Remove engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 2113 of 3573

6E±220

4JX1±TC ENGINE DRIVEABILITY AND EMISSIONS

Installation Procedure

1. Install the EVRV.

035RW064

2. Connect the EVRV hose and the EVRV connector.

035RW065

3. Connect the negative battery cable.

Wiring and Connectors

Wiring Harness Service

The ECM harness electrically connects the ECM to the

various solenoids, switches and sensors in the vehicle

engine compartment and passenger compartment.

Replace wire harnesses with the proper part number

replacement.

Because of the low amperage and voltage levels utilized

in powertrain control systems, it is essential that all wiring

in environmentally exposed areas be repaired with crimp

and seal splice sleeves.The following wire harness repair information is intended

as a general guideline only. Refer to

Chassis Electrical for

all wire harness repair procedures.

Connectors and Terminals

Use care when probing a connector and when replacing

terminals. It is possible to short between opposite

terminals. Damage to components could result. Always

use jumper wires between connectors for circuit

checking. NEVER probe through Weather-Pack seals.

Use an appropriate connector test adapter kit which

contains an assortment of flexible connectors used to

probe terminals during diagnosis. Use an appropriate

fuse remover and test tool for removing a fuse and to

adapt the fuse holder to a meter for diagnosis.

Open circuits are often difficult to locate by sight because

oxidation or terminal misalignment are hidden by the

connectors. Merely wiggling a connector on a sensor, or

in the wiring harness, may temporarily correct the open

circuit. Intermittent problems may also be caused by

oxidized or loose connections.

Be certain of the type of connector/terminal before

making any connector or terminal repair. Weather-Pack

and Com-Pack III terminals look similar, but are serviced

differently.

Wire Harness Repair: Twisted

Shielded Cable

Removal Procedure

1. Remove the outer jacket.

2. Unwrap the aluminum/mylar tape. Do not remove the

mylar.

