ISUZU TROOPER 1998 Service Repair Manual

Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 941 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 63

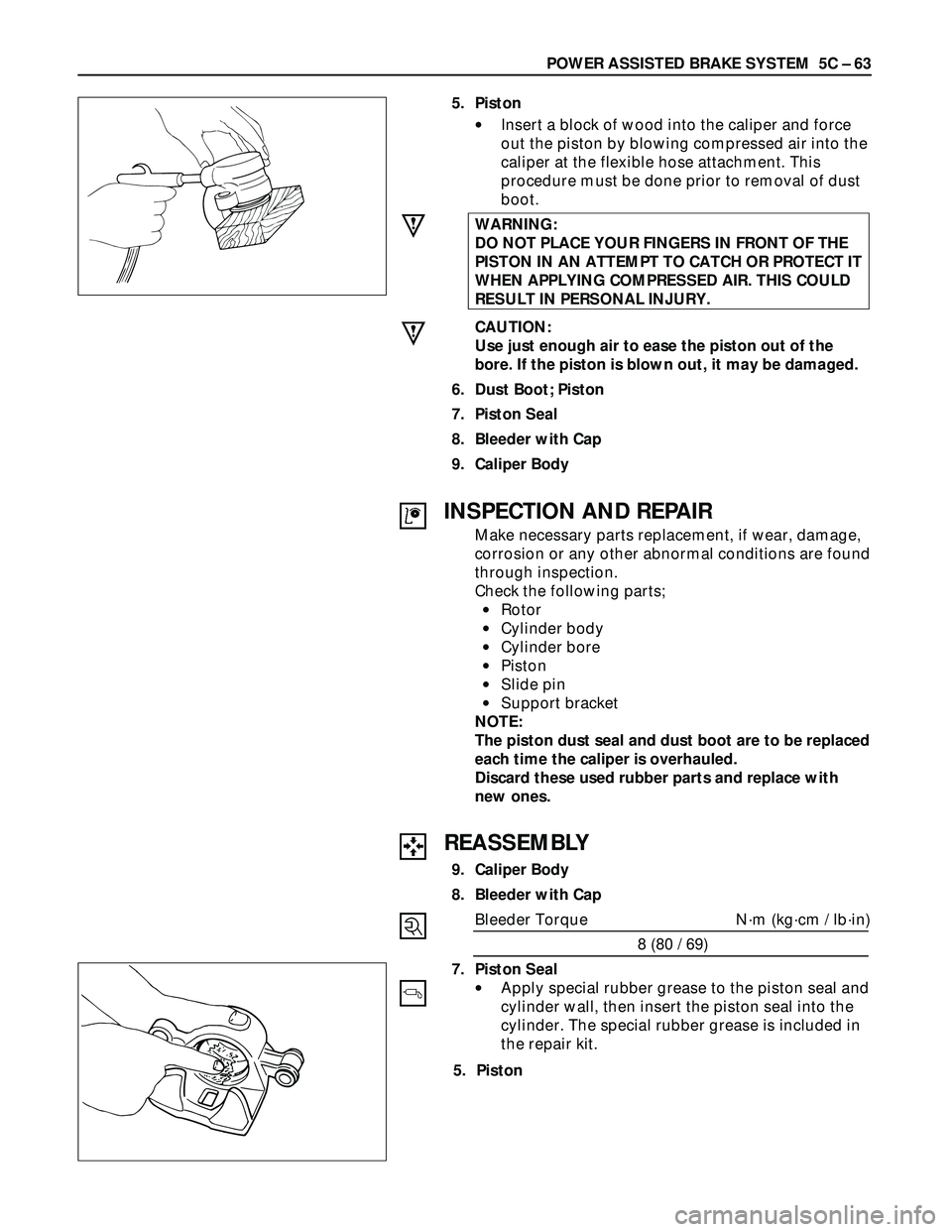

5. Piston

•Insert a block of wood into the caliper and force

out the piston by blowing compressed air into the

caliper at the flexible hose attachment. This

procedure must be done prior to removal of dust

boot.

WARNING:

DO NOT PLACE YOUR FINGERS IN FRONT OF THE

PISTON IN AN ATTEMPT TO CATCH OR PROTECT IT

WHEN APPLYING COMPRESSED AIR. THIS COULD

RESULT IN PERSONAL INJURY.

