ISUZU TROOPER 1998 Service Repair Manual

TROOPER 1998

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57184/w960_57184-0.png

ISUZU TROOPER 1998 Service Repair Manual

Trending: spark plugs, oil change, start stop button, tcm, maintenance schedule, tyre pressure, high beam

Page 321 of 3573

REMOVAL

Preparation:

•Place a drain pan below the pump.

1. Hose, Suction

2. Hose, Flexible

3. Adjust Nut

4. Bolt

5. Adjust Bolt

6. Belt

7. Bracket

8. Pulley

9. Bolt

10. Bracket

11. Pump Assembly

INSTALLATION

11. Pump Assembly

10. Bracket

9. Bolt

Pump Bolt Torque N·m (kg·m/lb·ft)

37 (3.8 / 27)

8. Pulley

Pulley Nut Torque N·m (kg·m/lb·ft)

78 (8.0 / 58)

7. Bracket

6. Belt

5. Adjust Bolt

4. Bolt

After adjusting drive belt tension, tighten bolt to

specified toque.

Bracket Bolt Torque N·m (kg·m/lb·ft)

37 (3.8 / 27)

3. Adjust Nut

After adjusting drive belt tension, tighten bolt to

specified toque.

Adjust Nut Torque N·m (kg·m/lb·ft)

37 (3.8 / 27)

2. Hose, Flexible

Hose Nut Torque N·m (kg·m/lb·ft)

20 (2.0 / 14)

1. Hose, Suction

Fill and bleed the system. Refer to “Bleeding the

Power Steering System” in this section.POWER STEERING 2A – 19

Page 322 of 3573

2A – 20 POWER STEERING

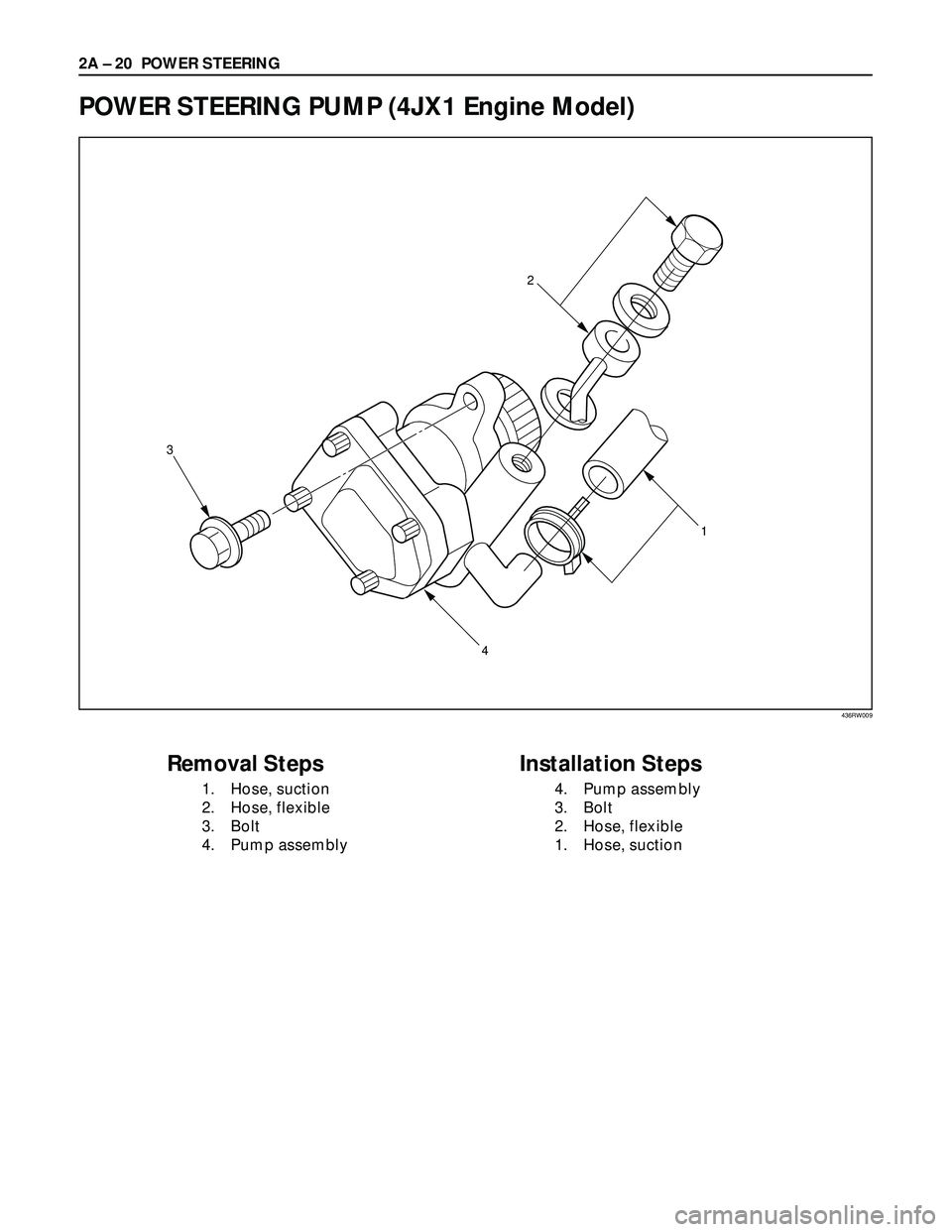

POWER STEERING PUMP (4JX1 Engine Model)

3

2

1

4

Removal Steps

1. Hose, suction

2. Hose, flexible

3. Bolt

4. Pump assembly

Installation Steps

4. Pump assembly

3. Bolt

2. Hose, flexible

1. Hose, suction

436RW009

Page 323 of 3573

POWER STEERING 2A – 21

REMOVAL

Preparation:

•Place a drain pan below the pump.

