cooling system JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 11 of 2490

Valve

Co

ver

LH (12.29.43)

Valve

Cover RH (12.29.44)

Valve

Cover Gasket LH (12.29.40)

Valve

Cover Gasket RH (12.29.41)

Valve

Springs LH

Valve

Springs RH

Variable

Camshaft Timing Oil Con

trol Unit LH (12.65.71)

Variable

Camshaft Timing Oil Control Unit RH (12.65.70)

Variable

Camshaft Timing Oil Control Unit Housing LH (12.65.52)

Variable

Camshaft Timing Oil Control Unit Housing RH (12.65.51)

303‐03A : Engine Cooling

Descriptio

n and Operation

Engine Cooling

Diagnosis and Testing

Engine Cooling

Related Faults / Codes

DTC P0116 ECT circuit range / performance problem

DTC P0125 Insufficient coolant temperature for closed loop fuel control

DTC P0117 ECT circuit low input

DTC P0118 ECT circuit high input

DTC P1474 Intercooler coolant pum

p relay malfunction

Pinpoint test A: P0116, P0125

Pinpoint test B: P0117

Pinpoint test C: P0118

Pinpoint test D: P1474

General Procedures

Cooling System Draining, Filling and Bleeding ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 –

AJ27

Cooling System Draining, Filling and Bleeding ‐ 4.0L SC V8 ‐ AJ26

Cooling Sy

stem Draining and Vacuum Filling

Removal and Installation

Removal

Engine ‐ Re m

oval

(12.41.01)

Installation

Engine ‐ Installation (12.41.01)

Page 44 of 2490

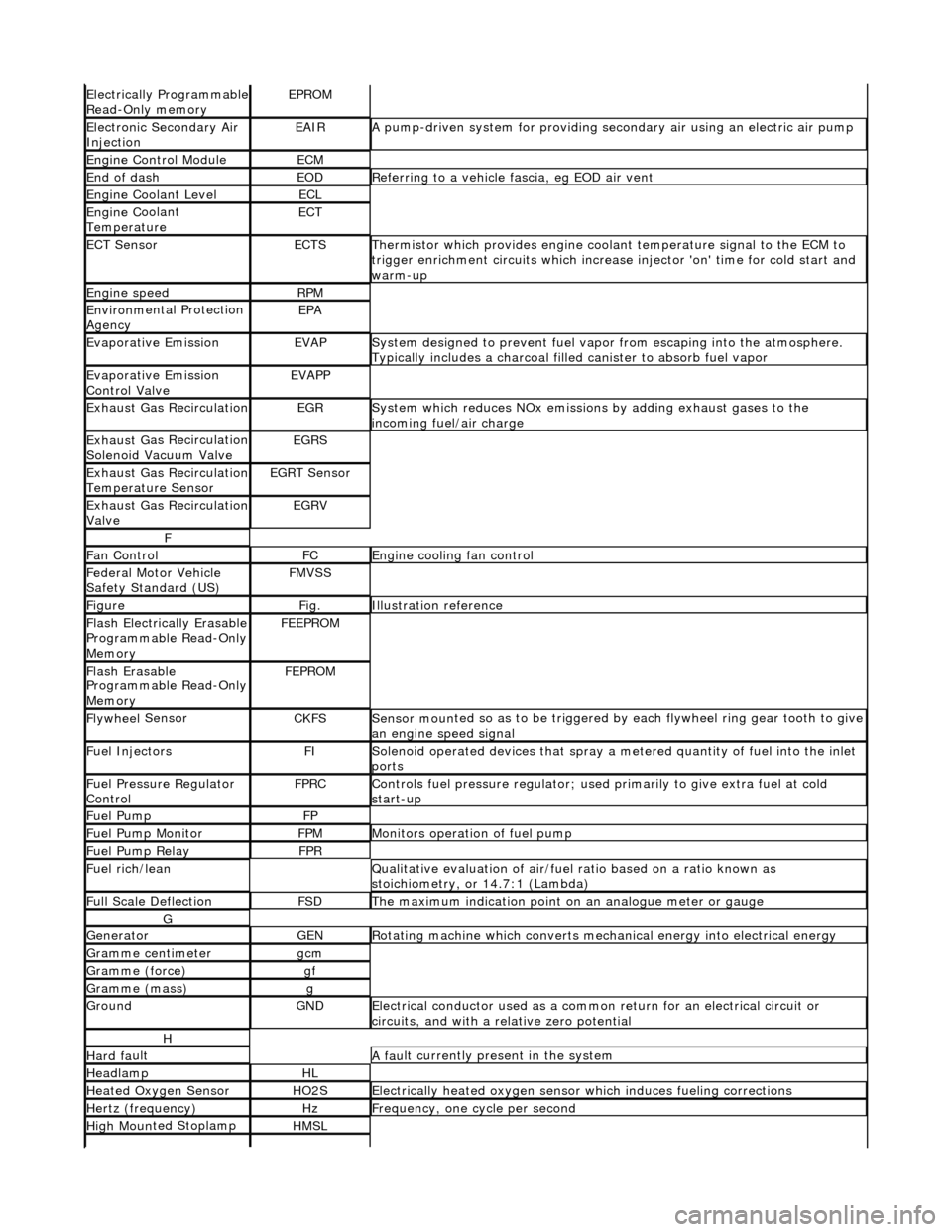

Electrically Programmable

R

ead-Only memory

EPROM

Ele

c

tronic Secondary Air

Injection

EAIRA p

ump-driven system for providing seco

ndary air using an electric air pump

Engine C

ontrol Module

ECM

End of dashEODR

e

ferring to a vehicle fascia, eg EOD air vent

Engine

C

oolant Level

ECL

Engine

C

oolant

Temperature

ECT

ECT Sen s

or

ECTSTherm

i

stor which provides engine coolant temperature signal to the ECM to

trigger enrichment circuits which increase injector 'on' time for cold start and

warm-up

Engine s

peed

RP

M

Environ m

ental Protection

Agency

EPA

Evaporative EmissionEVAPSy stem designed to prevent fu

el vapor from escaping into the atmosphere.