CAUTION:

Use just enough air to ease the piston out of the

bore. If the piston is blown out, it may be damaged.

6. Dust Boot; Piston

7. Piston Seal

8. Bleeder with Cap

9. Caliper Body

REASSEMBLY

9. Caliper Body

8. Bleeder with Cap

Bleeder Torque N·m (kg·cm / lb·in)

8 (80 / 69)

7. Piston Seal

•Apply special rubber grease to the piston seal and

cylinder wall, then insert the piston seal into the

cylinder. The special rubber grease is included in

the repair kit.

INSPECTION AND REPAIR

Make necessary parts replacement, if wear, damage,

corrosion or any other abnormal conditions are found

through inspection.

Check the following parts;

•Rotor

•Cylinder body

•Cylinder bore

•Piston

•Slide pin

•Support bracket

NOTE:

The piston dust seal and dust boot are to be replaced

each time the caliper is overhauled.

Discard these used rubber parts and replace with

new ones.

5. Piston

Page 942 of 3573

5C – 64 POWER ASSISTED BRAKE SYSTEM

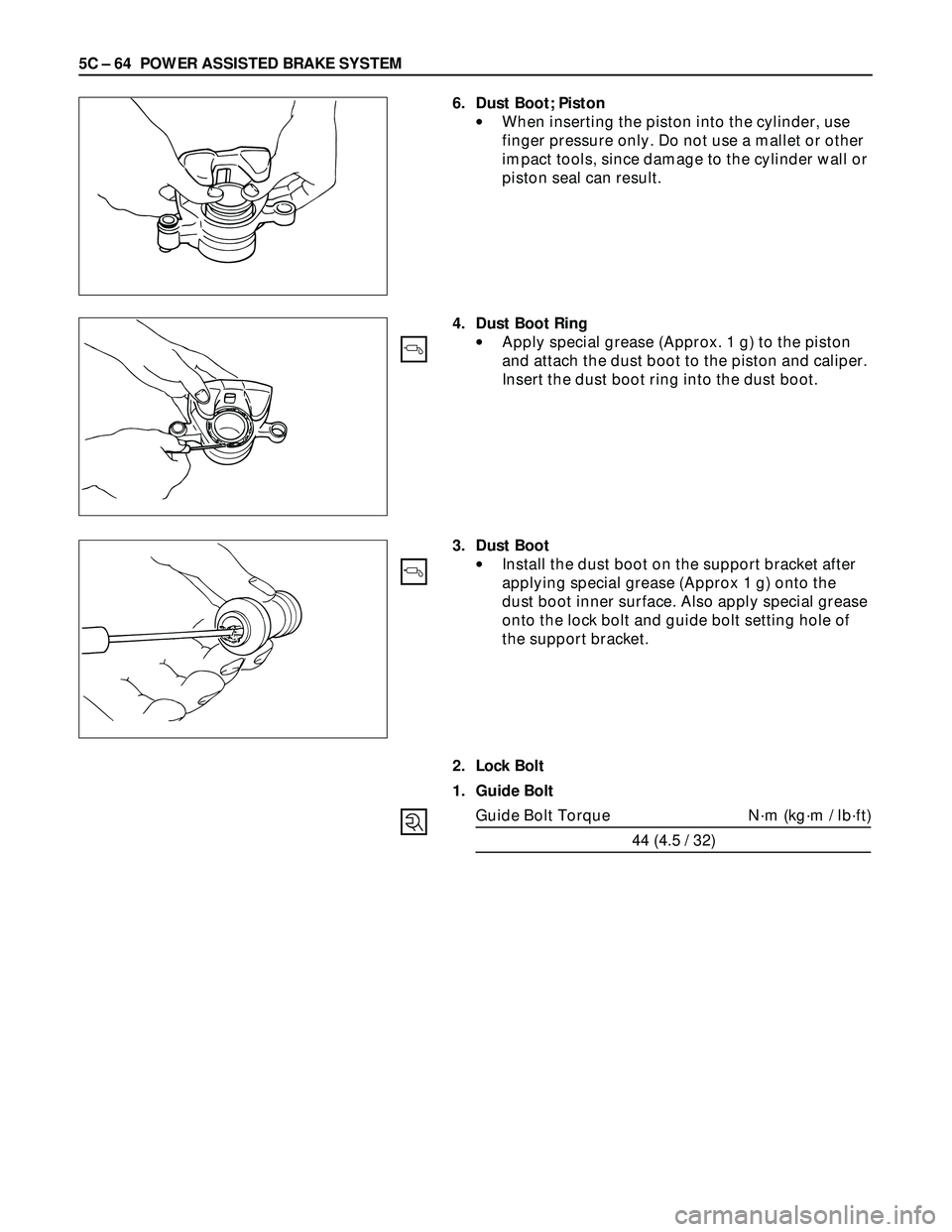

6. Dust Boot; Piston

•When inserting the piston into the cylinder, use

finger pressure only. Do not use a mallet or other

impact tools, since damage to the cylinder wall or

piston seal can result.

4. Dust Boot Ring

•Apply special grease (Approx. 1 g) to the piston

and attach the dust boot to the piston and caliper.

Insert the dust boot ring into the dust boot.

3. Dust Boot

•Install the dust boot on the support bracket after

applying special grease (Approx 1 g) onto the

dust boot inner surface. Also apply special grease

onto the lock bolt and guide bolt setting hole of

the support bracket.

2. Lock Bolt

1. Guide Bolt

Guide Bolt Torque N·m (kg·m / lb·ft)

44 (4.5 / 32)

Page 943 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 65

UNIT REPAIR

MASTER CYLINDER

The master cylinder is not repairable and must be

replaced as complete assembly if found defective.

INSPECTION

Excessive brake pedal travel, malfunction or dragging

brake suggests that the master cylinder is defective.

In such cases perform the following visual check.

Visual check

Make parts replacement as required if wear,

distortion, nicks, cuts, corrosion, or other abnormal

conditions are found through the following parts

inspection;

