ECU JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 324 of 2490

Brake System - Gener

al Information - Front Brake Disc Runout

CheckVehicles With: Standard Brakes

Gen e

ral Procedures

S

p

ecial Tool(s)

Dial Test Indicator

G

auge and Stand.

1. Raise front of vehicle and support on stands. Refer to section

100-02.

2. Remove wheel.

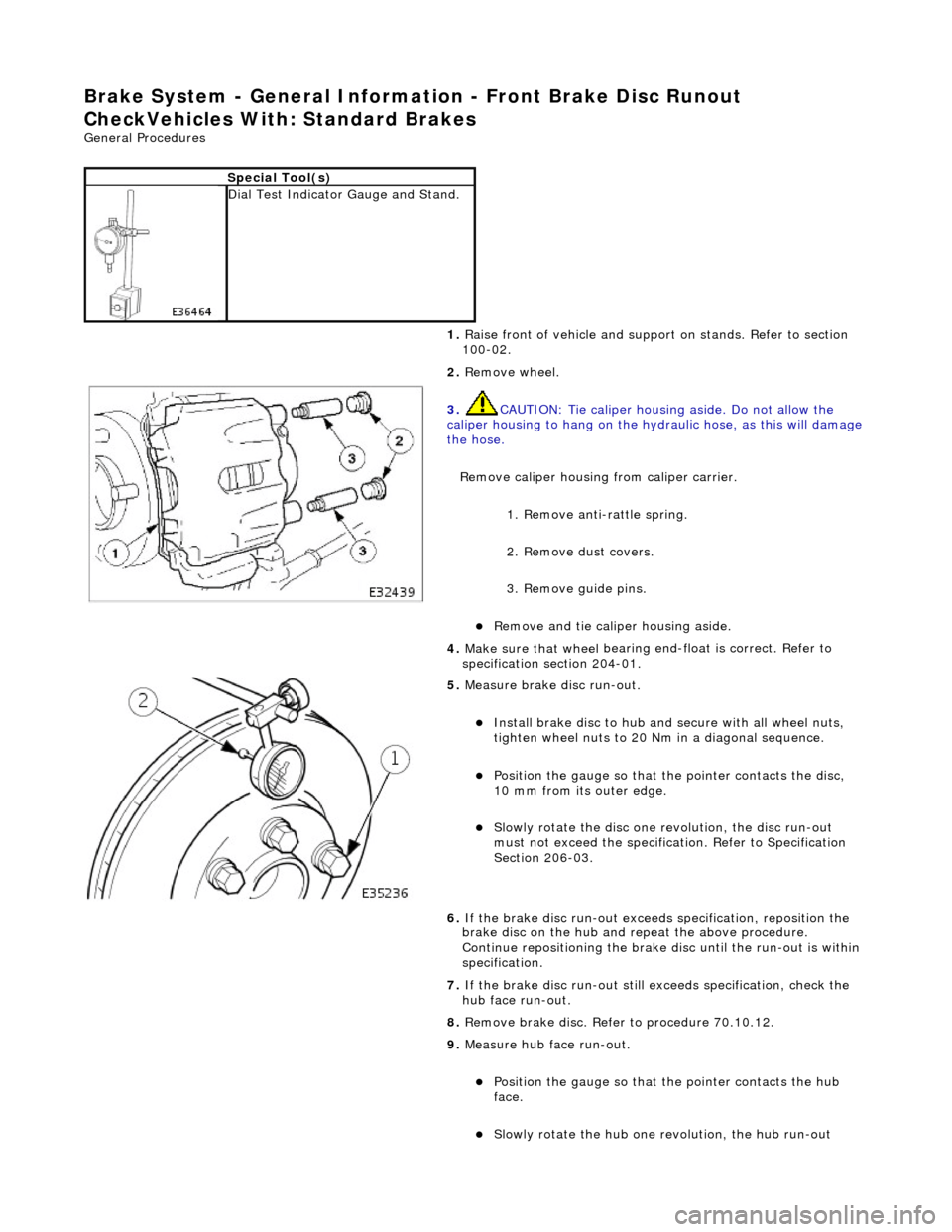

3. CAUT

ION: Tie caliper housing aside. Do not allow the

caliper housing to hang on the hydraulic hose, as this will damage

the hose.

Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

Remove an

d tie caliper housing aside.

4.

Make sure that wheel

bearing en

d-float is correct. Refer to

specification section 204-01.

5. Measure brake d

isc run-out.

