sensor ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 3024 of 3573

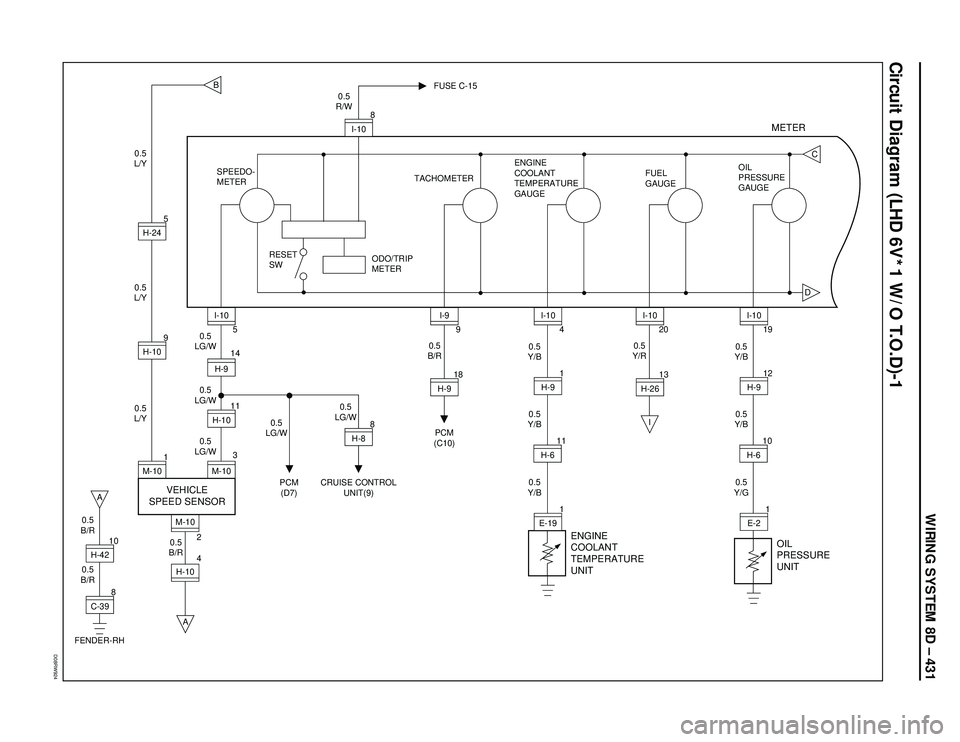

WIRING SYSTEM 8D – 431

D08RW924

Circuit Diagram (LHD 6V*1 W/O T.O.D)-1

8

C-3910H-42

0.5

B/R0.5

B/R 0.5

B/R

B

DC

A

FENDER-RH

H-104M-10

2A

I 0.5

L/Y0.5

L/Y0.5

L/Y

1

M-109H-105H-24

0.5

LG/W0.5

LG/W

0.5

LG/W0.5

LG/W 0.5

LG/W0.5

R/W

SPEEDO-

METER

RESET

SWTACHOMETERENGINE

COOLANT

TEMPERATURE

GAUGEFUEL

GAUGEOIL

PRESSURE

GAUGE FUSE C-15

3

M-10145H-9

11H-10

VEHICLE

SPEED SENSOR

I-10

0.5

Y/B0.5

Y/B0.5

Y/B

1

E-191 4H-9

11H-6I-10

8

H-8

PCM

(D7)CRUISE CONTROL

UNIT(9)0.5

B/R

18

H-9

PCM

(C10)9I-9

0.5

Y/R

13H-2620I-10

ENGINE

COOLANT

TEMPERATURE

UNIT

0.5

Y/G0.5

Y/B0.5

Y/B

1E-212 19H-9

10H-6I-10

OIL

PRESSURE

UNIT

8

I-10

METER

ODO/TRIP

METER

Page 3029 of 3573

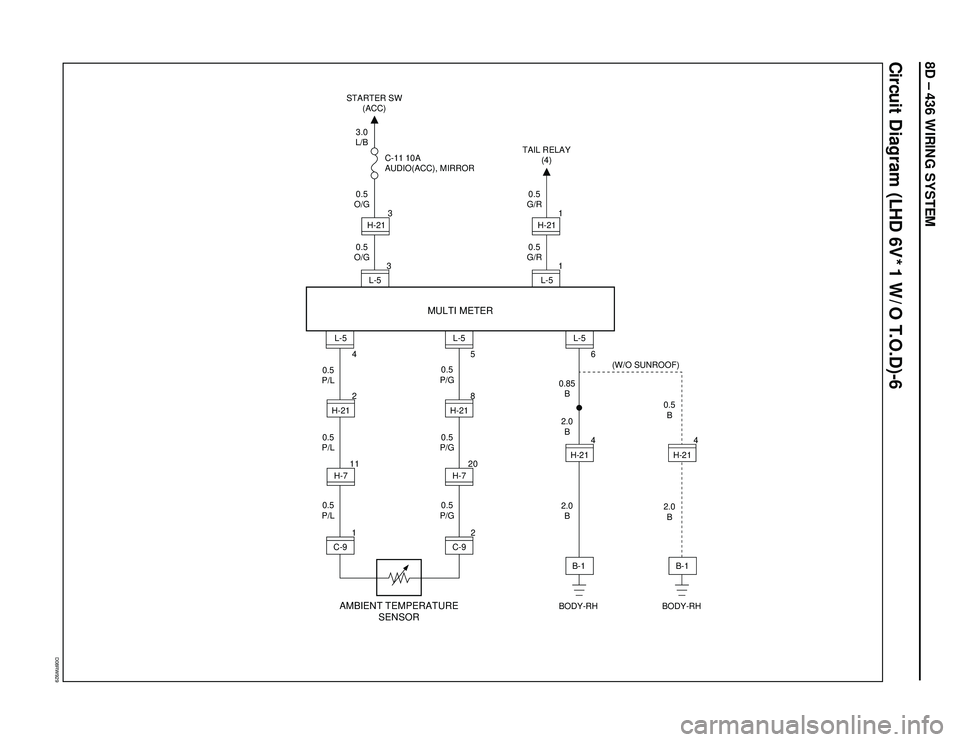

8D – 436 WIRING SYSTEM

Circuit Diagram (LHD 6V*1 W/O T.O.D)-6

D08RW929

BODY-RH BODY-RH TAIL RELAY

(4)

(W/O SUNROOF) STARTER SW

(ACC)