•Master cylinder body

•Fluid reservoir

•O-ring

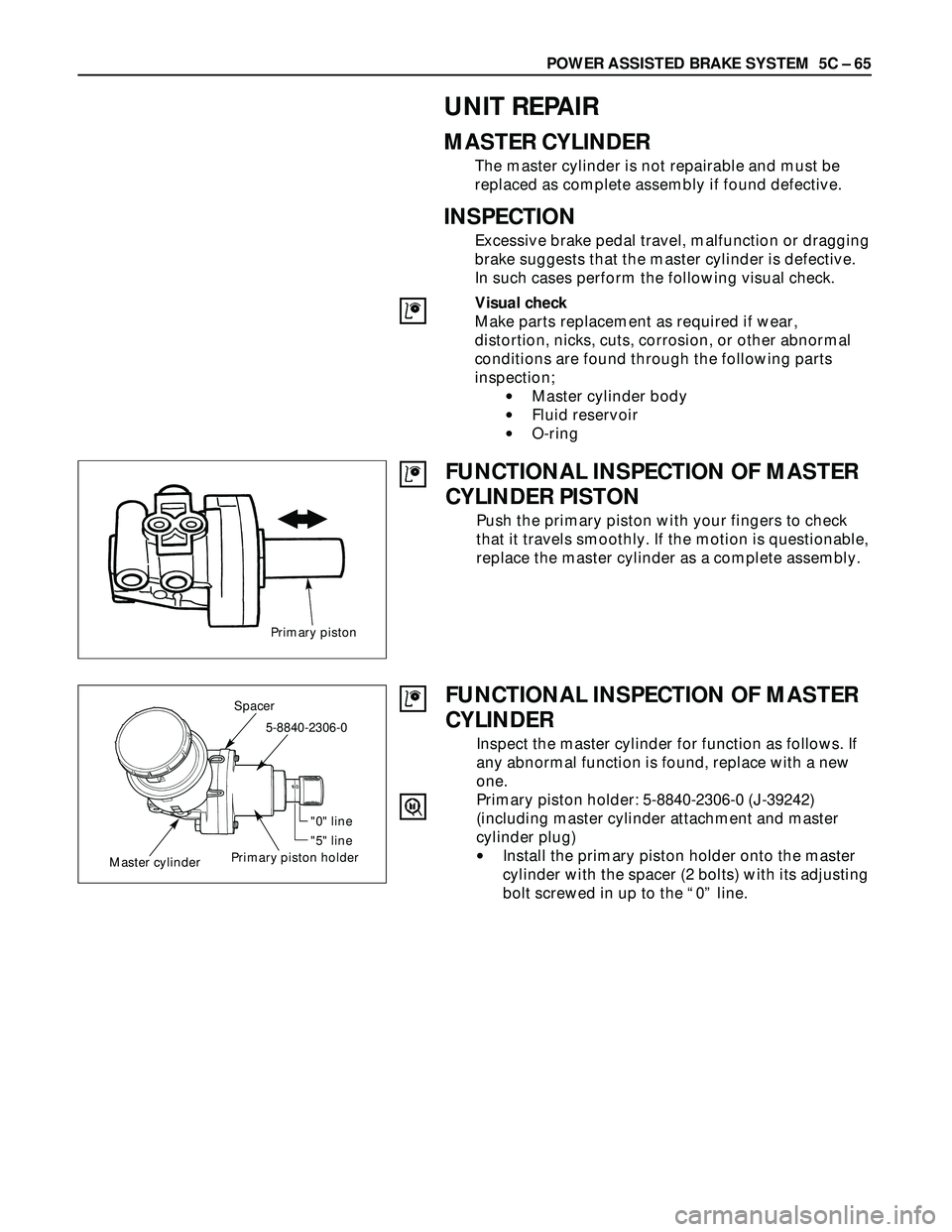

Primary piston

FUNCTIONAL INSPECTION OF MASTER

CYLINDER PISTON

Push the primary piston with your fingers to check

that it travels smoothly. If the motion is questionable,

replace the master cylinder as a complete assembly.

FUNCTIONAL INSPECTION OF MASTER

CYLINDER

Inspect the master cylinder for function as follows. If

any abnormal function is found, replace with a new

one.

Primary piston holder: 5-8840-2306-0 (J-39242)

(including master cylinder attachment and master

cylinder plug)

•Install the primary piston holder onto the master

cylinder with the spacer (2 bolts) with its adjusting

bolt screwed in up to the “0” line.