047

Page 2114 of 3573

6E±221 4JX1±TC ENGINE DRIVEABILITY AND EMISSIONS

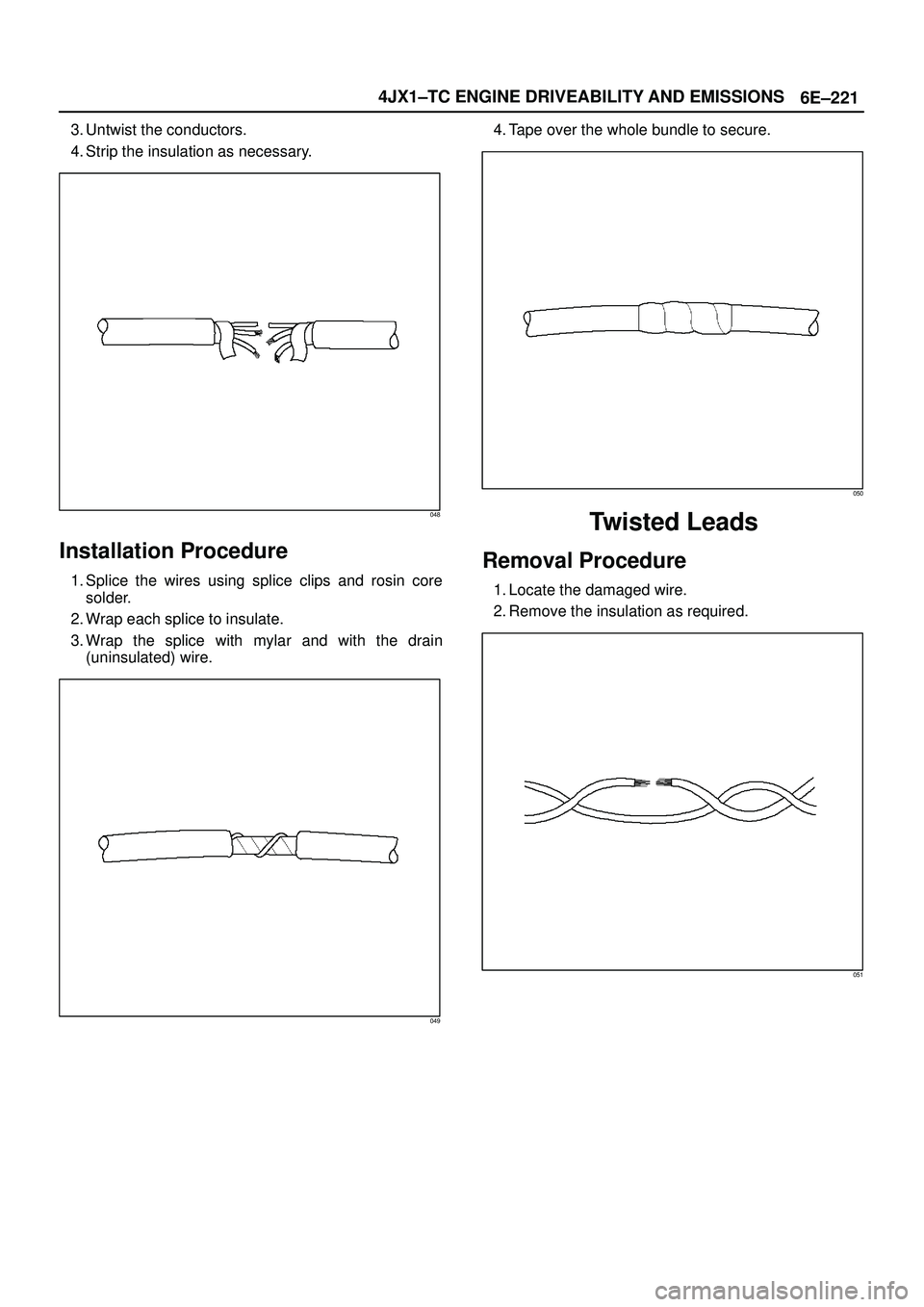

3. Untwist the conductors.

4. Strip the insulation as necessary.

048

Installation Procedure

1. Splice the wires using splice clips and rosin core

solder.

2. Wrap each splice to insulate.

3. Wrap the splice with mylar and with the drain

(uninsulated) wire.

049

4. Tape over the whole bundle to secure.

050

Twisted Leads

Removal Procedure

1. Locate the damaged wire.

2. Remove the insulation as required.

051

Page 2116 of 3573

6E±223 4JX1±TC ENGINE DRIVEABILITY AND EMISSIONS

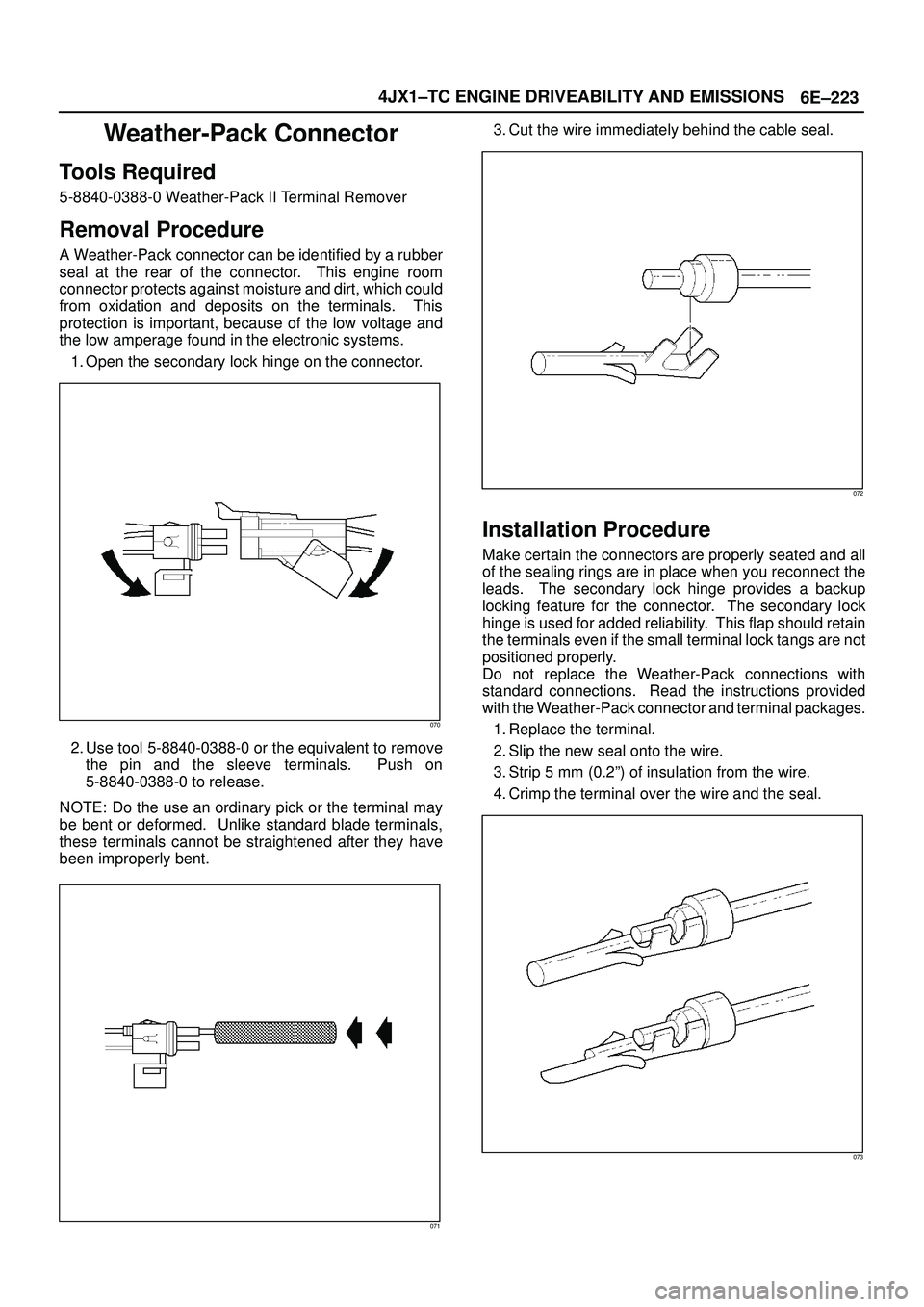

Weather-Pack Connector

Tools Required

5-8840-0388-0 Weather-Pack II Terminal Remover

Removal Procedure

A Weather-Pack connector can be identified by a rubber

seal at the rear of the connector. This engine room

connector protects against moisture and dirt, which could

from oxidation and deposits on the terminals. This

protection is important, because of the low voltage and

the low amperage found in the electronic systems.