1. Hose, Suction

2. Hose, Flexible

3. Bolt

4. Pump Assembly

INSTALLATION

4. Pump Assembly

3. Bolt

Bolt Torque N·m (kg·m/lb·ft)

22 (2.2 / 16)

2. Hose, Flexible

Hose, Bolt Torque N·m (kg·m/lb·ft)

54 (5.5 / 40)

1. Hose, Suction

Fill and bleed the system. Refer to “Bleeding the

Power Steering System” in this section.

Page 324 of 3573

2A – 22 POWER STEERING

UNIT REPAIR

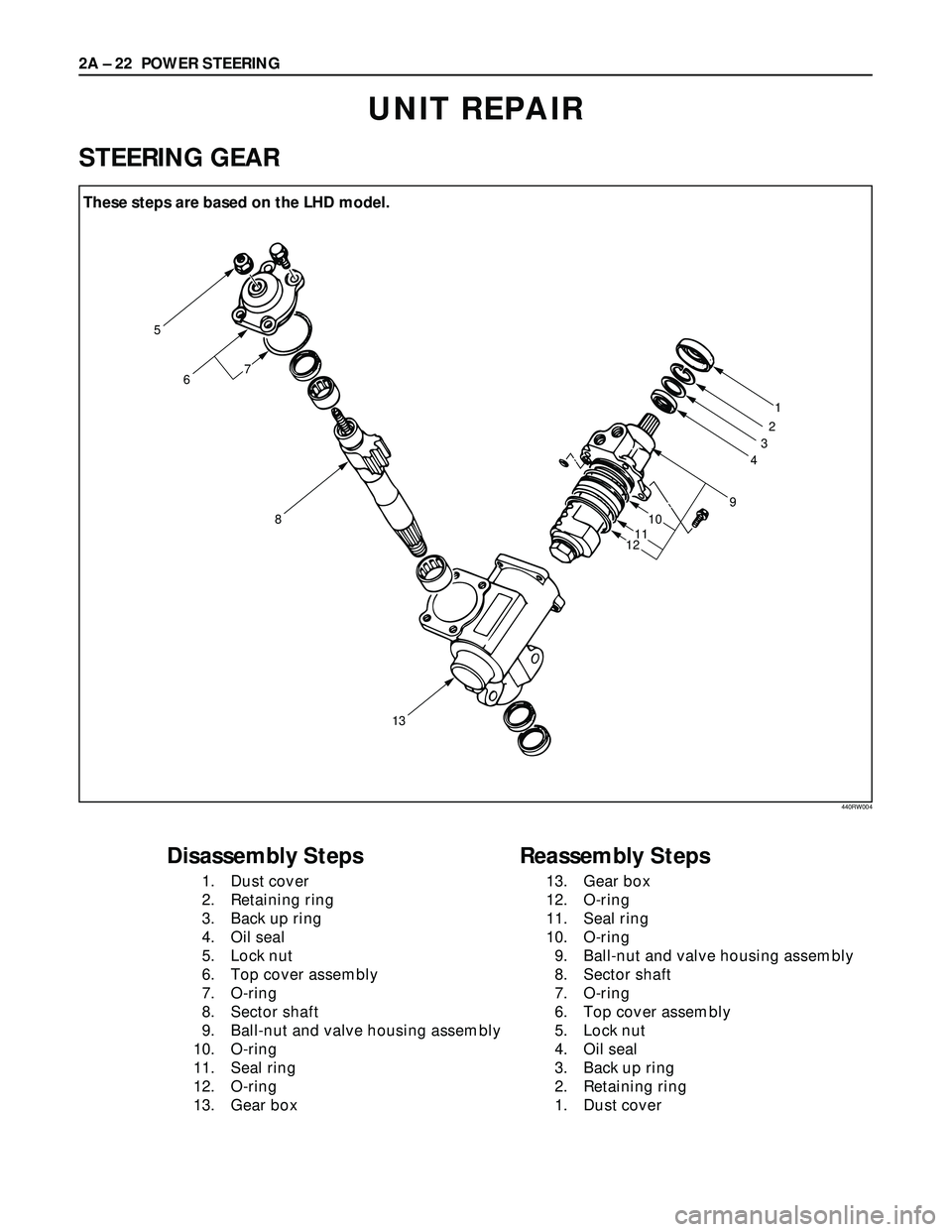

STEERING GEAR

5 These steps are based on the LHD model

6

8

131

2

3

4

9

10

11

12

7

Disassembly Steps

1. Dust cover

2. Retaining ring

3. Back up ring

4. Oil seal

5. Lock nut

6. Top cover assembly

7. O-ring

8. Sector shaft

9. Ball-nut and valve housing assembly

10. O-ring

11. Seal ring

12. O-ring

13. Gear box

Reassembly Steps

13. Gear box

12. O-ring

11. Seal ring

10. O-ring

9. Ball-nut and valve housing assembly

8. Sector shaft

7. O-ring

6. Top cover assembly

5. Lock nut

4. Oil seal

3. Back up ring

2. Retaining ring

1. Dust cover

440RW004

These steps are based on the LHD model.

