brakes JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 316 of 2490

Road test the veh

icle and a

pply the brake pe dal lightly.

1

Do th

e brakes lockup?

Yes GO to H2

.

No

Vehicle is OK.

H2: INSPECT BRAKE PADS

Inspect brake pads for con

t

amination,

correct installation , damage and type.

1

Ar

e any concerns found?

Yes CHECK the front brake pads. For additi onal information, refer toSection 206

-03 Fr

ont Disc Brake

.

CHECK

the rear brake pads. For additi

onal information, refer toSection 206

-04

Rear Disc Brake

.

INST ALL new brake pads as ne ce

ssary. REPEAT

road test.

No GO to H3

.

H3: INSPECT BRAKE CALI

PERS

Inspect brake cali

pers for bindi

ng, leaking or sticking.

1

A

r

e any concerns found?

Yes CHECK the front brake calipers. For addi tional information, refer toSection 206

-03 Fr

ont Disc Brake

.

CHECK

the rear brake calipers. For addi

tional information, refer toSection 206

-04

Rear Disc Brake

.

IN ST

ALL the brake calipers correctly or INSTALL new

brake calipers as necessary. TEST the system for

normal operation. REPEAT road test if necessary.

No Vehicle is OK.

PI

NPOINT TEST I : BRAKES DRAG

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

I1

:

ROAD TEST VEHICLE

Ro

ad t

est the vehicle

and apply the brakes.

1

Are the brakes

functioning correctly?

Yes Vehicle is OK.

No GO to I2

.

I2

: CHECK CALIPERS

Check the fr

on

t caliper pistons for binding, leakin

g or sticking. For additional information, refer

toSection 206

-03 Fr

ont Disc Brake

. Check the rear cal

i

per pistons for

binding, leaking or sticking. For

additional information, refer toSection 206

-04

Rear Disc Brake

.

1

Do t

h

e disc brake caliper pistons

and pins bind, leak or stick?

Yes INSPECT the brake calipers and pa rking brake cables. INSTALL new co mponents as necessary. Road

test vehicle.

No GO to I3

.

I3

: CHECK BRAKE BOOSTER

Check the brake booster con

n

ecting rod alignment

and travel. For additional information, refer

toSection 206

-0 7

Power Brake Actuation

. 1

Is the co

nnecti

ng rod OK?

Yes Vehicle is OK.

No INSTALL a new brake booster. For addi tional information, refer toSection 206

-07

Power Brake

Actuation. TEST

the system for

normal operation.

PINPO

I

NT TEST J : EXCESSIVE/ERRATIC BRAKE PEDAL TRAVEL

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

J

1

: TEST ON ROUGH ROAD

R

oad test the vehi

cle on rough road conditions.

1

Apply the brakes slowly. 2

Is th

e brake pedal ef

fort an

d brake pedal travel normal?

Page 319 of 2490

cap ven

t holes clogged or air in the hydraulic system.

Brake ped

al effort is excessive. This ma

y be caused by a bind or obstruction in the pedal/linkage, a faulty non return

valve, booster or insuffi cient booster vacuum.

R

ear brakes lock up during light pedal force. This may

be caused by damaged brake pads, an incorrectly adjusted

parking brake, a partially applied parking brake, a damaged ABS sensor or bearing failure.

Brake ped

al effort erratic. This condition could be caused by the brake booste

r or incorrectly installed brake pads.

Brake warning indicator i

s on. This may be caused

by low fluid level or float assembly damaged.

No

n Pressure Leaks

Any reduced fluid v

olume in the brake ma

ster cylinder reservoir condition may be caused by two types of none pressure

external leaks.

Type 1: An external leak may be occur at the master cylinder reservoir cap because of incorre ct positioning of gasket and

cap. Reposition cap and gasket.

Type 2: An external leak may occur at th e reservoir mounting seals. Repair such a leak by installing new seals and make

sure that the reservoir retainin g bolt is correctly installed.