Typically includes a charcoal filled canister to absorb fuel vapor

Evaporative Emission

Control ValveEVAPP

Exhaust G

as Recirculation

EGRSys

t

em which reduces NOx emissions by adding exhaust gases to the

incoming fuel/air charge

Exhaus t G

as Recirculation

Solenoid Vacuum Valve

EGRS

Exhaus t G

as Recirculation

Temperature Sensor

EGRT Sen s

or

Exhaus

t G

as Recirculation

Valve

EGRV

F

F a

n Control

FCEngine

cooling fan control

F

e

deral Motor Vehicle

Safety Standard (US)

FMV S

S

Fi

gur

e

Fi

g.Illustrati

on reference

Flash

E

lectrically Erasable

Programmable Read-Only

Memory

FEE PR

OM

Flash

E

rasable

Programmable Read-Only

Memory

FEP R

OM

Flywhee

l

Sensor

CKFSSens

or moun

ted so as to be

triggered by each flywheel ring gear tooth to give

an engine speed signal

Fue l

Injectors

FISol

e

noid operated devices that spray a metered quantity of fuel into the inlet

ports

F u

el Pressure Regulator

Control

FP RCControls fuel pressure regu l

ator; used primarily to

give extra fuel at cold

start-up

Fue l

Pump

FP

Fue

l

Pump Monitor

FP

MMonitors operation of fuel pump

Fue l

Pump Relay

FP

R

Fu

el rich/lean

Q

u

alitative evaluation

of air/fuel ratio based on a ratio known as

stoichiometry, or 14.7:1 (Lambda)

F u

ll Scale Deflection

FSDTh

e

maximum indication point on

an analogue meter or gauge

G

Gene

rator

GENRot

a

ting machine which converts mechanical energy into electrical energy

G

r

amme centimeter

gcm

Gramm

e

(force)

gf

Gramm

e

(mass)