Inst

al

l brake disc to hub and secure with all wheel nuts,

tighten wheel nuts to 20 Nm in a diagonal sequence.

Posi

tion the gauge so that the pointer contacts the disc,

10 mm from its outer edge.

Slo w

ly rotate the disc one revolution, the disc run-out

must not exceed the specification. Refer to Specification

Section 206-03.

6. If the brake disc run-out exceeds specification, reposition the

brake disc on the hub and re peat the above procedure.

Continue repositioning the brake di sc until the run-out is within

specification.

7. If the brake disc run-out still exceeds specification, check the

hub face run-out.

8. Remove brake disc. Refer to procedure 70.10.12.

9. Measure hub face run-out.

Posi

tion the gauge so that the pointer contacts the hub

face.

Slo w

ly rotate the hub one revolution, the hub run-out

Page 326 of 2490

Fr

ont Brake Disc Runout Check Vehicles With: Brembo Brakes

Special Service tools

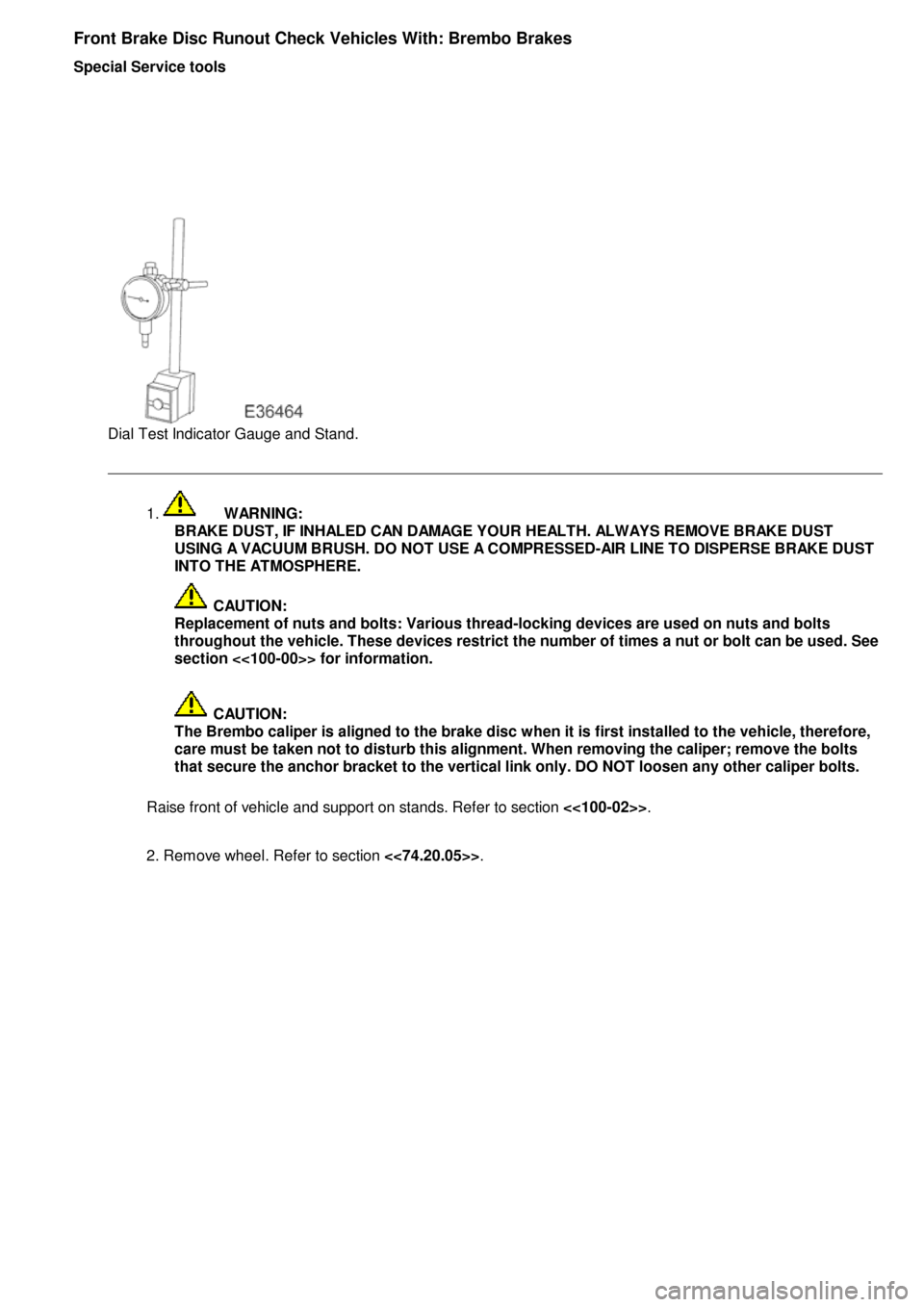

Di

al Test Indicator Gauge and Stand.

