ad blue JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1383 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Transmission

Installation

Installation

Special Tool(s)

Engine support

303-021

Engine lifting brackets

303-536

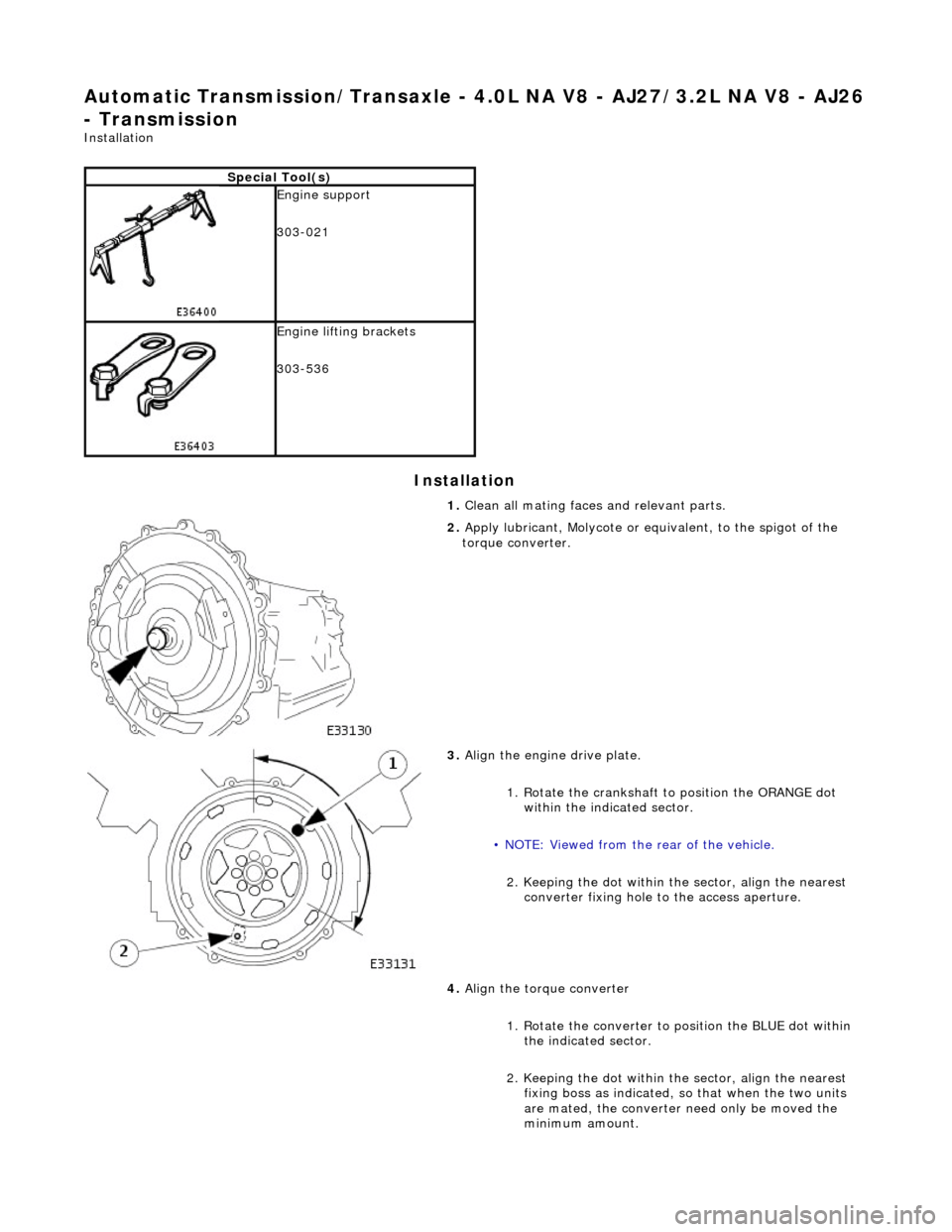

1. Clean all mating faces and relevant parts.

2. Apply lubricant, Molycote or equivalent, to the spigot of the

torque converter.

3. Align the engine drive plate.

1. Rotate the crankshaft to position the ORANGE dot

within the indicated sector.

• NOTE: Viewed from the rear of the vehicle.

2. Keeping the dot within the sector, align the nearest converter fixing hole to the access aperture.

4. Align the torque converter

1. Rotate the converter to position the BLUE dot within the indicated sector.

2. Keeping the dot within the sector, align the nearest fixing boss as indicated, so that when the two units

are mated, the converter need only be moved the

minimum amount.