g

GroundGNDEle

c

trical conductor used

as a common return for an electrical circuit or

circuits, and with a relative zero potential

H

Hard f a

ult

A

fau

lt currently present in the system

HeadlampHL

Heat

ed Oxygen

Sensor

HO2SElectrically

h

eated oxygen sensor which induces fueling corrections

Hertz (frequency)HzFrequ

e

ncy, one cycle per second

High

Moun

ted Stoplamp

HMSL

Page 341 of 2490

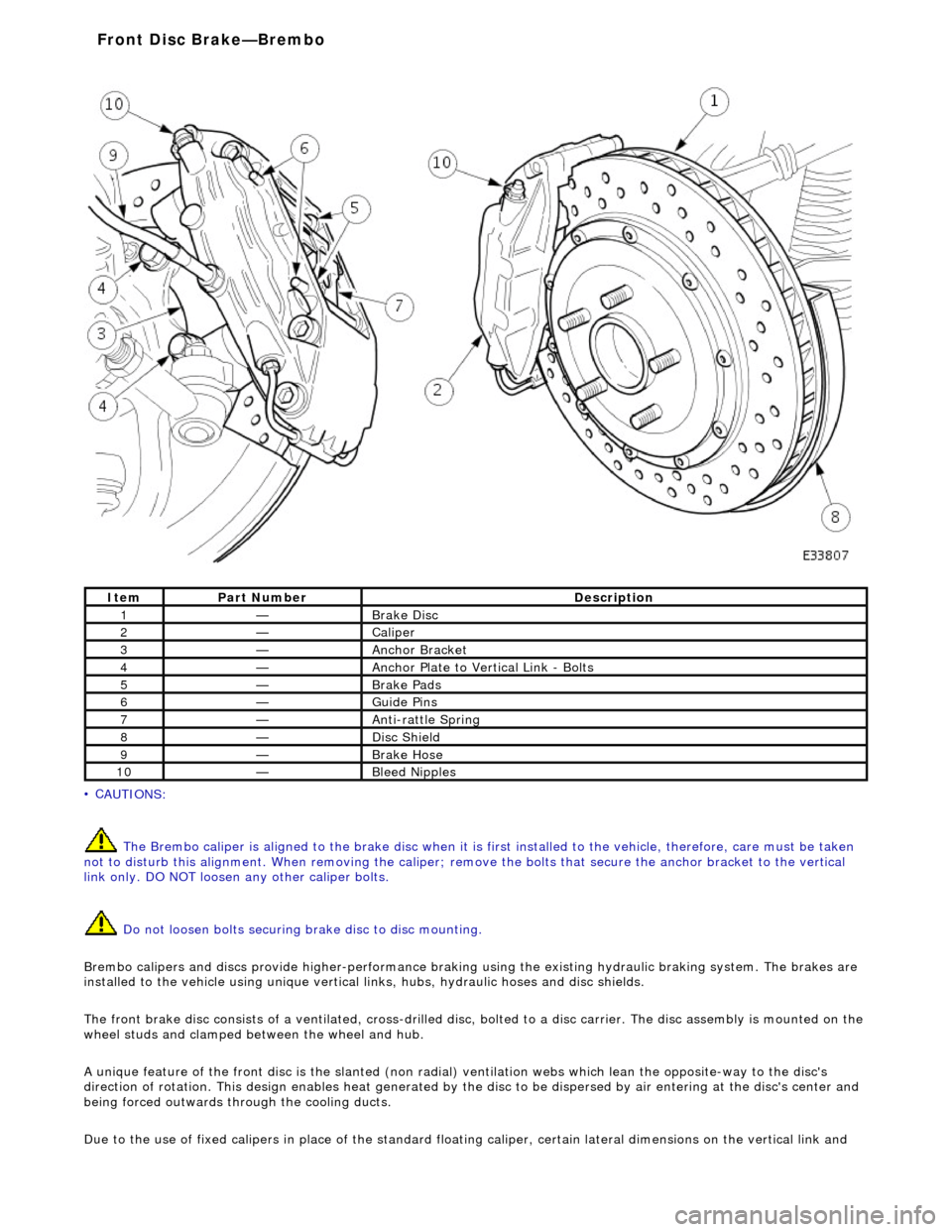

• C

AUTIONS:

The Brembo caliper is aligned to the brak e disc when it is first installed to the vehicle, therefore, care must be taken

not to disturb this alignment. When removi ng the caliper; remove the bolts that secure the anchor bracket to the vertical

link only. DO NOT loosen any other caliper bolts.

Do not loosen bolts securing brake disc to disc mounting.

Brembo calipers and discs provide higher -performance braking using the existing hydraulic braking system. The brakes are

installed to the vehicle using unique vertical links, hubs, hydraulic hoses and disc shields.

The front brake disc consists of a ventilated, cross-drilled disc, bolted to a disc carrier. The disc assemb ly is mounted on the

wheel studs and clamped be tween the wheel and hub.

A unique feature of the front disc is th e slanted (non radial) ventilation webs which lean the opposite-way to the disc's

direction of rotation. This design enables he at generated by the disc to be dispersed by air entering at the disc's center and

being forced outwards through the cooling ducts.

Due to the use of fixed calipers in place of the standard floating caliper, certain lateral dimensions on the vertical link and