1.

WA

RNING:

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

CA

UTION:

Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts

throughout the vehicle. These devices restrict the number of times a nut or bolt can be used. See

section <<100-00>> for information.

CA

UTION:

The Brembo caliper is aligned to the brake disc when it is first installed to the vehicle, therefore,

care must be taken not to disturb this alignment. When removing the caliper; remove the bolts

that secure the anchor bracket to the vertical link only. DO NOT loosen any other caliper bolts.

Raise front of vehicle and support on stands. Refer to section <<100-02>>.

2. Remove wheel. Refer to section <<74.20.05>>.

Page 327 of 2490

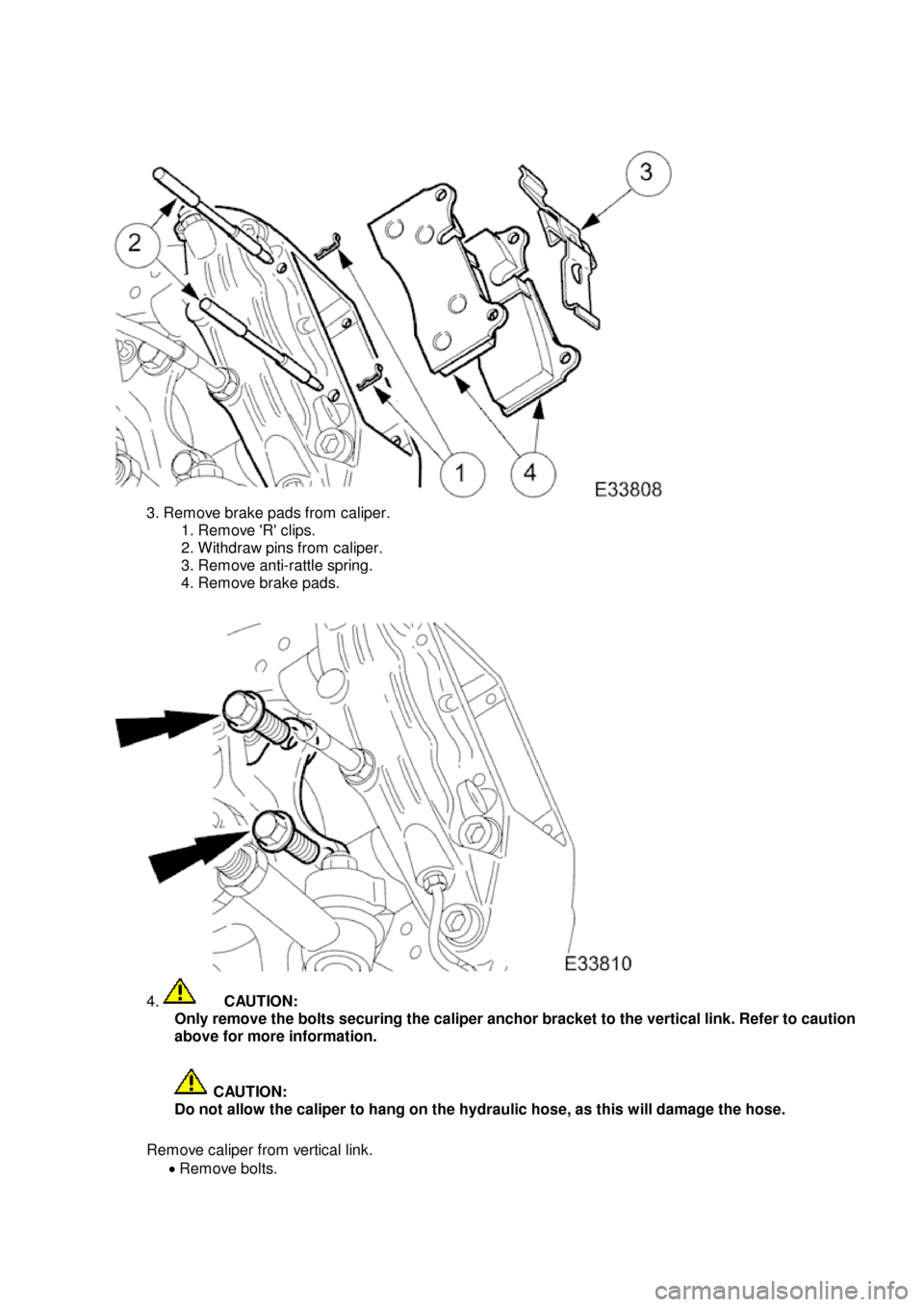

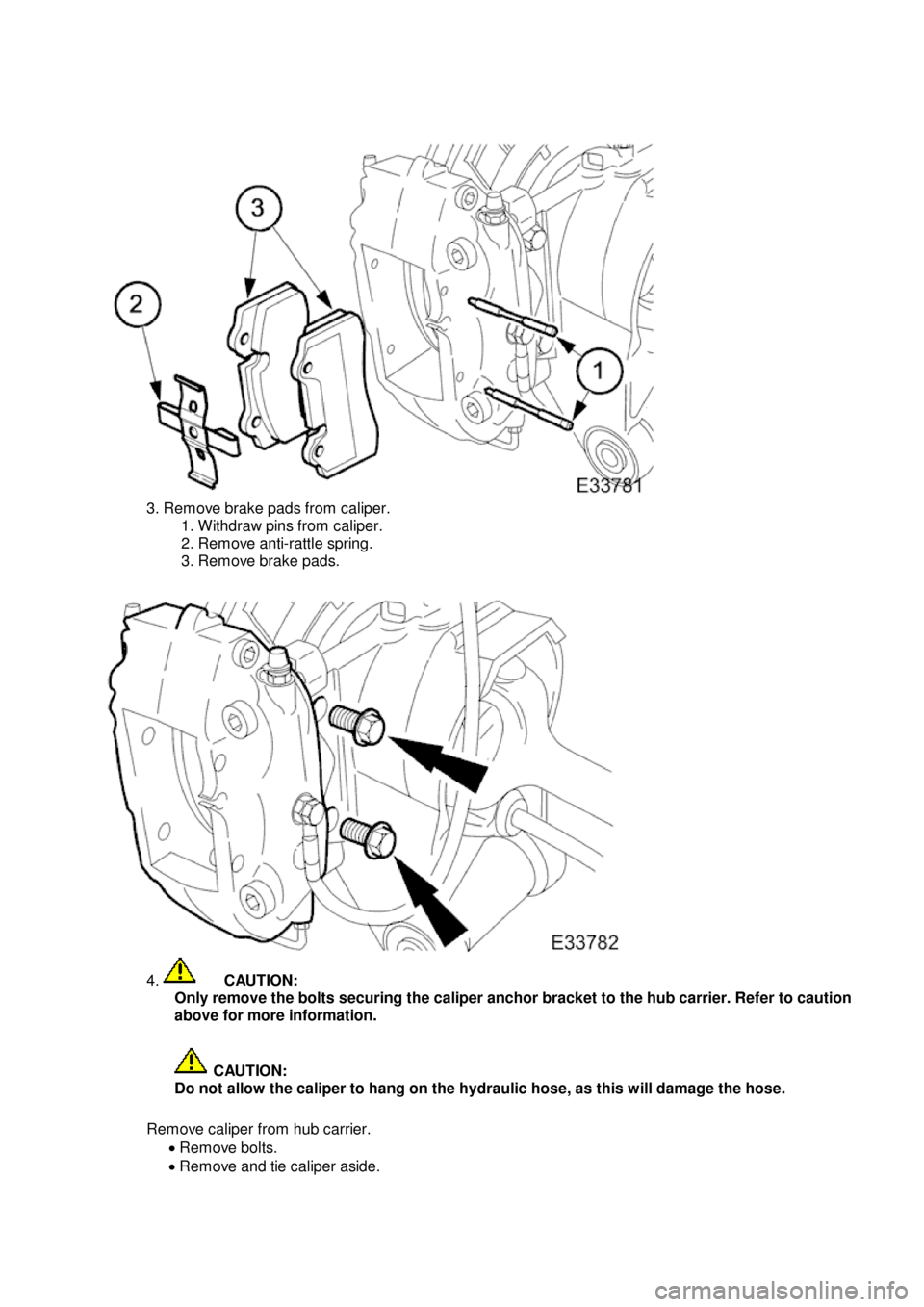

3

. Remove brake pads from caliper.

1. Remove 'R' clips.

2. Withdraw pins from caliper.

3. Remove anti-rattle spring.

4. Remove brake pads.

4

.