1. Open the secondary lock hinge on the connector.

070

2. Use tool 5-8840-0388-0 or the equivalent to remove

the pin and the sleeve terminals. Push on

5-8840-0388-0 to release.

NOTE: Do the use an ordinary pick or the terminal may

be bent or deformed. Unlike standard blade terminals,

these terminals cannot be straightened after they have

been improperly bent.

071

3. Cut the wire immediately behind the cable seal.

072

Installation Procedure

Make certain the connectors are properly seated and all

of the sealing rings are in place when you reconnect the

leads. The secondary lock hinge provides a backup

locking feature for the connector. The secondary lock

hinge is used for added reliability. This flap should retain

the terminals even if the small terminal lock tangs are not

positioned properly.

Do not replace the Weather-Pack connections with

standard connections. Read the instructions provided

with the Weather-Pack connector and terminal packages.

1. Replace the terminal.

2. Slip the new seal onto the wire.

3. Strip 5 mm (0.2º) of insulation from the wire.

4. Crimp the terminal over the wire and the seal.

073

Page 2117 of 3573

6E±224

4JX1±TC ENGINE DRIVEABILITY AND EMISSIONS

5. Push the terminal and the connector to engage the

locking tangs.

070

6. Close the secondary locking hinge.

Com-Pack III

General Information

The Com-Pack III terminal looks similar to some

Weather-Pack terminals. This terminal is not sealed and

is used where resistance to the environment is not

required. Use the standard method when repairing a

terminal. Do not use the Weather-Pack terminal tool

5-8840-0388-0 or equivalent. These will damage the

terminals.

Metri-Pack

Tools Required

5-8840-0632-0 Terminal Remover

Removal Procedure

Some connectors use terminals called Metri-Pack Series

150. These may be used at the engine coolant

temperature (ECT) sensor.

1. Slide the seal (1) back on the wire.2. Insert the 5-8840-0632-0 tool or equivalent (3) in

order to release the terminal locking tang (2).

060

3. Push the wire and the terminal out through the

connector. If you reuse the terminal, reshape the

locking tang.

Installation Procedure

Metri-Pack terminals are also referred to as ªpull-to-seatº

terminals.

1. In order to install a terminal on a wire, the wire must be

inserted through the seal (2) and through the

connector (3).

2. The terminal (1) is then crimped onto the wire.

061

3. Then the terminal is pulled back into the connector to

seat it in place.

Page 2127 of 3573

6F – 4 ENGINE EXHAUST

REMOVAL

1. Battery negative cable.

2. Raise the vehicle and support with suitable safety

stands.

3. Remove front exhaust pipe fixing nuts from engine

side.

4. Remove fixing nuts between front exhaust pipe and

center exhaust pipe, remove front exhaust pipe.

5. Disconnect center exhaust pipe and silencer,

remove center exhaust pipe.

6. Remove fixing nuts from connection part of tail pipe,

remove mounting rubber and remove silencer

bracket, silencer.

7. Remove mounting rubber for tail pipe, remove tail

pipe.

INSTALLATION

1. Install front exhaust pipe and tighten it temporarily.

2. Tighten fixing nuts of front exhaust pipe to the

specified torque. (for engine side)

Torque: 67 N·m (6.8 kg·m/50 lb ft)

3. Tighten fixing nuts of front exhaust pipe to the

specified torque. (for center pipe side)

Torque: 43 N·m (4.4 kg·m/32 lb ft)

4. Install silencer and tighten silencer bracket nuts to

the specified torque.

Torque: 16 N·m (1.6 kg·m/12 lb ft)

5. Install tail pipe and tighten it.

Torque: 43 N·m (4.4 kg·m/32 lb ft)

