brake fluid JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 6 of 2490

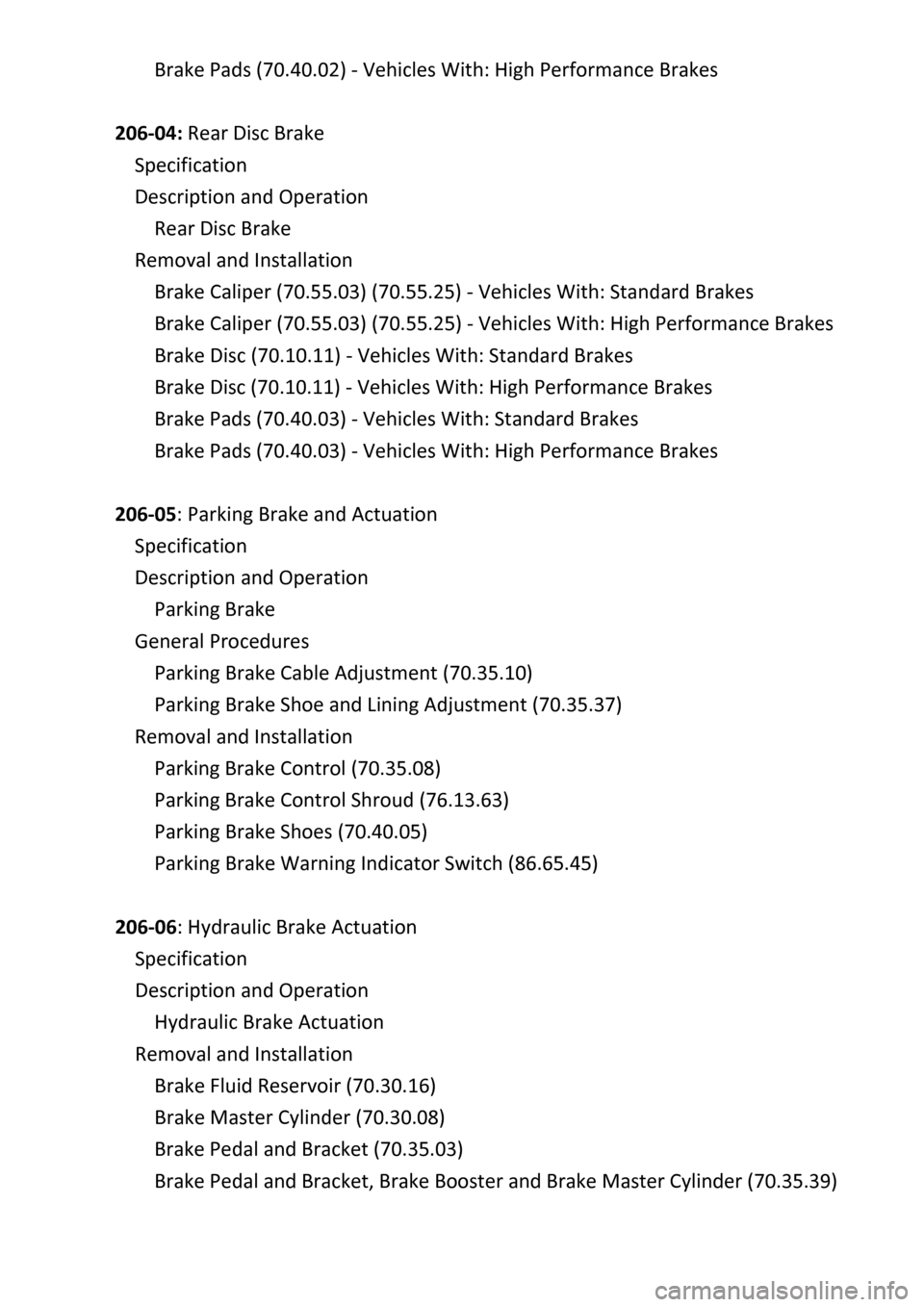

Brake Pads (70.40.02) ‐ Vehicles With:

High Performance Brakes

206‐04: Rear Disc Brake

Specification

Description and Operation

Rear Disc Brake

Removal and Installation

Brake Caliper (70.55.03) (70.55.25) ‐ Vehicles With: Standard Brakes

Brake Caliper (70.55.03) (70.55.25) ‐ Vehicles With: High Performance Brakes

Brake Disc (70.10.11) ‐ Vehicles With: Standard Brakes

Brake Dis

c (70.10.11) ‐ Vehicles With: High Performance Brakes

Brake Pads (70.40.03) ‐ Vehicles With: Standard Brakes

Brake Pads (70.40.03) ‐ Vehicles With: High Performance Brakes

206‐05: Parking Brake and Actuation

Specification

Description and Operation

Parking Brake

General Procedures

Parking Brake Cable Adjustment (70.35.10)

Parking Brake Shoe and Li

ning Adjustment (70.35.37)

Removal and Installation

Parking Brake Control (70.35.08)

Parking Brake Control Shroud (76.13.63)

Parking Brake Shoes (70.40.05)

Parking Brake Warning Indicator Switch (86.65.45)

206‐06: Hydraulic Brake Actuation

Specification

Description and Operation

Hydraulic Brake Actuation

Removal and Installation

Brake Fluid Reservoir (70.30.16)

Brake Master Cylinder (70.30.

08)

Brake Pedal and Bracket (70.35.03)

Brake Pedal and Bracket, Brake Booster and Brake Master Cylinder (70.35.39)

Page 38 of 2490

Torque Specifications

Torque sp

ecifications are shown in maintenance procedure illustra

tions and also in the torque specifications chart located at

the front of the relevant section.

Disconnecting/Connecting the Battery

Ow ing t

o the electronic components used on the vehicle, it is important that the battery is disconnected when specified in a

maintenance procedure.

When the battery is connected, the specified procedure must be followed, to ensure the correct operation of all vehicle

systems; refer to Section 414-01.

Use of Control Modules

Control modu les may

only be used on the ve

hicle to which they were originally fitted. Do not attempt to use or test a control

module on any other vehicle.

Function

al Test

On

completion of a maintenance procedure, a thorough test should be carried out, to ensu

re that the relevant vehicle

systems are working correctly.

Protecting the Vehicle

Al ways

fit covers to protect

the fenders before commencing work in the engi ne compartment. Cover the seats and carpets,

wear clean overalls and wash hands or wear gloves before working inside the vehicle. Avoid spilling hydraulic fluid,

antifreeze or battery acid on the paintwork. In the event of spillage, wash off with water imme diately. Use polythene sheets

in the trunk to protect carpets. Always use the recommended service tool, or a satisfactory equivalent, where specified.

Protect temporarily exposed screw thread s by replacing nuts or fitting caps.