Page 1762 of 2490

Climate Control System - General Infor

mation - Air Conditioning (A/C)

System Recovery, Evacuation and Charging

Gen e

ral Procedures

Recover / Reclaim

Ev

acuation

Charging

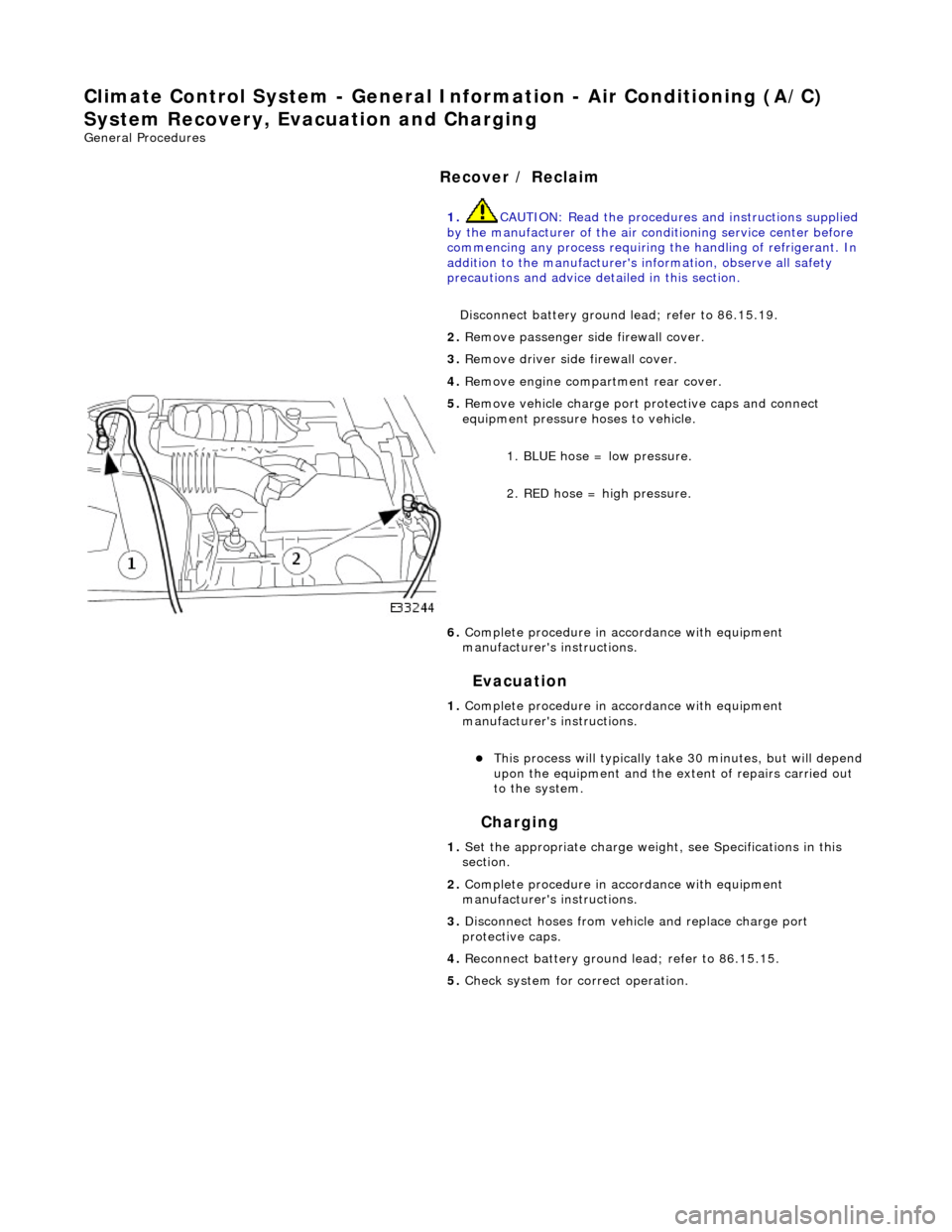

1.

CAUTIO

N: Read the procedures and instructions supplied

by the manufacturer of the air co nditioning service center before

commencing any process requiring the handling of refrigerant. In

addition to the manufacturer's in formation, observe all safety

precautions and advice deta iled in this section.

Disconnect battery ground lead; refer to 86.15.19.

2. Remove passenger side fi

rewall cover.

3. Remove driver side firewall cover.

4. Remove engine compar tment rear cover.

5. Re

move vehicle charge port

protective caps and connect

equipment pressure hoses to vehicle.