Page 325 of 3573

POWER STEERING 2A – 23

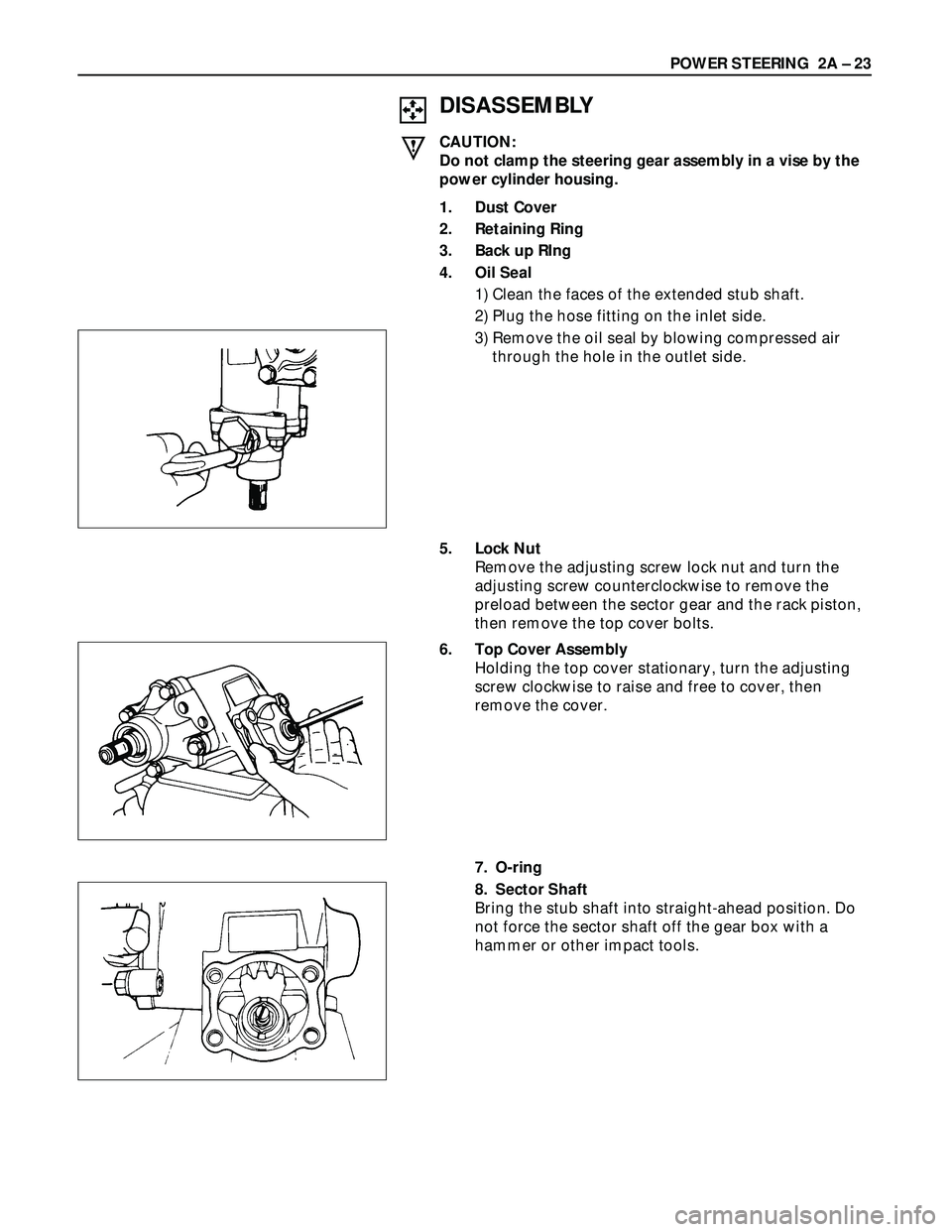

DISASSEMBLY

CAUTION:

Do not clamp the steering gear assembly in a vise by the

power cylinder housing.

1. Dust Cover

2. Retaining Ring

3. Back up RIng

4. Oil Seal

1) Clean the faces of the extended stub shaft.

2) Plug the hose fitting on the inlet side.

3) Remove the oil seal by blowing compressed air

through the hole in the outlet side.

5. Lock Nut

Remove the adjusting screw lock nut and turn the

adjusting screw counterclockwise to remove the

preload between the sector gear and the rack piston,

then remove the top cover bolts.

6. Top Cover Assembly

Holding the top cover stationary, turn the adjusting

screw clockwise to raise and free to cover, then

remove the cover.

7. O-ring

8. Sector Shaft

Bring the stub shaft into straight-ahead position. Do

not force the sector shaft off the gear box with a

hammer or other impact tools.

