front axle JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 343 of 2490

Front Disc Brake - Brake CaliperVehicles

With: Standard Brakes

Re

moval and Installation

Remov

al

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

A new brake hose must be installe d when replacing a brake caliper.

The brake pad adhesive backing must not be reused, therefore always install new brake pads, irrespective of the

condition of the original pads when replacing a brake caliper. Always replace brake pads as an axle set.

S

pecial Tool(s)

Brake Pedal

Hold Tool

JDS 9013

1. O

pen engine compartment and fit

paint work protection covers

to fenders.

2. Raise vehicle on a four-post lift.

3. Raise front of vehicle and support on stands. Refer to Section

100-02.

4. Remove front wheels. See Section 204-04.

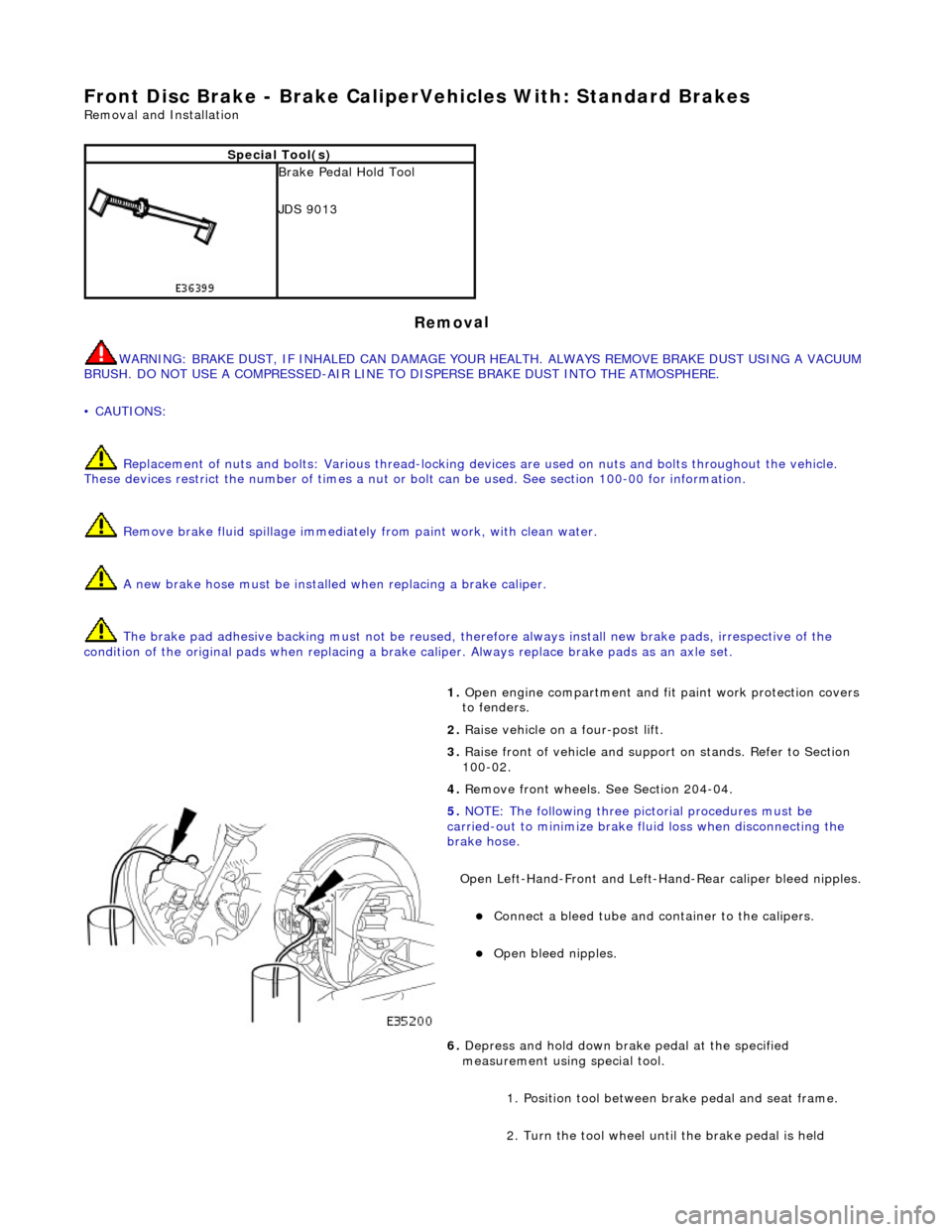

5. NOTE

: The following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect

a bleed tube and co

ntainer to the calipers.