6. Install mounting rubbers.

Page 2128 of 3573

ENGINE EXHAUST 6F – 5

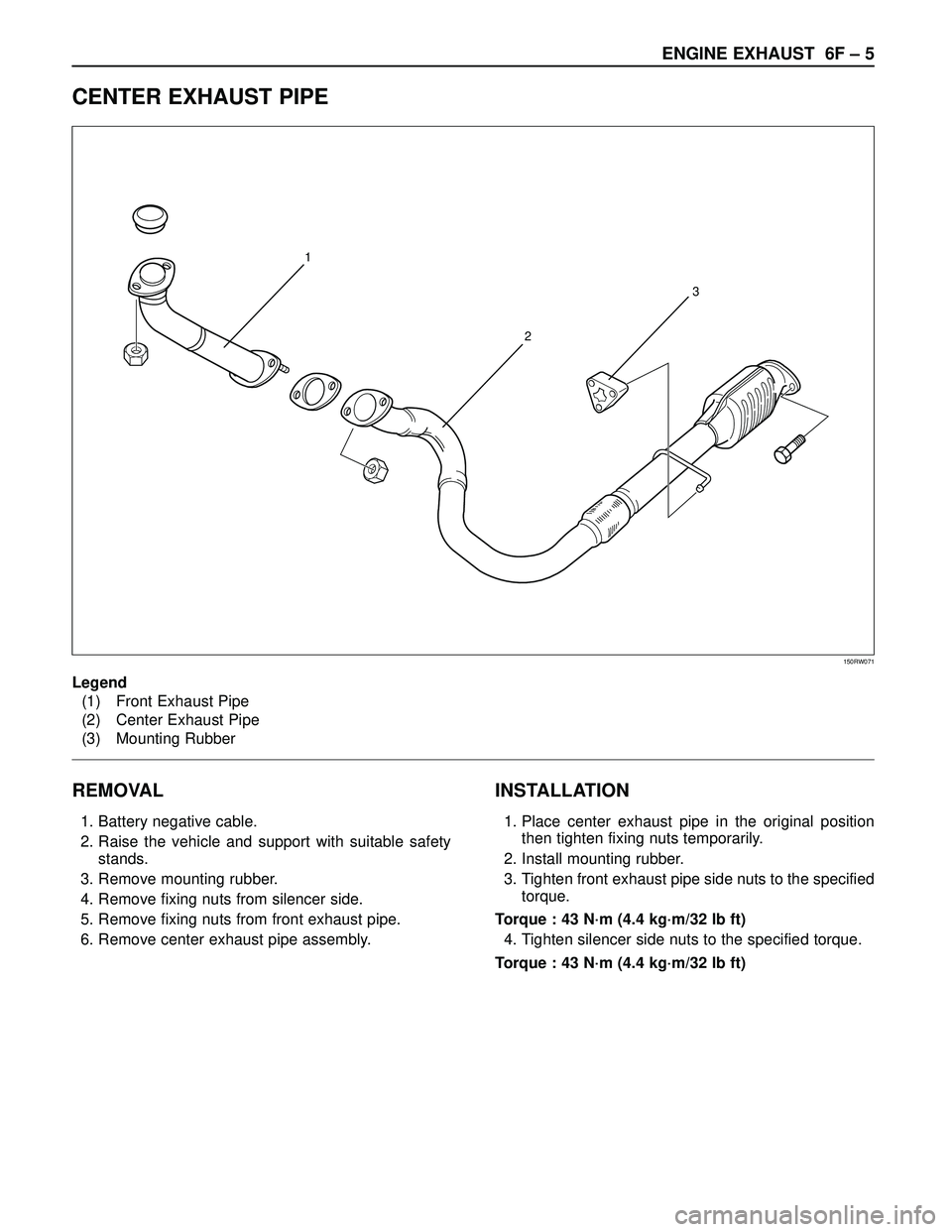

CENTER EXHAUST PIPE

REMOVAL

1. Battery negative cable.

2. Raise the vehicle and support with suitable safety

stands.

3. Remove mounting rubber.

4. Remove fixing nuts from silencer side.

5. Remove fixing nuts from front exhaust pipe.

6. Remove center exhaust pipe assembly.

INSTALLATION

1. Place center exhaust pipe in the original position

then tighten fixing nuts temporarily.

2. Install mounting rubber.

3. Tighten front exhaust pipe side nuts to the specified

torque.

Torque : 43 N·m (4.4 kg·m/32 lb ft)

4. Tighten silencer side nuts to the specified torque.

Torque : 43 N·m (4.4 kg·m/32 lb ft)