AMBIENT TEMPERATURE

SENSOR

0.5

B

2.0

B 2.0

B 2.0

B 0.5

P/G0.5

G/R0.5

G/R

0.5

O/G0.5

O/G3.0

L/B

0.5

P/G 0.5

P/L0.5

P/L

0.5

P/G 0.5

P/L0.85

B

4

H-21 4 6

H-21 H-21H-21

H-7

C-9L-5

5

8

H-212

20

H-711

2

C-91L-5

4 L-53

L-51 1

H-213

L-5

B-1 B-1

MULTI METER

C-11 10A

AUDIO(ACC), MIRROR

Page 3030 of 3573

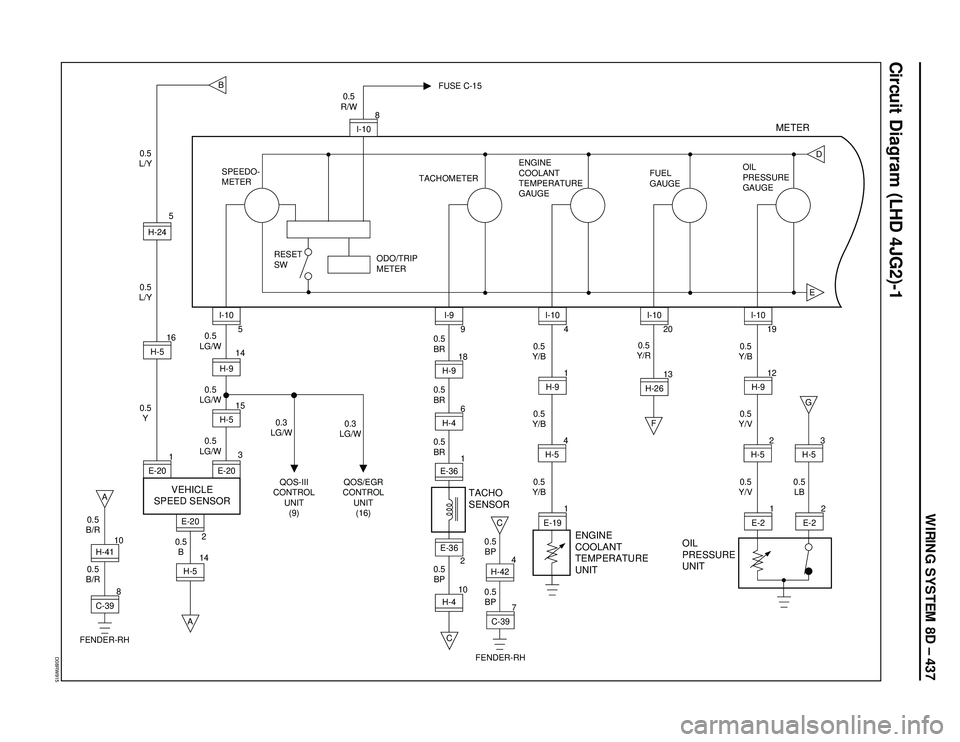

WIRING SYSTEM 8D – 437

D08RW915

Circuit Diagram (LHD 4JG2)-1

8

C-3910H-41

0.5

B/R0.5

B 0.5

B/R

B

EG

F

D

A

FENDER-RH

H-514E-20

2A 0.5

Y 0.5

L/Y0.5

L/Y

1

E-2016H-5H-245

0.5

LG/W0.5

LG/W

0.3

LG/W0.3

LG/W 0.5

LG/W0.5

R/W

SPEEDO-

METER

RESET

SWTACHOMETERENGINE

COOLANT

TEMPERATURE

GAUGEFUEL

GAUGEOIL

PRESSURE

GAUGE FUSE C-15

3

E-20145H-9

15H-5

VEHICLE

SPEED SENSOR

I-10

0.5

Y/B0.5

Y/B0.5

Y/B

1

E-191 4H-9

4H-5I-10

QOS-III

CONTROL

UNIT

(9)QOS/EGR

CONTROL

UNIT

(16)0.5

BR

0.5

BR

0.5

BR

0.5

BP18

H-9

6H-49I-9

1E-36

0.5

Y/R

13H-2620I-10

ENGINE

COOLANT

TEMPERATURE

UNIT TACHO

SENSOR

0.5

Y/V0.5

LB 0.5

Y/V0.5

Y/B

1E-212 19H-9

2H-5

2

E-23H-5

C

0.5

BP 0.5

BP

7

C-39

FENDER-RH4H-42

I-10

OIL

PRESSURE

UNIT

8

I-10

METER

ODO/TRIP

METER

E-36

2

10H-4C

Page 3035 of 3573

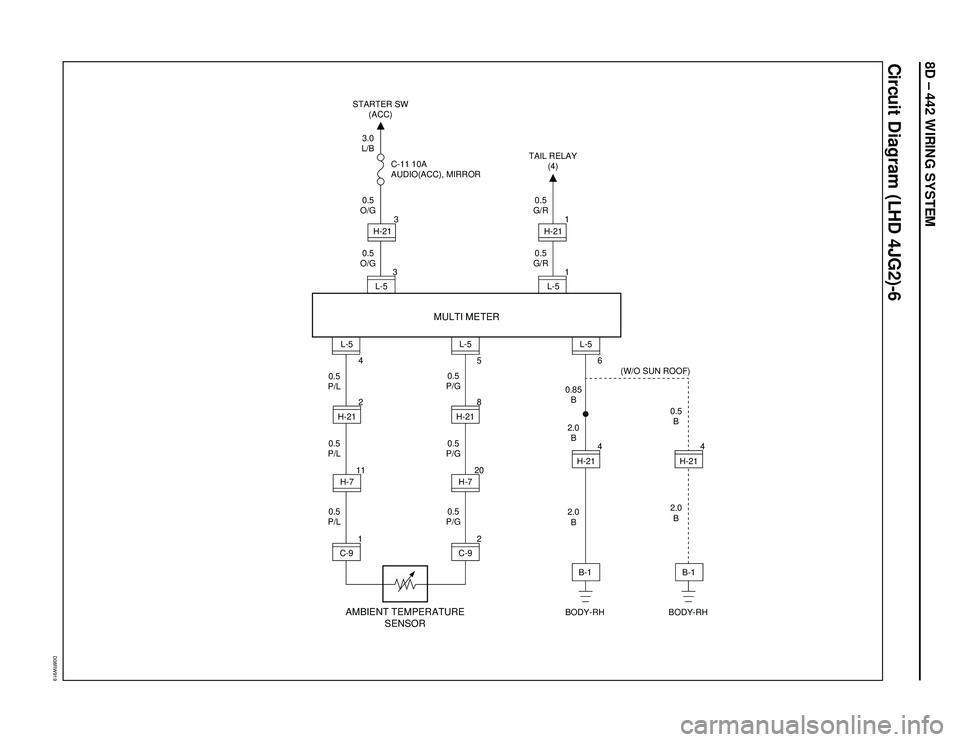

8D – 442 WIRING SYSTEM

D08RW919

Circuit Diagram (LHD 4JG2)-6

BODY-RH BODY-RH TAIL RELAY

(4)

(W/O SUN ROOF) STARTER SW

(ACC)