O

pen bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

Page 361 of 2490

Front Dis

c Brake - Brake PadsVehicl

es With: High Performance Brakes

Re

moval and Installation

Remov

al

1.

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Brake pads must always be replaced in axle sets.

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

For additional information, refer to: General Service Information

(10

0-00 General Information,

Description and Operation).

The High Performance brake ca liper is aligned to the brake

disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the

caliper; remove the bolts that se cure the anchor bracket to the

vertical link only. DO NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise front of vehicle an

d support on stands.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

3. Remove front wheels. Refer to operation.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

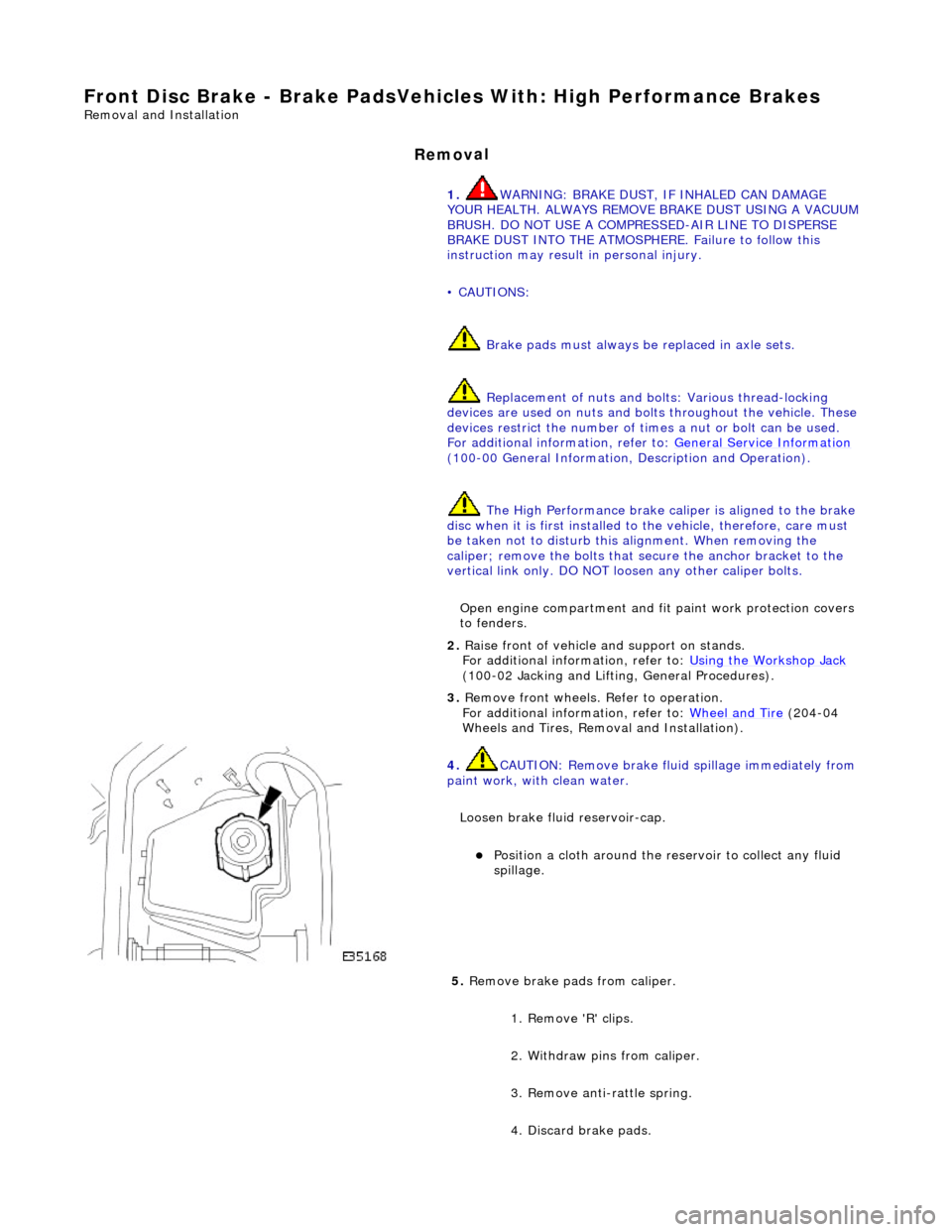

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

Position a cloth around the

reservoir to collect any fluid

spillage.

5. Remove brake

pads from caliper.

1. Remove 'R' clips.

2. Withdraw pins from caliper.

3. Remove anti-rattle spring.

4. Discard brake pads.

Page 368 of 2490

Rear Disc Brake - Brake CaliperVehicles W

ith: Standard Brakes

Re

mo

val and Installation

Remov

a

l

WA

RNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

The brake pad adhesive backing must not be reused, therefore always install new brake pads, irrespective of the

condition of the original pads when replacing a brake caliper. Always replace brake pads as an axle set.

Sp

ecial Tool(s)

Brake Pedal

H

old Tool

JDS 9013

1. Op

en luggage compartment lid and fit suitable paintwork

protection equipment.

2. Raise vehicle on a four-post lift.

3. Raise rear of vehicl e and support on stan ds. See Section 100-

02.