3

2 1

Legend

(1) Front Exhaust Pipe

(2) Center Exhaust Pipe

(3) Mounting Rubber

150RW071

Page 2129 of 3573

6F – 6 ENGINE EXHAUST

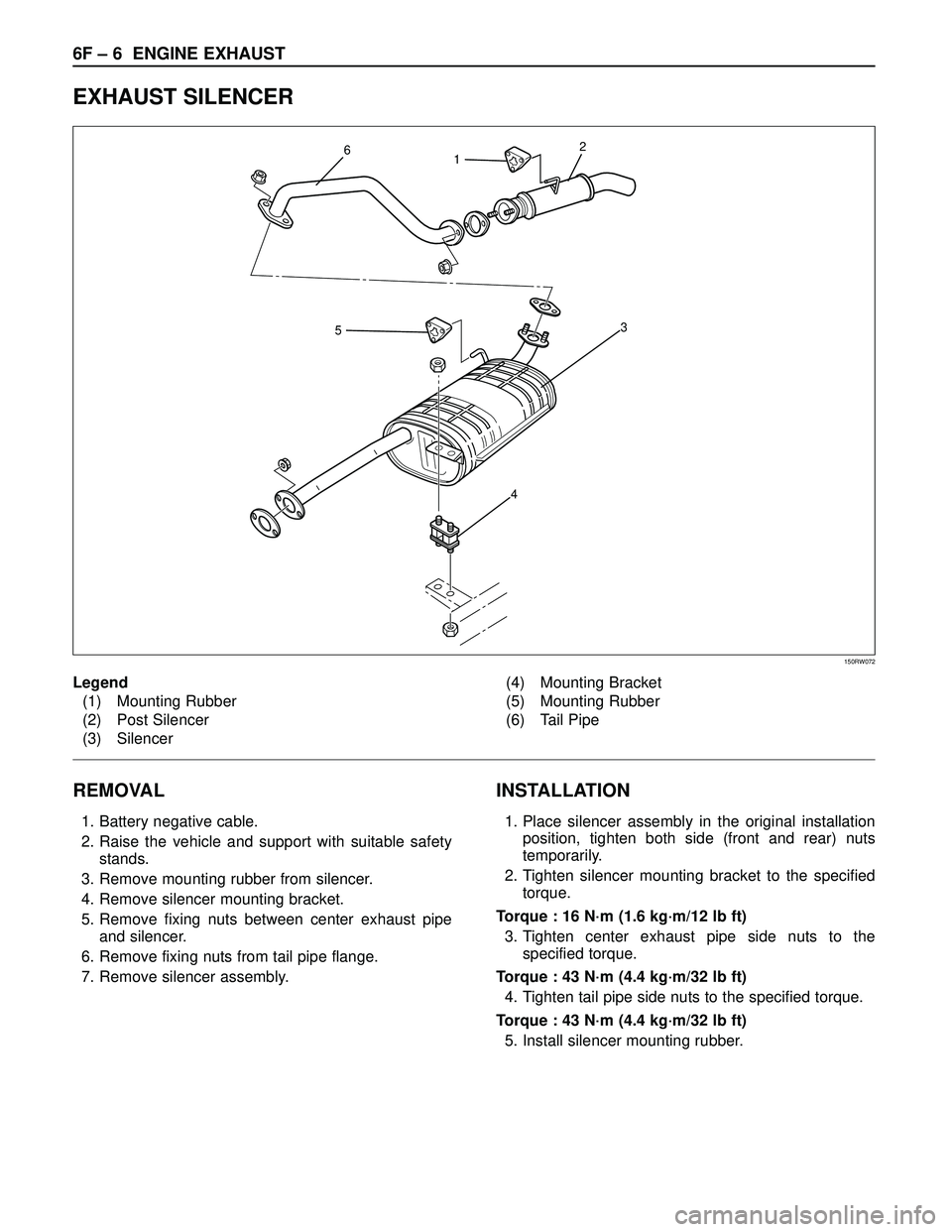

EXHAUST SILENCER

REMOVAL

1. Battery negative cable.

2. Raise the vehicle and support with suitable safety

stands.

3. Remove mounting rubber from silencer.

4. Remove silencer mounting bracket.

5. Remove fixing nuts between center exhaust pipe

and silencer.

6. Remove fixing nuts from tail pipe flange.

7. Remove silencer assembly.

INSTALLATION

1. Place silencer assembly in the original installation

position, tighten both side (front and rear) nuts

temporarily.

2. Tighten silencer mounting bracket to the specified

torque.

Torque : 16 N·m (1.6 kg·m/12 lb ft)

3. Tighten center exhaust pipe side nuts to the

specified torque.

Torque : 43 N·m (4.4 kg·m/32 lb ft)

4. Tighten tail pipe side nuts to the specified torque.

Torque : 43 N·m (4.4 kg·m/32 lb ft)

