wheel bolts JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 52 of 133

JAGUARS-TYPEChassis

47

Front Suspension

The independent front wheel suspension is a

double wishbone axle arrangement with

aluminium control arms. The two arms are of

different lengths, which minimises the changes in

track and camber. Inclination of the upper control

arm axis provides anti-dive front suspension

action. There are two front cross members,

known as Number 1 and Number 2.

Number 1, the forward cross member, is a steel

fabrication, non-isolated, which locates the lower

control arm front mounting, the anti-roll bar and

the cooling module.

The rear cross member, Number 2, is an

aluminium casting, non-isolated and it locates the

lower control arm rear mounting, the power

steering rack and the engine hydro-mounts.

WARNING: No attempt must be made to

weld or repair the aluminium cross

member. If it is damaged, a new one must

be installed.

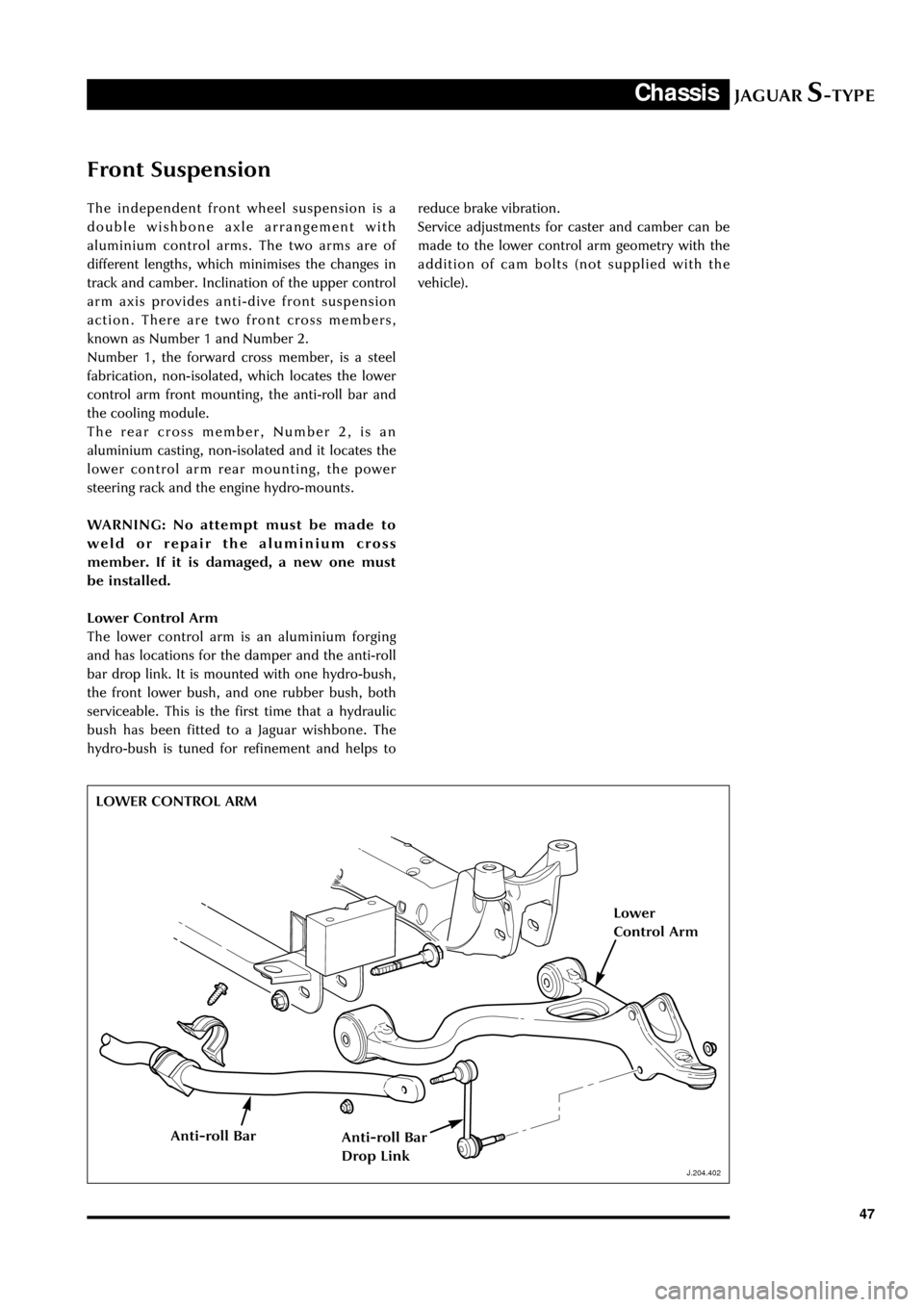

Lower Control Arm

The lower control arm is an aluminium forging

and has locations for the damper and the anti-roll

bar drop link. It is mounted with one hydro-bush,

the front lower bush, and one rubber bush, both

serviceable. This is the first time that a hydraulic

bush has been fitted to a Jaguar wishbone. The

hydro-bush is tuned for refinement and helps to

J.204.402

reduce brake vibration.

Service adjustments for caster and camber can be

made to the lower control arm geometry with the

addition of cam bolts (not supplied with the

vehicle).