Page 320 of 2490

Brake Sys

tem - General Informatio

n - Brake System BleedingVehicles

With: Standard Brakes

Gen e

ral Procedures

WARNING: WASH HANDS AFTER HANDLING BRAKE FLUID. IF BRAKE FLUID COMES INTO CONTACT WITH THE EYES,

FLUSH EYES WITH COLD RUNNING WATER. IF IRRITATION PERSISTS SEEK MEDICAL ATTENTION. IF BRAKE FLUID IS

TAKEN INTERNALLY, DRINK WATER AND INDUCE VO MITING. GET MEDICAL ATTENTION IMMEDIATELY.

CAUTION: Remove brake fluid spillage imme diately from paint work with clean water.

1. Position vehi cl

e on a four-post lift.

2. Open engine compartment and fit paint work protection covers

to fenders.

3. NO

TE: Make sure the

brake-fluid level does not fall below the

fluid reservoir 'MIN' (minimum) mark when bleeding the brake

system.

Fill fluid reservoir to the 'MAX' (maximum) mark.

4. Prepare l e

ft-hand front, br

ake-caliper for bleeding.

Remove du

st cap.

Connect b

l

eed pipe

and fluid container to bleed nipple.

5. Bleed the brake.

1. Apply pressure to brake pedal

2. Open bleed nipple.

3. Fully depres s brake pedal.

4. Close bleed nipple.

5. Release brake pedal.

6. Wait two seconds to allow system to prime.

7. Repeat procedure until air- free brake fluid is expelled

from the caliper.

6. Tighten bleed nipple, see torque settings below.

Page 321 of 2490

Front caliper bleed

nipple: 4-6

Nm.

Rear caliper

bleed

nipple: 8-11 Nm.

7. F

ollowing the procedure below,

bleed the brakes in the order

shown:

1. Left-Hand Front,

2. Right-Hand Front,

3. Left- Hand Rear,

4. Right-Hand Rear.

8. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work with clean water.

Fill fluid reservoir.

F

ill reservoir to the 'MAX' mark.

F

it filler cap.

9.

Start e

ngine.

10. Check for correct brake-pedal travel and pressure.

11. Apply brake pedal and check around vehicle for brake fluid

leaks.

12. Make sure brake fluid level is at the 'MAX' mark.

Page 322 of 2490

Brake Sys

tem - General Informatio

n - Brake System BleedingVehicles

With: High Performance Brakes

Gen e

ral Procedures

1. WARNINGS:

IF BRAKE FLUID IS TAKEN INTERNALLY, DRINK WATER

AND INDUCE VOMITING. GET MEDICAL ATTENTION

IMMEDIATELY.

WASH HANDS AFTER HANDLING BRAKE FLUID. IF BRAKE

FLUID COMES INTO CONTACT WITH THE EYES, FLUSH EYES

WITH COLD RUNNING WATER. IF IRRITATION PERSISTS SEEK

MEDICAL ATTENTION.

CAUTION: Remove brake flui d spillage immediately from

paint work with clean water.

Position vehicle on a four-post lift.

2. Op

en engine compartment and fit

paint work protection covers

to fenders.

3. NO

TE: Make sure the

brake-fluid level does not fall below the

fluid reservoir 'MIN' (minimum) mark when bleeding the brake

system.

Fill fluid reservoir to the 'MAX' (maximum) mark.

4. Pr

epare the left-hand front,

brake-caliper for bleeding.

Connect b

leed pipes an

d fluid containers to bleed nipples.

5. Bleed the brake.

1. Apply pressure to brake pedal.

2. Open caliper's outer bleed nipple.

3. Fully depres s brake pedal.

Page 323 of 2490

4

. Close bleed nipple.

5. Release brake pedal.

6. Wait two seconds to allow system to prime.

7. Repeat procedure until air- free brake fluid is expelled

from the bleed nipple.

8. Repeat procedure to ca liper's inner bleed nipple.

6. Tigh

ten bleed nipples to 12-16 Nm.

