Drive shaft JAGUAR X308 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 747 of 2490

3. Fit the five bolts which secure the adaptor assembly to the cylinder head.

4. Fit new seals to the fuel rail.

2. Fit the fuel rail to the intercooler adaptor.

1. Align the fuel rail to the adaptor; still connected to the fuel crossover pipe and fuel return pipe. Locate

the fuel rail into the adaptor.

2. Fit the three bolts which secure the fuel rail to the adaptor.

3. Connect the fuel injector harness.

1. Reposition the harness.

2. Tighten the nuts which secure the harness to the

camshaft cover.

3. Connect the multi-plugs to the A-Bank injectors.

4. Fit the A-Bank intercooler. Refer to Operation 18.50.18.

5. Fit the supercharger assembly. Refer to operation 18.50.15.

6. Fit the supercharger drive belt . Refer to Operation 18.50.08.

7. Fit the coolant output pipe. Refer to Operation 26.31.08.

8. Fit the throttle induction elbow. Refer to Operation 19.70.28.

9. Fit the throttle housing. Refer to Operation 19.70.04.

10. Fit the supercharger outlet duct and gasket. Refer to

Operation 18.50.17.

11. Fit the intake tube / air flow meter / air cleaner cover

assembly.

1. Fit a new rubber seal; air in take tube to throttle body.

2. Fit the intake tube / air flow meter / air cleaner cover

assembly.

