engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1596 of 3573

6A Ð 46 ENGINE MECHANICAL

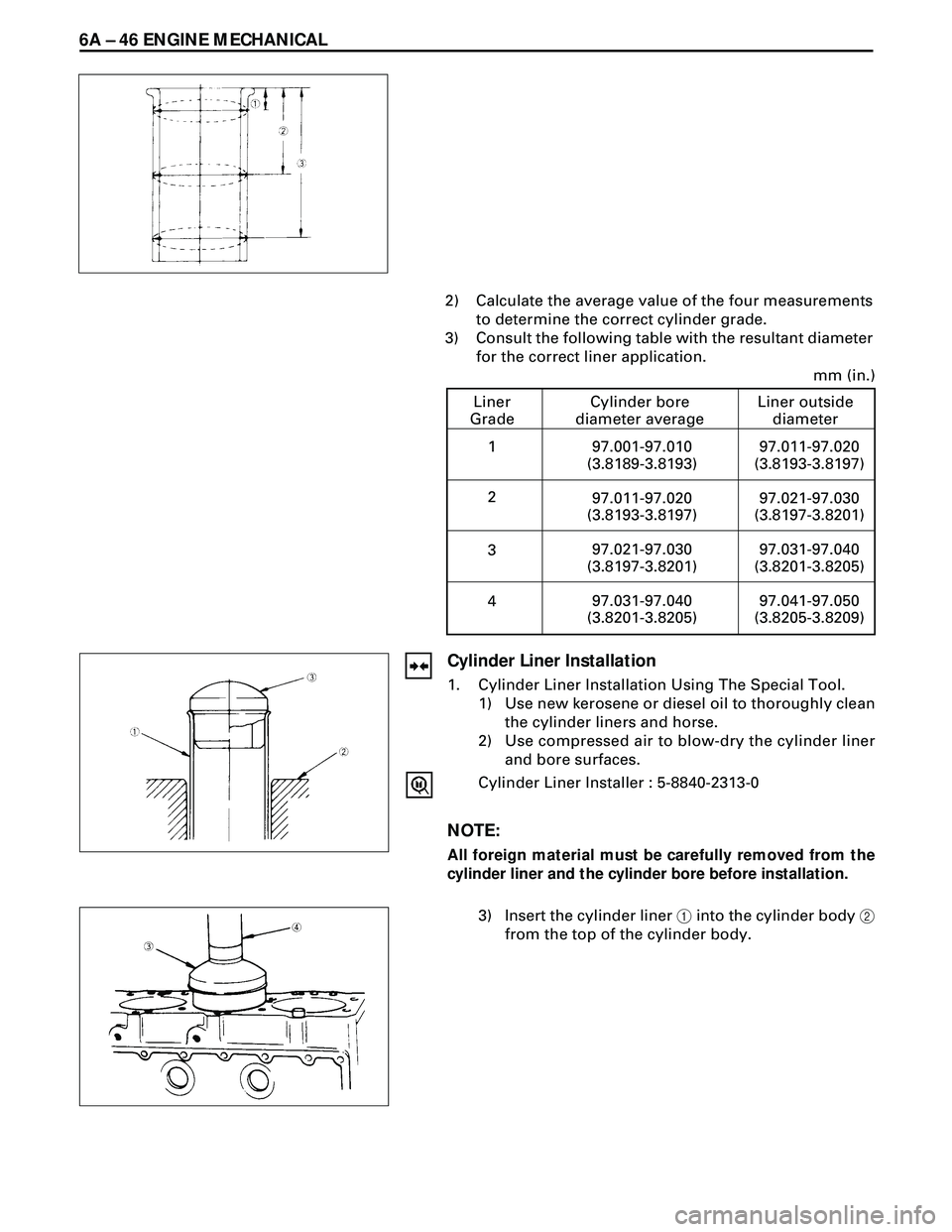

Cylinder bore

diameter average

1Liner outside

diameterLiner

Grade

97.001-97.010

(3.8189-3.8193)

97.011-97.020

(3.8193-3.8197)

97.021-97.030

(3.8197-3.8201)

97.031-97.040

(3.8201-3.8205)97.011-97.020

(3.8193-3.8197)

97.021-97.030

(3.8197-3.8201)

97.031-97.040

(3.8201-3.8205)

97.041-97.050

(3.8205-3.8209)

2

3

4

mm (in.) 2) Calculate the average value of the four measurements

to determine the correct cylinder grade.

3) Consult the following table with the resultant diameter

for the correct liner application.