LOWER CONTROL ARM

J.204.402

Lower

Control Arm

Anti-roll BarAnti-roll Bar

Drop Link

Page 55 of 133

JAGUARS-TYPEChassis

50

D.204.399

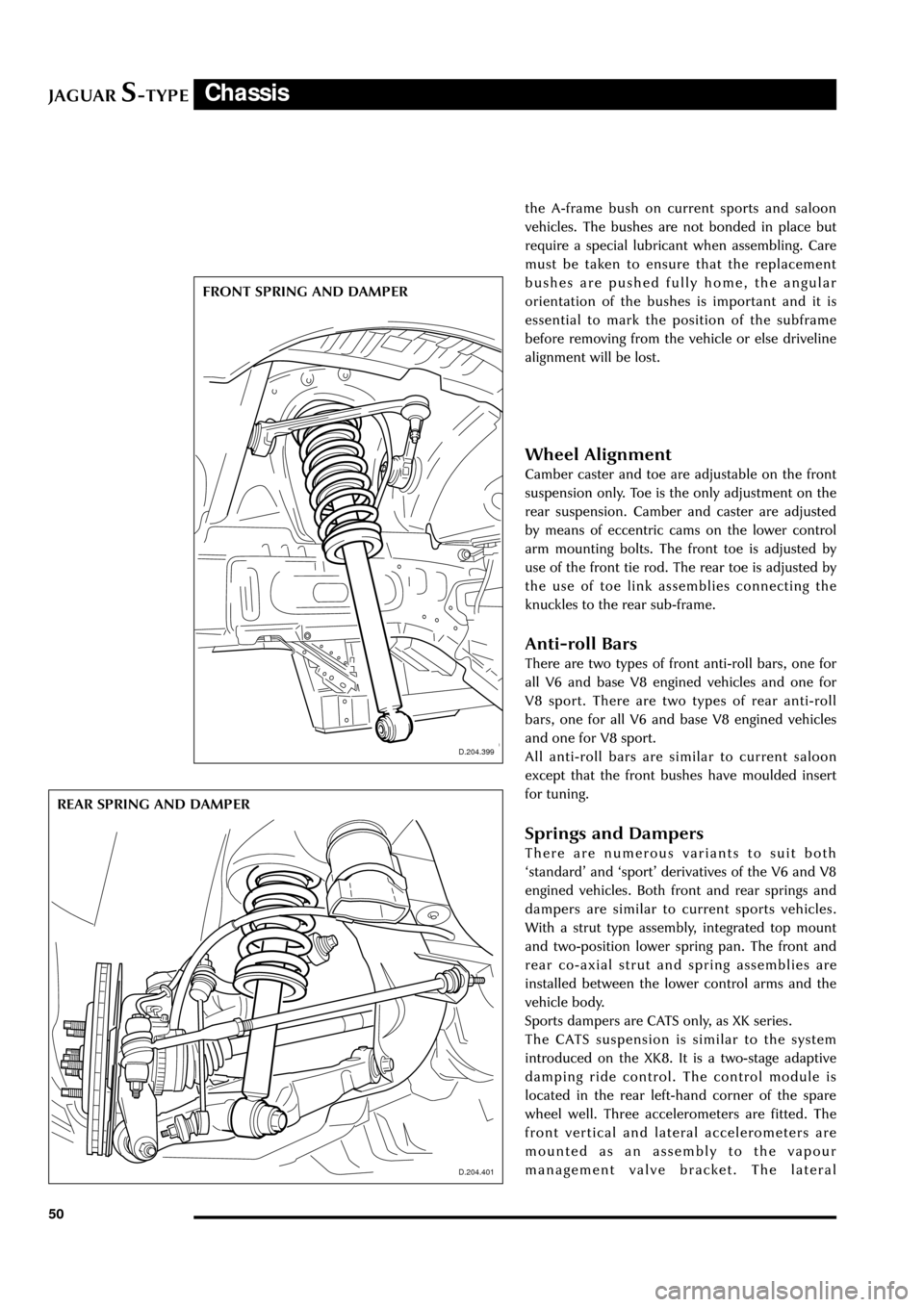

FRONT SPRING AND DAMPER

D.204.399

Wheel Alignment

Camber caster and toe are adjustable on the front

suspension only. Toe is the only adjustment on the

rear suspension. Camber and caster are adjusted

by means of eccentric cams on the lower control

arm mounting bolts. The front toe is adjusted by

use of the front tie rod. The rear toe is adjusted by

the use of toe link assemblies connecting the

knuckles to the rear sub-frame.

Anti-roll Bars

There are two types of front anti-roll bars, one for

all V6 and base V8 engined vehicles and one for

V8 sport. There are two types of rear anti-roll

bars, one for all V6 and base V8 engined vehicles

and one for V8 sport.

All anti-roll bars are similar to current saloon

except that the front bushes have moulded insert

for tuning.

Springs and Dampers

There are numerous variants to suit both

ÔstandardÕ and ÔsportÕ derivatives of the V6 and V8

engined vehicles. Both front and rear springs and

dampers are similar to current sports vehicles.

With a strut type assembly, integrated top mount

and two-position lower spring pan. The front and

rear co-axial strut and spring assemblies are

installed between the lower control arms and the

vehicle body.

Sports dampers are CATS only, as XK series.

The CATS suspension is similar to the system

introduced on the XK8. It is a two-stage adaptive

damping ride control. The control module is

located in the rear left-hand corner of the spare

wheel well. Three accelerometers are fitted. The

front vertical and lateral accelerometers are

mounted as an assembly to the vapour

management valve bracket. The lateral

D.204.401

the A-frame bush on current sports and saloon

vehicles. The bushes are not bonded in place but

require a special lubricant when assembling. Care

must be taken to ensure that the replacement

bushes are pushed fully home, the angular

orientation of the bushes is important and it is

essential to mark the position of the subframe

before removing from the vehicle or else driveline

alignment will be lost.