Master cylinder

Spacer

5-8840-2306-0

Primary piston holder"0" line

"5" line

Page 944 of 3573

5C – 66 POWER ASSISTED BRAKE SYSTEM

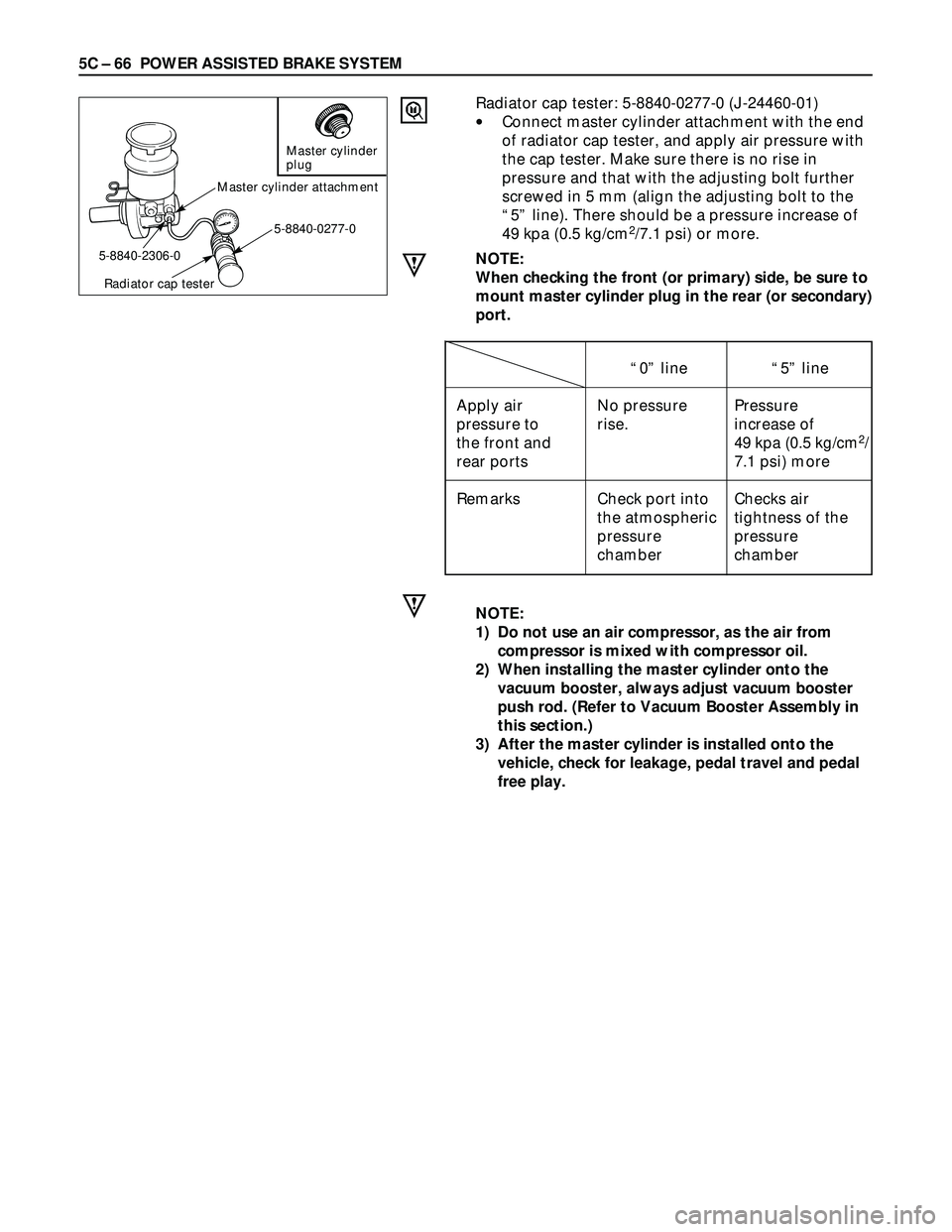

Radiator cap tester: 5-8840-0277-0 (J-24460-01)

•Connect master cylinder attachment with the end

of radiator cap tester, and apply air pressure with

the cap tester. Make sure there is no rise in

pressure and that with the adjusting bolt further

screwed in 5 mm (align the adjusting bolt to the

“5” line). There should be a pressure increase of

49 kpa (0.5 kg/cm

2/7.1 psi) or more.

NOTE:

When checking the front (or primary) side, be sure to

mount master cylinder plug in the rear (or secondary)

port.

NOTE:

1) Do not use an air compressor, as the air from

compressor is mixed with compressor oil.

2) When installing the master cylinder onto the

vacuum booster, always adjust vacuum booster

push rod. (Refer to Vacuum Booster Assembly in

this section.)

3) After the master cylinder is installed onto the

vehicle, check for leakage, pedal travel and pedal

free play.

Master cylinder

plug

Master cylinder attachment

5-8840-0277-0

Radiator cap tester

5-8840-2306-0

“0” line“5” line

Apply air No pressure Pressure

pressure to rise. increase of

the front and

49 kpa (0.5 kg/cm2/

rear ports 7.1 psi) more

Remarks Check port into Checks air

the atmospheric tightness of the

pressure pressure

chamber chamber

Page 945 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 67

VACUUM BOOSTER

•The vacuum booster cannot be disassembled for

repair. Replace a defective vacuum booster with a

new one.

Page 946 of 3573

PARKING BRAKES 5D Ð 1

SECTION 5D

PARKING BRAKES

CONTENTS

PAGE

Service Precaution .............................................................................................................5D- 1

Main Data and Specifications ........................................................................................... 5D- 2

Service Standard................................................................................................................ 5D- 2

Servicing ............................................................................................................................. 5D- 3

Fixing Torque ...................................................................................................................... 5D- 5

General Description ........................................................................................................... 5D- 6

On-Vehicle Service .............................................................................................................5D- 7

Parking Brake Lever Replacement ............................................................................... 5D- 7

Parking Brake Cable ...................................................................................................... 5D- 9

SERVICE PRECAUTION

WARNING:

IF SO EQUIPPED WITH A SUPPLEMENTAL RESTRAINT SYSTEM (SRS), REFER TO THE SRS COMPONENT

AND WIRING LOCATION VIEW IN ORDER TO DETERMINE WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS WIRING. WHEN YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS WIRING, REFER TO THE SRS SERVICE INFORMATION.