Preparation

Before disassembly, clean the surrounding ar ea

as thoroughly as possible. When co

mponents have been removed, blank off

any exposed openings using grease-proof paper and masking tape. Immediately seal fuel, oil and hydraulic lines when

separated, using plastic caps or plugs, to prevent loss of fluid and the entry of dirt. Close the open ends of oilways, exposed

by component removal, with tapered hardw ood plugs or readily visible plastic plugs. Immediately a component is removed,

place it in a suitable container; use a se parate container for each component and its associated pa rts. Before dismantling a

component, clean it thoroughly with a recommended cleaning agent; check that the agent will not damage any of the

materials within the component. Clean the bench and obtain ma rking materials, labels, containers and locking wire before

dismantling a component.

Dismantling

O b

serve scrupulous cleanliness when dismantling components,

particularly when parts of the brake, fuel or hydraulic

systems are being worked on. A particle of dirt or a fragment of cloth could caus e a dangerous malfunction if trapped in

these systems. Clean all tapped holes, crev ices, oilways and fluid passages with compressed air. Do not permit compressed

air to enter an open wound. Always use ey e protection when using compressed air.

Ensure that any O-rings used for sealing are correctly refitted or renewed if disturbed. Mark mating parts to ensure that

they are replaced as dismantled. Whenever possible use markin g materials which avoid the possibilities of causing distortion

or the initiation of cracks, which could occur if a center pu nch or scriber were used. Wire together mating parts where

necessary to prevent accidental interchange (e.g roller bearing components). Tie labels on to all parts to be renewed and to

parts requiring further inspection before being passed fo r reassembly. Place labelled parts and other parts for rebuild in

separate containers. Do not disc ard a part which is due for renewal until it ha s been compared with the new part, to ensure

that the correct part has been obtained.

Page 42 of 2490

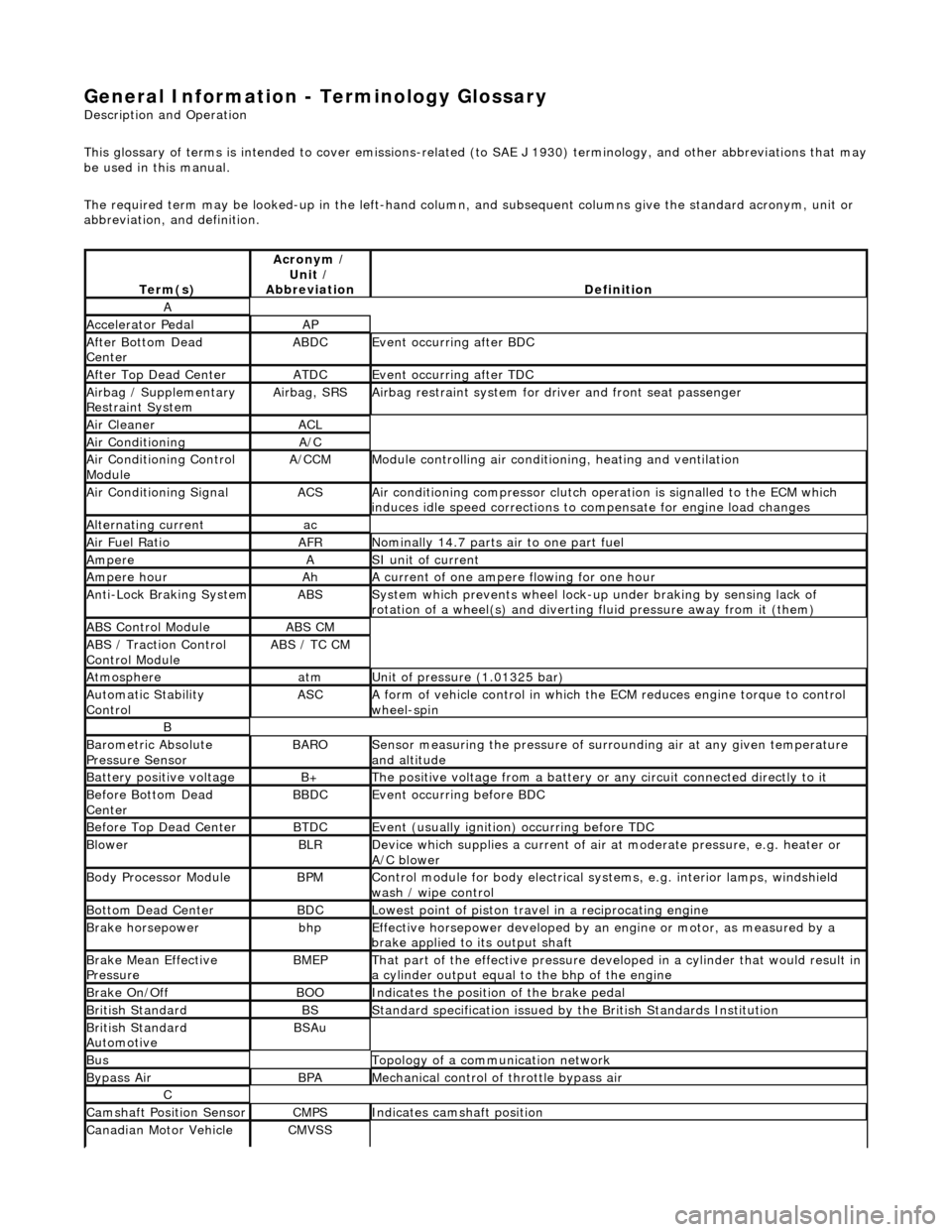

General Information - Terminology Glossary

Description an

d Operation

This glossary of terms is intended to cover emissions-related (to SAE J 1930) term inology, and other abbreviations that may

be used in this manual.

The required term may be looked-up in th e left-hand column, and subsequent columns give the standard acronym, unit or

abbreviation, and definition.

Te rm

(s)

Acr

ony

m /

Unit /

Abbreviation

De fi

nition

A

Accel

e

rator Pedal

AP

Af

ter Botto

m Dead

Center

ABDCEvent occurri ng after

BDC

Af

ter Top Dead CenterATDCEvent occurri ng after

TDC

Ai

rbag /

Supplementary

Restraint System

Airbag, SRSAi rbag restraint system for

dr

iver and front seat passenger

Air Cleane rACL

Air ConditioningA/C

Air Conditioning Con t

rol

Module

A/CCMModule c

ontrolling air conditioning, heating and ventilation

Air Conditioning SignalACSA

i

r conditioning compressor clutch operation is signalled to the ECM which

induces idle speed corrections to co mpensate for engine load changes

Alternating cu

rrent

ac

Ai

r Fuel R

atio

AFRN

omi

nally 14.7 parts air to one part fuel

Ampe

reASI unit of current

Ampere hourAhA current of one ampere

fl

owing for one hour

Anti-Lock Braking SystemABSS

y

stem which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and divertin g fluid pressure away from it (them)

ABS Control Mo

dule

ABS CM

ABS /

T

raction Control

Control Module

ABS / T

C CM

Atmosph

e

re

atmU

n

it of pressure (1.01325 bar)