AMBIENT TEMPERATURE

SENSOR

0.5

B

2.0

B 2.0

B 2.0

B 0.5

P/G0.5

G/R0.5

G/R

0.5

O/G0.5

O/G3.0

L/B

0.5

P/G 0.5

P/L0.5

P/L

0.5

P/G 0.5

P/L0.85

B

4

H-21 4 6

H-21 H-21H-21

H-7

C-9L-5

5

8

H-212

20

H-711

2

C-91L-5

4 L-53

L-51 1

H-213

L-5

B-1 B-1

MULTI METER

C-11 10A

AUDIO(ACC), MIRROR

Page 3038 of 3573

WIRING SYSTEM 8DÐ445

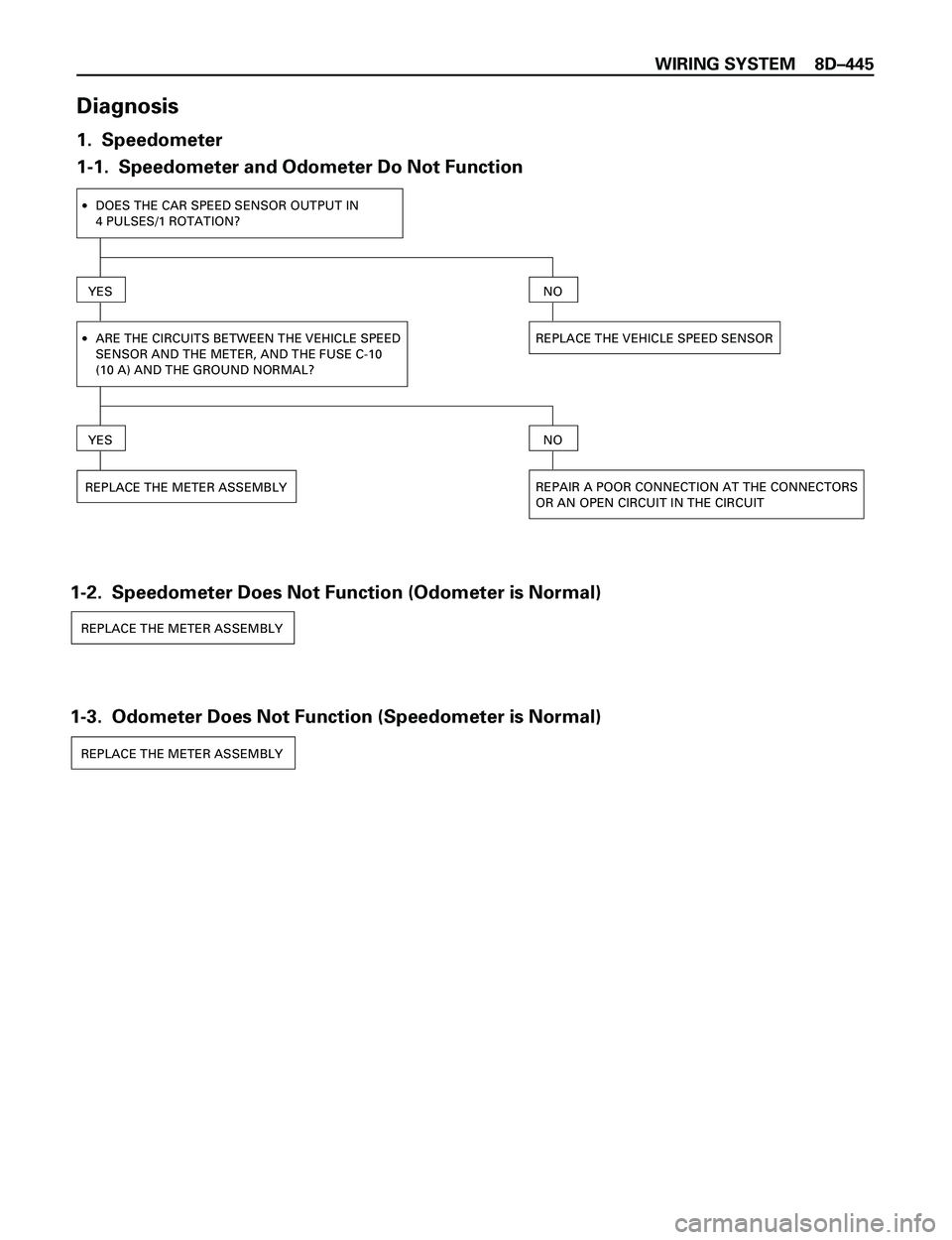

Diagnosis

1. Speedometer

1-1. Speedometer and Odometer Do Not Function

·DOES THE CAR SPEED SENSOR OUTPUT IN

4 PULSES/1 ROTATION?

YES

·ARE THE CIRCUITS BETWEEN THE VEHICLE SPEED

SENSOR AND THE METER, AND THE FUSE C-10

(10 A) AND THE GROUND NORMAL?

YES

REPLACE THE VEHICLE SPEED SENSOR

NO

REPAIR A POOR CONNECTION AT THE CONNECTORS

OR AN OPEN CIRCUIT IN THE CIRCUIT

NO

REPLACE THE METER ASSEMBLY

1-2. Speedometer Does Not Function (Odometer is Normal)

REPLACE THE METER ASSEMBLY

1-3. Odometer Does Not Function (Speedometer is Normal)