5. Install silencer mounting rubber.

6

3

4

2

1

5

Legend

(1) Mounting Rubber

(2) Post Silencer

(3) Silencer(4) Mounting Bracket

(5) Mounting Rubber

(6) Tail Pipe

150RW072

Page 2130 of 3573

ENGINE EXHAUST 6F – 7

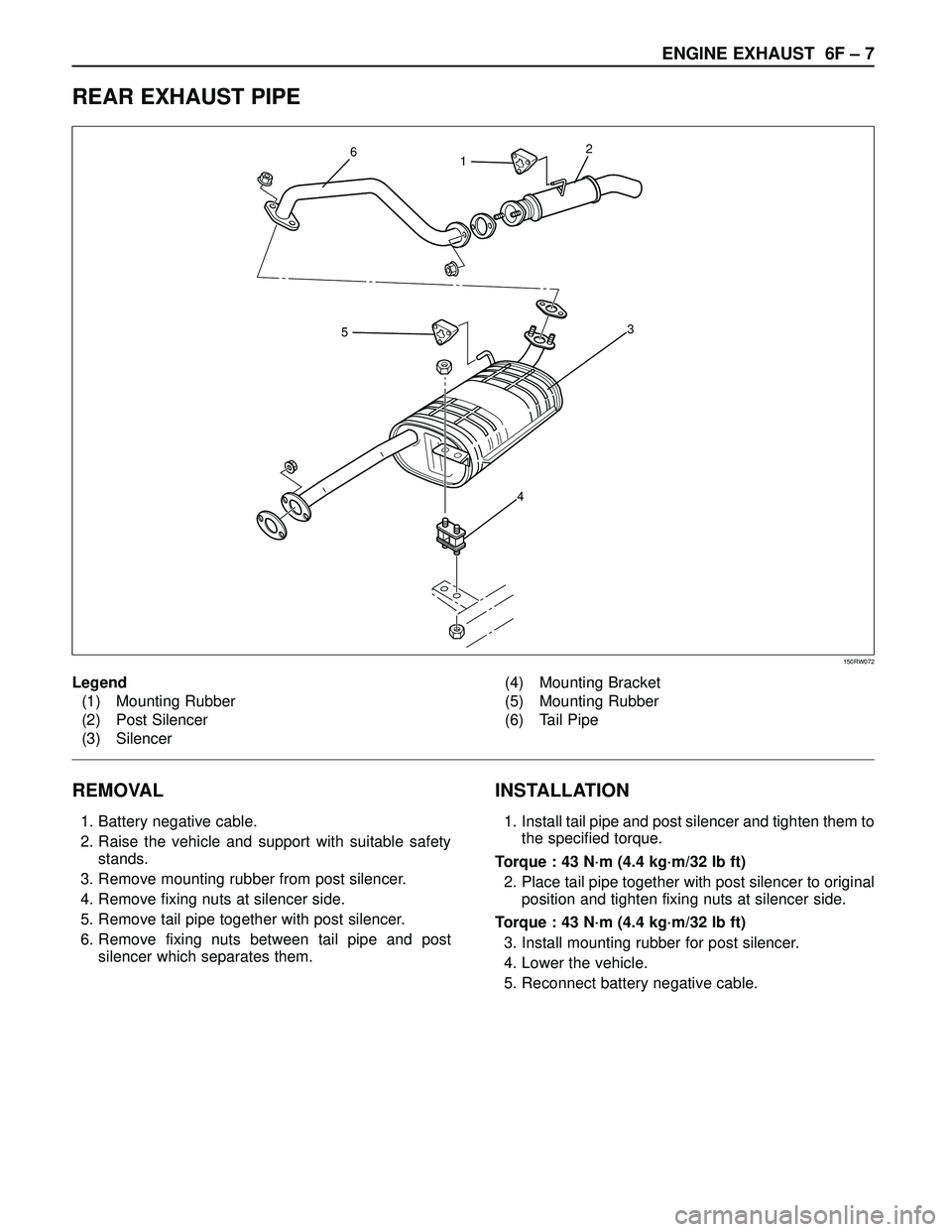

REAR EXHAUST PIPE

REMOVAL

1. Battery negative cable.

2. Raise the vehicle and support with suitable safety

stands.

3. Remove mounting rubber from post silencer.

4. Remove fixing nuts at silencer side.

5. Remove tail pipe together with post silencer.

6. Remove fixing nuts between tail pipe and post

silencer which separates them.

INSTALLATION

1. Install tail pipe and post silencer and tighten them to

the specified torque.

Torque : 43 N·m (4.4 kg·m/32 lb ft)

2. Place tail pipe together with post silencer to original

position and tighten fixing nuts at silencer side.

Torque : 43 N·m (4.4 kg·m/32 lb ft)