It

em

Par

t Number

De

scription

1—B

rake Disc

2—Caliper

3—Anch

or Bracket

4—Anchor Pl

ate to Vertical Link - Bolts

5—Brake Pad

s

6—Guide P

ins

7—Anti-r

attle Spring

8—Di

sc Shield

9—Brake Hos

e

10—Bleed Nipp

les

Front Disc Brake—

Brembo

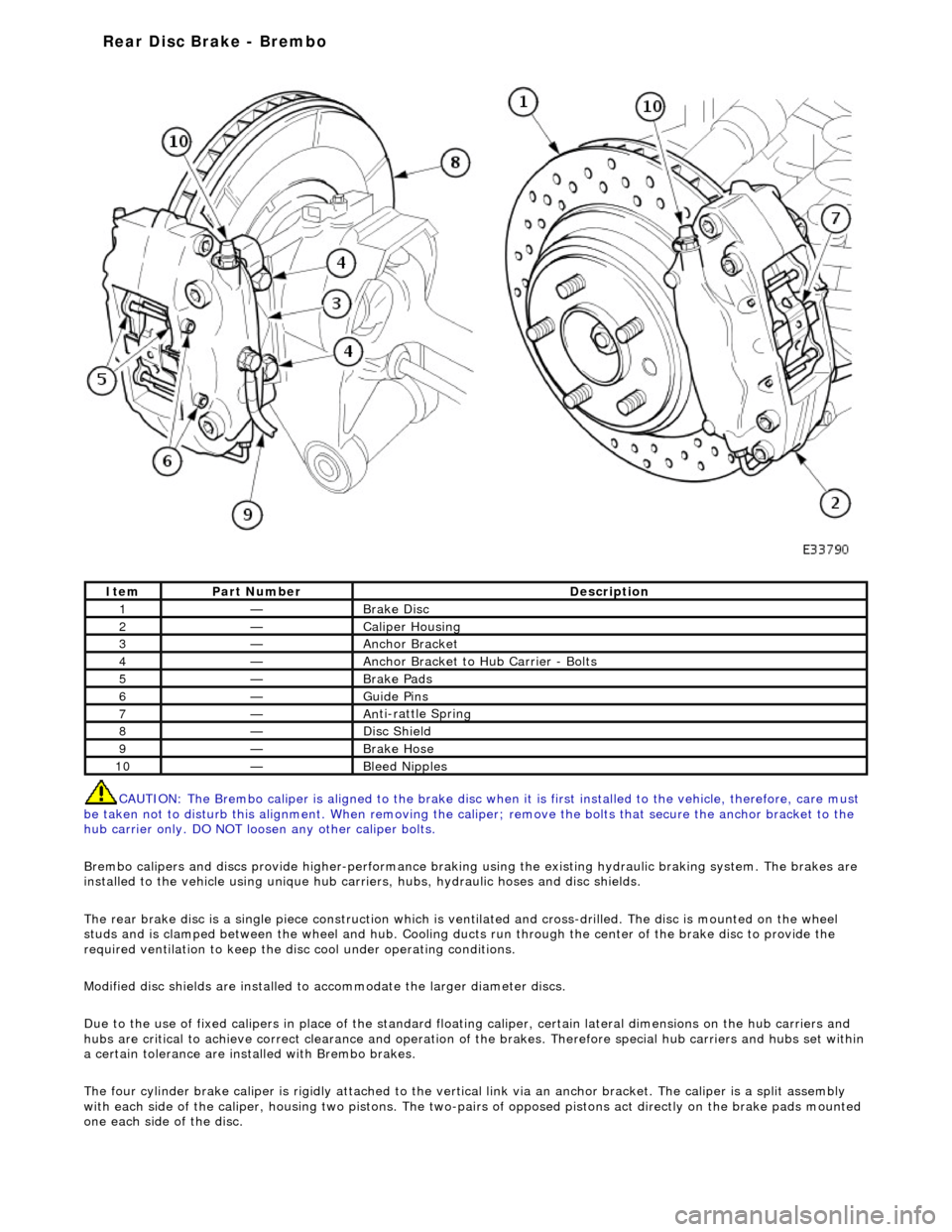

Page 366 of 2490

CAUTI O

N: The Brembo caliper is aligned to

the brake disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the ca liper; remove the bolts that secure the anchor bracket to the

hub carrier only. DO NOT loos en any other caliper bolts.

Brembo calipers and discs provide higher -performance braking using the existing hydraulic braking system. The brakes are

installed to the vehicle using unique hub carr iers, hubs, hydraulic hoses and disc shields.

The rear brake disc is a single piece co nstruction which is ventilated and cross-drilled. The disc is mounted on the wheel

studs and is clamped between the wheel and hub. Cooling ducts run through the ce nter of the brake disc to provide the

required ventilation to keep the disc cool under operating conditions.

Modified disc shields are installed to accommodate the larger diameter discs.

Due to the use of fixed calipers in place of the standard floating caliper, certain lateral dimensions on the hub carriers and

hubs are critical to achieve correct cleara nce and operation of the brakes. Therefore special hub carriers and hubs set within

a certain tolerance are inst alled with Brembo brakes.

The four cylinder brake caliper is rigidly attached to the vert ical link via an anchor bracket. The caliper is a split assembly

with each side of the caliper, housing two pistons. The two-pairs of opposed pistons act direct ly on the brake pads mounted

one each side of the disc.

It e

m

Par

t

Number

De

scr

iption

1—Brake D

i

sc

2—Caliper Housin

g

3—Anchor Bracke

t

4—Anchor Bracket to H

u

b Carrier - Bolts

5—Brake Pads

6—Guide Pi

ns

7—An

ti

-rattle Sprin

g

8—Di

sc

Shield

9—Brake Hos

e

10—Bleed Nipp

les

Rear Disc Brake - Brembo

Page 464 of 2490

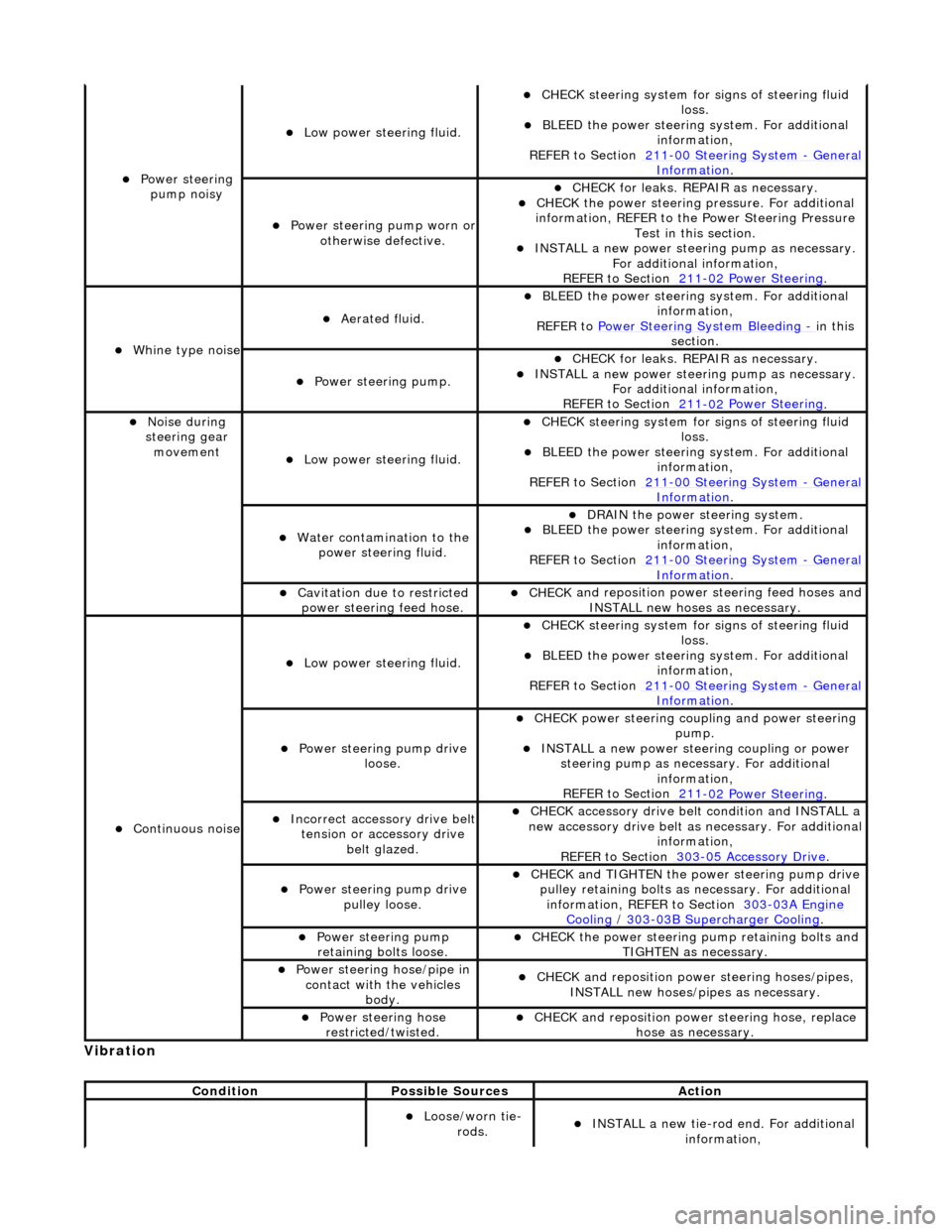

Vibrati

on

Power steeri

ng

pump noisy

Low power steer i

ng fluid.