7. F

ollowing the procedure above,

bleed the brakes in the order

shown:

1. Left-Hand Front,

2. Right-Hand Front,

3. Left- Hand Rear,

4. Right-Hand Rear.

8. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work with clean water.

Fill fluid reservoir.

F

ill reservoir to the 'MAX' mark.

F

it filler cap.

9.

Start e

ngine.

10. Check for correct brake-pedal travel and pressure.

11. Apply brake pedal and check around vehicle for brake fluid

leaks.

12. Make sure brake fluid level is at the 'MAX' mark.

Page 324 of 2490

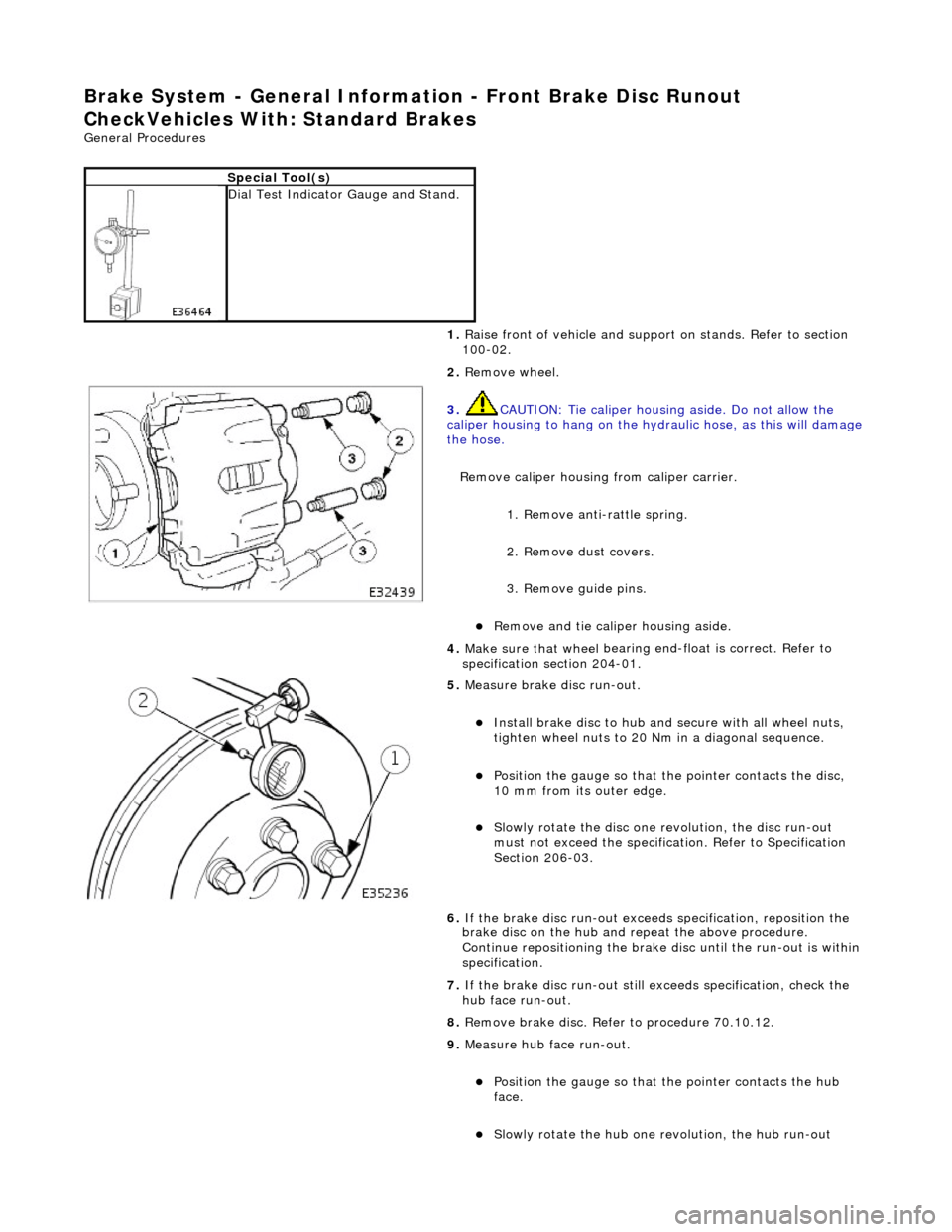

Brake System - Gener

al Information - Front Brake Disc Runout

CheckVehicles With: Standard Brakes

Gen e

ral Procedures

S

p

ecial Tool(s)

Dial Test Indicator

G

auge and Stand.

1. Raise front of vehicle and support on stands. Refer to section

100-02.

2. Remove wheel.

3. CAUT

ION: Tie caliper housing aside. Do not allow the

caliper housing to hang on the hydraulic hose, as this will damage

the hose.

Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

Remove an

d tie caliper housing aside.

4.

Make sure that wheel

bearing en

d-float is correct. Refer to

specification section 204-01.

5. Measure brake d

isc run-out.

Inst

al

l brake disc to hub and secure with all wheel nuts,

tighten wheel nuts to 20 Nm in a diagonal sequence.

Posi

tion the gauge so that the pointer contacts the disc,

10 mm from its outer edge.