Au

to

matic Stability

Control

ASCA form of vehicle

control

in which the ECM reduces en gine torque to control

wheel-spin

B

Baro me

tric Absolute

Pressure Sensor

BAR OSensor measuring the pressure of surr ou

nding air at any given temperature

and altitude

Bat t

ery positive voltage

B+The posi

ti

ve voltage from a battery or

any circuit connected directly to it

Before Bottom Dead

CenterBBDCEvent occurri ng before BD

C

Before Top Dead

Center

BTD

CEvent (usual ly

ignition) occurring before TDC

Blowe

rBLRDe

vice which supplies a current of air at

moderate pressure, e.g. heater or

A/C blower

Body Processor M

odule

BPMControl modu

le

for body electrical systems, e.g. interior lamps, windshield

wash / wipe control

Bott om D

ead Center

BD

CLowest poin t of piston

travel in a reciprocating engine

Brake hors

epowe

r

bhpEffecti

ve horsepower devel

oped by an

engine or motor, as measured by a

brake applied to its output shaft

Brake Mean Effective

Pres sureBME PThat p

art of the effective

pressure developed in a cyli nder that would result in

a cylinder output equal to the bhp of the engine

Brake On/ O

ff

BOOIn

dic

ates the position of the brake pedal

Br

it

ish Standard

BSStan

dar

d specification issued by the British Standards Institution

Br

it

ish Standard

Automotive

BSAu

BusTopology of a commu n

ication network

Bypass

AirBPAMechanica l

control of throttle bypass air

C

Camshaft Posit

i

on Sensor

CMPSIndi

cat

es camshaft position

Canadian Motor

V

ehicle

CMVSS

Page 67 of 2490

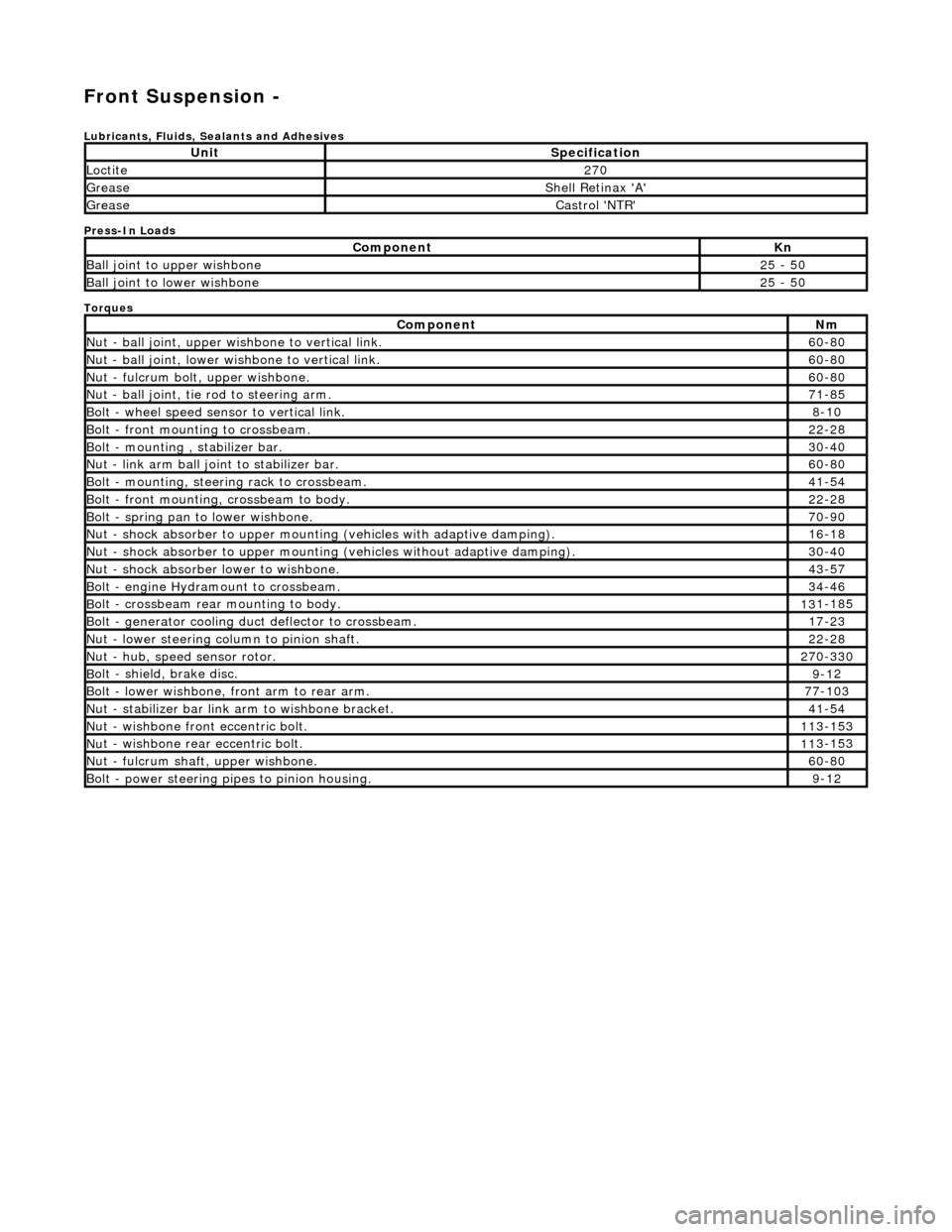

Front Suspension -

Lubri

cants, Fluids, Sealants and Adhesives

Press-In Loads

Torques

UnitS

pecification

Loctite27

0

Greas

e

Shell Retin

ax 'A'

Greas

e

Castro

l 'NTR'

Com

ponent

Kn

Ball join

t to upper wishbone

25

- 50

B

all joint to lower wishbone

25

- 50

Com

ponent

Nm

N

ut - ball joint, upper wishbone to vertical link.

60

-80

N

ut - ball joint, lower wishbone to vertical link.

60

-80

Nu

t - fulcrum bolt, upper wishbone.

60

-80

N

ut - ball joint, tie rod to steering arm.

71

-85

Bol

t - wheel speed sensor to vertical link.

8-1

0

Bol

t - front mounting to crossbeam.

22

-28

Bolt

- mounting , stabilizer bar.

30

-40

N

ut - link arm ball joint to stabilizer bar.

60

-80

Bolt

- mounting, steering rack to crossbeam.

41

-54

B

olt - front mounting, crossbeam to body.

22

-28

Bol

t - spring pan to lower wishbone.

70

-90

N

ut - shock absorber to upper mounting

(vehicles with adaptive damping).

16

-18

Nu

t - shock absorber to upper mounting (vehicles without adaptive damping).

30

-40

N

ut - shock absorber lower to wishbone.

43

-57

B

olt - engine Hydramount to crossbeam.

34

-46

B

olt - crossbeam rear mounting to body.

13

1-185

Bol

t - generator cooling du

ct deflector to crossbeam.

17

-23

N

ut - lower steering column to pinion shaft.

22

-28

N

ut - hub, speed sensor rotor.

27

0-330

B

olt - shield, brake disc.

9-1

2

Bol

t - lower wishbone, front arm to rear arm.

77

-103

Nu

t - stabilizer bar link arm to wishbone bracket.

41

-54

N

ut - wishbone front

eccentric bolt.