Page 326 of 3573

2A – 24 POWER STEERING

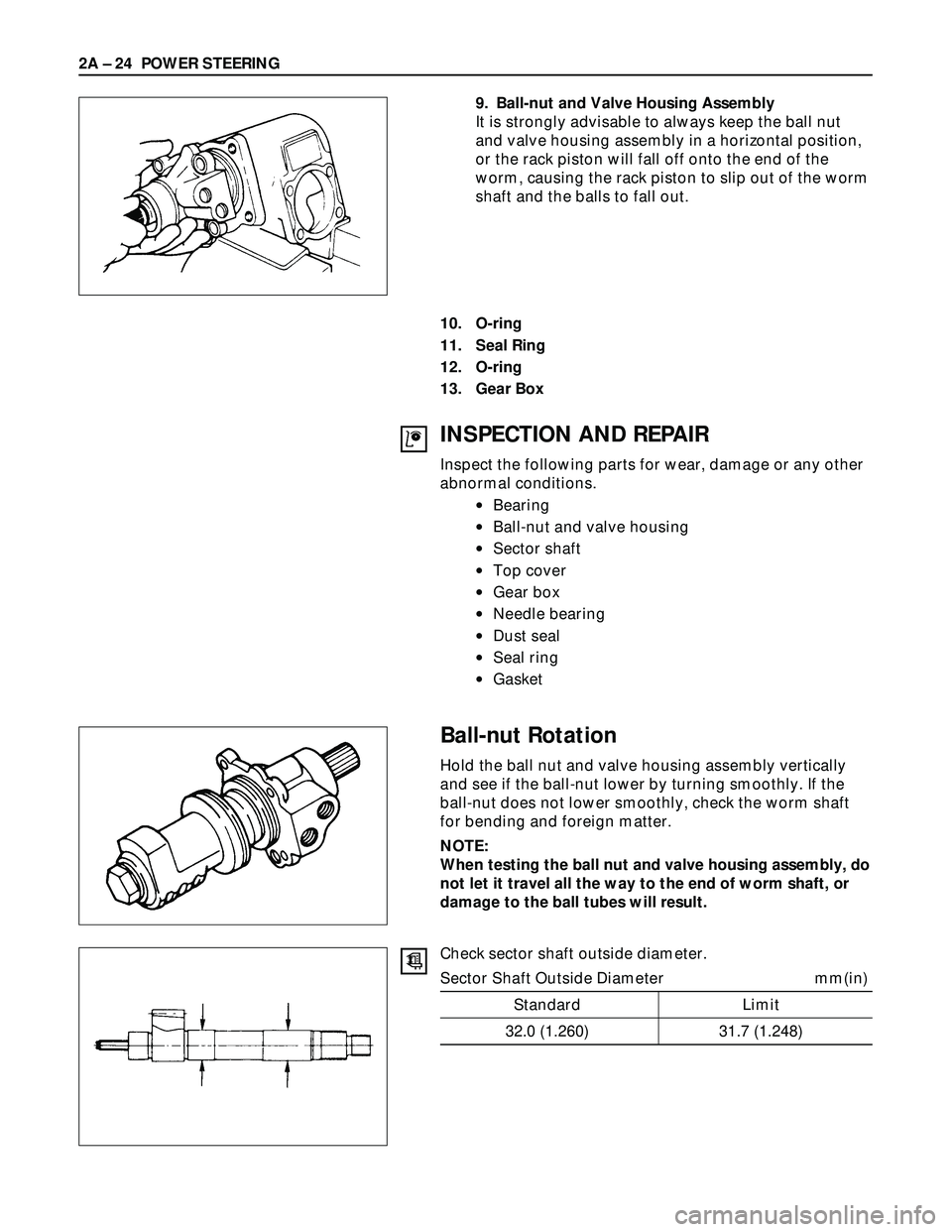

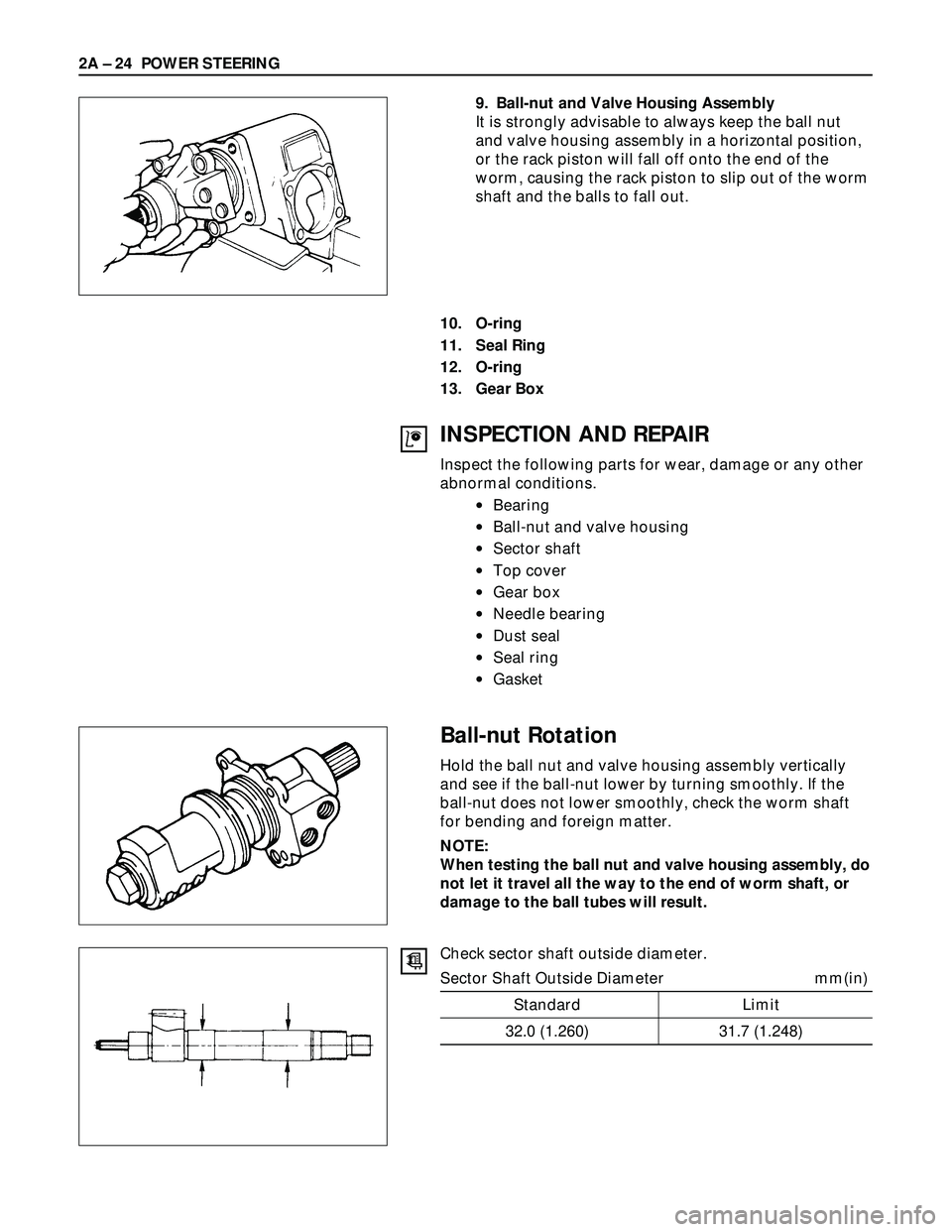

9. Ball-nut and Valve Housing Assembly

It is strongly advisable to always keep the ball nut

and valve housing assembly in a horizontal position,

or the rack piston will fall off onto the end of the

worm, causing the rack piston to slip out of the worm

shaft and the balls to fall out.

10. O-ring

11. Seal Ring

12. O-ring

13. Gear Box

INSPECTION AND REPAIR

Inspect the following parts for wear, damage or any other

abnormal conditions.

•Bearing

•Ball-nut and valve housing

•Sector shaft

•Top cover

•Gear box

•Needle bearing

•Dust seal

•Seal ring

•Gasket

Ball-nut Rotation

Hold the ball nut and valve housing assembly vertically

and see if the ball-nut lower by turning smoothly. If the

ball-nut does not lower smoothly, check the worm shaft

for bending and foreign matter.

NOTE:

When testing the ball nut and valve housing assembly, do

not let it travel all the way to the end of worm shaft, or

damage to the ball tubes will result.

Check sector shaft outside diameter.

Sector Shaft Outside Diameter mm(in)

Standard Limit

32.0 (1.260) 31.7 (1.248)