Page 755 of 2490

Engine - Oil Pump4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

In-vehicle Repair

Removal

Installation

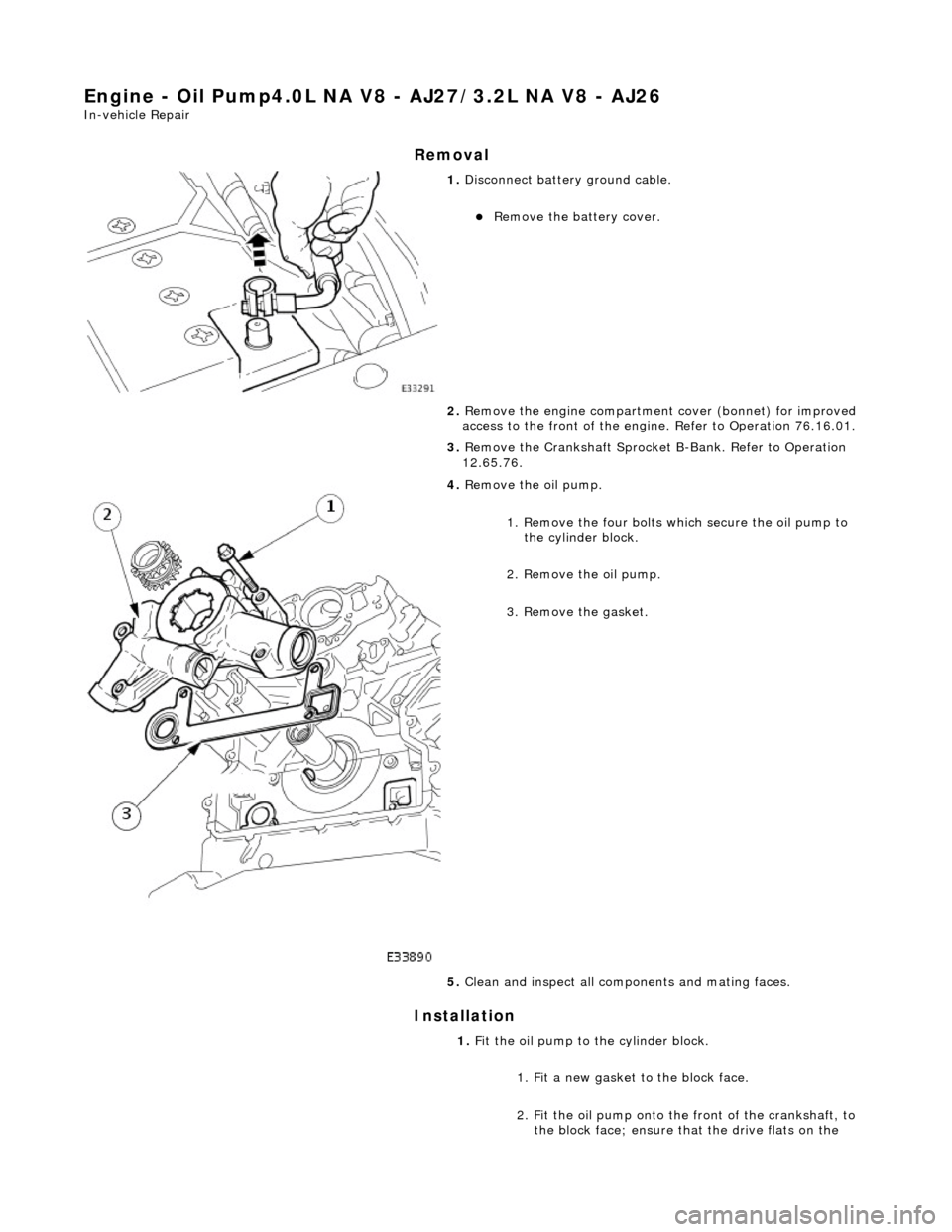

1. Disconnect battery ground cable.

Remove the battery cover.

2. Remove the engine compartment cover (bonnet) for improved

access to the fro nt of the engine. Refer to Operation 76.16.01.

3. Remove the Crankshaft Sprocket B-Bank. Refer to Operation

12.65.76.