FAILURE TO FOLLOW WARNINGS COULD RESULT IN POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION:

Always use the correct fastener in the proper location. When you replace a fastener, use ONLY the exact

part number for that application. ISUZU will call out those fasteners that require a replacement after

removal. ISUZU will also call out the fasteners that require thread lockers or thread sealant. UNLESS

OTHERWISE SPECIFIED, do not use supplemental coatings (Paints, greases, or other corrosion inhibitors)

on threaded fasteners or fastener joint interfaces. Generally, such coatings adversely affect the fastener

torque and the joint clamping force, and may damage the fastener. When you install fasteners, use the

correct tightening sequence and specification. Following these instructions can help you avoid damage to

parts and systems.

Page 947 of 3573

5D Ð 2 PARKING BRAKES

MAIN DATA AND SPECIFICATIONS

REAR PARKING BRAKE

Type Duo-servo

Lining Dimensions cm

2(in2) 121.2 (18.79)

Adjusting Method Manual Adjusting

Rear Drum (in Disc)

Inside Diameter mm (in) 210 (8.27)

Parking Brake Lever Stroke 6 to 7 notches

When pulled with a force of 30 kg (66 lb)

SERVICE STANDARD

REAR PARKING BRAKE

Rear Drum (in Disc) Minimum Wear

Inside Diameter mm (in) 211.4 (8.32)

Parking Brake Lining Thickness

Minimum Limit mm (in) 1.0 (0.039)

Parking Brake Lever Stroke 6 to 7 notches

When pulled with a force of 30 kg (66 lb)