1. BLUE hose = low pressure.

2. RED hose = high pressure.

6. Complete procedure in ac cordance with equipment

manufacturer's instructions.

1. Complete procedure in ac cordance with equipment

manufacturer's instructions.

This proc

ess will typically ta

ke 30 minutes, but will depend

upon the equipment and the ex tent of repairs carried out

to the system.

1. Set the appropriate charge weight, see Specifications in this

section.

2. Complete procedure in ac cordance with equipment

manufacturer's instructions.

3. Disconnect hoses from vehicle and replace charge port

protective caps.

4. Reconnect battery ground lead; refer to 86.15.15.

5. Check system for correct operation.

Page 1764 of 2490

Clima

te Control System - General Inform

ation - Manifold Gauge Set Connection

Ge

neral Procedures

Mani

fol

d.

Low Side Pressure Gauge.

High Side Pressure Gauge.

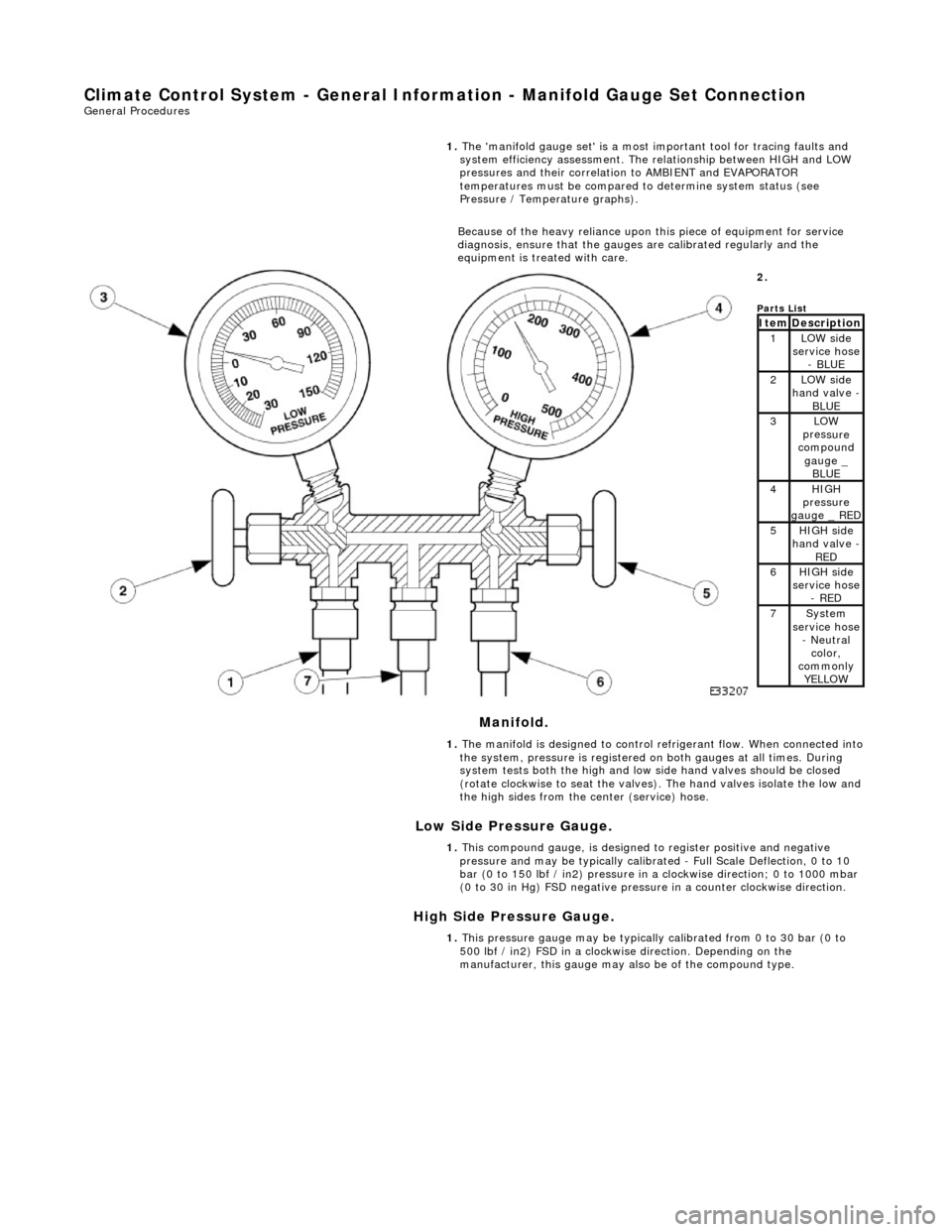

1.