Slo w

ly rotate the disc one revolution, the disc run-out

must not exceed the specification. Refer to Specification

Section 206-03.

6. If the brake disc run-out exceeds specification, reposition the

brake disc on the hub and re peat the above procedure.

Continue repositioning the brake di sc until the run-out is within

specification.

7. If the brake disc run-out still exceeds specification, check the

hub face run-out.

8. Remove brake disc. Refer to procedure 70.10.12.

9. Measure hub face run-out.

Posi

tion the gauge so that the pointer contacts the hub

face.

Slo w

ly rotate the hub one revolution, the hub run-out

Page 326 of 2490

Fr

ont Brake Disc Runout Check Vehicles With: Brembo Brakes

Special Service tools

Di

al Test Indicator Gauge and Stand.

1.

WA

RNING:

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

CA

UTION:

Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts

throughout the vehicle. These devices restrict the number of times a nut or bolt can be used. See

section <<100-00>> for information.

CA

UTION:

The Brembo caliper is aligned to the brake disc when it is first installed to the vehicle, therefore,

care must be taken not to disturb this alignment. When removing the caliper; remove the bolts

that secure the anchor bracket to the vertical link only. DO NOT loosen any other caliper bolts.

Raise front of vehicle and support on stands. Refer to section <<100-02>>.