Page 948 of 3573

PARKING BRAKES 5D Ð 3

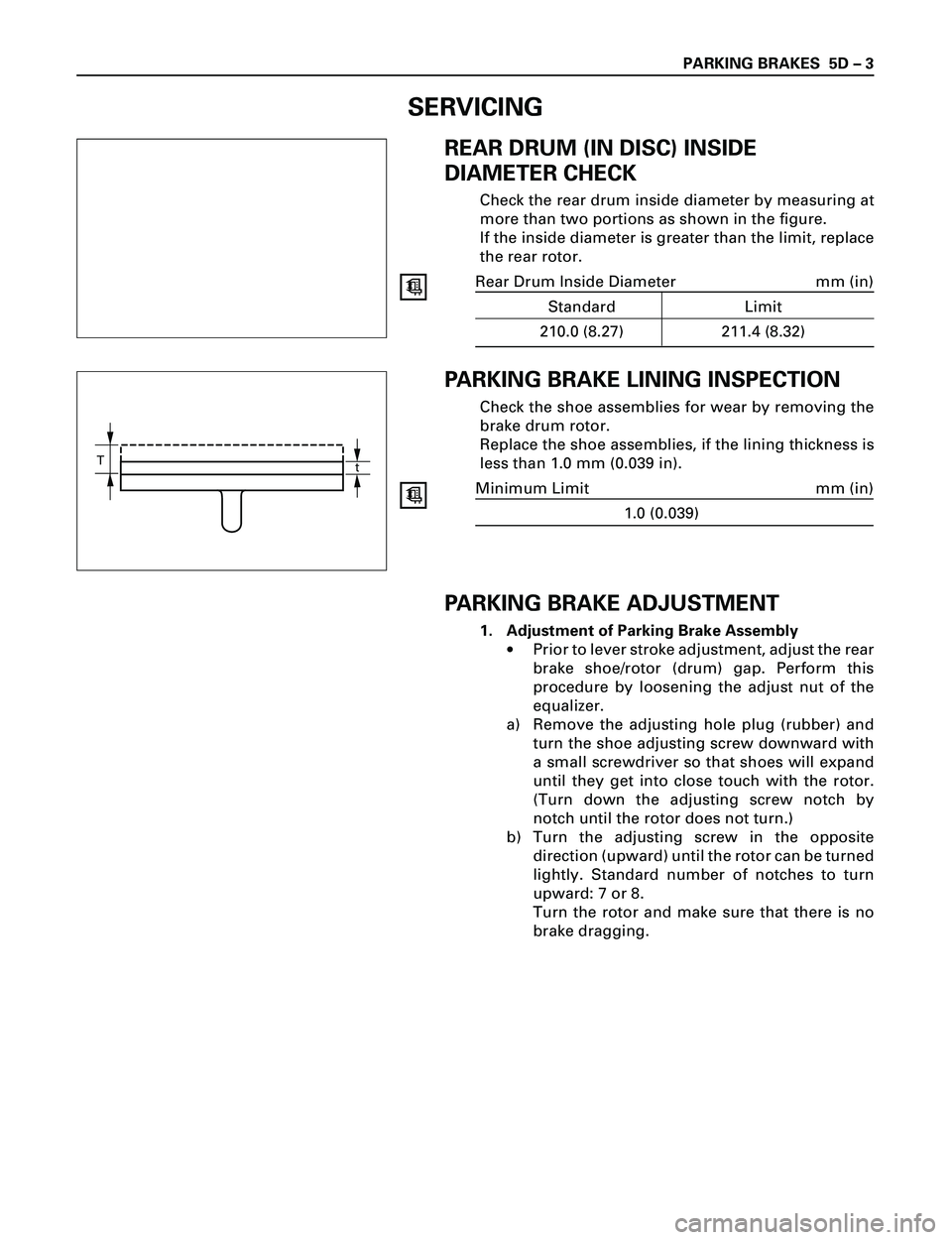

REAR DRUM (IN DISC) INSIDE

DIAMETER CHECK

Check the rear drum inside diameter by measuring at

more than two portions as shown in the figure.

If the inside diameter is greater than the limit, replace

the rear rotor.

Rear Drum Inside Diameter mm (in)

Standard Limit

210.0 (8.27) 211.4 (8.32)

PARKING BRAKE LINING INSPECTION

Check the shoe assemblies for wear by removing the

brake drum rotor.

Replace the shoe assemblies, if the lining thickness is

less than 1.0 mm (0.039 in).

Minimum Limit mm (in)

1.0 (0.039)

PARKING BRAKE ADJUSTMENT

1. Adjustment of Parking Brake Assembly

·Prior to lever stroke adjustment, adjust the rear

brake shoe/rotor (drum) gap. Perform this

procedure by loosening the adjust nut of the

equalizer.

a) Remove the adjusting hole plug (rubber) and

turn the shoe adjusting screw downward with

a small screwdriver so that shoes will expand

until they get into close touch with the rotor.

(Turn down the adjusting screw notch by

notch until the rotor does not turn.)

b) Turn the adjusting screw in the opposite

direction (upward) until the rotor can be turned

lightly. Standard number of notches to turn

upward: 7 or 8.

Turn the rotor and make sure that there is no