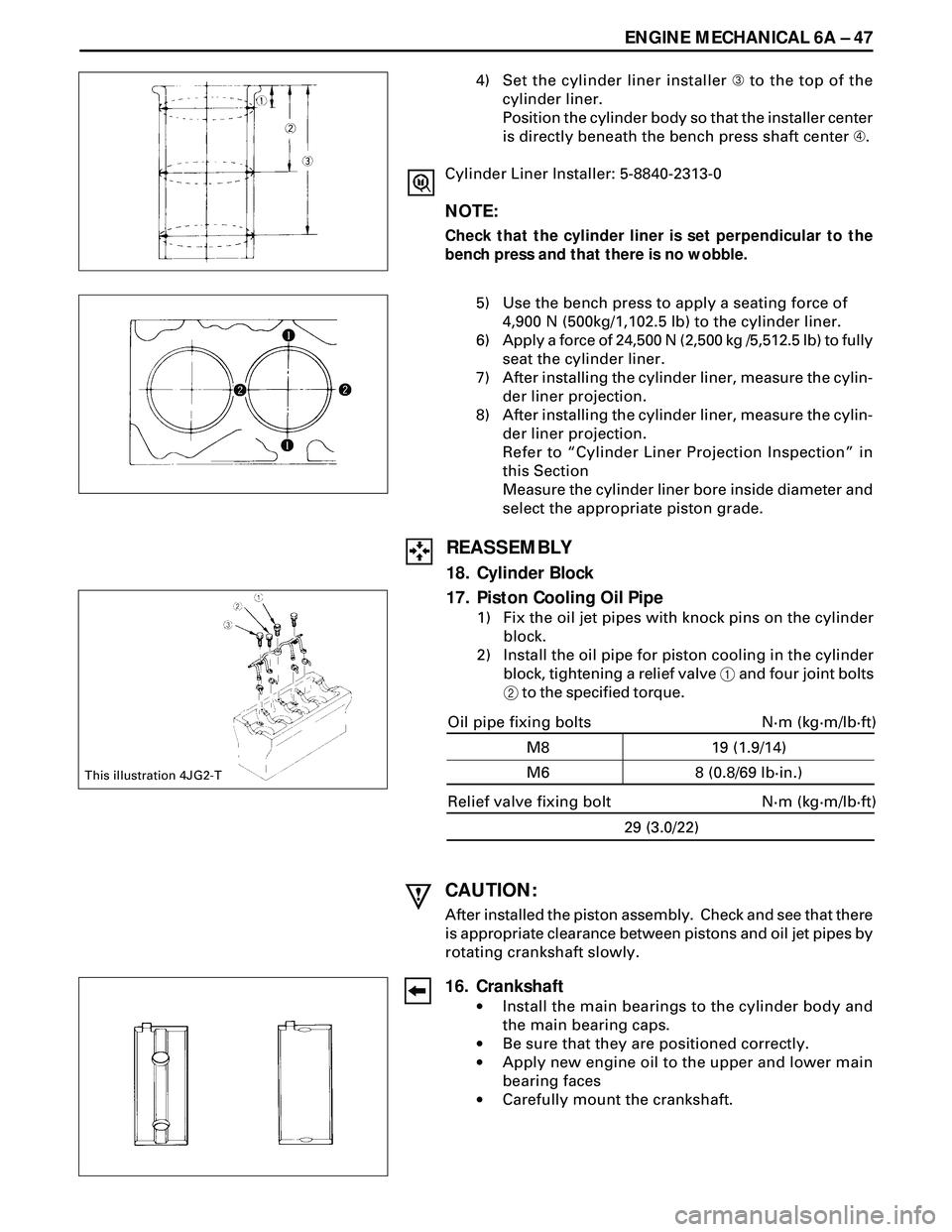

Cylinder Liner Installation

1. Cylinder Liner Installation Using The Special Tool.

1) Use new kerosene or diesel oil to thoroughly clean

the cylinder liners and horse.

2) Use compressed air to blow-dry the cylinder liner

and bore surfaces.

Cylinder Liner Installer : 5-8840-2313-0

NOTE:

All foreign material must be carefully removed from the

cylinder liner and the cylinder bore before installation.

3) Insert the cylinder liner 1 into the cylinder body 2

from the top of the cylinder body.

Page 1597 of 3573

ENGINE MECHANICAL 6A Ð 47

4) Set the cylinder liner installer  to the top of the

cylinder liner.

Position the cylinder body so that the installer center

is directly beneath the bench press shaft center Ã.

Cylinder Liner Installer: 5-8840-2313-0

NOTE:

Check that the cylinder liner is set perpendicular to the

bench press and that there is no wobble.

5) Use the bench press to apply a seating force of

4,900 N (500kg/1,102.5 lb) to the cylinder liner.

6) Apply a force of 24,500 N (2,500 kg /5,512.5 lb) to fully

seat the cylinder liner.

7) After installing the cylinder liner, measure the cylin-

der liner projection.

8) After installing the cylinder liner, measure the cylin-

der liner projection.

Refer to ÒCylinder Liner Projection InspectionÓ in

this Section

Measure the cylinder liner bore inside diameter and

select the appropriate piston grade.