REPLACE THE METER ASSEMBLY

Page 3039 of 3573

8DÐ446 WIRING SYSTEM

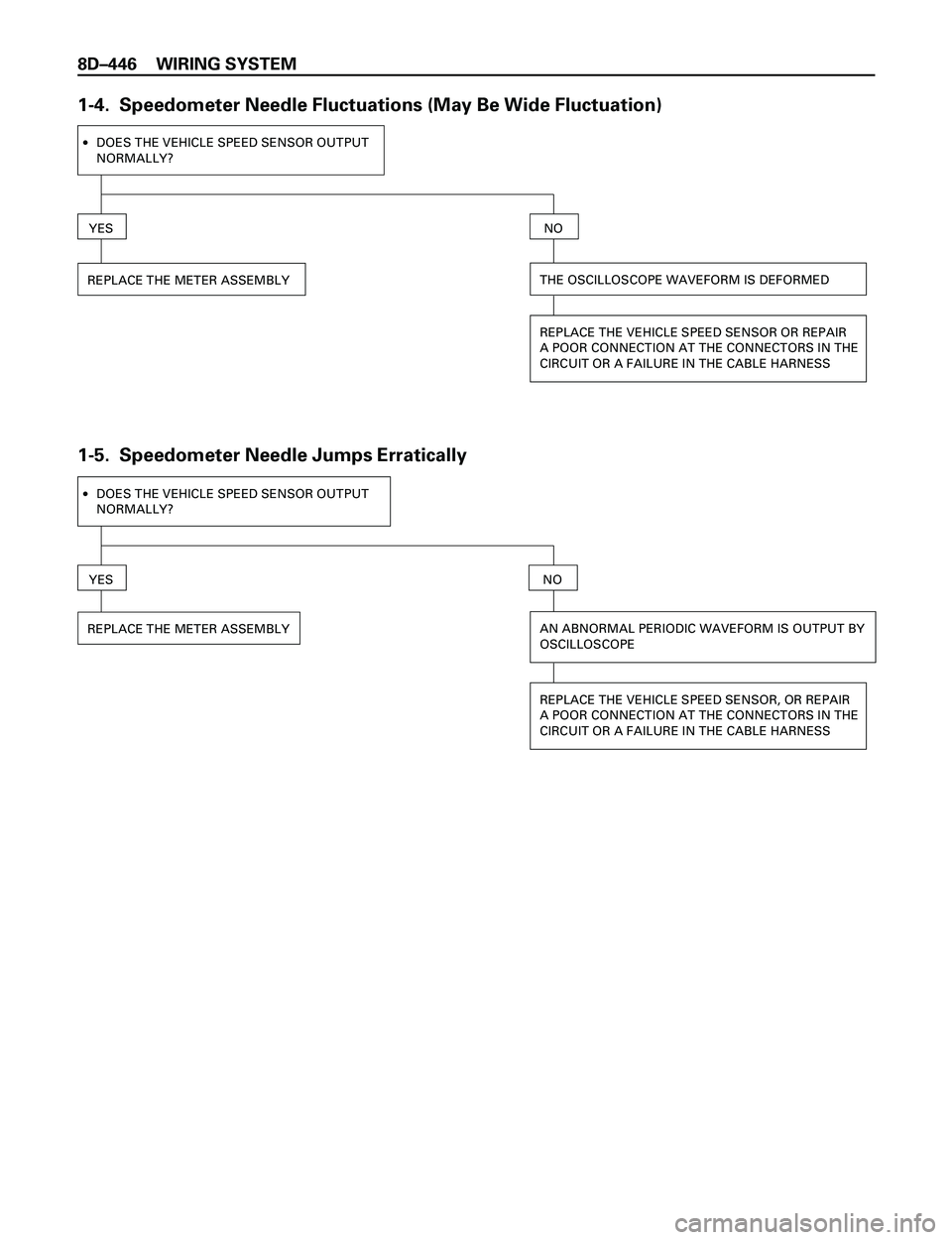

1-4. Speedometer Needle Fluctuations (May Be Wide Fluctuation)

·DOES THE VEHICLE SPEED SENSOR OUTPUT

NORMALLY?

YES

THE OSCILLOSCOPE WAVEFORM IS DEFORMEDREPLACE THE METER ASSEMBLY

REPLACE THE VEHICLE SPEED SENSOR OR REPAIR

A POOR CONNECTION AT THE CONNECTORS IN THE

CIRCUIT OR A FAILURE IN THE CABLE HARNESS

NO

1-5. Speedometer Needle Jumps Erratically

·DOES THE VEHICLE SPEED SENSOR OUTPUT

NORMALLY?