2. Remove wheel. Refer to section <<74.20.05>>.

Page 331 of 2490

R

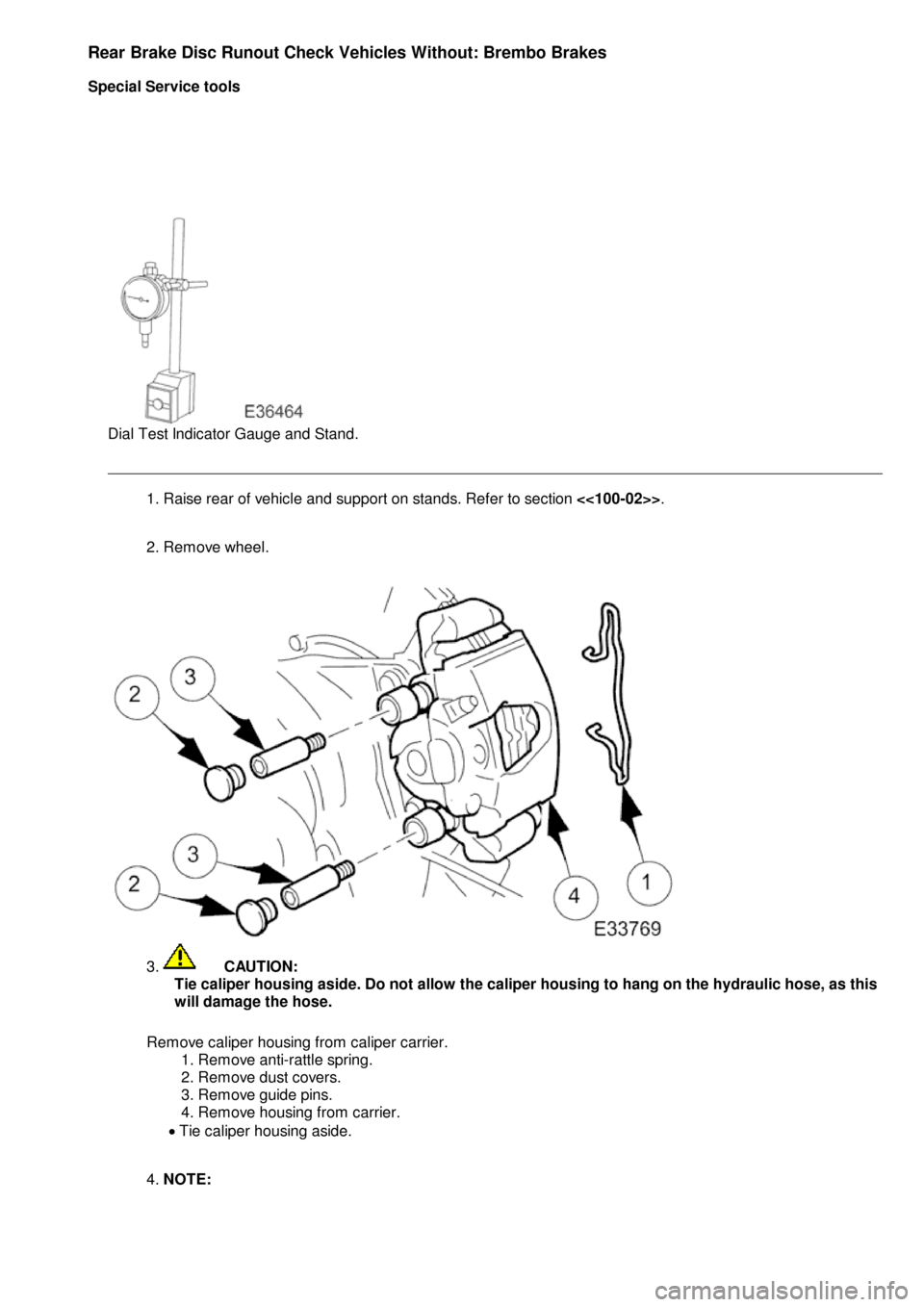

ear Brake Disc Runout Check Vehicles Without: Brembo Brakes

Special Service tools

D

ial Test Indicator Gauge and Stand.

1

. Raise rear of vehicle and support on stands. Refer to section

<<100-02>>.

2. Remove wheel.

3

.

C

AUTION:

Tie caliper housing aside. Do not allow the caliper housing to hang on the hydraulic hose, as this

will damage the hose.

Remove caliper housing from caliper carrier. 1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

4. Remove housing from carrier.

Tie caliper housing aside.