C

AUTION:

Only remove the bolts securing the caliper anchor bracket to the vertical link. Refer to caution

above for more information.

C

AUTION:

Do not allow the caliper to hang on the hydraulic hose, as this will damage the hose.

Remove caliper from vertical link. Remove bolts.

Page 328 of 2490

R

emove and tie caliper aside.

5. Make sure that wheel bearing end-float is within specification. Refer to specification section <<204-01>>.

6.

Measure brake disc run-out.

1. Install brake disc to hub and secure with all wheel nuts, tighten wheel nuts to 20 Nm in a diagonal sequence.

2. Position the gauge so that the pointer contacts the disc, between the disc's outer drill holes and the disc's outer edge.

Slowly rotate the disc one revolution, the disc run-out must not exceed the specification. Refer to

Specification Section <<206-03>>.

7. If the brake disc run-out exceeds specification, reposition the brake disc on the hub and repeat the above

procedure. Continue repositioning the brake disc until the run-out is within specification.

8. If the brake disc run-out still exceeds specification, check the hub face run-out.

9. Remove brake disc.

Page 332 of 2490

Me

asurement of the brake disc run-out, must be carried-out with the disc and hub parking-brake

adjuster-holes aligned.

Make sure that wheel bearing end-float is correct. Refer to specification section <<204-02>>.

5.

Measure brake disc run-out.

Install brake disc to hub and secure with all wheel nuts, tighten wheel nuts to 20 Nm in a diagonal

sequence.

Position the gauge so that the pointer contacts the disc 10 mm from its outer edge.

Slowly rotate the disc one revolution, the disc run-out must not exceed the specification. Refer to

specifications in section <<206-04>>.

6. If the brake disc run-out exceeds specification, check the hub face run-out.

7. Remove brake discs. Refer to procedure 70.10.13.

8.

Measure hub face run-out.

