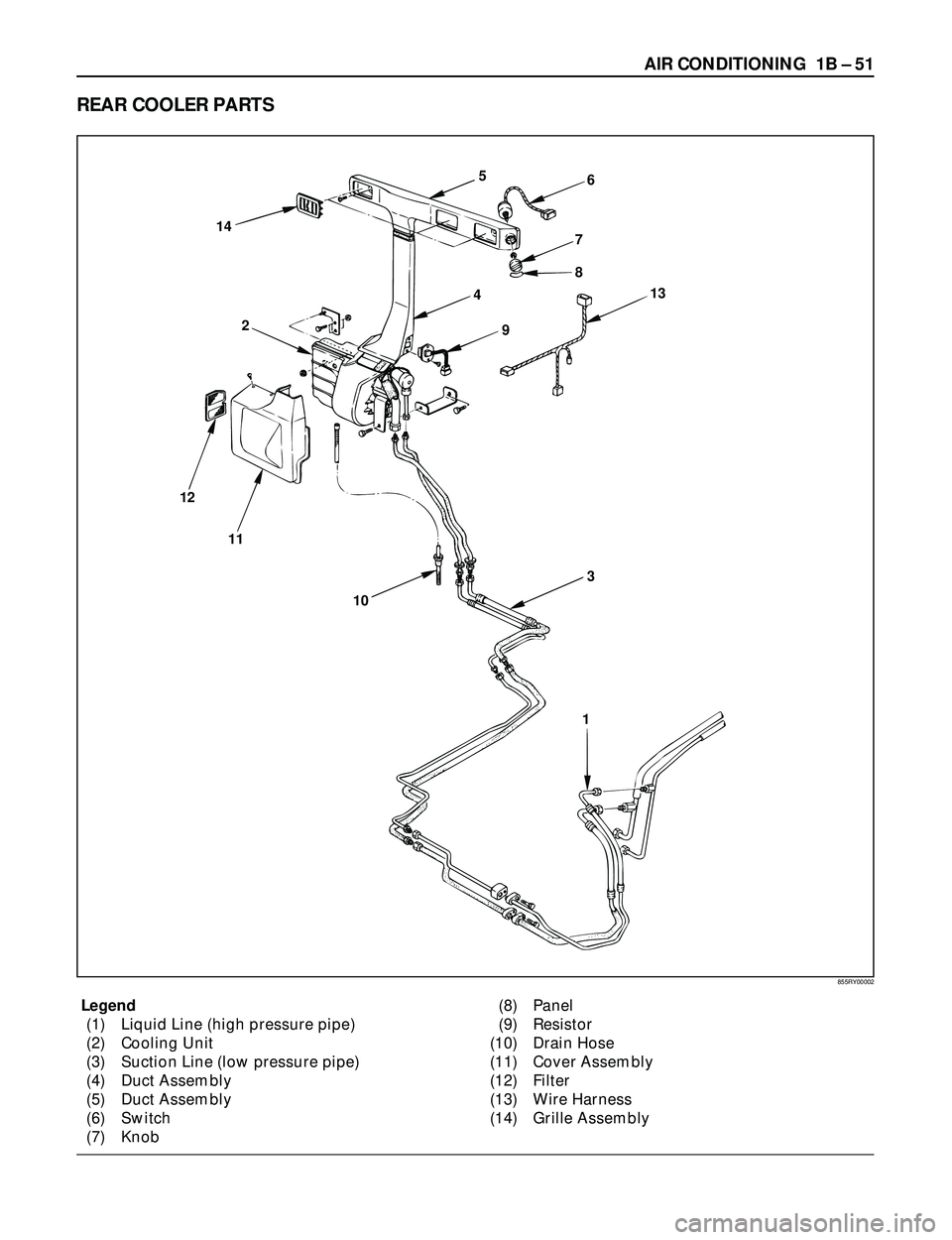

REAR COOLER PARTS

5

6

7

8

13

4

9 14

2

12

11

103

1

Legend

(1) Liquid Line (high pressure pipe)

(2) Cooling Unit

(3) Suction Line (low pressure pipe)