brake dragging.

T

t

SERVICING

Page 949 of 3573

5D Ð 4 PARKING BRAKES

2. Adjustment of Parking Brake Cable

a) Turn the equalizer nut so that the parking

brake lever travels 6 or 7 notches when pulled

up with a force of 30 kg (66 lb).

b) Make sure there is no brake dragging and

tighten the cable lock nut.

Cable Lock Nut Torque Nám (kgácm/lbáin)

6 (60 / 52)

3. Break-in of Parking Brake Shoe

·When poor braking effect possibly resulting

from insufficient break-in is felt, or just after

replacement of parking brake shoe, be sure to

conduct break-in by driving vehicle as follows:

a) Forward 50 km/h (30 mph) x 400 m (About 30

seconds) with a lever pull force of 15 kg (33 lb),

and

b) Backward 10 km/h (6 mph) x 50 m (18 seconds)

with a lever pull force of 15kg (33 lb).

NOTE:

Break-in procedure must be performed under the

safety conditions and traffic rules.

·If braking effect still remains poor after the

above break-in, wait for some time until

parking brake shoe cools down and repeat the

procedures a) and b) notes above.

·On completion of break-in, inspect parking

brake lever stroke, and if the lever does not

come within the specified number of notches

when pulled up, readjust.

·Excessive break-in may cause premature wear

of the parking brake lining.