Page 334 of 2490

Rear

Brake Disc Runout Check Vehicles With: Brembo Brakes

Special Service tools

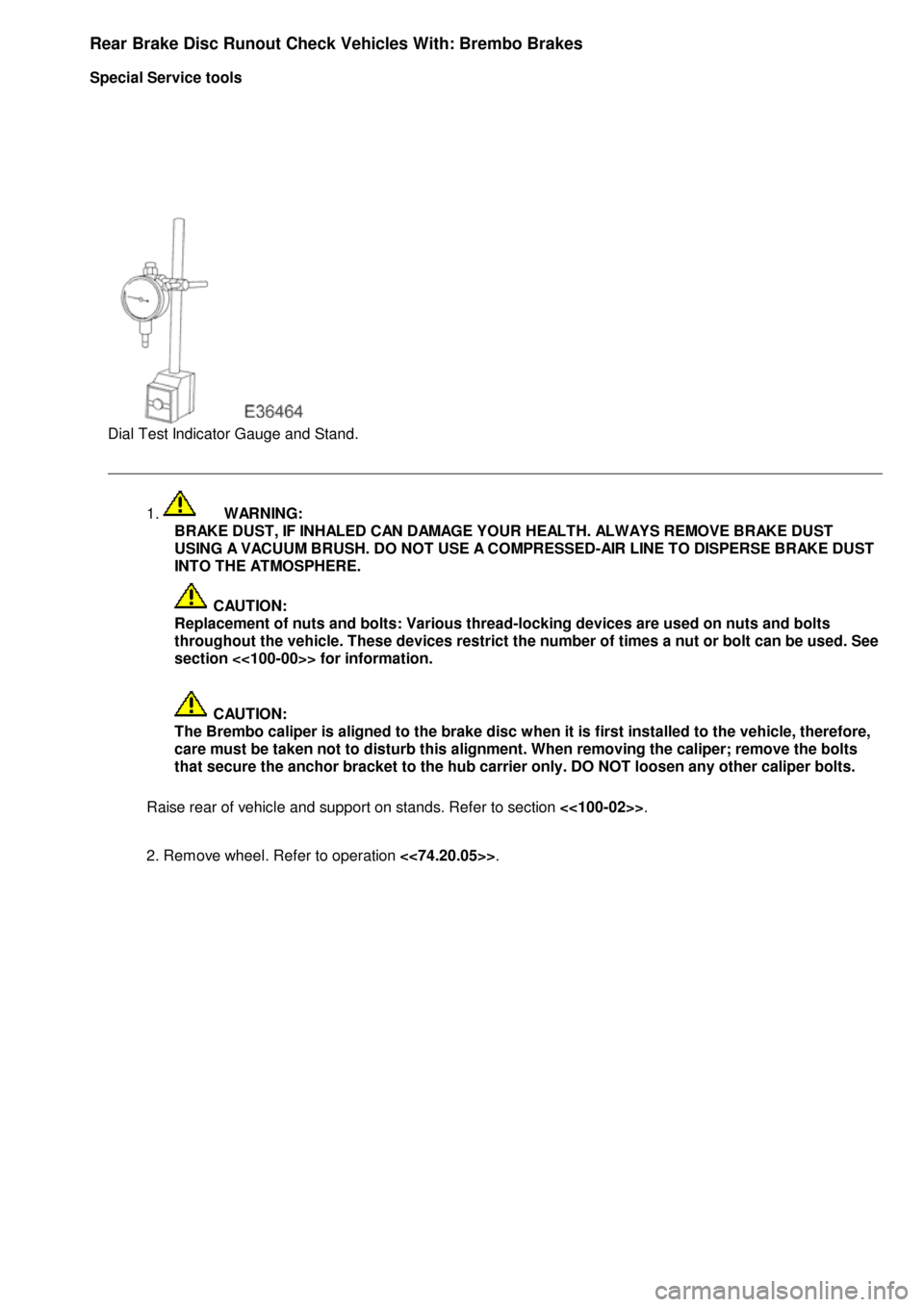

Di

al Test Indicator Gauge and Stand.

1.

WA

RNING:

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

CA

UTION:

Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts

throughout the vehicle. These devices restrict the number of times a nut or bolt can be used. See

section <<100-00>> for information.

CA

UTION:

The Brembo caliper is aligned to the brake disc when it is first installed to the vehicle, therefore,

care must be taken not to disturb this alignment. When removing the caliper; remove the bolts

that secure the anchor bracket to the hub carrier only. DO NOT loosen any other caliper bolts.

Raise rear of vehicle and support on stands. Refer to section <<100-02>>.

2. Remove wheel. Refer to operation <<74.20.05>>.

Page 335 of 2490

3

. Remove brake pads from caliper.

1. Withdraw pins from caliper.

2. Remove anti-rattle spring.

3. Remove brake pads.

4

.

C

AUTION:

Only remove the bolts securing the caliper anchor bracket to the hub carrier. Refer to caution

above for more information.

C

AUTION:

Do not allow the caliper to hang on the hydraulic hose, as this will damage the hose.

Remove caliper from hub carrier. Remove bolts.

Remove and tie caliper aside.

Page 336 of 2490

5.

Make sure that wheel bearing end-float is within specification. Refer to specification section

<<204-02>>.

6.

NOTE:

Measurement of the brake disc run-out, must be carried-out with the disc and hub access holes aligned.

7.

Measure brake disc run-out.

1. Install brake disc to hub and secure with all wheel nuts, tighten wheel nuts to 20 Nm in a diagonal sequence.

2. Position the gauge so that the pointer contacts the disc, between the disc's outer drill holes and the disc's outer edge.

Slowly rotate the disc one revolution, the disc run-out must not exceed the specification. Refer to

specifications in section <<206-04>>.