The 'ma

nifold gauge set' is a most important tool for tracing faults and

system efficiency assessment. The relationship between HIGH and LOW

pressures and their correlation to AMBIENT and EVAPORATOR

temperatures must be compared to determine system status (see

Pressure / Temperature graphs).

Because of the heavy reliance upon this piece of equipment for service

diagnosis, ensure that the gauges are calibrated regularly and the

equipment is treated with care.

2.

Parts

List

ItemDescri

ption1LOW side

serv

ice hose

- BLUE

2LOW side

ha

nd valve -

BL

UE3LOW

pres

sure

compound

gauge _ BLUE

4HI GH

pressure

gauge _ RED

5HI GH

side

hand valve -

RED6HI GH

side

service hose

- RED

7Sys t

em

service hose

- Neutral color,

commonly YELLOW

1. The manifold is designed to control refrigerant flow. When connected into

the system, pressure is registered on both gauges at all times. During

system tests both the high and low side hand valves should be closed

(rotate clockwise to seat the valves). The hand valves isolate the low and

the high sides from the center (service) hose.

1. This compound gauge, is designed to register positive and negative

pressure and may be typically calibrate d - Full Scale Deflection, 0 to 10

bar (0 to 150 lbf / in2) pressure in a clockwise direction; 0 to 1000 mbar

(0 to 30 in Hg) FSD negative pressu re in a counter clockwise direction.

1. This pressure gauge may be typically calibrated from 0 to 30 bar (0 to

500 lbf / in2) FSD in a clockwise direction. Depending on the

manufacturer, this gauge may also be of the compound type.

Page 1824 of 2490

External temperature < -10 °C Vehicle speed > 65 km / h The first two conditions exist > 2 minutes. Engine speed > 50 revs / min

14. 14. Heated Backlight (R)

Pressing the heated backlight button will simultaneously energize the heater elements for timed cycles of;

21 minutes backlight 11 minutes exterior mirrors

Pressing the button again within the 21 minute timer will cancel the request.

If the engine is stalled, or the ignition switched OFF, the backlight and door mirror timers will be cleared, resulting in both

functions being switched off.

• NOTE: Both the backlight and door mirrors may be activated with the climate control system OFF, but the engine must be

running.