Page 950 of 3573

PARKING BRAKES 5D Ð 5

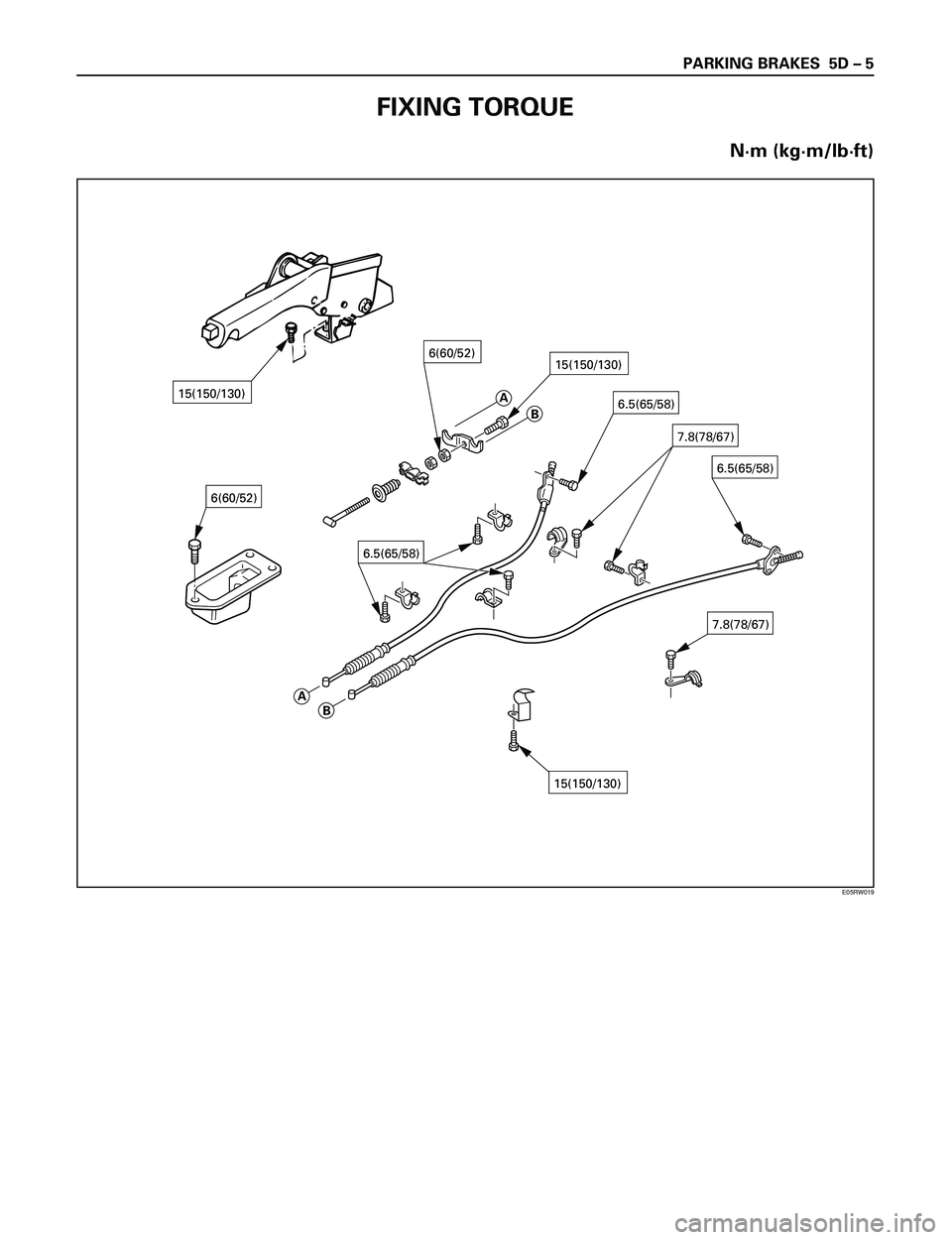

FIXING TORQUE

Nám (kgám/lbáft)

15(150/130)

6(60/52)

6.5(65/58)6.5(65/58)

6.5(65/58)

15(150/130)

6(60/52)15(150/130)

7.8(78/67)

7.8(78/67)

A

B

AB

E05RW019