8. If the brake disc run-out exceeds specification, check the hub face run-out.

Page 340 of 2490

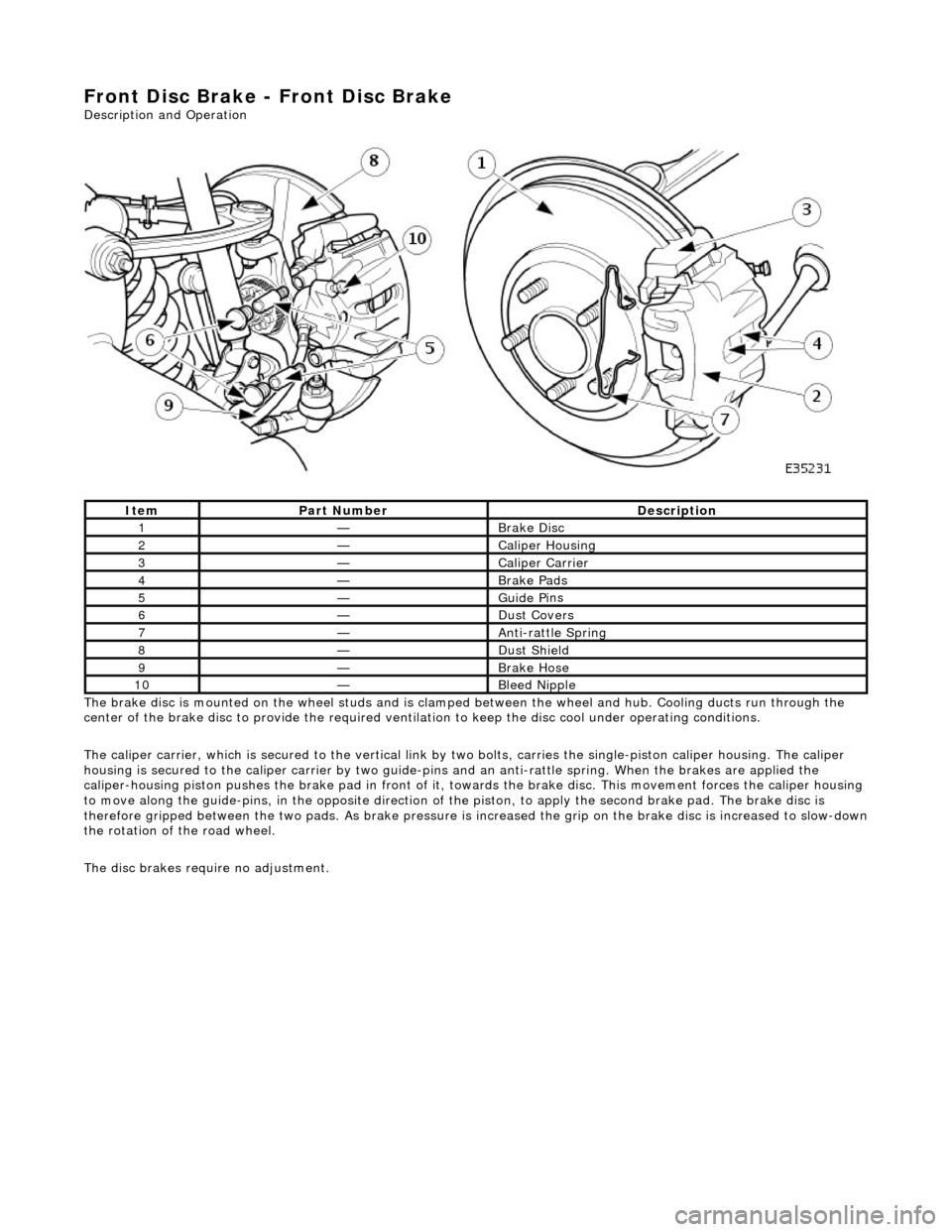

Front Disc Brake - Front Disc Brake

Description and Operation

The brake disc is mounted on the wheel studs and is clamped between the wheel and hub. Cooling ducts run through the

center of the brake disc to provide the required ventilation to keep the disc cool under operating conditions.

The caliper carrier, which is se cured to the vertical link by two bolts, carries the single-pis ton caliper housing. The caliper

housing is secured to the caliper carrier by two guide-pins and an anti-rattle spring. When the brakes are applied the

caliper-housing piston pushes th e brake pad in front of it, towards the brake di sc. This movement forces the caliper housing

to move along the guide-pins, in the oppo site direction of the piston, to apply the second brake pad. The brake disc is

therefore gripped between the two pads. As brake pressure is increased the grip on the brake disc is increased to slow-down

the rotation of the road wheel.

The disc brakes requ ire no adjustment.