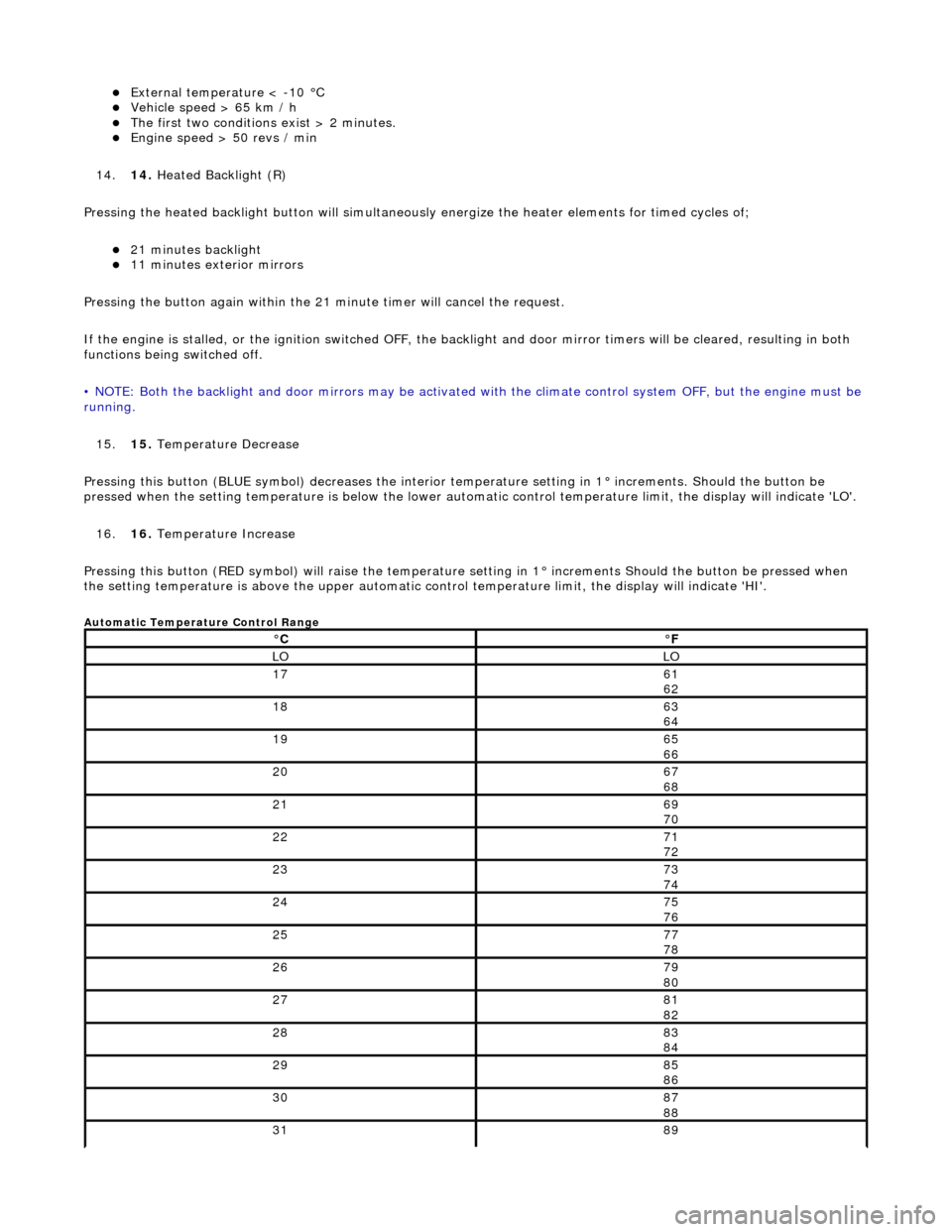

15. 15. Temperature Decrease

Pressing this button (BLUE symbol) decreases the interior temperature setting in 1° increments. Should the button be

pressed when the setting temperature is below the lower automatic control temperature limit, the display will indicate 'LO'.

16. 16. Temperature Increase

Pressing this button (RED symbol) will raise the temperature setting in 1° increments Should the button be pressed when

the setting temperature is above the upper automatic control temperature limit, the display will indicate 'HI'.