4. Remove the oil pump.

1. Remove the four bolts which secure the oil pump to the cylinder block.

2. Remove the oil pump.

3. Remove the gasket.

5. Clean and inspect all compon ents and mating faces.

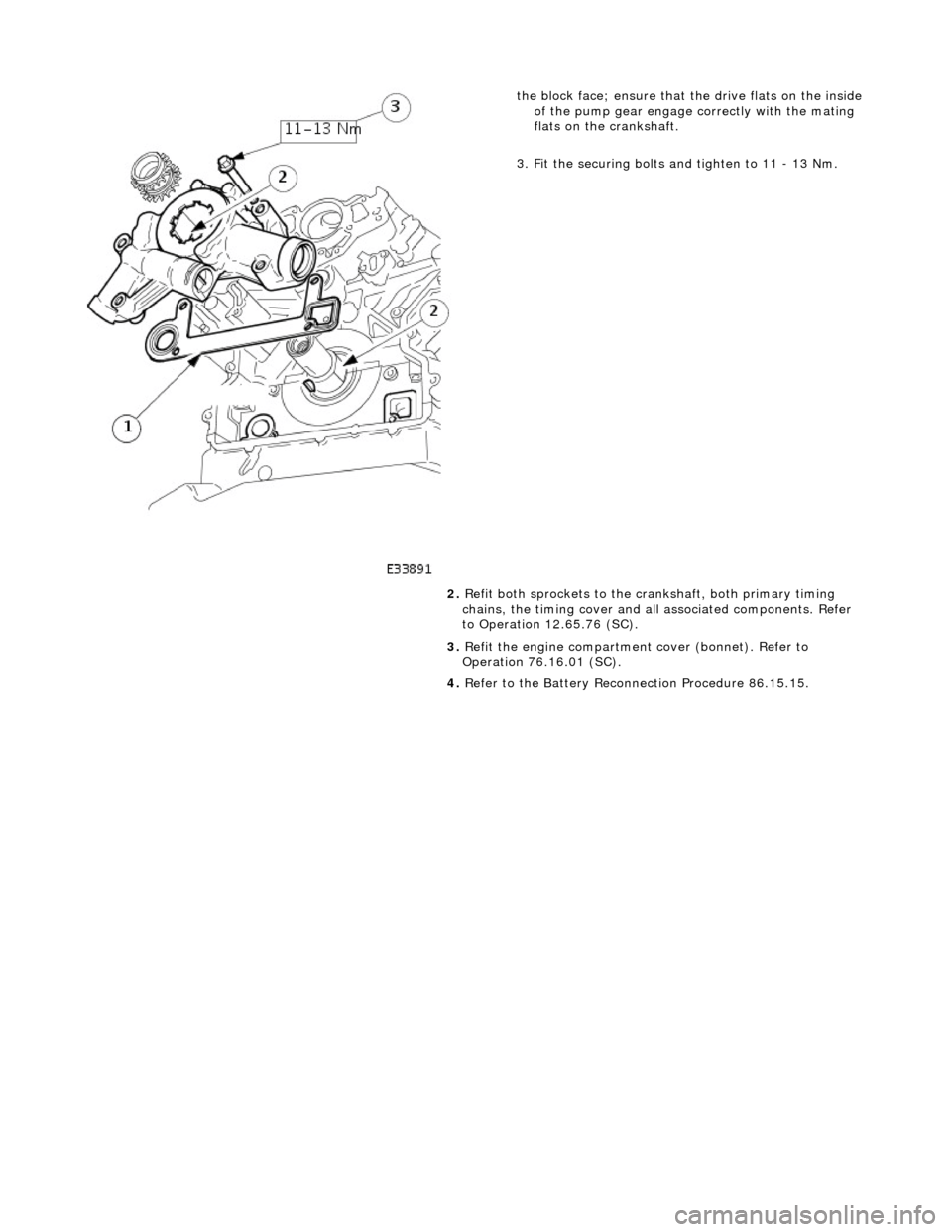

1. Fit the oil pump to the cylinder block.

1. Fit a new gasket to the block face.

2. Fit the oil pump onto the front of the crankshaft, to

the block face; ensure that the drive flats on the

Page 758 of 2490

the block face; ensure that the drive flats on the inside

of the pump gear engage correctly with the mating

flats on the crankshaft.

3. Fit the securing bolts and tighten to 11 - 13 Nm.

2. Refit both sprockets to the crankshaft, both primary timing

chains, the timing cover and al l associated components. Refer

to Operation 12.65.76 (SC).

3. Refit the engine compartment cover (bonnet). Refer to

Operation 76.16.01 (SC).

4. Refer to the Battery Reconnection Procedure 86.15.15.

Page 761 of 2490

2. Remove the access grommet (for torque converter bolts) from the housing.

11. Fit the damper securing bolt (old one) to the crankshaft,

hand-tight only.

12. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

13. Fit the crankshaft setting peg 303 - 531 to the crankshaft

position sensor location.

1. Fit the crankshaft setting peg 303 - 531.

1. Position the crankshaft so that the setting peg engages fully into the timing slot.

2. Fit and tighten the bolt to secure the setting peg.

14. Remove the damper securing bolt from the crankshaft.

15. Lower the vehicle on the ramp.

16. Fit the camshaft locking tool 303 - 530 to the A-Bank

camshafts, aligning the shafts slightly as necessary.

17. Loosen the bolt which secures the sprocket to the camshaft.

Page 765 of 2490

sprocket, B-Bank.

Reposition the sprocket (and the VVT unit) for the most

advantageous position for use of the tool.

Remove the tool.

2. Refit the primary timing chain, B-Bank.

1. Fit the primary chain over the crankshaft sprocket and the VVT unit sprocket. There must be no slack on

the drive side of the primary chain and the VVT unit

must not be rotate d on the camshaft.

Slide the VVT and exhaust sprocket fully rearwards onto

the respective camshafts.

3. Fit the primary chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

2. Fit the retaining / pivot bolt and tighten it to 12 - 16 Nm.

4. Refit the primary chain tensione r assembly. Refer to Operation

12.65.55 in this Section.

Use a wedge 303 - 533 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

5. Tighten the exhaust camshaft sprocket securing bolt.

1. Fit the chain tensioner tool 303 - 532 to the sprocket holes.

1. Apply force to the tool in an anti-clockwise direction

to tension the chain on its drive side.

2. Whilst applying the opposing force to the sprocket

Page 766 of 2490

and chain, tighten the sprocket securing bolt to 115 -

125 Nm.

6. Tighten the VVT unit securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303 - 532), check that the

wedges are still in place, tighten the VVT unit

securing bolt to 115 - 125 Nm.