(4) Duct Assembly

(5) Duct Assembly

(6) Switch

(7) Knob(8) Panel

(9) Resistor

(10) Drain Hose

(11) Cover Assembly

(12) Filter

(13) Wire Harness

(14) Grille Assembly

855RY00002

Page 178 of 3573

1B Ð 52 AIR CONDITIONING

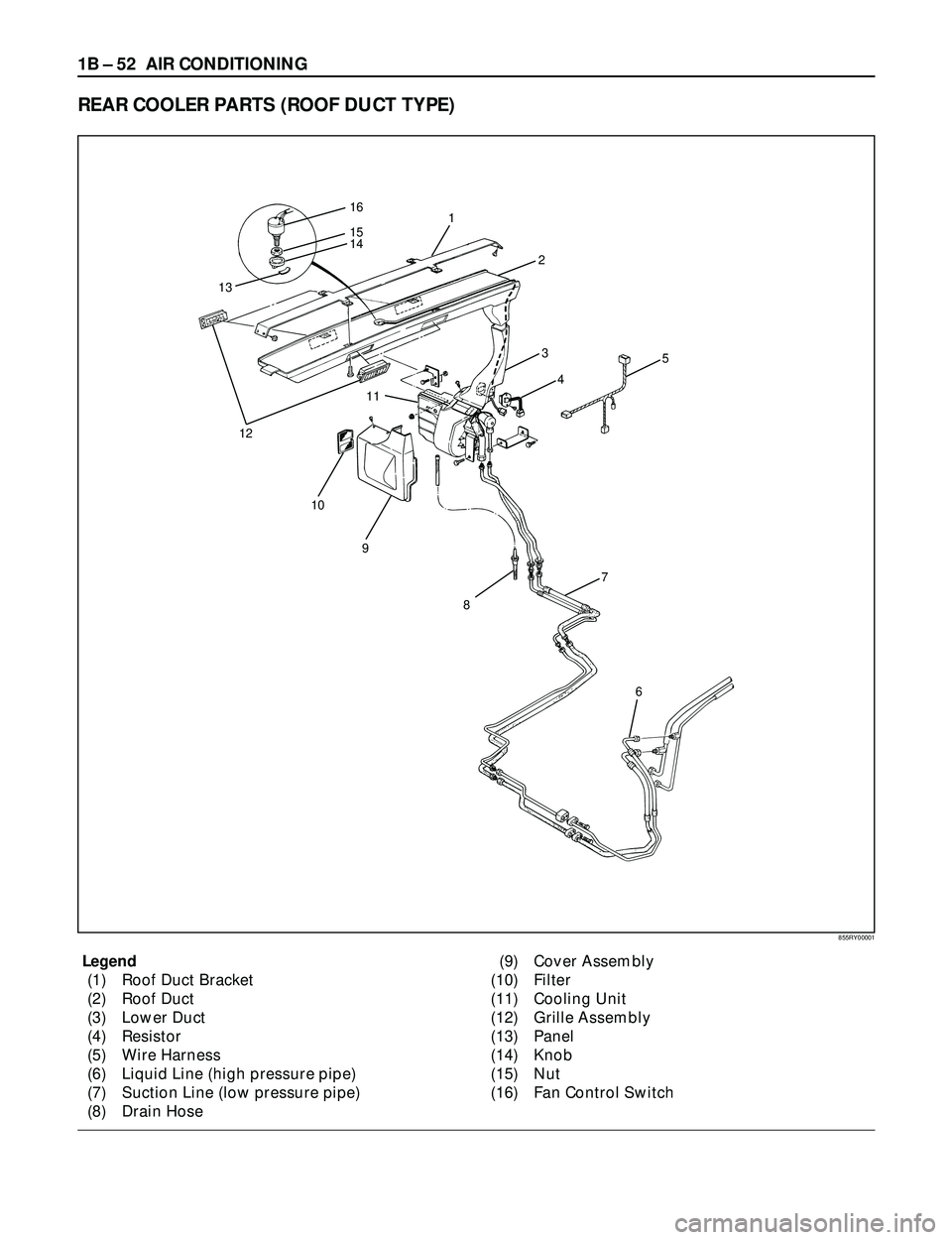

REAR COOLER PARTS (ROOF DUCT TYPE)

16

15

14

2

3

4

5

7

6 1

13

11

12

10

9

8

Legend

(1) Roof Duct Bracket

(2) Roof Duct

(3) Lower Duct

(4) Resistor

(5) Wire Harness

(6) Liquid Line (high pressure pipe)

(7) Suction Line (low pressure pipe)