Automatic Temperature Control Range

°C°F

LOLO

1761

62

1863

64

1965

66

2067

68

2169

70

2271

72

2373

74

2475

76

2577

78

2679

80

2781

82

2883

84

2985

86

3087

88

3189

Page 1836 of 2490

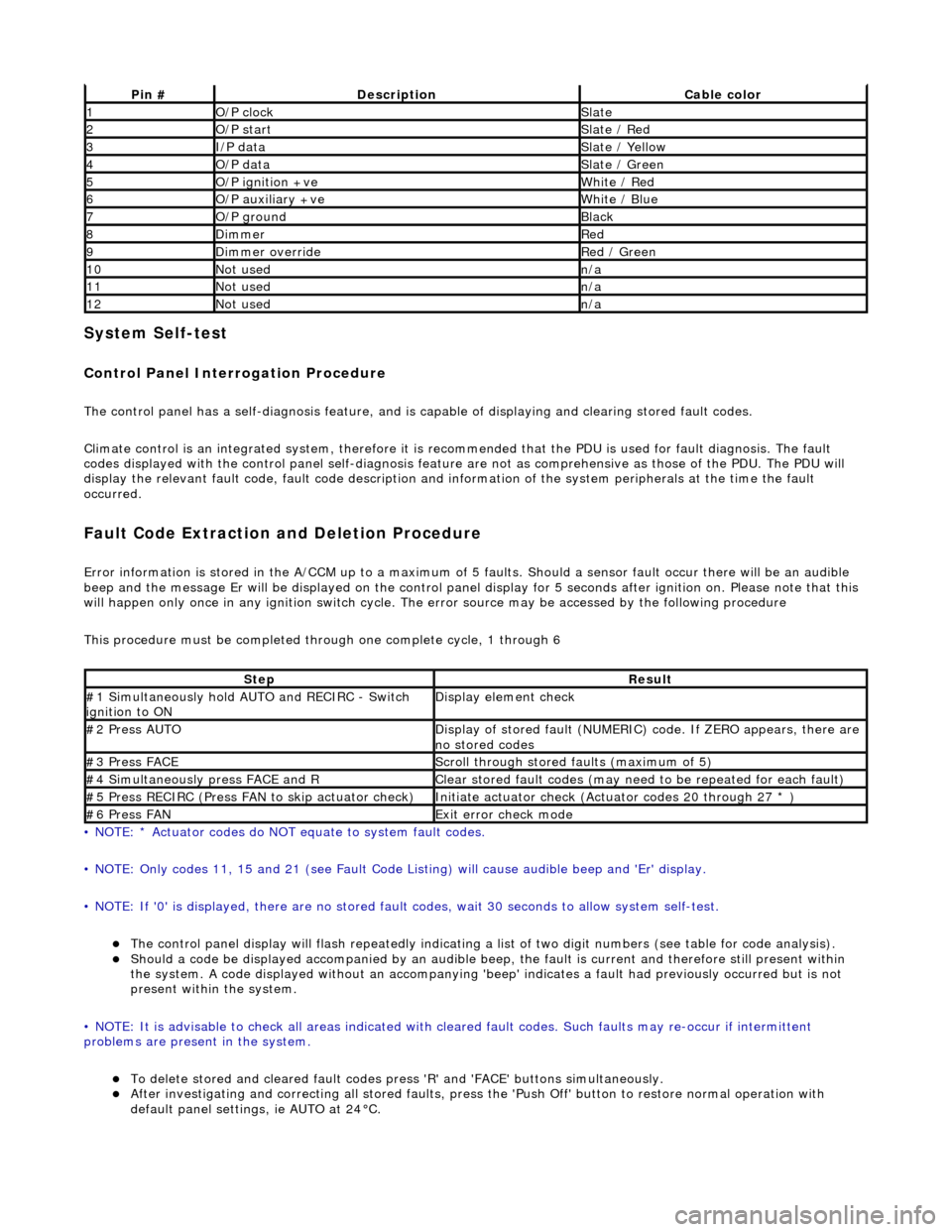

System Self-test

Control Panel Interrogation Procedure

The control panel has a self-diagnosis feature, and is capable of displaying and clearing stored fault codes.

Climate control is an integrated system, therefore it is recommended that the PDU is used for fault diagnosis. The fault

codes displayed with the control panel self -diagnosis feature are not as comprehensive as those of the PDU. The PDU will

display the relevant fault code, fault co de description and information of the system peripherals at the time the fault

occurred.

Fault Code Extraction and Deletion Procedure

Error information is stored in the A/CCM up to a maximum of 5 faults. Should a sensor fault occur there will be an audible

beep and the message Er will be displayed on the control panel display for 5 seco nds after ignition on. Please note that this

will happen only once in any ignition switch cycle. The error source may be accessed by the following procedure

This procedure must be completed through one complete cycle, 1 through 6

• NOTE: * Actuator codes do NOT equate to system fault codes.

• NOTE: Only codes 11, 15 and 21 (see Fault Code List ing) will cause audible beep and 'Er' display.

• NOTE: If '0' is displayed, there are no stored faul t codes, wait 30 seconds to allow system self-test.

The control panel display will flash repeatedly indicating a list of two digit numbers (see table for code analysis). Should a code be displayed accompanied by an audible beep, the fault is current and therefore still present within

the system. A code displayed without an accompanying 'bee p' indicates a fault had previously occurred but is not

present within the system.

• NOTE: It is advisable to check all areas indicated with cleared fault codes. Such faults may re-occur if intermittent

problems are present in the system.

To delete stored and cleared fault codes press 'R' and 'FAC E' buttons simultaneously. After investigating and correcting all stored faults, press the 'Push Off' button to restore normal operation with

default panel settings, ie AUTO at 24°C.

Pin #DescriptionCable color

1O/P clockSlate

2O/P startSlate / Red

3I/P dataSlate / Yellow

4O/P dataSlate / Green

5O/P ignition +veWhite / Red

6O/P auxiliary +veWhite / Blue

7O/P groundBlack

8DimmerRed

9Dimmer overrideRed / Green

10Not usedn/a

11Not usedn/a

12Not usedn/a

StepResult

#1 Simultaneously hold AU TO and RECIRC - Switch

ignition to ONDisplay element check

#2 Press AUTODisplay of stored fault (NUMERIC) code. If ZERO appears, there are

no stored codes

#3 Press FACEScroll through stored faults (maximum of 5)

#4 Simultaneously press FACE and RClear stored fault codes (may need to be repeated for each fault)

#5 Press RECIRC (Press FAN to skip actuator check)Initiate actuator check (Actuator codes 20 through 27 * )