11

3-153

Nu

t - wishbone rear

eccentric bolt.

11

3-153

N

ut - fulcrum shaft, upper wishbone.

60

-80

Bolt -

power steering pi

pes to pinion housing.

9-1

2

Page 307 of 2490

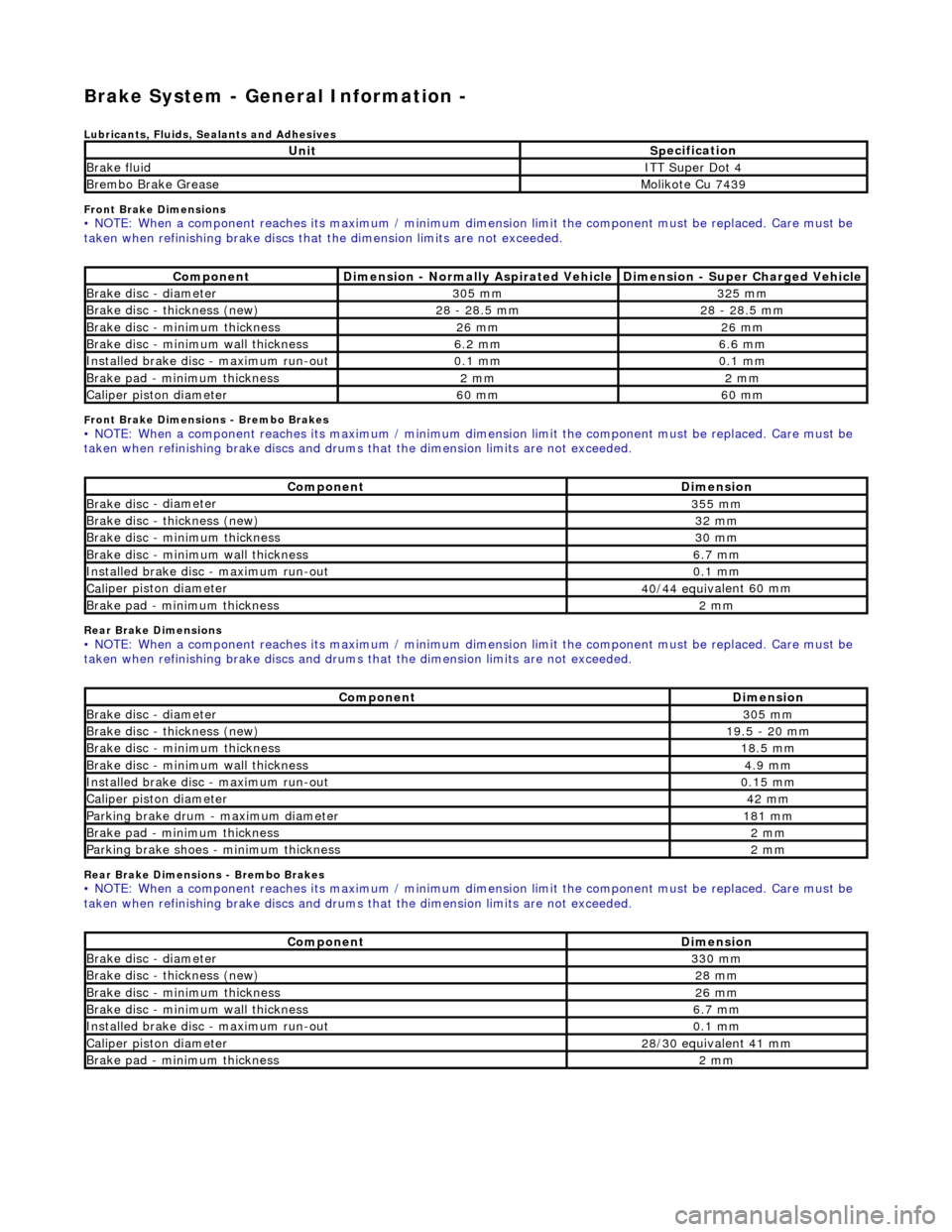

Brake S

ystem - General Information -

Lu

bricants, Fluids, Sealants and Adhesives

Front Brake Dimensions

• NO

TE: When a component reaches its maximum / minimum dimension limit the component must be replaced. Care must be

taken when refinishing brake discs that the dimension limits are not exceeded.

F

ront Brake Dimensions - Brembo Brakes

• NO

TE: When a component reaches its maximum / minimum dimension limit the component must be replaced. Care must be

taken when refinishing brake discs and drums that the dimension limits are not exceeded.

R

ear Brake Dimensions

• NO

TE: When a component reaches its maximum / minimum dimension limit the component must be replaced. Care must be

taken when refinishing brake discs and drums that the dimension limits are not exceeded.

R

ear Brake Dimensions - Brembo Brakes

• NO

TE: When a component reaches its maximum / minimum dimension limit the component must be replaced. Care must be

taken when refinishing brake discs and drums that the dimension limits are not exceeded.

UnitSp

ecification

Bra

ke fluid

IT

T Super Dot 4

Brembo Br

ake Grease

M

olikote Cu 7439

Co

mponent

Dimension - Normall

y Aspirated Vehicle

Dimension

- Super Charged Vehicle

Brake disc

- diameter

305 mm325 mm

Brake disc

- thickness (new)

28

- 28.5 mm

28 -

28.5 mm

B

rake disc - minimum thickness

26 mm26 mm

B

rake disc - minimum wall thickness

6.2 mm6.6 mm

I

nstalled brake disc - maximum run-out

0.1 mm0.1 mm

B

rake pad - minimum thickness

2 mm2 mm

Cal

iper piston diameter

60 mm60 mm

Co

mponent

Dimension

Brake disc

- diameter

355 mm

Brake disc

- thickness (new)

32 mm

B

rake disc - minimum thickness

30 mm

B

rake disc - minimum wall thickness

6.7 mm

I

nstalled brake disc - maximum run-out

0.1 mm

Cal

iper piston diameter

40/44 equiv

alent 60 mm

B

rake pad - minimum thickness

2 mm

Co

mponent

Dimension

Brake disc

- diameter

305 mm

Brake disc

- thickness (new)

19.5

- 20 mm

B

rake disc - minimum thickness

18.5 mm

B

rake disc - minimum wall thickness

4.9 mm

I

nstalled brake disc - maximum run-out

0.15 mm

Cal

iper piston diameter

42 mm

Pa

rking brake drum - maximum diameter

181 mm

B

rake pad - minimum thickness

2 mm

Pa

rking brake shoes - minimum thickness

2 mm

Co

mponent

Dimension

Brake disc

- diameter

330 mm

Brake disc

- thickness (new)