4. Remove rear wheel. See Section 204-04.

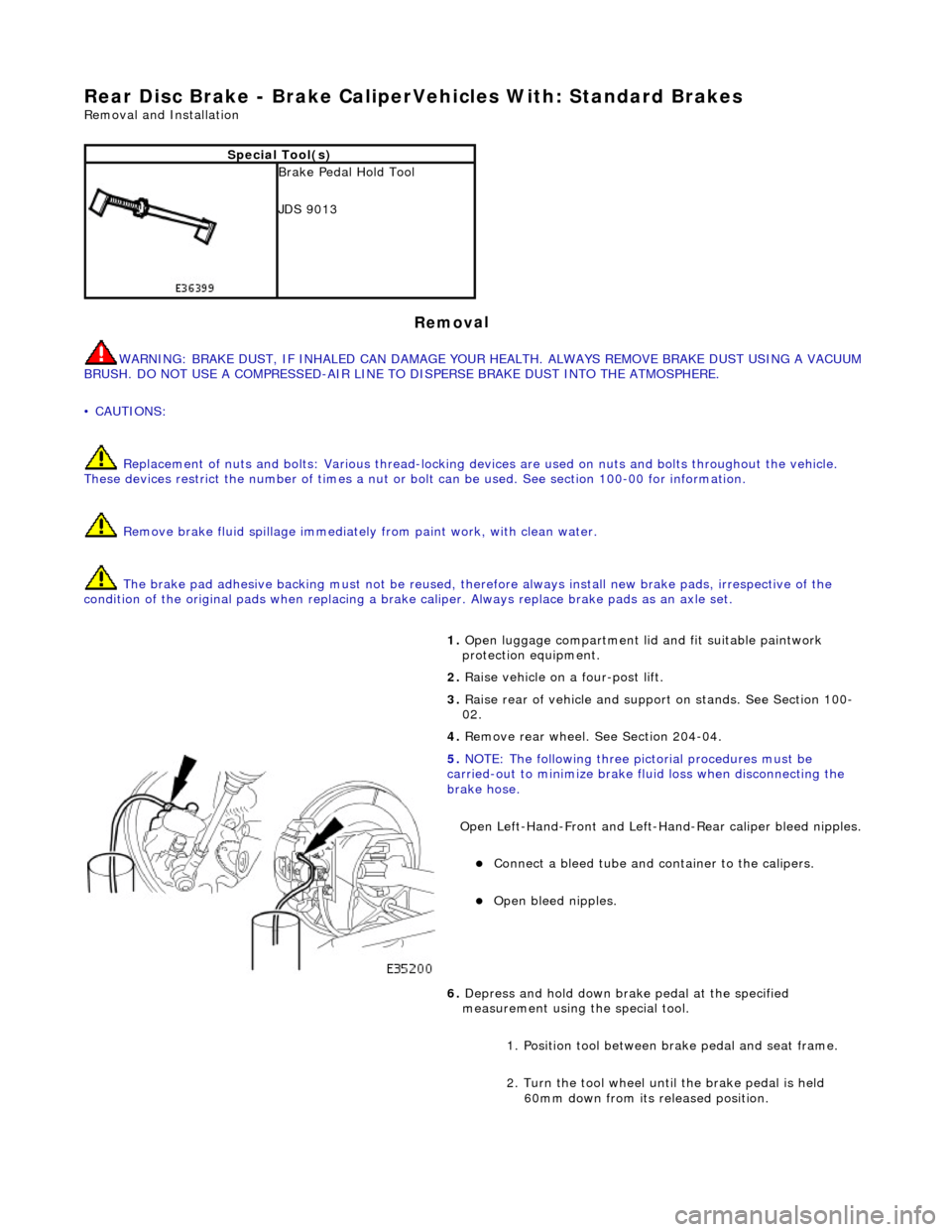

5. NOTE

: Th

e following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect a

bleed tube and co

ntainer to the calipers.

Op

en bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using the special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

60mm down from its released position.

Page 1345 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Extension Housing O-Ring Seal

In-vehicle Repair

Removal

1. Select N position.

2. Raise the vehicle for access.

3. Remove the front muffler, 30.10.18.

4. Locate a transmission jack, Epco V-100 or similar, under the

transmission unit.

Adjust the angle of the jack to suit the transmission.

Secure the side clamps.

Pass the safety chain over the transmission unit and

secure.

Take the weight of the transmission and engine.

5. Remove the engine rear mounting bracket.

1. Remove the engine rear mounting to bracket bolt.

2. Remove the mounting bracket to body bolts.

6. Gently lower the transmission jack.

7. CAUTION: Under no circumstan ces remove the driveshaft

to flexible coupling fixings.

Detach the driveshaft fro m the transmission unit.

Mark the position of the coupling to drive flange.

Remove the three bolts which secure the transmission

drive flange to the flexible coupling .

8. Remove the rear extension housing assembly.

1. Remove the ten bolts, noting their location for installation.

2. Remove and discard the O-ring.