#6 Press FANExit error check mode

Page 1979 of 2490

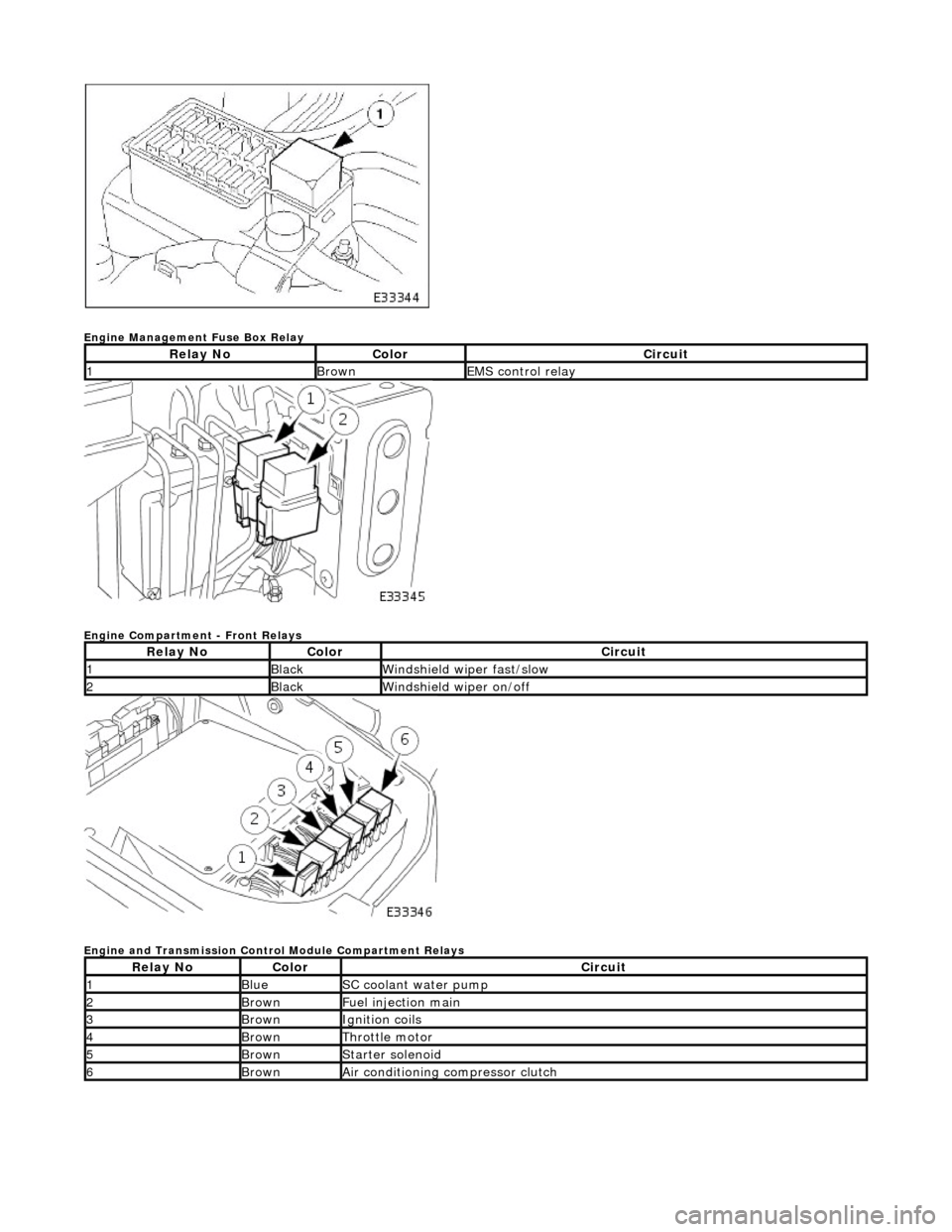

Engine Management Fuse Box Relay

Engine Compartment - Front Relays

Engine and Transmission Control Module Compartment Relays

Relay NoColorCircuit

1BrownEMS control relay

Relay NoColorCircuit

1BlackWindshield wiper fast/slow

2BlackWindshield wiper on/off

Relay NoColorCircuit

1BlueSC coolant water pump

2BrownFuel injection main

3BrownIgnition coils

4BrownThrottle motor

5BrownStarter solenoid

6BrownAir conditioning compressor clutch

Page 1980 of 2490

Front Firewall Relays

Heelboard Fuse Box Relays - Right hand side

* not illustrated

Heelboard Fuse Box Relays - Left hand side

Relay NoColorCircuit

1BlackWindshield RH heater (where fitted)

2BlackWindshield LH heater (where fitted)

Relay NoColorCircuit

1BlueDoor mirror heater

2BlueAir conditioning RH blower

3BlueLeft rear seat lumbar deflate (where fitted) *

4BrownAuxiliary +

5BlueAir conditioning LH blower

Relay NoColorCircuit

1BrownIgnition +

2VioletDoor mirror fold flat (where fitted)

3VioletAir conditioning isolate

4VioletDoor locks

Page 1990 of 2490

the bag securely before opening another bag. Also, replace the bag in its mating part number compartment within the case.