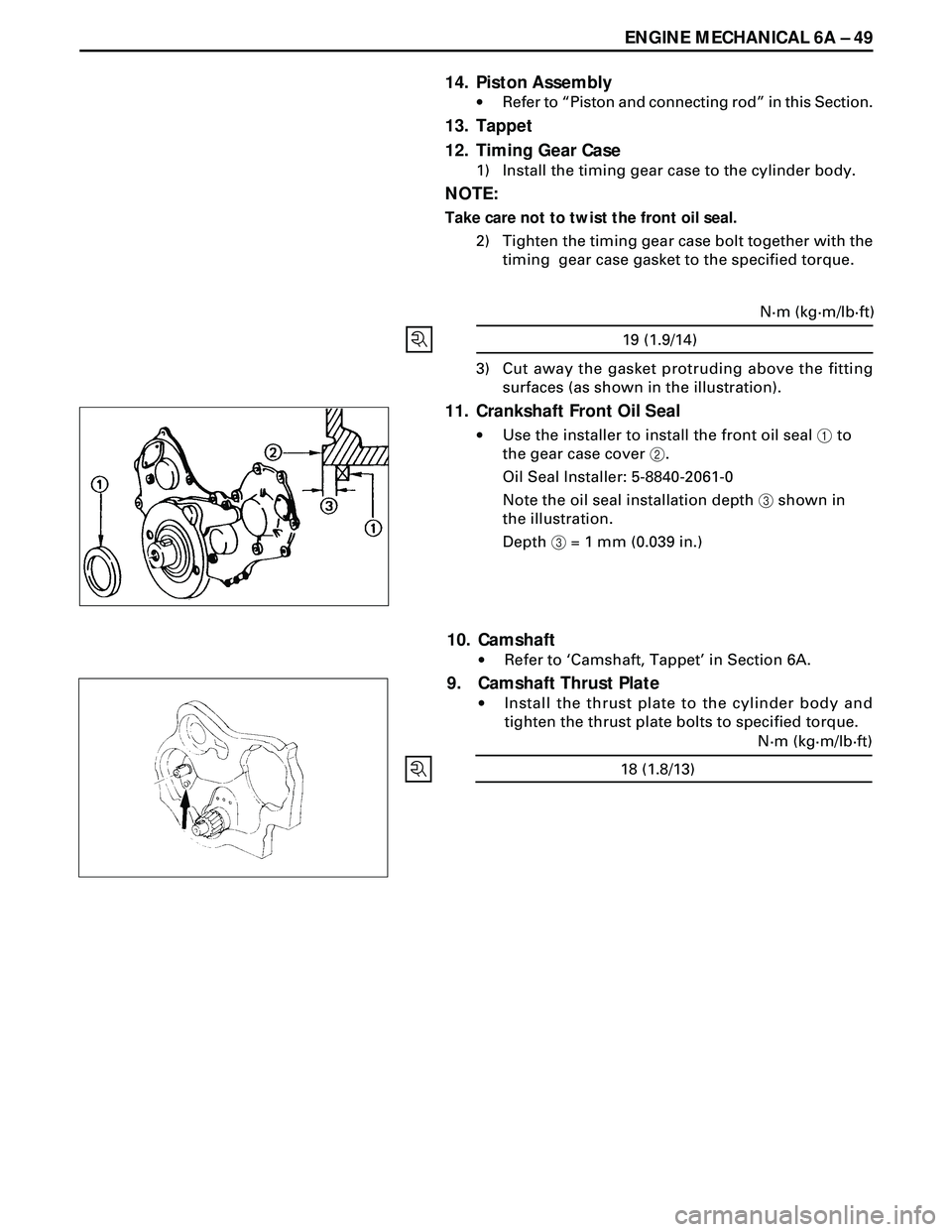

CAUTION:

After installed the piston assembly. Check and see that there

is appropriate clearance between pistons and oil jet pipes by

rotating crankshaft slowly.

16. Crankshaft

·Install the main bearings to the cylinder body and

the main bearing caps.

·Be sure that they are positioned correctly.

·Apply new engine oil to the upper and lower main

bearing faces

·Carefully mount the crankshaft.

This illustration 4JG2-T

REASSEMBLY

18. Cylinder Block

17. Piston Cooling Oil Pipe

1) Fix the oil jet pipes with knock pins on the cylinder

block.

2) Install the oil pipe for piston cooling in the cylinder

block, tightening a relief valve 1 and four joint bolts

2 to the specified torque.

Relief valve fixing bolt

29 (3.0/22)

Oil pipe fixing bolts

19 (1.9/14)

8 (0.8/69 lb·in.) M8

M6N·m (kg·m/lb·ft)

N·m (kg·m/lb·ft)

Page 1598 of 3573

6A Ð 48 ENGINE MECHANICAL

·Apply engine oil to the thrust washer.

·Assemble the thrust washer to the No. 3 bearing

journal. The oil grooves must face the crankshaft.

15. Main Bearing Cap Assembly

·Apply the recommended liquid gasket or its equiva-

lent to the No. 5 crankshaft bearing cap cylinder

body fiting surfaces at points 1 and 2 shown in the

illustration.

NOTE:

Be sure that the bearing cap fitting surface is completely

free of oil before applying the liquid gasket.

Do not allow the liquid gasket to obstruct the cylinder

thread holes and bearings.

·Install the bearing caps with the bearing cap head

arrow mark facing the front of the engine.

·Apply engine oil to the crankshaft bearing cap bolts.

·Tighten the crankshaft bearing cap bolts to the

specified torque a little at a time in the sequence

shown in the illustration.

NOTE:

Check to see that the crankshaft turns smoothly by rotating

it manually.

·Apply the recommended liquid packing or its equiva-

lent to the No. 5 crankshaft bearing cap 3 as shown

in the illustration.

Install the arch packing 4 to the No. 5 bearing cap.

NOTE:

Take care to install the arch packing in the groove of bearing

cap correctly.

Take care not to scratch the arch packing outer surface.

167 (17.0/123)N·m (kg·m/lb·ft)

Page 1599 of 3573

ENGINE MECHANICAL 6A Ð 49

14. Piston Assembly

·Refer to ÒPiston and connecting rodÓ in this Section.