CHECK

steering system for s

igns of steering fluid

loss.

BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

Power steeri

ng pump wor

n or

otherwise defective.

CHECK for leaks. R

EPAIR as necessary.

CHECK

the power steering pressure. For additional

information, REFER to th e Power Steering Pressure

Test in this section.

INST ALL a ne

w power steering pump as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

Wh

in

e type noise

Aerated flui

d.

BLEE

D the

power steering system. For additional

information,

REFER to Power Steering System Bleeding

- in t h

is

section.

Power steering pump.

CHECK for leaks. R

EPAIR as necessary.

INSTALL a ne

w power steering pump as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

No

i

se during

steering gear movement

Low power steer i

ng fluid.

CHECK

steering system for s

igns of steering fluid

loss.

BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

Water co

n

tamination to the

power steering fluid.

DR AIN

the power steering system.

BLEE

D the

power steering system. For additional

information,

REFER to Section 211

-00

Steering System

-

Gen

eral

Informati

o

n

.

Cavi

tation due to restricted

po

wer steering feed hose.

CHECK

and reposition power

steering feed hoses and

INSTALL new hoses as necessary.

Continu o

us noise

Low power steer i

ng fluid.

CHECK

steering system for s

igns of steering fluid

loss.

BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

Power steeri

ng pump dri

ve

loose.

CHECK

power steering coupli

ng and power steering

pump.

IN ST

ALL a new power steering coupling or power

steering pump as nece ssary. For additional

information,

REFER to Section 211

-0 2

Power Steering

.

Incorre

ct

accessory drive belt

tension or accessory drive belt glazed.

CHECK acc

essory drive belt condition and INSTALL a

new accessory drive belt as necessary. For additional

information,

REFER to Section 303

-0 5 Ac

cessory Drive

.

Power steeri

ng pump dri

ve

pulley loose.

CHECK

and TIGHTEN the power steering pump drive

pulley retaining bolts as necessary. For additional

information, REFER to Section 303

-03A En

gine

Coo

ling / 30 3-03

B Supercharger Cooling

.

Power steeri

ng pump

r

etaining bolts loose.

CHECK

the power steering pump retaining bolts and

TIGHTEN as necessary.

Power steering hose/pipe in c

ontact with the vehicles

body.

CHECK

and reposition powe

r steering hoses/pipes,

INSTALL new hoses/pipes as necessary.

Power steeri ng hose

r

estricted/twisted.

CHECK

and reposition powe

r steering hose, replace

hose as necessary.

Conditi

on

Possibl

e Sources

Actio

n

Loose/worn tie-

ro

ds.

INST

ALL a new tie-r

od end. For additional

information,

Page 522 of 2490

diverter val

ve (if fitted) and oil filter.

Main

bearings

which are grooved in the upper positions and plain in

the lower positions. They are manufactured from

aluminium / tin material.

A c

rankshaft with under

cuts and rolled fillets for extra strength.

Fracture

-split connecting rods in sintered-forged steel.

Brackets

bolted to the front of

the cylinder

block are used to mo unt all accessories.

A sin

gle, seven ribbed vee belt

drives the accessories.

An au

tomatic belt tensioner for the front accessory drive,

incorporating a wear indicator.

An advanced en

gine management system inco

rporating electronic throttle control.

The un

it meets the requirements of the CARB OBDII USA legislation.

Ancillary Systems

The an

ci

llary systems, driven by the engine, each have a

detailed Description and Operation along with Diagnostic

Procedures, and Removal and Installation instructions ; refer to the following sections of this manual:

Power Steeri

ng Pump - Section 211-02

Ai

r Conditioning Compressor - Sectio

n 412-03

Engine

C

ooling Pump - Section 303-03

Generator

- Sectio

n 414-02

The drive belt, idler pulley and automatic tensioner are described in Section 303-05.

The engine starting system is described in Section 303-06.

En

gine Management and Emission Control System

Engine Control Modu

le (ECM)

Engine

management and exhaust emissions are controlled by the ECM, which has the

following main functions:

Fu

el injection

Idle

s

peed

Ignition Ev

aporative loss system

Engine

cooling fans Clim

ate control compressor clutch demand

The microprocessor within the ECM receiv es signals from various sensors and other modules and uses a pre-determined

program to compute engine management functions.

Adaptive functions are incorporated in the ECM to cater for co ntinuous adjustments to its computations to suit prevailing

conditions. Because the system also controls emissions to suit all modes, neither CO levels nor idle speed require service

attention or adjustment, except if an error should occur.

On Board Diagnostics are controlled by the ECM with the continuous monitoring of incoming signals and the subsequent

verification against what the module expects to 'see'. Should a si gnal be incorrect or missing, the ECM will substitute a fixed

value to provide the 'limp home mode' and alert the driver of the problem. Fixed values may be adopted for:

Transmission oil

temperature

Mechanica

l

guar

d position

Throttle blade angle Camshaft position

Inta

k

e air temperature

Diagnostic trouble codes (DTC), including OBD II codes, are stored in the ECM memo ry and can be read by an appropriate

retrieval tool.