28 mm

B

rake disc - minimum thickness

26 mm

B

rake disc - minimum wall thickness

6.7 mm

I

nstalled brake disc - maximum run-out

0.1 mm

Cal

iper piston diameter

28/30 equiv

alent 41 mm

B

rake pad - minimum thickness

2 mm

Page 309 of 2490

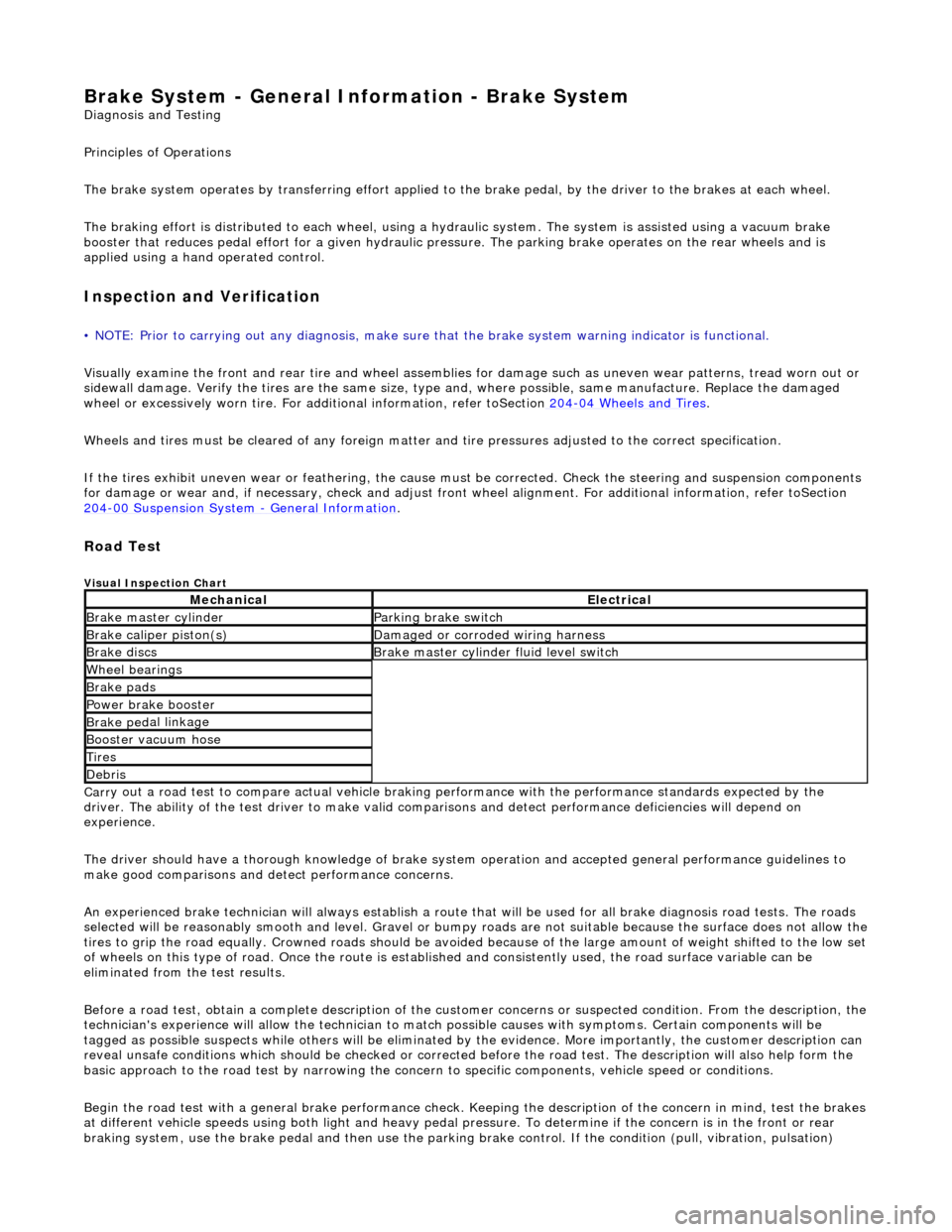

Brake System - General Inform

ation - Brake System

D

iagnosis and Testing

Principles of Operations

The brake system operates by transferring effort applied to th e brake pedal, by the driver to the brakes at each wheel.

The braking effort is distributed to each wheel, using a hydraulic system. The system is assisted using a vacuum brake

booster that reduces pedal effort for a given hydraulic pressure. The parking brake operates on the rear wheels and is

applied using a hand operated control.

I

nspection and Verification

•

NOTE: Prior to carrying out any diagno

sis, make sure that the brake system warning indicator is functional.

Visually examine the front and rear tire and wheel assemblies for damage such as un even wear patterns, tread worn out or

sidewall damage. Verify the tires are th e same size, type and, where possible, same manufacture. Replace the damaged

wheel or excessively worn tire. For a dditional information, refer toSection 204

-0

4 Wheels and Tires

.

W

heels and tires must be cleared of an

y foreign matter and tire pressures ad justed to the correct specification.

If the tires exhibit uneven wear or feathering, the cause must be corrected. Check the steering and suspension components

for damage or wear and, if ne cessary, check and adjust front wheel alignment. For additional information, refer toSection

204

-00 Suspen

sion System

- General Informati

on

.

Road Test

V

isual Inspection Chart

Carr

y out a road test to compare actual vehicle braking performance with the

performance standards expected by the

driver. The ability of the test driver to make valid compar isons and detect performance deficiencies will depend on

experience.

The driver should have a thorough knowledge of brake system operation and accepted general performance guidelines to

make good comparisons and de tect performance concerns.

An experienced brake technician will always establish a route that will be used for all br ake diagnosis road tests. The roads

selected will be reasonably smooth and level. Gravel or bump y roads are not suitable because the surface does not allow the

tires to grip the road equally. Crowned roads should be avoide d because of the large amount of weight shifted to the low set

of wheels on this type of road. Once th e route is established and consistently used, the road surface variable can be

eliminated from the test results.

Before a road test, obtain a complete description of the customer concerns or suspec ted condition. From the description, the

technician's experience will allow the te chnician to match possible causes with symptoms. Certain components will be

tagged as possible suspects while others wi ll be eliminated by the evidence. More importantly, the customer description can

reveal unsafe conditions which should be ch ecked or corrected before the road test. The description will also help form the

basic approach to the road test by narrowing the concern to specific components, vehicle speed or conditions.