13. Tappet

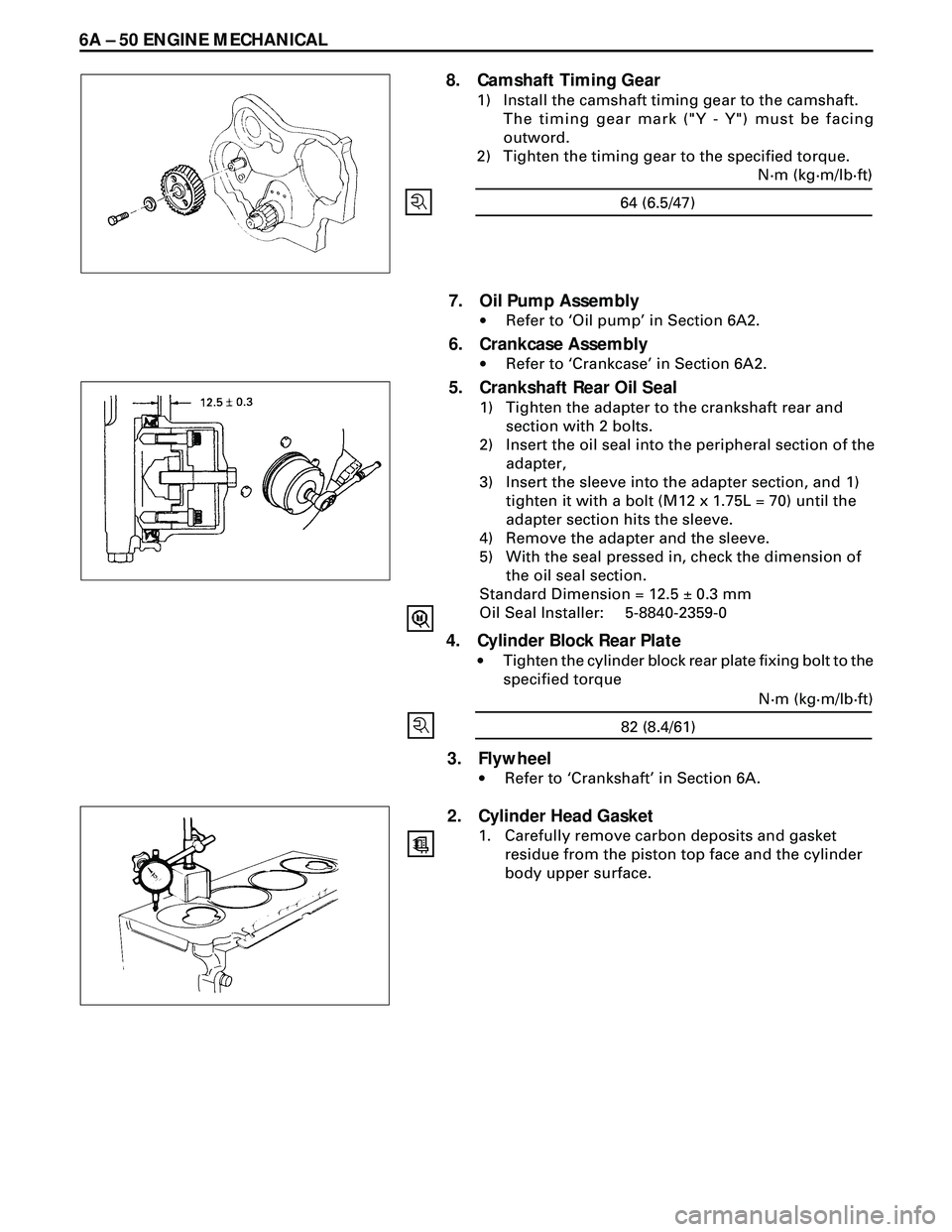

12. Timing Gear Case

1) Install the timing gear case to the cylinder body.

NOTE:

Take care not to twist the front oil seal.

2) Tighten the timing gear case bolt together with the

timing gear case gasket to the specified torque.

19 (1.9/14)N·m (kg·m/lb·ft)

3) Cut away the gasket protruding above the fitting

surfaces (as shown in the illustration).

11. Crankshaft Front Oil Seal

·Use the installer to install the front oil seal 1 to

the gear case cover 2.

Oil Seal Installer: 5-8840-2061-0

Note the oil seal installation depth 3 shown in

the illustration.

Depth 3 = 1 mm (0.039 in.)

10. Camshaft

·Refer to ÔCamshaft, TappetÕ in Section 6A.

9. Camshaft Thrust Plate

·Install the thrust plate to the cylinder body and

tighten the thrust plate bolts to specified torque.

18 (1.8/13)N·m (kg·m/lb·ft)

Page 1600 of 3573

6A Ð 50 ENGINE MECHANICAL

8. Camshaft Timing Gear

1) Install the camshaft timing gear to the camshaft.

The timing gear mark ("Y - Y") must be facing

outword.

2) Tighten the timing gear to the specified torque.

64 (6.5/47)N·m (kg·m/lb·ft)

7. Oil Pump Assembly

·Refer to ÔOil pumpÕ in Section 6A2.

6. Crankcase Assembly

·Refer to ÔCrankcaseÕ in Section 6A2.

5. Crankshaft Rear Oil Seal

1) Tighten the adapter to the crankshaft rear and

section with 2 bolts.