Should either the ECM or TCM fa il, ensure that the control housing cooling fan is operating correctly. Failure of the cooling

fan MUST be rectified before renewing a control module and details of a fa n failure should accompany a returned control

module.

Page 528 of 2490

Speed an

d load

Coo

l

ant temperature

Ti

me el

apsed from start up

Cl

osed l

oop fuelling

Determination of the vapour concentration is made by stepped opening of the EVAP valve and subsequent monitoring of the

fuelling correction. This function is performed prior to purging, so that at the onse t of purging the EVAP valve can be set to

the optimum position. Should the ECM be unable to determine the concentration before purging, a default value is

employed, which is then modified whilst purging is in progress.

When the purging process is operational th e ECM modifies the basic fuelling calculation to maintain the correct air / fuel

ratio.

Purging is inhibited during fuel cut-off and stability / traction control intervention.

Coolant Temperature Sen

sor

Th

e

sensor outputs a voltage to the ECM which decreases as temperature increases.

Cooling Fans

In response to engi

ne coolant temperat

u

re and climate control system demand, the ECM will energize the cooling fans.

Climate Control Compressor

The E

C

M will allow the compressor clutch to be engaged if th

e engine temperature and load demand are normal. Should the

driver require maximum engine powe r or the coolant temperature be high, the request will be denied.

Cranking Signal

The ECM reacts to a signal fr

om th

e Body Processor Module (BPM) when the starter motor relay is energi

zed. This signal is

used to trigger starting, fu el and ignition strategies.

Engine Speed and Cranksh

aft Position

Engine

speed and cran

k position are moni

tored by a sensor which is mounted on the cylinder block (flywheel housing)

behind the crankshaft drive plat e. It indicates rotational speed to the ECM in the form of 12 pulses per crank revolution.

Engine speed is used for synchronization of fuel an d ignition systems, as well as other functions.

Camshaft Position

The ca

mshaft position sensor is mounted at

the rear of Bank 2 cylinder head on the inlet side and provides one signal every

720 degrees of crankshaft rotation. The signal, in conjunction with the signal from the crankshaft position sensor, indicates

to the ECM that the piston of cylinder 1A is approaching TDC on the compression stroke.

Variable Valve

Timing (Where Fitted)

By energi

si

ng a solenoid to allow the pass

age of pressurized oil on each of the inle t camshaft drives, the ECM can vary by a

single stepped amount, the relati ve timing of the inlet valves.

Ign

ition

Ignit

i

on spark is produced by

individual on-plug coil units.

There are two ignition amplifiers; module #1 drives coils 1A, 2B, 3B and 4A, whilst module #2 drives coils 1B, 2A, 3A and

4B. The ECM controls the amplifiers.