Page 327 of 3573

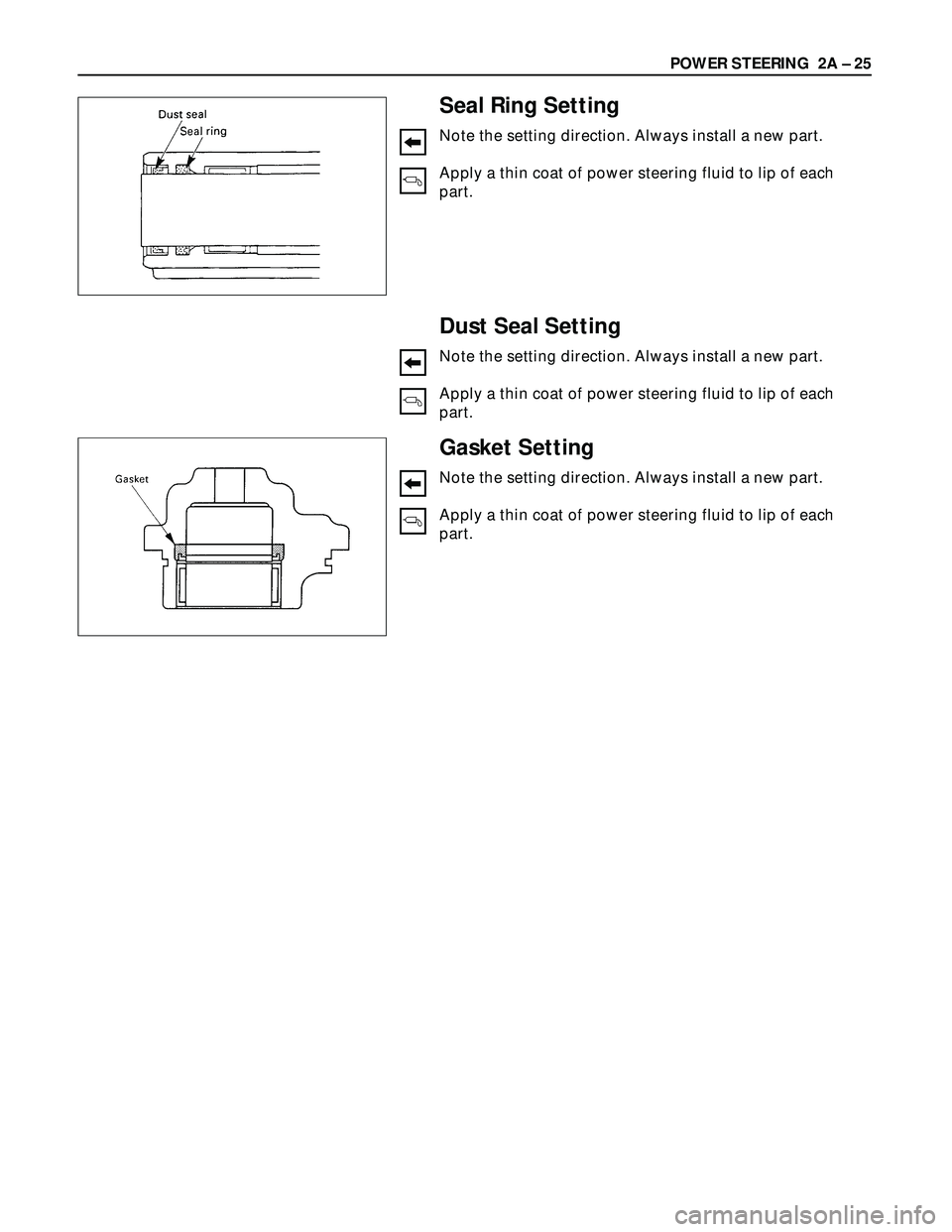

POWER STEERING 2A – 25

Seal Ring Setting

Note the setting direction. Always install a new part.

Apply a thin coat of power steering fluid to lip of each

part.

Dust Seal Setting

Note the setting direction. Always install a new part.

Apply a thin coat of power steering fluid to lip of each

part.

Gasket Setting

Note the setting direction. Always install a new part.

Apply a thin coat of power steering fluid to lip of each

part.

Page 328 of 3573

2A – 26 POWER STEERING

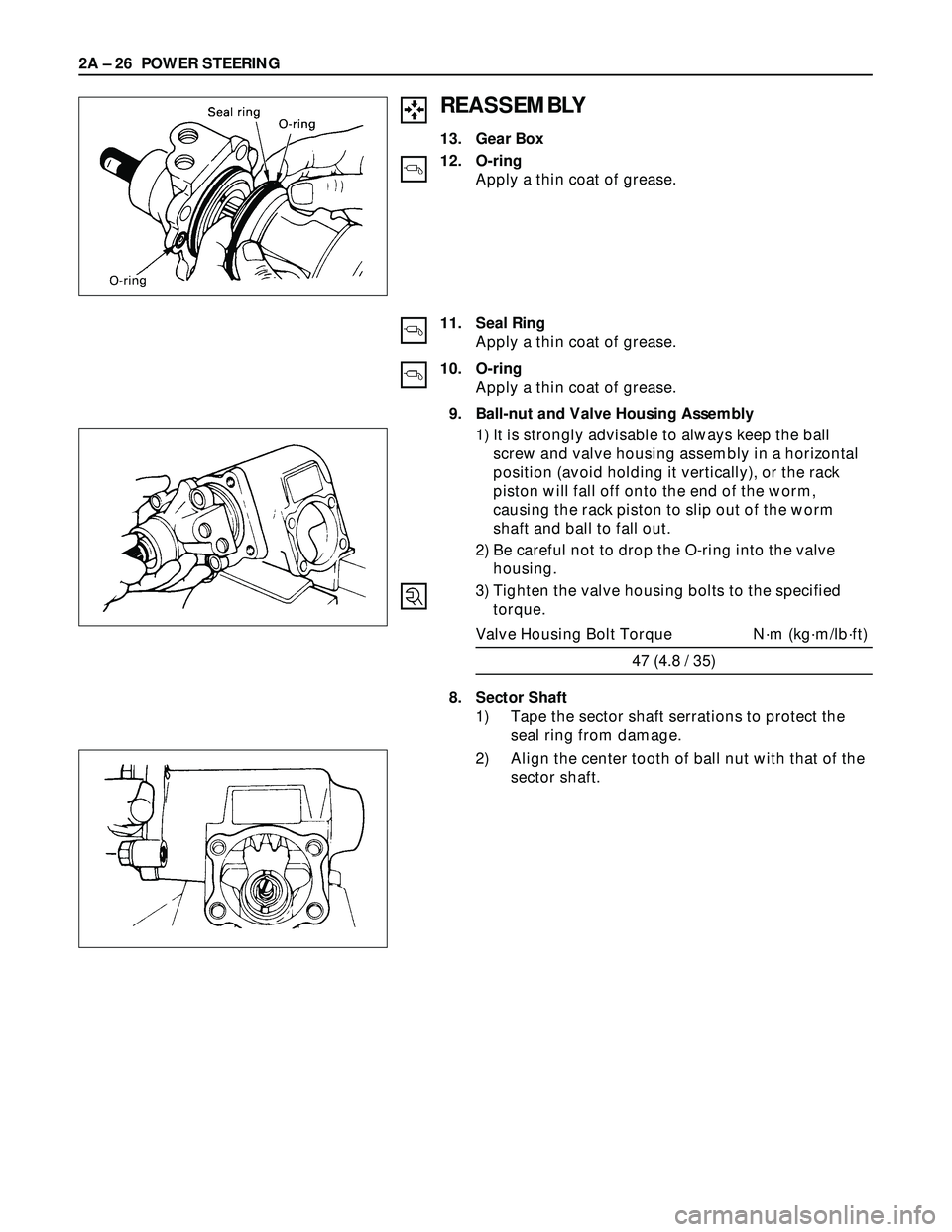

REASSEMBLY

13. Gear Box

12. O-ring

Apply a thin coat of grease.

11. Seal Ring

Apply a thin coat of grease.

10. O-ring

Apply a thin coat of grease.