2) Insert the oil seal into the peripheral section of the

adapter,

3) Insert the sleeve into the adapter section, and 1)

tighten it with a bolt (M12 x 1.75L = 70) until the

adapter section hits the sleeve.

4) Remove the adapter and the sleeve.

5) With the seal pressed in, check the dimension of

the oil seal section.

Standard Dimension = 12.5 ± 0.3 mm

Oil Seal Installer: 5-8840-2359-0

4. Cylinder Block Rear Plate

·Tighten the cylinder block rear plate fixing bolt to the

specified torque

82 (8.4/61)N·m (kg·m/lb·ft)

3. Flywheel

·Refer to ÔCrankshaftÕ in Section 6A.

2. Cylinder Head Gasket

1. Carefully remove carbon deposits and gasket

residue from the piston top face and the cylinder

body upper surface.

Page 1601 of 3573

ENGINE MECHANICAL 6A Ð 51

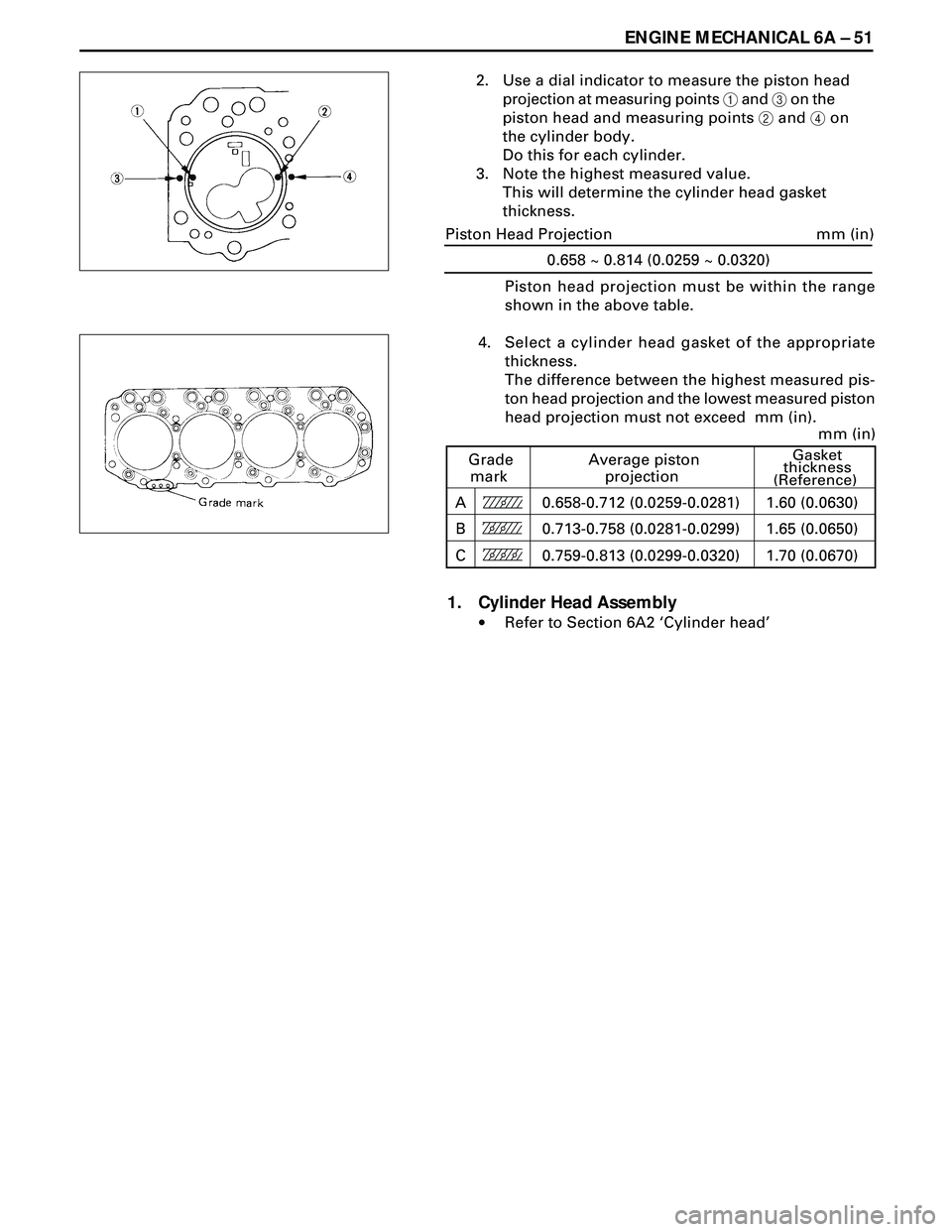

2. Use a dial indicator to measure the piston head

projection at measuring points 1 and 3 on the

piston head and measuring points 2 and 4 on

the cylinder body.

Do this for each cylinder.