Page 650 of 2490

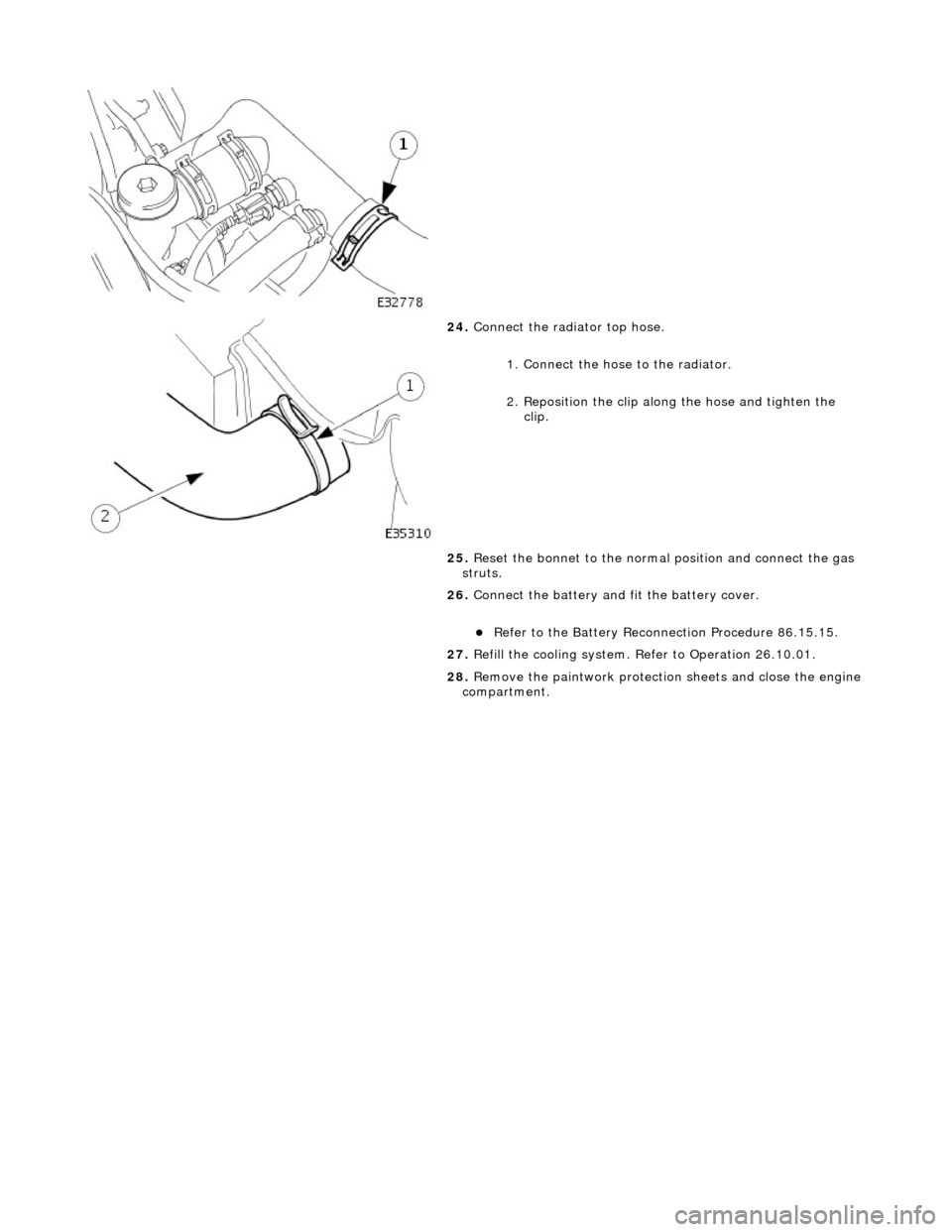

24.

Connect

the radiator top hose.

1. Connect the hose to the radiator.

2. Reposition the clip along the hose and tighten the clip.

25. Reset the bonnet to the normal position and connect the gas

struts.

26. Connect the battery and fit the battery cover.

Refe

r to the Battery Reconnection Procedure 86.15.15.

27. Refill the cooling system. Refer to Operation 26.10.01.

28. Remove the paintwork protection sheets and close the engine

compartment.

Page 659 of 2490

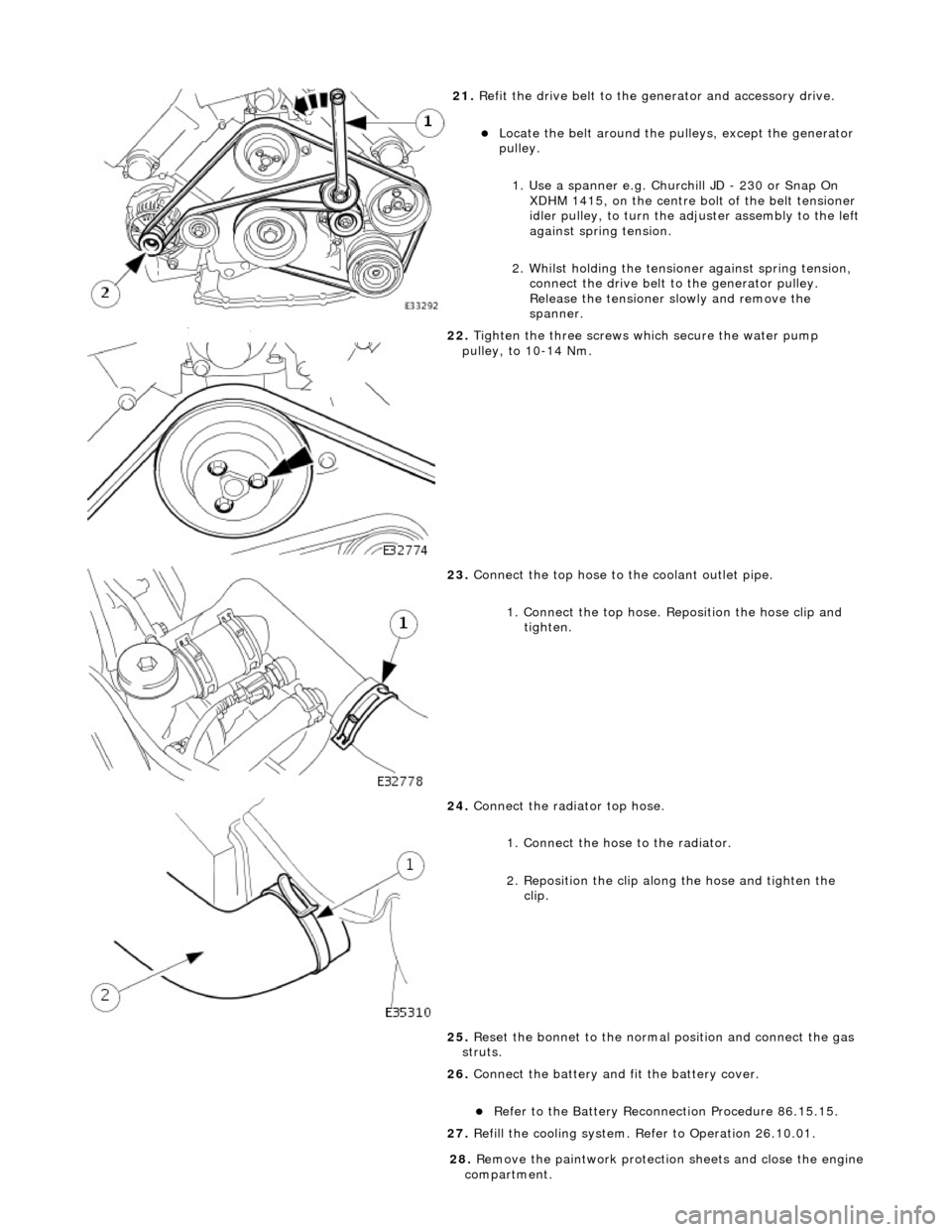

21

.

Refit the drive belt to the generator and accessory drive.

Locat

e the belt around the pulleys, except the generator

pulley.