(8) Drain Hose(9) Cover Assembly

(10) Filter

(11) Cooling Unit

(12) Grille Assembly

(13) Panel

(14) Knob

(15) Nut

(16) Fan Control Switch

855RY00001

Page 182 of 3573

1B Ð 56 AIR CONDITIONING

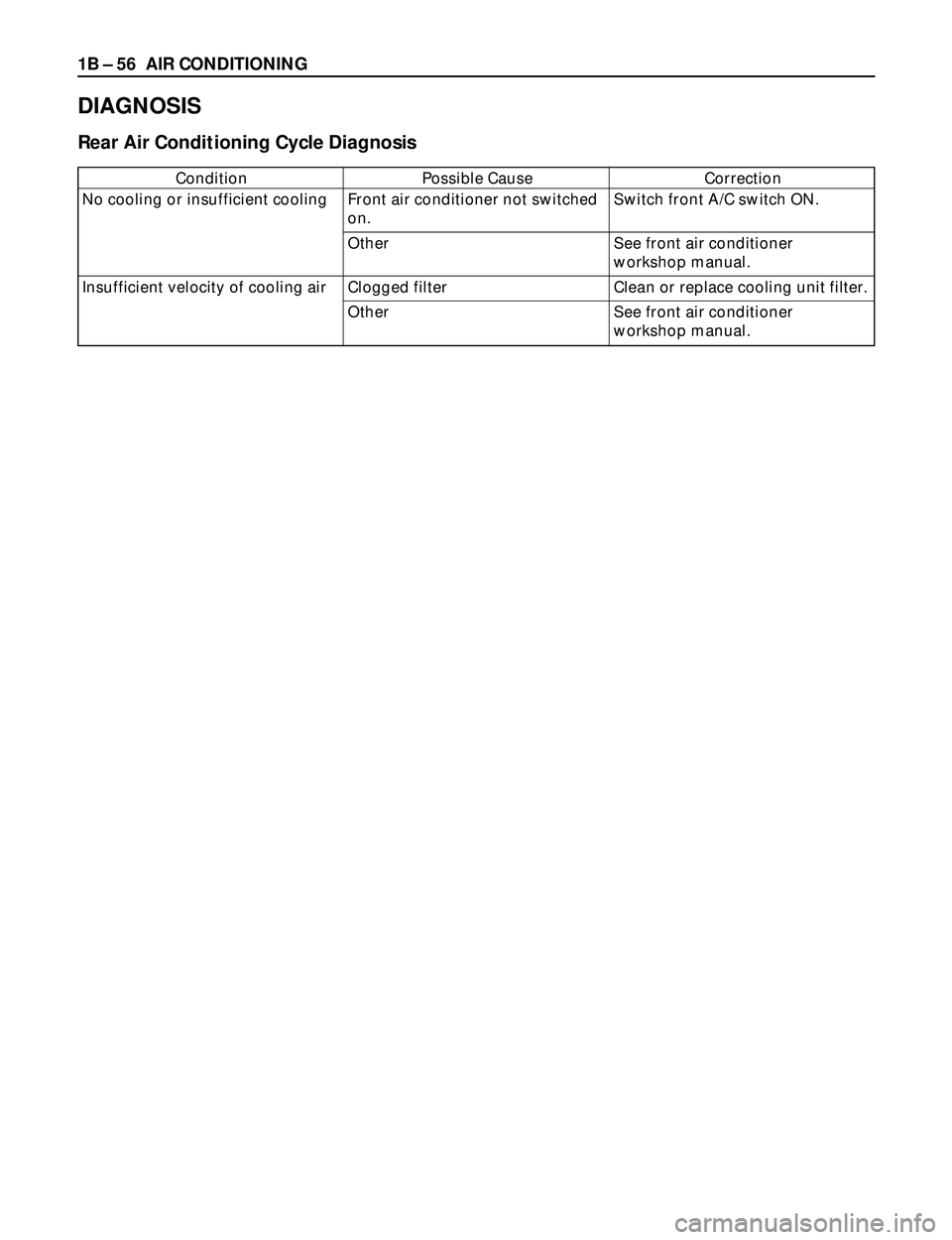

DIAGNOSIS

Rear Air Conditioning Cycle Diagnosis

Condition Possible Cause Correction

No cooling or insufficient cooling

Insufficient velocity of cooling airFront air conditioner not switched

on.

Other

Clogged filter

OtherSwitch front A/C switch ON.

See front air conditioner

workshop manual.

Clean or replace cooling unit filter.

See front air conditioner

workshop manual.

Page 184 of 3573

1B Ð 58 AIR CONDITIONING

COOLING UNIT

Main Components

2

3

1

Legend

(1) Evaporator Assembly

(2) Expansion Valve

(3) Fan Motor

872RY00001