9. Ball-nut and Valve Housing Assembly

1) It is strongly advisable to always keep the ball

screw and valve housing assembly in a horizontal

position (avoid holding it vertically), or the rack

piston will fall off onto the end of the worm,

causing the rack piston to slip out of the worm

shaft and ball to fall out.

2) Be careful not to drop the O-ring into the valve

housing.

3) Tighten the valve housing bolts to the specified

torque.

Valve Housing Bolt Torque N·m (kg·m/lb·ft)

47 (4.8 / 35)

8. Sector Shaft

1) Tape the sector shaft serrations to protect the

seal ring from damage.

2) Align the center tooth of ball nut with that of the

sector shaft.

Page 329 of 3573

POWER STEERING 2A – 27

7. O-ring

6. Top Cover Assembly

Top Cover Bolt Torque N·m (kg·m/lb·ft)

47 (4.8 / 35)

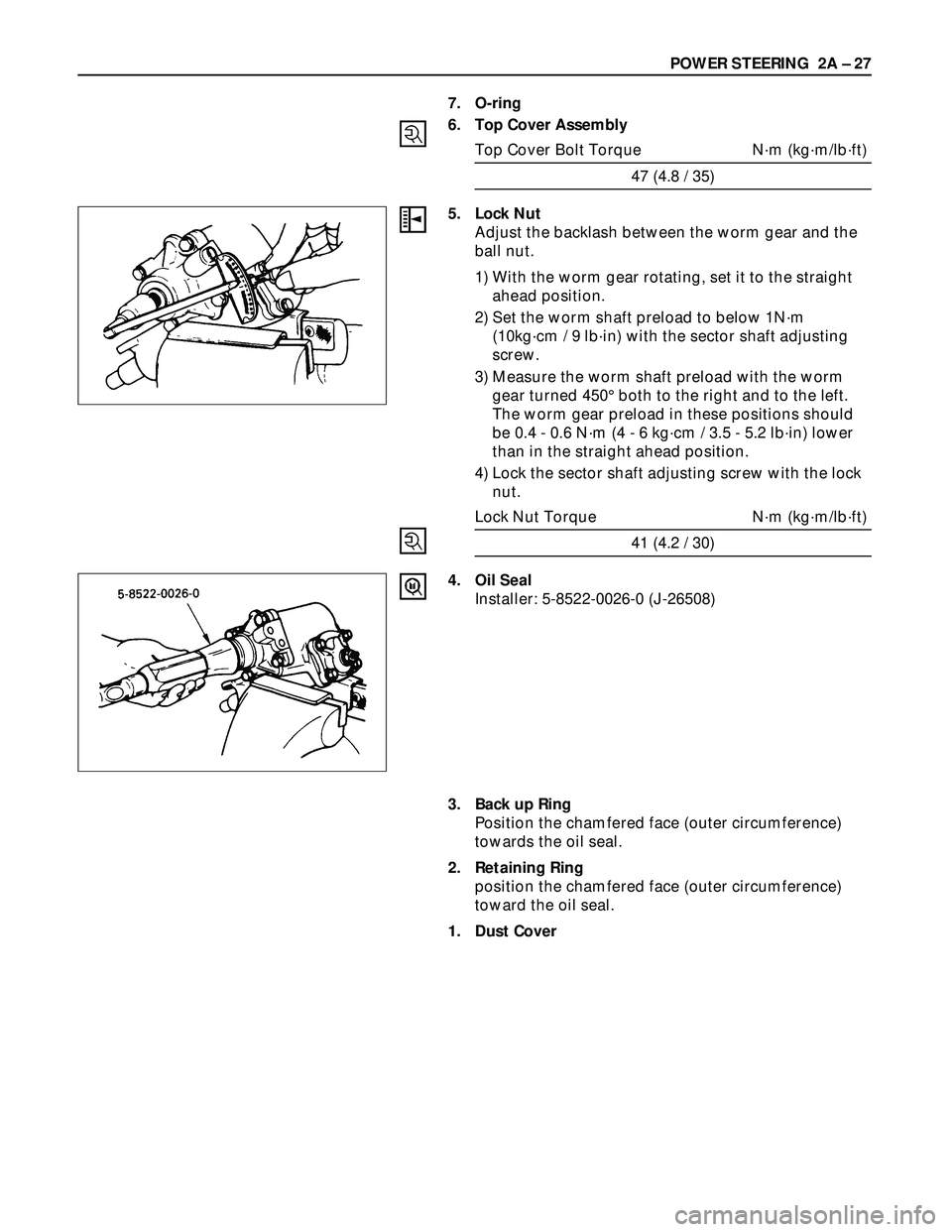

5. Lock Nut

Adjust the backlash between the worm gear and the

ball nut.

1) With the worm gear rotating, set it to the straight

ahead position.

2) Set the worm shaft preload to below 1N·m

(10kg·cm / 9 lb·in) with the sector shaft adjusting

screw.

3) Measure the worm shaft preload with the worm

gear turned 450°both to the right and to the left.

The worm gear preload in these positions should

be 0.4 - 0.6 N·m (4 - 6 kg·cm / 3.5 - 5.2 lb·in) lower

than in the straight ahead position.

4) Lock the sector shaft adjusting screw with the lock

nut.

Lock Nut Torque N·m (kg·m/lb·ft)

41 (4.2 / 30)

4. Oil Seal

Installer: 5-8522-0026-0 (J-26508)

3. Back up Ring

Position the chamfered face (outer circumference)

towards the oil seal.