1. Use a spanner e.g. Churchill JD - 230 or Snap On XDHM 1415, on the centre bo lt of the belt tensioner

idler pulley, to turn the adju ster assembly to the left

against spring tension.

2. Whilst holding the tensioner against spring tension, connect the drive belt to the generator pulley.

Release the tensioner sl owly and remove the

spanner.

22

.

Tighten the three screws wh ich secure the water pump

pulley, to 10-14 Nm.

23

.

Connect the top hose to the coolant outlet pipe.

1. Connect the top hose. Reposition the hose clip and tighten.

24

.

Connect the radiator top hose.

1. Connect the hose to the radiator.

2. Reposition the clip along the hose and tighten the clip.

25. Reset the bonnet to the normal position and connect the gas

struts.

26. Connect the battery and fit the battery cover.

Re

fer to the Battery Reconnection Procedure 86.15.15.

27. Refill the cooling system. Refer to Operation 26.10.01.

28

.

Remove the paintwork protection sheets and close the engine

compartment.

Page 733 of 2490

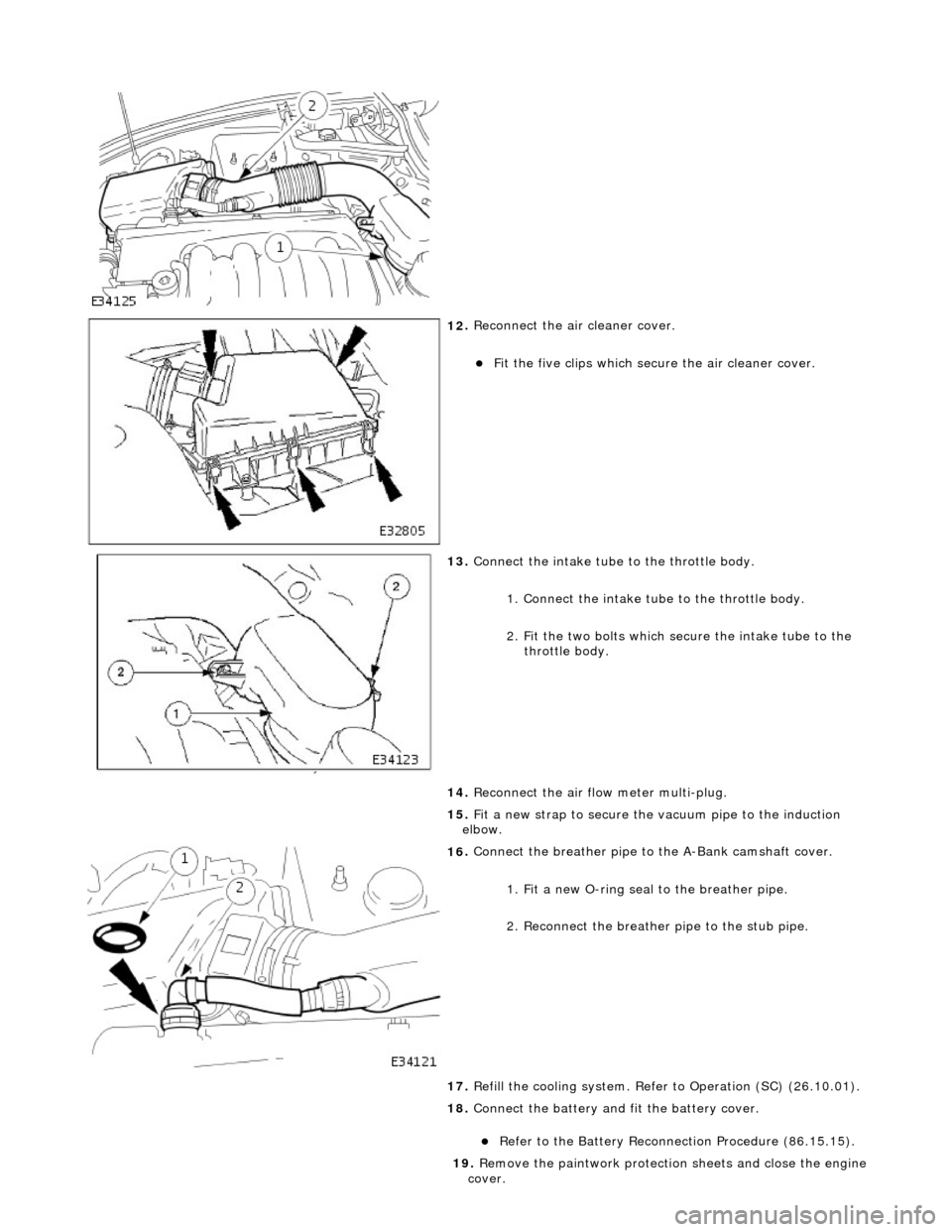

12

.

Reconnect the air cleaner cover.

F

it the five clips which secu

re the air cleaner cover.

13

.

Connect the intake tube to the throttle body.

1. Connect the intake tube to the throttle body.

2. Fit the two bolts which secure the intake tube to the throttle body.

14. Reconnect the air flow meter multi-plug.

15. Fit a new strap to secure the vacuum pipe to the induction

elbow.

16

.

Connect the breather pipe to the A-Bank camshaft cover.

1. Fit a new O-ring seal to the breather pipe.

2. Reconnect the breather pipe to the stub pipe.

17. Refill the cooling system. Refer to Operation (SC) (26.10.01).

18. Connect the battery and fit the battery cover.

Re

fer to the Battery Reconnection Procedure (86.15.15).

19. Remove the paintwork protection sheets and close the engine

cover.