It

e

m

Par

t

Number

De

scr

iption

1—B

r

ake Disc

2—Caliper Housin

g

3—Caliper Carrier

4—Brake Pads

5—Guide P i

ns

6—Du

st

Covers

7—An

ti

-rattle Spring

8—Du

st

Shield

9—Brake Hos

e

10—Bleed Nipp

le

Page 341 of 2490

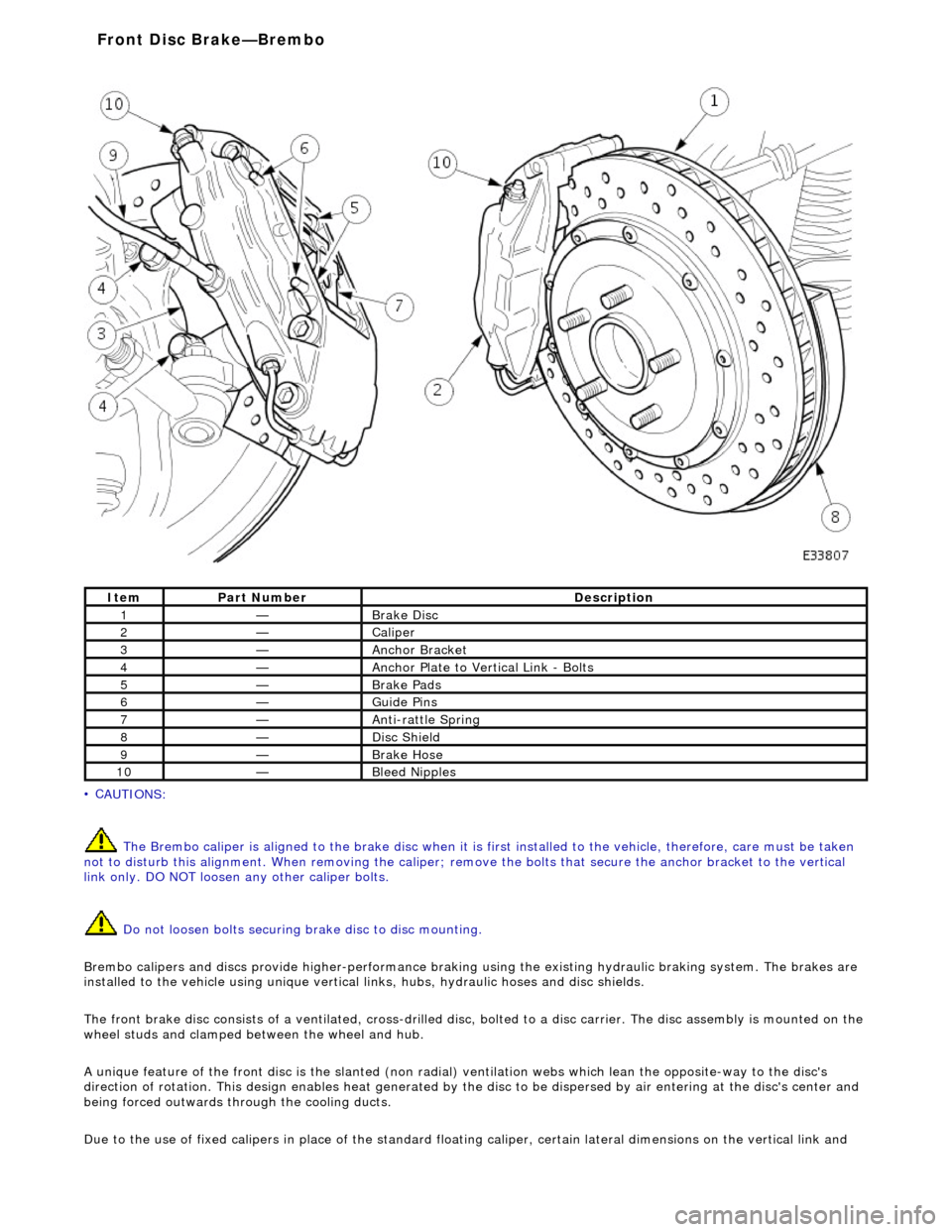

• C

AUTIONS:

The Brembo caliper is aligned to the brak e disc when it is first installed to the vehicle, therefore, care must be taken

not to disturb this alignment. When removi ng the caliper; remove the bolts that secure the anchor bracket to the vertical

link only. DO NOT loosen any other caliper bolts.

Do not loosen bolts securing brake disc to disc mounting.

Brembo calipers and discs provide higher -performance braking using the existing hydraulic braking system. The brakes are

installed to the vehicle using unique vertical links, hubs, hydraulic hoses and disc shields.

The front brake disc consists of a ventilated, cross-drilled disc, bolted to a disc carrier. The disc assemb ly is mounted on the

wheel studs and clamped be tween the wheel and hub.

A unique feature of the front disc is th e slanted (non radial) ventilation webs which lean the opposite-way to the disc's

direction of rotation. This design enables he at generated by the disc to be dispersed by air entering at the disc's center and

being forced outwards through the cooling ducts.

Due to the use of fixed calipers in place of the standard floating caliper, certain lateral dimensions on the vertical link and

It

em

Par

t Number

De

scription

1—B

rake Disc

2—Caliper

3—Anch

or Bracket

4—Anchor Pl

ate to Vertical Link - Bolts

5—Brake Pad

s

6—Guide P

ins

7—Anti-r

attle Spring

8—Di

sc Shield

9—Brake Hos

e

10—Bleed Nipp

les

Front Disc Brake—

Brembo