2. Retaining Ring

position the chamfered face (outer circumference)

toward the oil seal.

1. Dust Cover

Page 330 of 3573

2A – 28 POWER STEERING

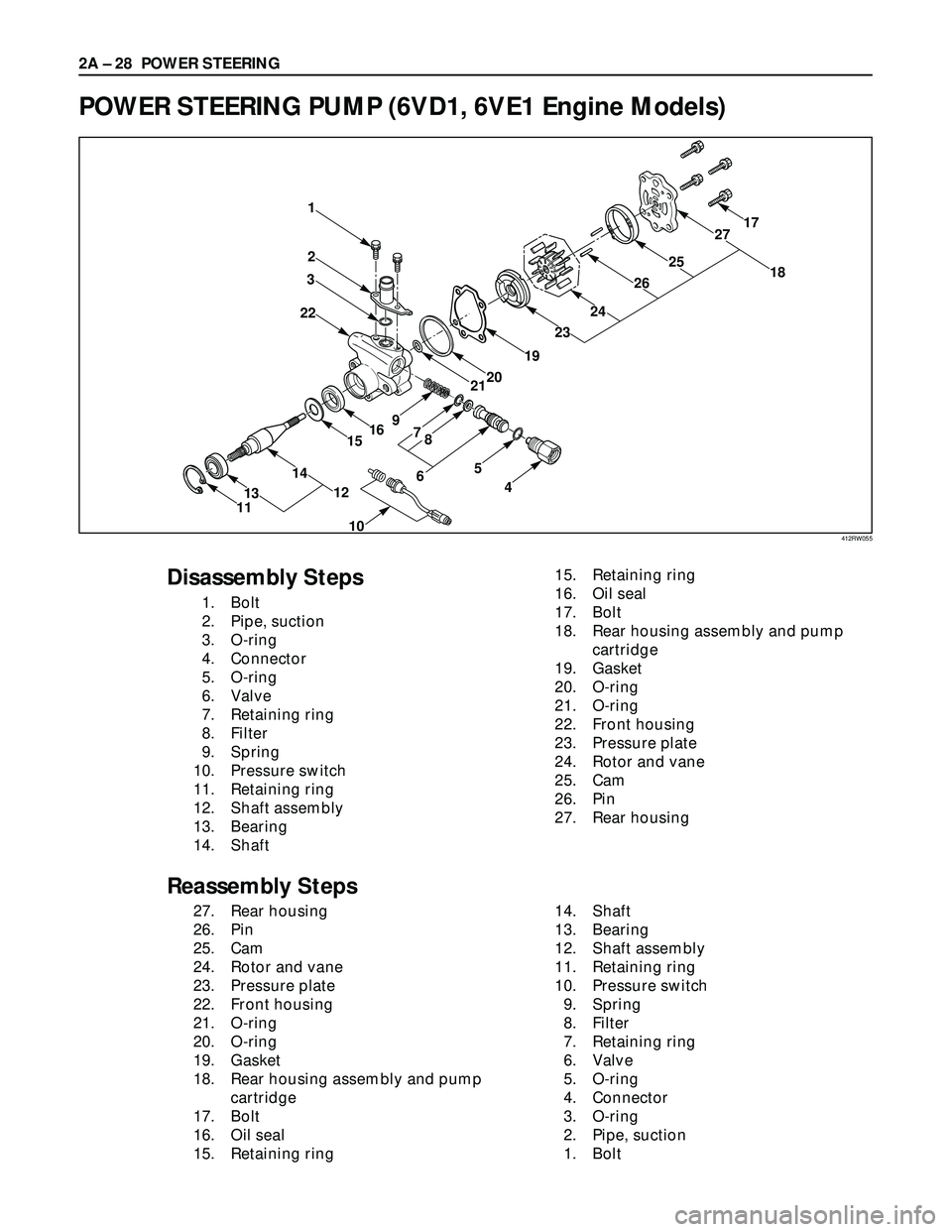

POWER STEERING PUMP (6VD1, 6VE1 Engine Models)

2

3

221

1615

12

11

56

879

4

17

1827

25

26

24

19

20

23

21

14

13

10

Disassembly Steps

1. Bolt

2. Pipe, suction

3. O-ring

4. Connector

5. O-ring

6. Valve

7. Retaining ring

8. Filter

9. Spring

10. Pressure switch

11. Retaining ring

12. Shaft assembly

13. Bearing

14. Shaft15. Retaining ring

16. Oil seal

17. Bolt

18. Rear housing assembly and pump

cartridge

19. Gasket

20. O-ring

21. O-ring

22. Front housing

23. Pressure plate

24. Rotor and vane

25. Cam

26. Pin

27. Rear housing

Reassembly Steps

27. Rear housing

26. Pin

25. Cam

24. Rotor and vane

23. Pressure plate

22. Front housing

21. O-ring

20. O-ring

19. Gasket

18. Rear housing assembly and pump

cartridge

17. Bolt

16. Oil seal

15. Retaining ring14. Shaft

13. Bearing

12. Shaft assembly

11. Retaining ring

10. Pressure switch

9. Spring

8. Filter

7. Retaining ring

6. Valve

5. O-ring

4. Connector

3. O-ring

2. Pipe, suction

1. Bolt

412RW055

Trending: ignition, fuel cap release, load capacity, change wheel, oil filter, rear entertainment, mileage