Remove the chain tensioning tool and the wedge(s).

7. Remove the camshaft locking tool 303 - 530 and transfer it to

the A-Bank camshafts, aligning the shafts slightly as necessary.

8. Fit the chain tensioning tool 303 - 532 to the exhaust camshaft

sprocket, A-Bank.

Reposition the sprocket (and the VVT unit) for the most

advantageous position for use of the tool.

Remove the tool.

9. Refit the primary timing chain, A-Bank.

1. Fit the primary chain over the crankshaft sprocket and the VVT unit sprocket. There must be no slack on

the drive side of the primary chain and the VVT unit

must not be rotate d on the camshaft.

Page 767 of 2490

10. Fit the primary chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

2. Fit the retaining / pivot bolt and tighten it to 12 - 16 Nm.

11. Refit the primary chain tens ioner assembly. Refer to

Operation 12.65.54 in this Section.

Use a wedge 303 - 533 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

12. Tighten the exhaust camshaft sprocket securing bolt.

1. Fit the chain tensioner tool 303 - 532 to the sprocket holes.

1. Apply force to the tool in an anti-clockwise direction

to tension the chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprock et securing bolt to 115 -

125 Nm.

13. Tighten the VVT unit securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303 - 532), check that the

wedges are still in place, tighten the VVT unit

securing bolt to 115 - 125 Nm.

Remove the chain tensioning tool and the wedge(s).

Page 771 of 2490

position sensor to the flywheel housing.

Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

7. Install the damper securing bolt (old one) to the crankshaft,

hand-tight only.

8. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

9. Install the crankshaft setting peg 303-531 to the crankshaft

position sensor location.

1. Install the crankshaft setting peg 303-531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Install and tighten the bolt to secure the setting peg.

10. Remove the damper securing bolt from the crankshaft.

11. Lower the vehicle on the ramp.

12. Install the camshaft locking tool 303-530 to Bank 1

camshafts, aligning the shafts slightly as necessary.

13. Loosen the bolt which secures the sprocket to the exhaust

camshaft.

Page 775 of 2490

camshaft sprocket, Bank 2.

Reposition the sprocket to the most advantageous position for use of the tool.

Remove the tool.

2. Install the primary timi ng chain, Bank 2.

1. Install the primary chain over the crankshaft sprocket and the intake camshaft sp rocket. There must be no

slack on the drive side of the primary chain and the

sprockets should not be rotated on the camshafts (or

the tensioning tool may not fit).

Slide the camshaft sprocket s fully rearwards onto the

respective camshafts.

3. Install the primary ch ain tensioner blade.

1. Position the tensioner blade to the cylinder block.

2. Install the retaining / pivo t bolt and tighten it to 12-

16 Nm.

4. Install the primary chain te nsioner assembly. Refer to

Operation 12.65.55.

Use a wedge 303-533 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

5. Tighten the exhaust camshaft sprocket securing bolt.

1. Install the chain tensioner tool 303-532 to the sprocket holes.

Apply force to the tool in an anti-clockwise direction to

tension the chain on its drive side.

Page 776 of 2490

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprock et securing bolt to 115-

125 Nm.

6. Tighten the intake camshaft sprocket securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303-532), check that the

wedges are still in place, ti ghten the securing bolt to

115-125 Nm.

Remove the chain tensioning tool and the wedge(s).

7. Remove the camshaft locking t ool 303-530 and transfer it to

Bank 1 camshafts, aligning the shafts slightly as necessary.

8. Install the chain tensioning tool 303-532 to the exhaust

camshaft sprocket, Bank 1.

Reposition the sprockets to the most advantageous

position for use of the tool.

Remove the tool.

9. Install the primary timi ng chain, Bank 1.

1. Install the primary chain over the crankshaft sprocket and the intake camshaft sp rocket. There must be no

slack on the drive side of the primary chain and the

sprockets should not be rotated on the camshafts (or

the tensioning tool may not fit).