Begin the road test with a general brake performance check. Keeping the description of the concern in mind, test the brakes

at different vehicle speeds using both ligh t and heavy pedal pressure. To determine if the concern is in the front or rear

braking system, use the brake pe dal and then use the parking brake control. If the condition (pull, vibration, pulsation)

MechanicalElectrical

Brake m

aster cylinder

Parkin

g brake switch

Brake ca

liper piston(s)

D

amaged or corroded wiring harness

Brake di

scs

B

rake master cylinder fluid level switch

Wh

eel bearin

gs

Brake pads

Power brake booster

Brake ped

al linkage

Boost

er vacuum hose

Tire

s

De

bris

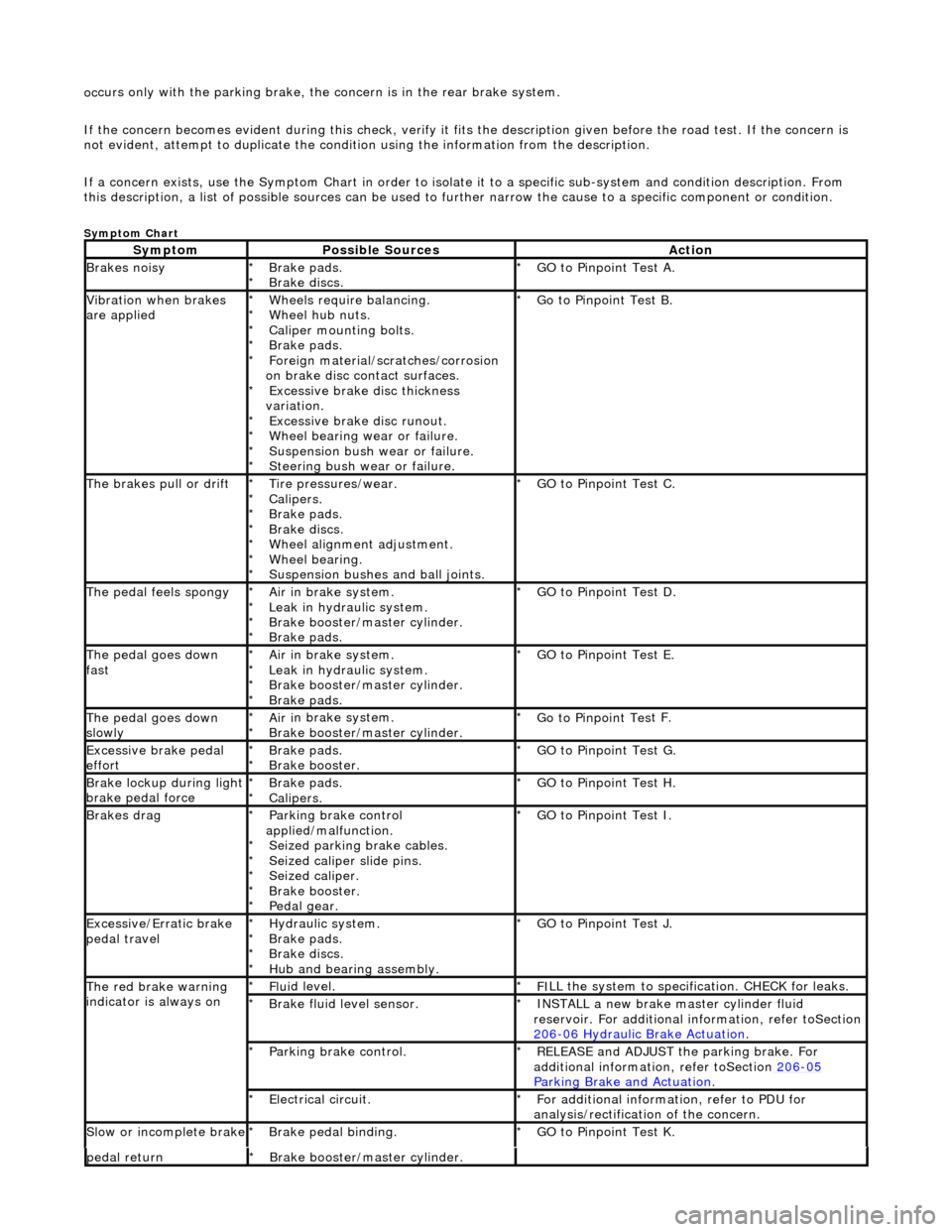

Page 310 of 2490

oc

curs only with the parking brake, th

e concern is in the rear brake system.

If the concern becomes evident during this check, verify it fits the description given before the road test. If the concern is

not evident, attempt to duplicate the condition using the information from the description.

If a concern exists, use the Symptom Chart in order to isolate it to a specific sub-system and condition description. From

this description, a list of possible sources can be used to further narrow the cause to a specific component or condition.

Sym

ptom Chart

Sy

m

ptom

Possib

l

e Sources

Acti

o

n

Brakes

n

oisy

Brake pads.

Brake di

scs

.

*

*

GO to Pinpoint

Tes

t A.

*

Vibration wh

en brakes

are applied

Wh eels require bala

ncing.

Wheel hub nuts.

Caliper mounting bolts.

Brake pads.

Foreign material/scr atches/corrosion

on brake disc contact surfaces. Excessive brake disc thickness

variation. Excessive brake disc runout.

Wheel bearing wear or failure.

Suspension bush wear or failure.

Steering bush wear or failure.

*

*

*

*

*

*

*

*

*

*

Go to Pinpoint

Tes

t B.

*

The brakes pull or drif tTire pressures/wear.

Calipers.

Brake pads.

Brake di

scs.

Wheel alignment adjustment.

Wheel bearing.

Suspension bushes and ball joints.

*

*

*

*

*

*

*

GO to Pinpoint

Tes

t C.

*

The pedal feels spongyAir i

n brake system.

Leak in hydraulic system.

Brake booster/master cylinder.

Brake pads.

*

*

*

*

GO to Pinpoint Tes

t D.

*

The pedal goes down

fa s

t

Ai

r i

n brake system.

Leak in hydraulic system.

Brake booster/master cylinder.

Brake pads.

*

*

*

*

GO to Pinpoint

Tes

t E.

*

The pedal goes down

slowl yAir i

n brake system.

Brake booster/master cylinder.

*

*

Go to Pinpoint

Tes

t F.

*

Excessive brake pedal

effor tBrake pads.

Brake booster.

*

*GO to Pinpoint

Tes

t G.

*

Brake lockup du ring ligh

t

brake pedal force

Brake pads.

Calipers.

*

*GO to Pinpoint

Tes

t H.

*

Brakes d r

ag

Parkin

g brake con

trol

applied/malfunction. Seized parking brake cables.

Seized caliper slide pins.

Seized caliper.

Brake booster.

Pedal gear.

*

*

*

*

*

*

GO to Pinpoint

Tes

t I.

*

Exce ssi

ve/Erratic brake

pedal travel

Hydrau li

c system.

Brake pads.

Brake discs.

Hub and bearing assembly.

*

*

*

*

GO to Pinpoint

Tes

t J.

*

The red brak e warning

indi

cator is always on

Fl

ui

d level.

*

F I

LL the system to specification. CHECK for leaks.

*

Brake flu i

d level sensor.

*

I N

STALL a new brake master cylinder fluid

reservoir. For additional in formation, refer toSection

206

-0 6

Hydraulic Brake Actuation

.

*

Parkin

g brake con

trol.

*

REL

E

ASE and ADJUST the parking brake. For

additional information, refer toSection 206

-05

Parkin g Brake an

d Actuation

.

*

E

l

ectrical circuit.

*

F or additional

information, refer to PDU for

analysis/rectification of the concern.

*

Sl

ow or i

ncomplete brake

Brake peda

l binding.

*

GO to Pinpoint Tes

t K.

*

pedal retu rnBr

ake booster/master cylinder.

*

Page 314 of 2490

D4: CHECK

BRAKE FLUID LEVEL

Check the brake master cyli

nd

er reservoir fluid level.