REAR SPRING AND DAMPER

D.204.401

Page 65 of 133

JAGUARS-TYPEChassis

60

D.211.255

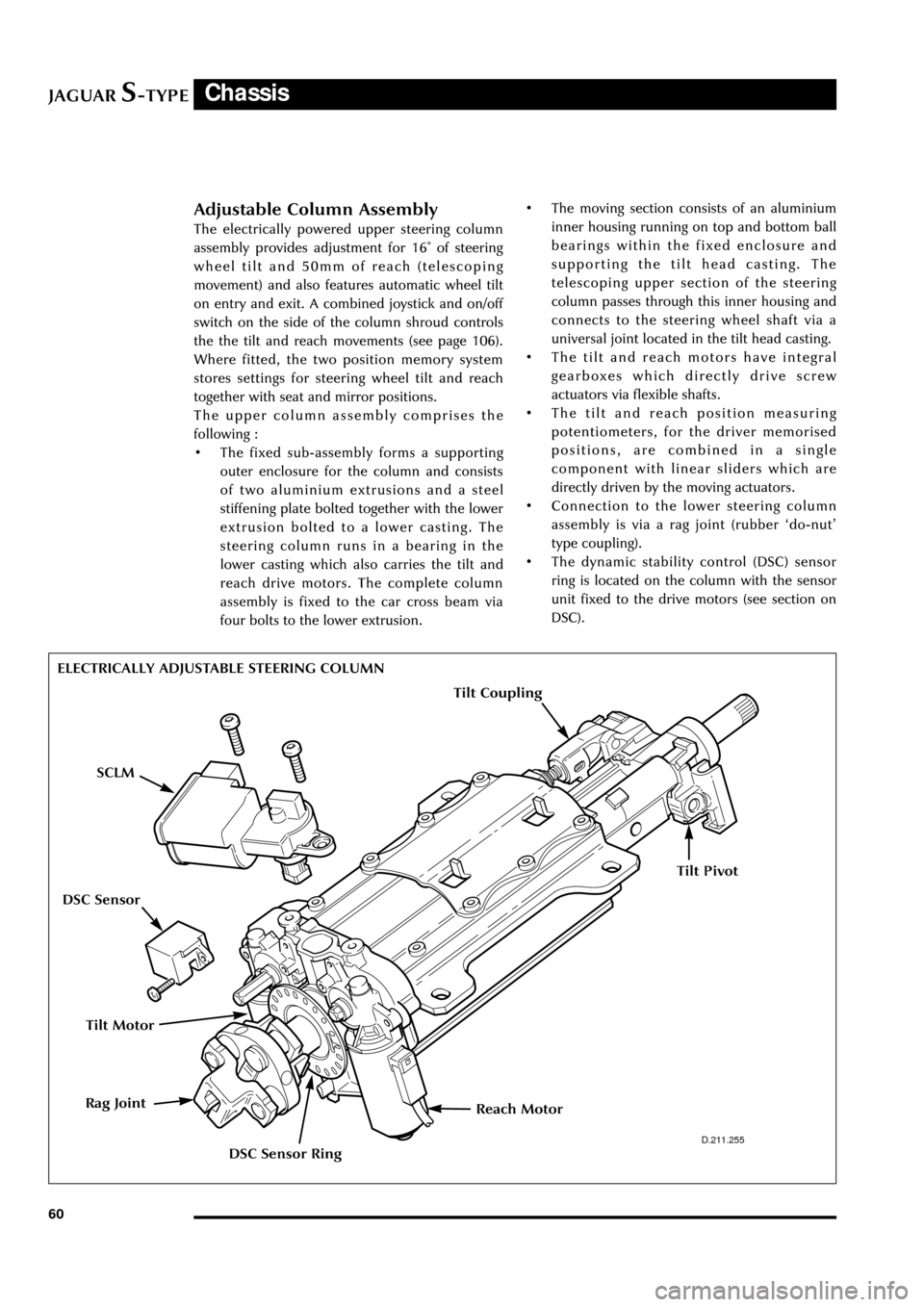

ELECTRICALLY ADJUSTABLE STEERING COLUMN

Adjustable Column Assembly

The electrically powered upper steering column

assembly provides adjustment for 16û of steering

wheel tilt and 50mm of reach (telescoping

movement) and also features automatic wheel tilt

on entry and exit. A combined joystick and on/off

switch on the side of the column shroud controls

the the tilt and reach movements (see page 106).

Where fitted, the two position memory system

stores settings for steering wheel tilt and reach

together with seat and mirror positions.

The upper column assembly comprises the

following :

¥ The fixed sub-assembly forms a supporting

outer enclosure for the column and consists

of two aluminium extrusions and a steel

stiffening plate bolted together with the lower

extrusion bolted to a lower casting. The

steering column runs in a bearing in the

lower casting which also carries the tilt and

reach drive motors. The complete column

assembly is fixed to the car cross beam via

four bolts to the lower extrusion.¥ The moving section consists of an aluminium

inner housing running on top and bottom ball

bearings within the fixed enclosure and

supporting the tilt head casting. The

telescoping upper section of the steering

column passes through this inner housing and

connects to the steering wheel shaft via a

universal joint located in the tilt head casting.

¥ The tilt and reach motors have integral

gearboxes which directly drive screw

actuators via flexible shafts.

¥ The tilt and reach position measuring

potentiometers, for the driver memorised

positions, are combined in a single

component with linear sliders which are

directly driven by the moving actuators.

¥ Connection to the lower steering column

assembly is via a rag joint (rubber Ôdo-nutÕ

type coupling).

¥ The dynamic stability control (DSC) sensor

ring is located on the column with the sensor

unit fixed to the drive motors (see section on

DSC).

Tilt Motor

Reach MotorRag Joint

SCLM

DSC Sensor Ring

DSC Sensor

Tilt Coupling

Tilt Pivot