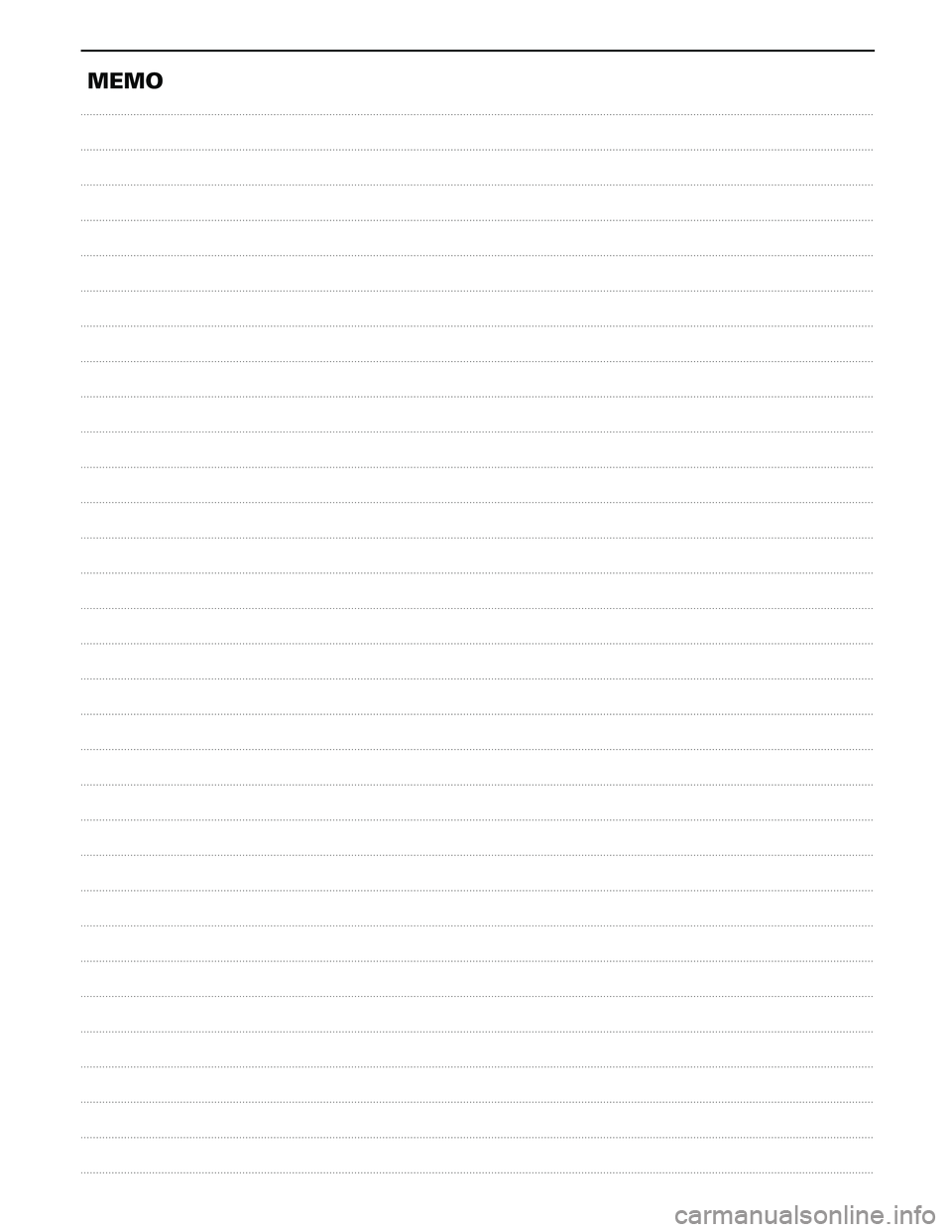

3. Note the highest measured value.

This will determine the cylinder head gasket

thickness.

Piston head projection must be within the range

shown in the above table.

4. Select a cylinder head gasket of the appropriate

thickness.

The difference between the highest measured pis-

ton head projection and the lowest measured piston

head projection must not exceed mm (in).

1. Cylinder Head Assembly

·Refer to Section 6A2 ÔCylinder headÕ

0.658 ~ 0.814 (0.0259 ~ 0.0320)

mm (in) Piston Head Projection

Grade

markAverage piston

projection

Gasket

thickness

(Reference)

A 0.658-0.712 (0.0259-0.0281) 1.60 (0.0630)

B 0.713-0.758 (0.0281-0.0299) 1.65 (0.0650)

C 0.759-0.813 (0.0299-0.0320) 1.70 (0.0670)

mm (in)