The pre-terminated wiring harness(s) are su pplied with the insulation in one of three colors, red, blue or yellow. The colors

do not apply to any particular circuit but to the harness wire size. See the Relationship Table in the Repair Method section.

Butt splice connectors are also supplied wi th red, blue or yellow coverings, which must be matched to the pre-terminated

wiring harness insulation color.

Pre-Terminated Wiring Harness(s)

Page 1992 of 2490

The part number of the pre-terminated wiring harness The letter showing the extractor tip which must be used to remove this type of electrical connector terminal Those electrical connector terminals which are gold

Some of the pre-terminated wiring harness( s) have seals installed to the insulation for sealed connector applications. It is

essential for prevention of mo isture ingress that a sealed pre-terminated wiring harness must be used where a sealed

terminal was removed.

CAUTION: Where the repair procedure indica tes that a glue lined heat shrink sleeve should be applied, apply sufficient

heat to the glue lined heat shrink to melt the glue in order to provide a water tight seal. Do not over heat the glue lined

heat shrink sleeve so that the wiring harness insulation becomes damaged.

Two sizes of heat shrink sleeving are supplied in the wiring harn ess repair kit. Each heat shrink sleeve contains a sealant

glue. These must be used when connecting wiring harness(s) or electrical connector terminal(s) at all times. The smaller

diameter heat shrink sleeve is to be used with the red and blue butt splice connectors and the larger di ameter sleeve with

the yellow butt sp lice connectors.

For ease and speed, some of the pre-term inated wiring harness(s) may already have the insulation partly stripped at the

splice end. If the repair requires insula tion to be stripped from the cable, refer to the Relationship Table fo r the correct

length of insulation to be stripped.

The Pre-Terminated Wiring Harness(s) illu stration shows the electrical connector terminal type, the part number of the pre-

terminated wiring harness and the letter of the extractor tip which must be used to extract the electrical connector terminal

from the connector housing. Additionally, those electrical conne ctor terminal(s) which are gold are identified, all others are

therefore, tinned and not gold.

Wiring Harness Cable Identification Sleeves

A selection of colored sleeves are contai ned in the wiring harness repair kit for maintaining the wiring harness cable

identification on the pre-term inated wiring harness. Place the correct colo red sleeve(s) over the pre-terminated wiring

harness insulation as near to the electr ical connector as possible with the main wiring harness cable color nearest to the

electrical connector.

For example, if the original wiring harness cable color is pink with a black trace put the pink wiring harness cable

identification sleeve on the pre-terminated wiring harness first followed by a black sleeve, and slide both along the wiring

harness cable to the electr ical connector terminal.

Extraction Handle and Tips

The extraction handle, in conjunction with th e correct tip, is used to remove a terminal from an elec trical connector. Each tip contained in the wiring harness repair kit is marked with an identification letter, A to K inclusive. Each tip has been special ly

designed to extract a particular ty pe of electrical connector terminal. The use of any other tool is not recommended and is

liable to cause damage to the electrical connector. The tip is fastened to the handle by a screw which holds the tip firmly yet

allows it to be easily replaced.

Extraction Handle and Tips

Page 1995 of 2490

The crimping pliers have a moving jaw and a stationary jaw, with three different sized crimping enclosures. Each of the

enclosures is identified by a red, blue or yellow coloured dot which correspon ds to the three colours of the pre-terminated

wiring harness(s) and butt splice connector colors.

List of Parts

DescriptionPart NumberQuantity

Wiring Harness Repair Kit 418-S0651

Pre-Terminated Wiring Harness(s)418-066 to 418-103

inclusive 10 each

Glue Lined Heat Shrink Pack – small diameter418-10425 per

pack

Glue Lined Heat Shrink Pack – larger diameter418-10510 per pack

Case Assembly Comprising – carry case, li d, inner lid, base, insert, trays foam

spacers418-1061

Butt Splice Connector – Red 418-10750 per pack

Butt Splice Connector – Blue 418-10850 per

pack

Butt Splice Connector – Yellow 418-10920 per pack

Extraction Tool Handle 418-1101

Extraction Tip Pack consists of 2 spare screws plus 418-S1111

Tip A418-1181

Tip B418-1191

Tip C418-1201

Tip D418-1211

Tip E418-1221

Tip F418-1231