Page 1381 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Input Shaft Seal

Disassembly and Assembly of Subassemblies

Special Tool(s)

Oil seal replacer

307-357

1. Remove the transmission unit, 44.20.01.

2. Remove the torque converter from the transmission unit,

44.17.07.

3. Remove the front pump seal.

Remove and discard the seal retaining snap-ring.

Using a 'Snap-on' oil seal puller, remove and discard the

seal.

4. Clean the seal housing.

5. Installation is th e reverse of the re moval procedure.

6. Use tool 307 - 357 to install the seal.

Lubricate the seal pr ior to fitting.

Page 1382 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Torque Converter

Disassembly and Assembly of Subassemblies

Special Tool(s)

Lifting handle

307-139

1. Remove the transmission unit from the vehicle; 44.20.01.

2. Remove the torque converter from the transmission unit.

Install lifting handles 307 - 139.

3. Remove lifting handles 307 - 139 from the torque converter.

4. Clean the torque conver ter and mating faces.

5. CAUTIONS:

Use extreme care NOT to damage the oil seal with the

converter spigot.

Ensure that the conver ter is fully located.

Install the torque converter.

1. Install lifting handles 307 - 139.

2. Lubricate the front pump seal.

To facilitate location, rotate the converter as it is being

fitted and note the engagement of splines and oil pump

drive.

6. Check that the three conver ter fixing boss faces are

approximately 8,0 mm proud of the transmission mounting

face.