4. NOTE:

Page 334 of 2490

Rear

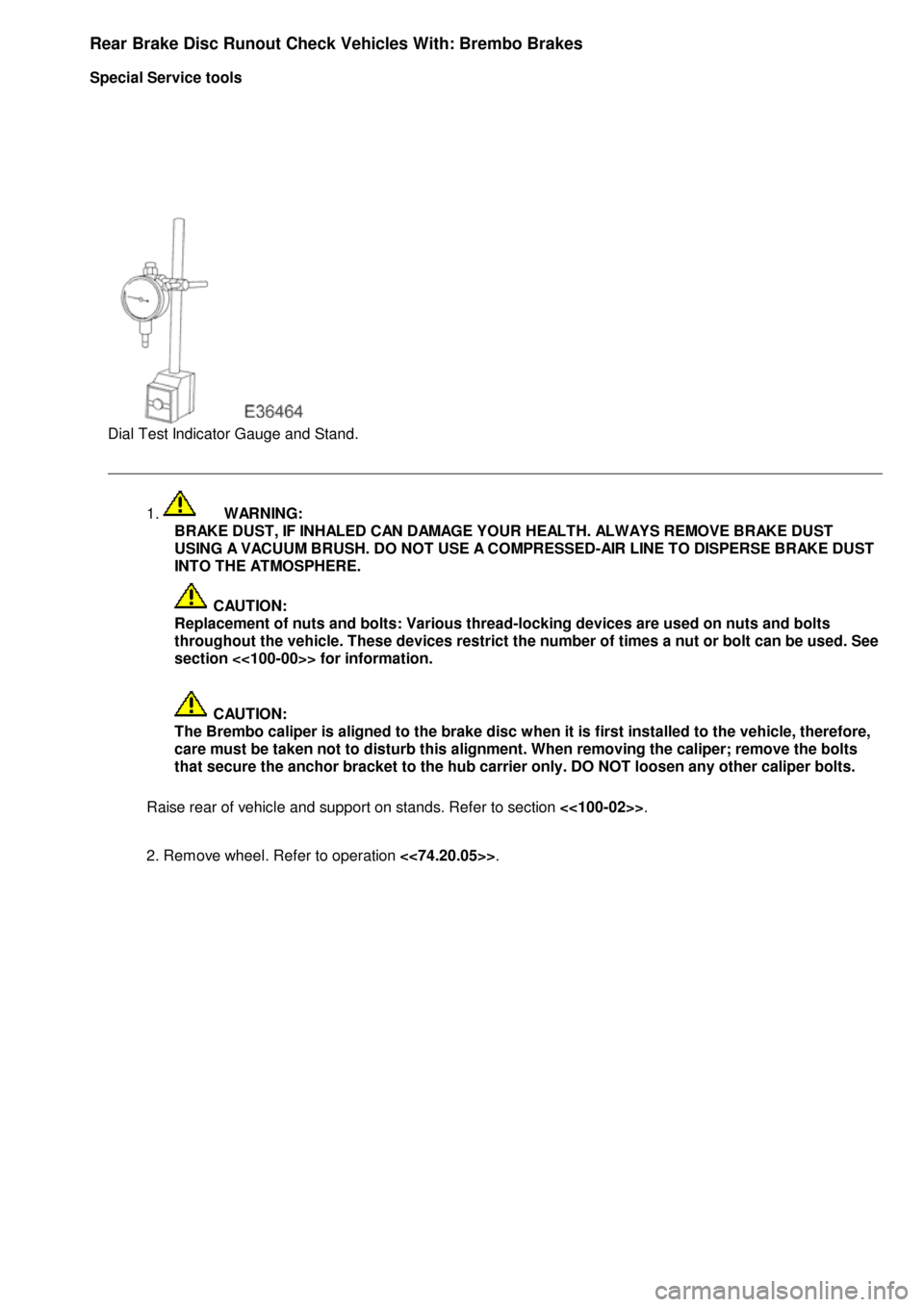

Brake Disc Runout Check Vehicles With: Brembo Brakes

Special Service tools

Di

al Test Indicator Gauge and Stand.

1.

WA

RNING:

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

CA

UTION:

Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts

throughout the vehicle. These devices restrict the number of times a nut or bolt can be used. See

section <<100-00>> for information.

CA

UTION:

The Brembo caliper is aligned to the brake disc when it is first installed to the vehicle, therefore,

care must be taken not to disturb this alignment. When removing the caliper; remove the bolts

that secure the anchor bracket to the hub carrier only. DO NOT loosen any other caliper bolts.

Raise rear of vehicle and support on stands. Refer to section <<100-02>>.

2. Remove wheel. Refer to operation <<74.20.05>>.