1

Is the fl

ui

d level OK?

Yes BLEED the brake system. For additional information, re fer to General Procedures in this section. TEST

the system for normal operation.

No CHECK brake master cylinder reservoir sealing points. For additional information, refer to Brake

Master Cylinder in this section. ADD fluid and BL EED the brake system. For additional information,

refer to General Procedures in this section. TEST the system for normal operation. REPEAT road test if

necessary.

P I

NPOINT TEST E : THE

PEDAL GOES DOWN FAST

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

E1

:

ROAD TEST VEHICLE

Road test and apply th

e brake peda

l.

1

Is th

e brake pedal ef

fort an

d brake pedal travel normal?

Yes Vehicle is OK.

No GO to E2

.

E2: CHECK BRAK

E FLUID LEVEL

Check the brake master cyli

nd

er reservoir fluid level.

1

Is

t

he fluid level within specification?

Yes GO to E3

.

No

CH

ECK the brake master cylinder reservoir sealing po

ints. For additional information, refer to Brake

Master Cylinder Component Test in this section. ADD fluid and BLEED brake system. For additional

information, refer to General Proc edures in this section. TEST the system for normal operation.

REPEAT road test if necessary.

E3 : CHECK BRAK

E PEDAL TRAVEL-PRESSURIZE SYSTEM

Pump th

e brake pedal rapidly (f

ive times).

1

Does th

e brake pedal trav

el build up and then hold?

Yes BLEED the brake system. For additional information, re fer to General Procedures in this section. TEST

the system for normal oper ation. REPEAT road test.

No GO to E4

.

E4: CHECK FOR

BRAKE SYSTEM LEAKS

Chec

k for e

xternal brake system leaks. For additional information, refer to Master Cylinder in this

section.

1

Are le aks foun

d?

Yes REPAIR as necessary, ADD fluid and BLEED brake syst em. For additional information, refer to General

Procedures in this section. TEST the system for normal operation. REPEAT road test.

No System is OK.

PINPOINT TEST

F : THE PEDAL GOES DOWN SLOWLY

TES

T

CONDITIONS

DE

TAILS/RESULTS/ACTIONS

F1

:

ROAD TEST VEHICLE - CHECK BRAKE PEDAL OPERATION

Chec

k

if the condition occurs duri

ng actual stopping application by applying the brake pedal while

the vehicle is moving.

1

Doe s

the condition occur when the vehicle is moving?

Yes GO to F2

.

No

GO to F

3

.

F2:

CHECK

FOR BRAKE SYSTEM LEAKS

Chec

k for e

xternal brake system leaks. For additional information, refer to Master Cylinder in this

section.

1

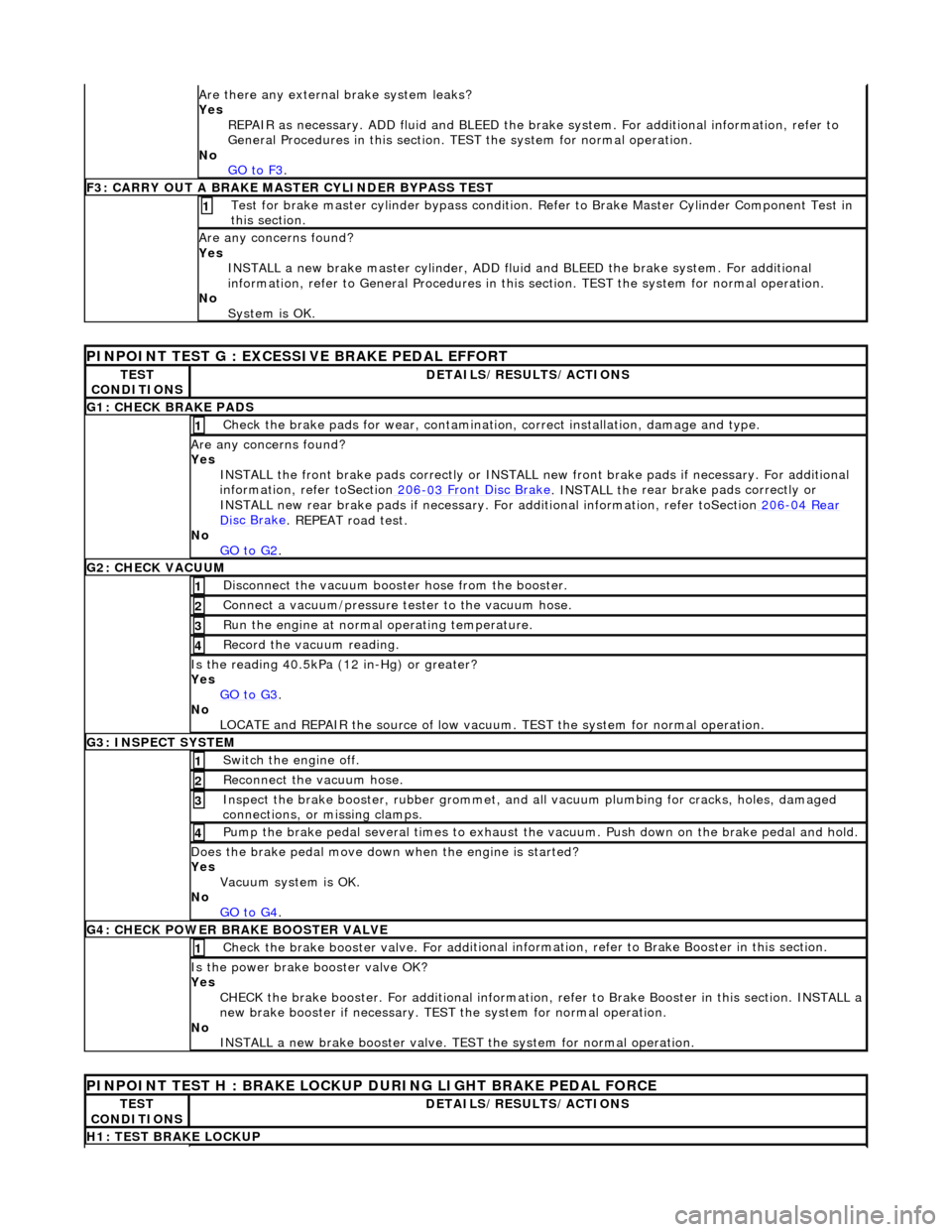

Page 315 of 2490

Are th

ere any external brake system leaks?

Yes REPAIR as necessary. ADD fluid and BLEED the brak e system. For additional information, refer to

General Procedures in this section. TEST the system for normal operation.

No GO to F3

.

F

3: CARRY OUT A BRAKE MASTER CYLINDER BYPASS TEST

Te

st for brake master cylinder bypass condition. Re

fer to Brake Master Cylinder Component Test in

this section.

1

A

re any concerns found?

Yes INSTALL a new brake master cylinder, ADD flui d and BLEED the brake system. For additional

information, refer to General Proc edures in this section. TEST the system for normal operation.

No System is OK.