YES

AN ABNORMAL PERIODIC WAVEFORM IS OUTPUT BY

OSCILLOSCOPEREPLACE THE METER ASSEMBLY

REPLACE THE VEHICLE SPEED SENSOR, OR REPAIR

A POOR CONNECTION AT THE CONNECTORS IN THE

CIRCUIT OR A FAILURE IN THE CABLE HARNESS

NO

Page 3133 of 3573

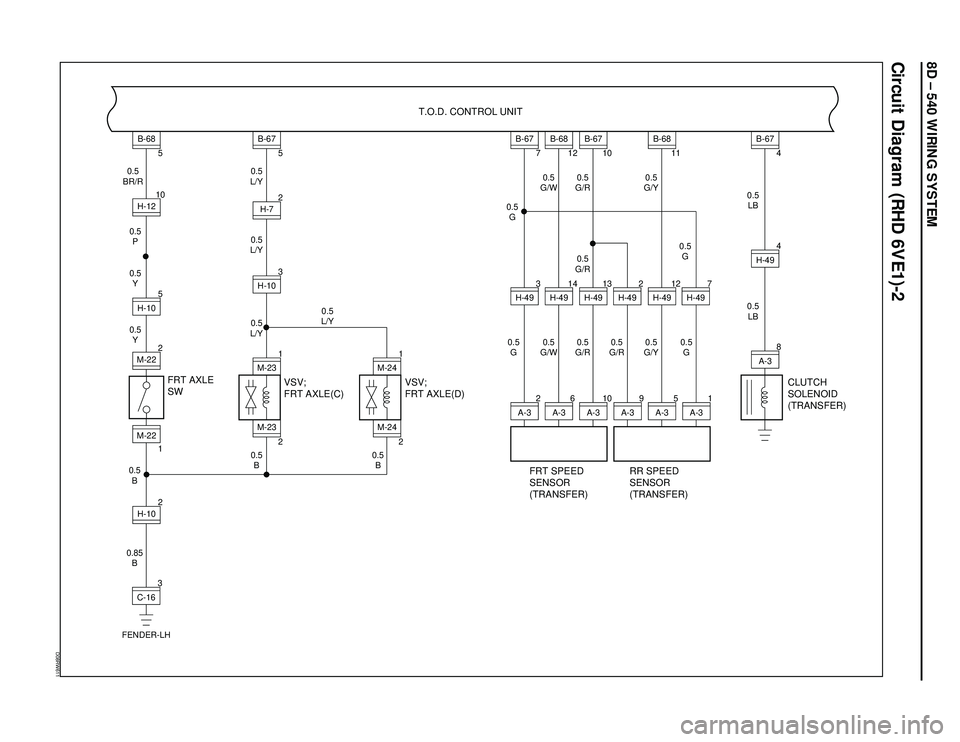

8D – 540 WIRING SYSTEM

Circuit Diagram (RHD 6VE1)-2

D08RW611

FRT AXLE

SWT.O.D. CONTROL UNIT3

C-16

FENDER-LHM-220.5

L/Y

0.5

G0.5

G/W0.5

G/R0.5

G/Y

0.5

LB

0.5

G/R0.5

G

0.5

G0.5

G 0.5

G/W0.5

G/R0.5

G/R0.5

G/Y0.5

LB 0.5

L/Y

0.5

L/Y 0.5

BR/R

0.5

P

0.5

Y

0.5

Y

0.5

B0.5

B

0.5

B

0.85

B0.5

L/Y

2M-225H-10

122B-68

5H-1210H-102

M-231M-233H-10B-67

5H-72

FRT SPEED

SENSOR

(TRANSFER)RR SPEED

SENSOR

(TRANSFER)CLUTCH

SOLENOID

(TRANSFER)

M-241M-24

2

A-33H-49B-67

7

6

A-314H-49B-68

12

10

A-313H-492

H-497

H-49

B-67

10

5

A-3 9

A-31

A-3 12

H-49B-68

11

8

A-3H-49B-67

4

4

VSV;

FRT AXLE(C)VSV;

FRT AXLE(D)

Page 3134 of 3573

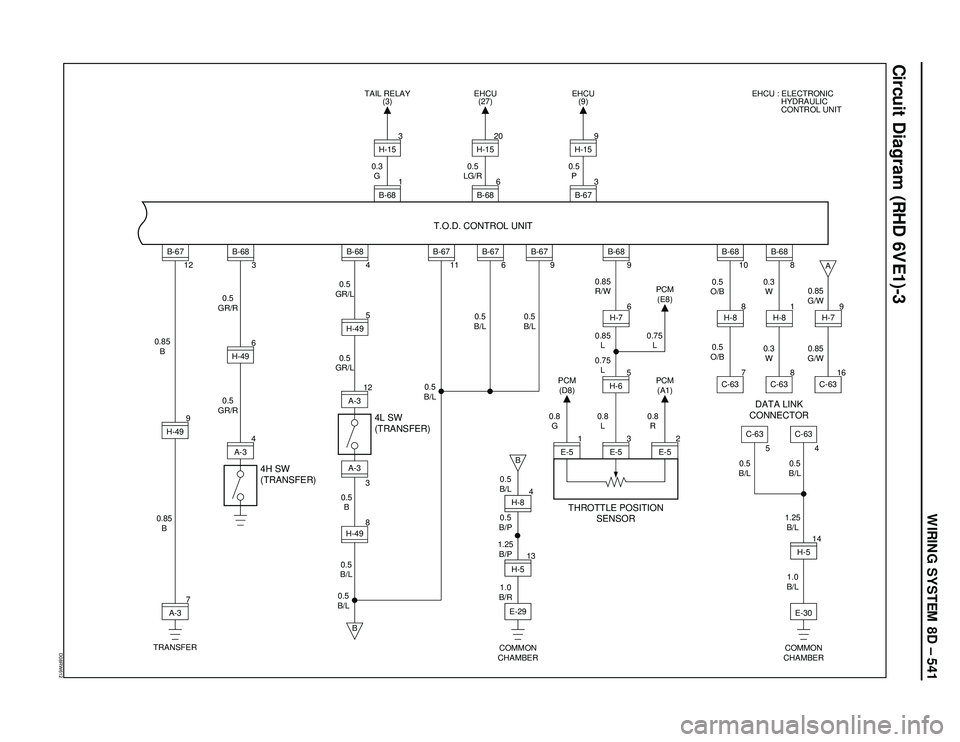

WIRING SYSTEM 8D – 541