3. Install mounting rubber for post silencer.

4. Lower the vehicle.

5. Reconnect battery negative cable.

6

3

4

2

1

5

Legend

(1) Mounting Rubber

(2) Post Silencer

(3) Silencer(4) Mounting Bracket

(5) Mounting Rubber

(6) Tail Pipe

150RW072

Page 2136 of 3573

ENGINE LUBRICATION 6G – 5

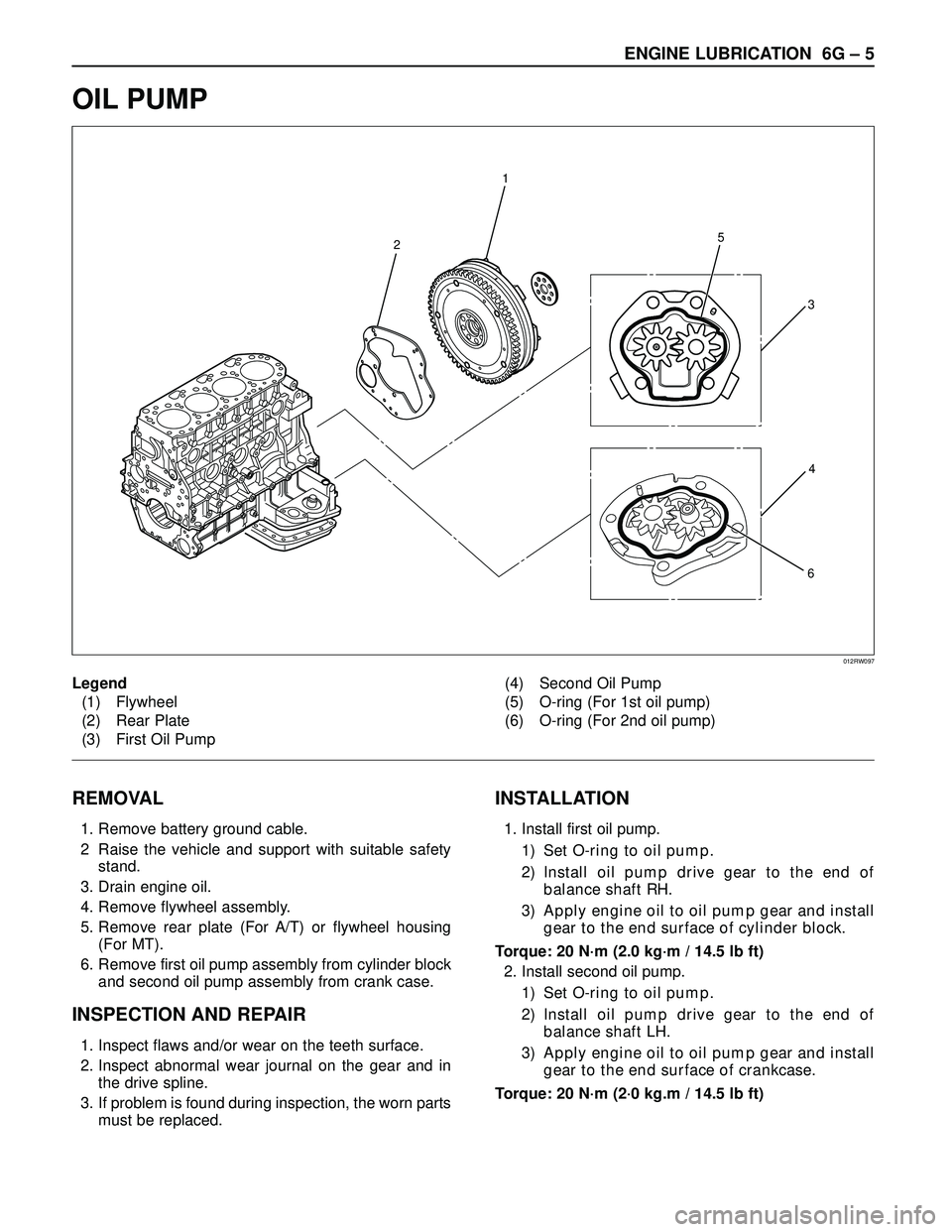

OIL PUMP

REMOVAL

1. Remove battery ground cable.

2 Raise the vehicle and support with suitable safety

stand.

3. Drain engine oil.

4. Remove flywheel assembly.

5. Remove rear plate (For A/T) or flywheel housing

(For MT).

6. Remove first oil pump assembly from cylinder block

and second oil pump assembly from crank case.

INSPECTION AND REPAIR

1. Inspect flaws and/or wear on the teeth surface.

2. Inspect abnormal wear journal on the gear and in

the drive spline.

3. If problem is found during inspection, the worn parts

must be replaced.

INSTALLATION

1. Install first oil pump.

1) Set O-ring to oil pump.

2) Install oil pump drive gear to the end of

balance shaft RH.

3) Apply engine oil to oil pump gear and install

gear to the end surface of cylinder block.

Torque: 20 N·m (2.0 kg·m / 14.5 lb ft)

2. Install second oil pump.

1) Set O-ring to oil pump.

2) Install oil pump drive gear to the end of

balance shaft LH.

3) Apply engine oil to oil pump gear and install

gear to the end surface of crankcase.

Torque: 20 N·m (2·0 kg.m / 14.5 lb ft)

2

1

5

6

3

4

Legend

(1) Flywheel

(2) Rear Plate

(3) First Oil Pump(4) Second Oil Pump

(5) O-ring (For 1st oil pump)

(6) O-ring (For 2nd oil pump)