Page 1602 of 3573

6A Ð 52 ENGINE MECHANICAL

MEMO

Page 1603 of 3573

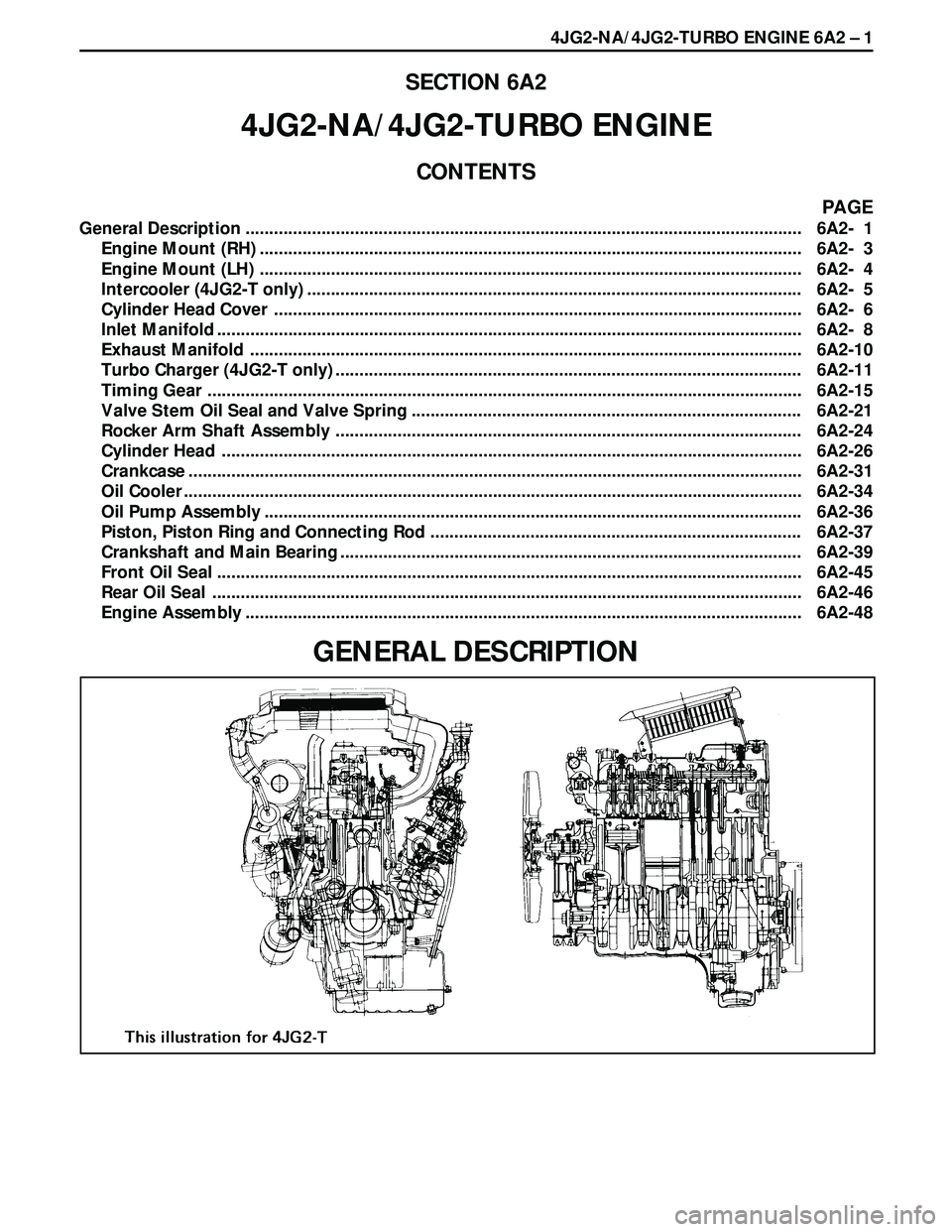

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 1

SECTION 6A2

4JG2-NA/4JG2-TURBO ENGINE

CONTENTS

PAGE

General Description ........................................................................\

............................................. 6A2- 1

Engine Mount (RH) ........................................................................\

...................................... .... 6A2- 3

Engine Mount (LH) ........................................................................\

...................................... .... 6A2- 4

Intercooler (4JG2-T only) ........................................................................\

.............................. .. 6A2- 5

Cylinder Head Cover ........................................................................\

.................................... ... 6A2- 6

Inlet Manifol d........................................................................\

........................................ .......... .6A2- 8

Exhaust Manifol d........................................................................\

...................................... ..... . 6A2-10

Turbo Charger (4JG2-T only) ........................................................................\

.......................... 6A 2-11

Timing Gear ........................................................................\

............................................ ......... 6A2-15

Valve Stem Oil Seal and Valve Spring ........................................................................\

.......... 6A2-21

Rocker Arm Shaft Assembly ........................................................................\

.......................... 6A2- 24

Cylinder Head ........................................................................\

.......................................... ........ 6A2-26

Crankcase ........................................................................\

.............................................. ........... 6A2-31

Oil Cooler ........................................................................\

............................................. ............. 6A2-34

Oil Pump Assembly ........................................................................\

...................................... ... 6A2-36

Piston, Piston Ring and Connecting Rod ........................................................................\

...... 6A2-37

Crankshaft and Main Bearing ........................................................................\

......................... 6A2 -39

Front Oil Seal ........................................................................\

......................................... .......... 6A2-45

Rear Oil Seal ........................................................................\

.......................................... .......... 6A2-46

Engine Assembly ........................................................................\

........................................ ..... 6A2-48

GENERAL DESCRIPTION

Page 1604 of 3573

6A2 Ð 2 4JG2-NA/4JG2-TURBO ENGINE

RECARD Comet V Type swirl combustion chamber which

provides superior driving performance, fuel economy and

silent combustion over a wide range of driving

conditions, is applied.

The cylinder head gasket is of laminated steel sheets.

Three grades of the gasket according to the measured

piston head projection from the cylinder block are

provided to give the engine a minimum compression

ration fluctuation.

The cylinder head fixing blots, flywheel bolts and con-

necting rod fixing bolts are tightened by the angular

Tightening Method.

The chrome plated steel dry type (Chromard) cylinder

liners provide the highest durability.

Auto-thermatic pistons having steel struts with 0.7 mm

offset from the piston pin center line, ate applied to

reduce thermal expansion and resulting engine noise

when the engine is cold.

The crankshaft bearings and connecting rod bearings are

of aluminum having a high bearing surface.