Circuit Diagram (RHD 6VE1)-3

D08RW612

4H SW

(TRANSFER)T.O.D. CONTROL UNIT

7

A-3

TRANSFER9H-49

A-3

0.5

B/L 0.85

B4

A-36H-495

H-49

3H-498

B-67

0.85

B0.5

GR/R0.5

GR/L

0.5

GR/L

0.5

B

0.5

B/L 0.5

GR/R 12

B-68

3

B-68

4

B-67

11

B-67

6

4L SW

(TRANSFER)12

A-3

H-84

13H-5

E-30 1.25

B/L

1.0

B/L

E-29

3

E-52

E-5

14

H-5 5

H-6

COMMON

CHAMBER COMMON

CHAMBERB-68

9H-76

C-63

C-63

C-63

B-68

10H-8

7

C-63B-68

8H-8

8

54

C-63H-7

16 819

B

B

A

B-67

9

0.5

B/L0.5

B/L0.5

B/L0.85

R/W

0.85

L

0.75

L

0.8

L0.8

R 0.8

G

0.5

B/L

0.5

B/P0.5

B/L0.5

B/L 0.5

O/B0.3

W

0.3

W0.85

G/W0.85

G/W

0.5

O/B

1.25

B/P

1.0

B/R0.75

LPCM

(E8)

PCM

(A1) PCM

(D8)

6

B-68 EHCU

(27)

1

E-5THROTTLE POSITION

SENSORDATA LINK

CONNECTOR

20

H-15

1

B-68 TAIL RELAY

(3)

3

H-15

0.3

G0.5

LG/R0.5

P

3

B-67 EHCU

(9)EHCU : ELECTRONIC

HYDRAULIC

CONTROL UNIT

9

H-15

Page 3178 of 3573

METER AND GAUGE8E–1

METER AND GAUGE

CONTENTS

Service Precaution 8E–1. . . . . . . . . . . . . . . . . . . . . .