7. Remove lifting handles 307 - 139 from the torque converter.

8. Install the transmission unit; refer to Operation 44.20.01,

noting especially the alignment instructions.

Page 1433 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Extension

Housing Seal

In-vehicle Repair

Removal

Special Tool(s)

Oil seal replacer

307-378

Driveshaft wrench

205-053

1. Disconnect the battery ground lead.

2. Select N and choc the road wheels.

3. Remove the front muffler, re fer to Operation 30.10.18.

4. Remove the engine rear mounting bracket.

1. Support the transmission.

2. Remove the bolt, engine rear mounting to transmission.

3. Remove the four bolts which secure the mounting

cross member to the body.

5. Detach the driveshaft from th e transmission drive flange.

1. If the transmission is to be refitted, mark the position of the coupling relative to the drive flange.

5. CAUTION: Under no circ umstances remove the

driveshaft to flexible coupling fixings.

2. Remove the three bolts, tr ansmission drive flange to

flexible coupling.

6. Secure the driveshaft wrench 205 - 053 to the output shaft

flange.

Page 1456 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Input Shaft Seal

Disassembly and Assembly of Subassemblies

Special Tool(s)

Oil seal replacer

307-378

1. Disconnect the battery ground lead.

2. Remove the air intake / MAFM assembly, refer to Operation

19.10.30.

3. Raise the vehicle for access.

4. Remove the front muffler, 30.10.18

5. Remove the RH and LH catalytic converters, refer to Operation

17.50.09 and 17.50.10.

6. Drain the transmission fluid, refer to Operation 44.24.02.

7. Remove the transmission unit, refer to Operation 44.20.01.

8. Remove the torque converter fro m the transmission unit, refer

to Operation 44.17.07.

9. Remove the front oil seal.

Using a proprietary tool remove the seal, taking care not

to damage the shaft or bore diameters.

10. Installation is the reverse of the removal procedure noting

that:

11. Fit the oil seal.

1. Lubricate the housing seal bore.

2. Lubricate the outside diameter of the seal.

3. Using seal replacer 307 - 379, drive the seal squarely into place.

Page 1457 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Torque Converter

Disassembly and Assembly of Subassemblies

CAUTION: If the transmission is to be renewed, renew the to rque converter also.

Special Tool(s)

Torque converter lifting handles

307-139

1. Remove the transmission unit from the vehicle; refer to

Operation 44.20.01.

2. Remove the torque converter from the transmission unit.

Fit lifting handles 307 - 139 ( JD-105).

3. Remove lifting handles 307 - 139 (JD-105) from the torque

converter.

4. Clean the torque conver ter and mating faces.

5. CAUTIONS:

Use extreme care NOT to damage the oil seal with the

converter spigot.

Ensure that the conver ter is fully located.

Fit the torque converter.

1. Fit lifting handles 307 - 139 (JD-105).

2. Lubricate the front pump seal.

To facilitate location, rotate the converter as it is being

fitted and feel for the engage ment of the splines and of

the oil pump drive.

6. Check that the converter fixing boss faces are approximately

8,0 mm proud of the transm ission mounting face.

7. Remove the lifting handles from the torque converter.

8. Install the transmission unit; refer to Operation 44.20.01.

Page 1487 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L NA V8 -

AJ27/3.2L NA V8 - AJ 26 - Selector Lever Cable and Bracket

Removal and Installation

Removal

1. Position the selector to N.

2. Remove the J-gate surround, Section 501-05.

3. Remove the console finisher ve neer panel, Section 501-12.

4. Remove the center console assembly, Section 501-12.

5. Raise the vehicle for access.

6. Detach the selector cable from the transmission unit.

1. Remove the cable inner to selector lever nut.

2. Remove the cable to transmission casing fixings.

7. Reposition the selector cable.

8. Remove the LH front seat, Section 501-10.

9. Reposition the LH floo r carpet for access.

10. Remove the selector cable to tunnel clip tie strap.

11. Detach the selector cable from the gear shift assembly.

1. Remove the inner cable to shift lever nut.

2. Slacken the outer cable locknuts.