These bearing are especially sensitive to foreign material

such as metal scraps. So, it is very important that the oil

ports and other related surfaces are kept clean and free of

foreign material.

Crank shaft bearing selection for optimum bearing and

journal clearance is applied to reduce vibration and noise.

As tufftriding (Nitrizing treatment) is applied to increase

crankshaft strength, crankpins and journals should not be

reground.

An oiling jet device for piston cooling is provided in the

lubricating oil circuit from cylinder block oil gallery via a

check valve.

Take care not to damage any oiling jet when removing

and installing piston and connecting assembly.

The DFI (Double Formation Injection) Pintaux Type

injection nozzle having a sub-injection hole is applied.

This nozzle contributes to substantially minimize the

diesel knocking sound noticeable in the cold engine idling

operation.

Install the injection nozzle, directing the sub-injection hole

to the specified direction.

QOS III preheating system which features a quick-on glow

plug with thermometer control of the glowing time and

the afterglow time function, is applied.

Page 1605 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 3

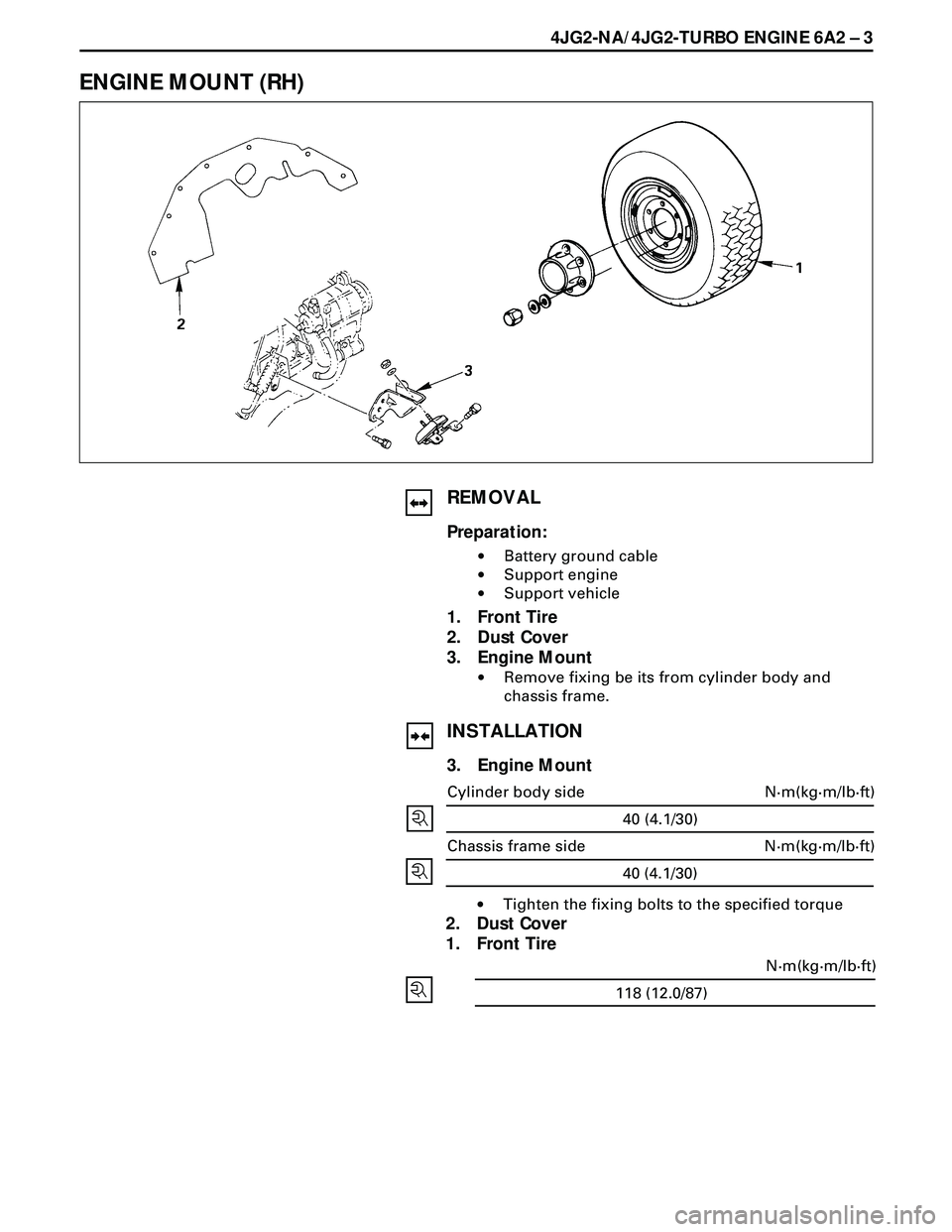

ENGINE MOUNT (RH)

REMOVAL

Preparation:

·Battery ground cable

·Support engine

·Support vehicle

1. Front Tire

2. Dust Cover

3. Engine Mount

·Remove fixing be its from cylinder body and

chassis frame.

INSTALLATION

3. Engine Mount

40 (4.1/30)

N·m(kg·m/lb·ft) Cylinder body side

40 (4.1/30)

N·m(kg·m/lb·ft) Chassis frame side

·Tighten the fixing bolts to the specified torque

2. Dust Cover

1. Front Tire

118 (12.0/87)N·m(kg·m/lb·ft)