General Description 8E–1. . . . . . . . . . . . . . . . . . . . .

Meter Assembly 8E–2. . . . . . . . . . . . . . . . . . . . . . . . .

General Description 8E–2. . . . . . . . . . . . . . . . . . . . .

Layout for Meters/Gauges, Warning Lights,

Indicator Lights and Illumination Lights 8E–2. . .

Table for Meter/Gauge Connector Terminal

Connections 8E–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning Light Bulb, Indicator Light Bulb,

Illumination Light Bulb, A/T Indicator

Light Bulb 8E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . Vehicle Speed Sensor 8E–15. . . . . . . . . . . . . . . . . . .

Removal 8E–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank Unit 8E–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8E–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi Meter 8E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ambient Sensor 8E–16. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 8E–17. . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

The circuit consists of the starter switch, meter assembly,

vehicle speed sensor, transmission switch, lighting

switch, turn signal switch, thermo unit, oil pressure unit,

Powertrain Control Module (PCM), fuel tank unit, 4WD

switch, oil pressure switch, parking brake switch, brake

fluid switch, seat belt switch, illumination controller, multi

meter and ambient sensor.

Page 3192 of 3573

METER AND GAUGE8E–15

Vehicle Speed Sensor

Removal

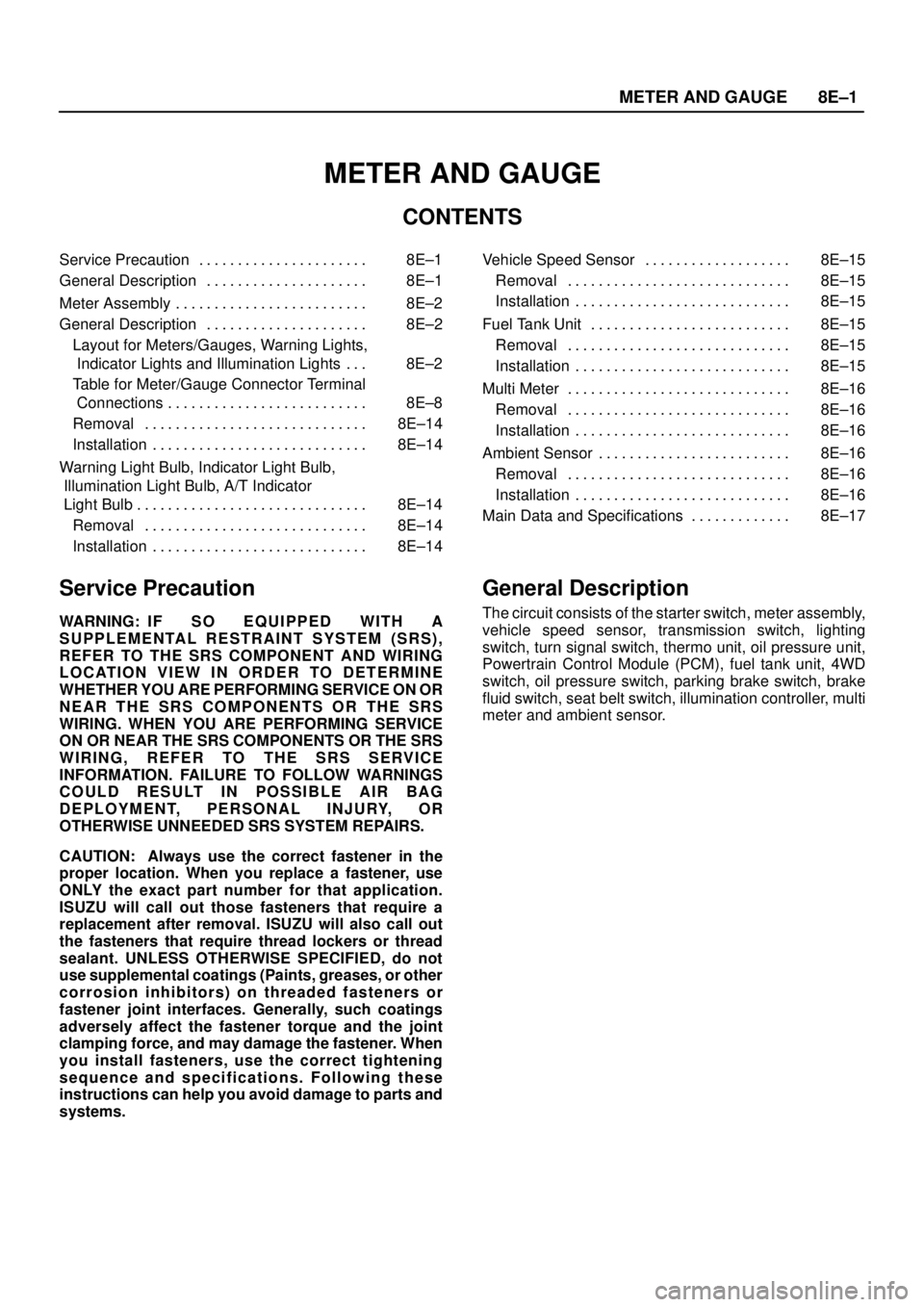

1. Disconnect the battery ground cable.

2. Disconnect the connector, remove the vehicle speed

sensor body by rotating it and then remove the vehicle

speed sensor(1).

826RS009

Installation

To install, follow the removal steps in the reverse order,

noting the following point.

1. Tighten the vehicle speed sensor to the specified

torque.

Torque: 27 N·m (2.8 kg·m/20 lb ft)

Fuel Tank Unit

Removal

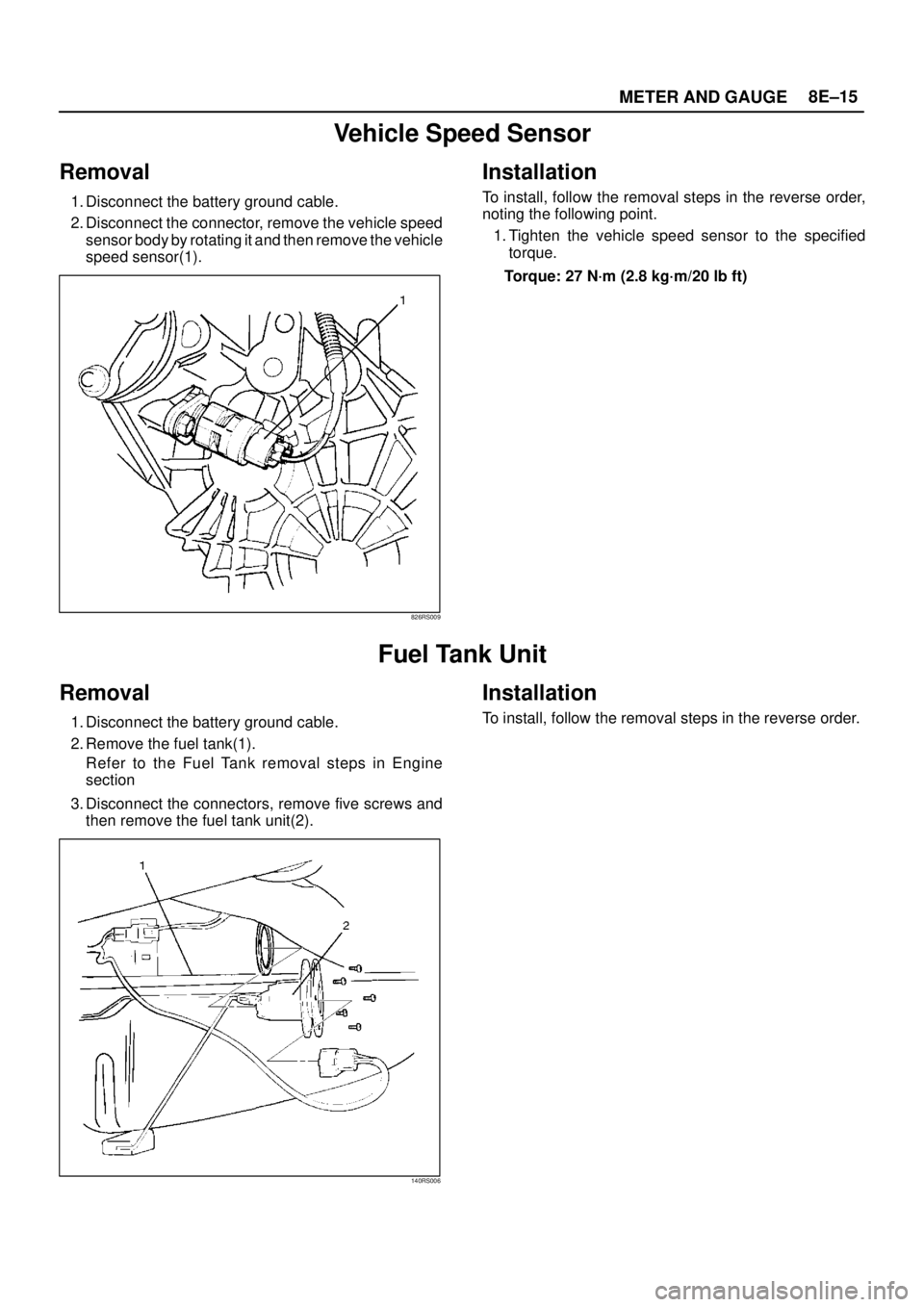

1. Disconnect the battery ground cable.

2. Remove the fuel tank(1).

Refer to the Fuel Tank removal steps in Engine

section

3. Disconnect the connectors, remove five screws and

then remove the fuel tank unit(2).

140RS006

Installation

To install, follow the removal steps in the reverse order.