012RW097

Page 2137 of 3573

6G – 6 ENGINE LUBRICATION

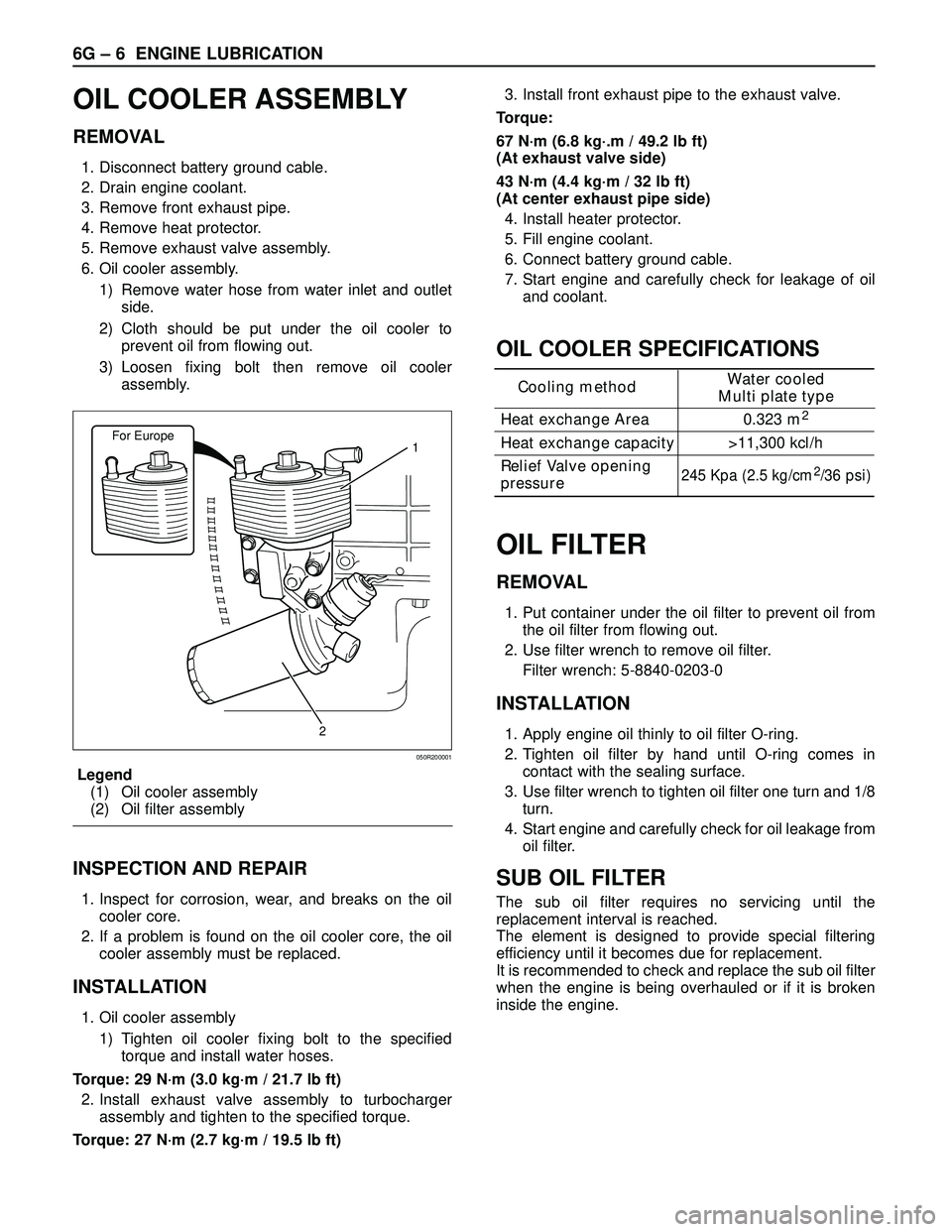

OIL COOLER ASSEMBLY

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove front exhaust pipe.

4. Remove heat protector.

5. Remove exhaust valve assembly.

6. Oil cooler assembly.

1) Remove water hose from water inlet and outlet

side.

2) Cloth should be put under the oil cooler to

prevent oil from flowing out.

3) Loosen fixing bolt then remove oil cooler

assembly.

Legend

(1) Oil cooler assembly

(2) Oil filter assembly

INSPECTION AND REPAIR

1. Inspect for corrosion, wear, and breaks on the oil

cooler core.

2. If a problem is found on the oil cooler core, the oil

cooler assembly must be replaced.

INSTALLATION

1. Oil cooler assembly

1) Tighten oil cooler fixing bolt to the specified

torque and install water hoses.

Torque: 29 N·m (3.0 kg·m / 21.7 lb ft)

2. Install exhaust valve assembly to turbocharger

assembly and tighten to the specified torque.

Torque: 27 N·m (2.7 kg·m / 19.5 lb ft)3. Install front exhaust pipe to the exhaust valve.

Torque:

67 N·m (6.8 kg·.m / 49.2 lb ft)

(At exhaust valve side)

43 N·m (4.4 kg·m / 32 lb ft)

(At center exhaust pipe side)

4. Install heater protector.

5. Fill engine coolant.

6. Connect battery ground cable.

7. Start engine and carefully check for leakage of oil

and coolant.

OIL COOLER SPECIFICATIONS

Cooling methodWater cooled

Multi plate type

Heat exchange Area 0.323 m

2

Heat exchange capacity >11,300 kcl/h

Relief Valve opening

245 Kpa (2.5 kg/cm2/36 psi)pressure

OIL FILTER

REMOVAL

1. Put container under the oil filter to prevent oil from

the oil filter from flowing out.

2. Use filter wrench to remove oil filter.

Filter wrench: 5-8840-0203-0

INSTALLATION

1. Apply engine oil thinly to oil filter O-ring.

2. Tighten oil filter by hand until O-ring comes in

contact with the sealing surface.

3. Use filter wrench to tighten oil filter one turn and 1/8

turn.

4. Start engine and carefully check for oil leakage from

oil filter.

SUB OIL FILTER

The sub oil filter requires no servicing until the

replacement interval is reached.

The element is designed to provide special filtering

efficiency until it becomes due for replacement.

It is recommended to check and replace the sub oil filter

when the engine is being overhauled or if it is broken

inside the engine.

For Europe1

2

050R200001