PINPO

INT TEST G : EXCESSIVE BRAKE PEDAL EFFORT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

G1

: CHECK BRAKE PADS

Check the brake pads for wear, contamin

atio

n, correct installation, damage and type.

1

A

re any concerns found?

Yes INSTALL the front brake pads correctly or INSTALL ne w front brake pads if necessary. For additional

information, refer toSection 206

-03

Front Disc Brake

. INSTALL the

rear brake pads correctly or

INSTALL new rear brake pads if necessary. For additional information, refer toSection 206

-04

Rear

Di

sc Brake

. REPEAT road test.

No

GO to G2

.

G2:

CHECK VACUUM

Di

sconnect the vacuum booster hose from the booster.

1

Conne

ct a vacuum/pressure tester to the vacuum hose.

2

Ru

n the engine at normal operating temperature.

3

Re

cord the vacuum reading.

4

Is

the reading 40.5kPa (1

2 in-Hg) or greater?

Yes GO to G3

.

No

LOCATE and REPAIR the source of low vacuum . TEST the system for normal operation.

G3

: INSPECT SYSTEM

Swi

tch the engine off.

1

Re

connect the vacuum hose.

2

Inspect th

e brake booster, rubber grommet, and al

l vacuum plumbing for cracks, holes, damaged

connections, or missing clamps.

3

Pump th

e brake pedal several time

s to exhaust the vacuum. Push down on the brake pedal and hold.

4

Does th

e brake pedal move down

when the engine is started?

Yes Vacuum system is OK.

No GO to G4

.

G4

: CHECK POWER BRAKE BOOSTER VALVE

Check the brake booster valve. For

add

itional information, refer to

Brake Booster in this section.

1

Is th

e power brake booster valve OK?

Yes CHECK the brake booster. Fo r additional information, refer to Brak e Booster in this section. INSTALL a

new brake booster if necessary. TEST the system for normal operation.

No INSTALL a new brake booster valve. TEST the system for normal operation.

P

INPOINT TEST H : BRAKE LOCKUP

DURING LIGHT BRAKE PEDAL FORCE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

H1

: TEST BRAKE LOCKUP

Page 317 of 2490

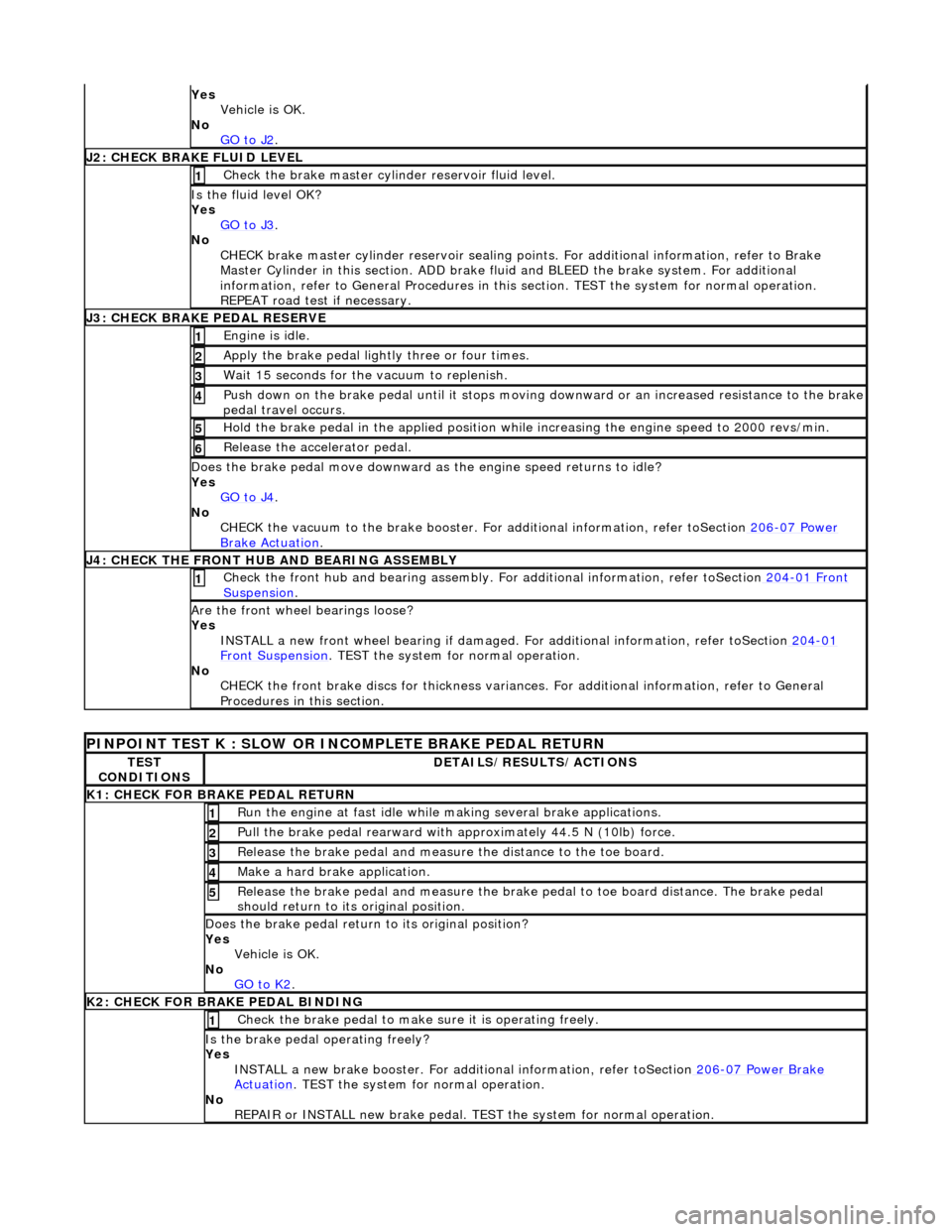

Yes

Vehicle is OK.

No GO to J2

.

J

2: CHECK BRAKE FLUID LEVEL

Check the brake master cyli

nder reservoir fluid level.

1

Is the fl

uid level OK?

Yes GO to J3

.

No

CHECK brake master cylinder reservoir sealing points. For additional information, refer to Brake

Master Cylinder in this section. ADD brake fl uid and BLEED the brake system. For additional

information, refer to General Proc edures in this section. TEST the system for normal operation.

REPEAT road test if necessary.

J

3: CHECK BRAKE PEDAL RESERVE

Engine is

idle.

1

Apply the brake pedal ligh

tl

y three or four times.

2

W

ait 15 seconds for the vacuum to replenish.

3

Push down on

the brake pedal until it stops moving

downward or an increased resistance to the brake

pedal travel occurs.

4

Hol

d the brake pedal in the applied position while increasing the engine speed to 2000 revs/min.

5

Re

lease the accelerator pedal.

6

Does th

e brake pedal move downward as

the engine speed returns to idle?

Yes GO to J4

.

No

CHECK the vacuum to the brake booster. Fo r additional information, refer toSection 206

-0

7 Power

Brake Ac

tuation

.

J

4: CHECK THE FRONT HUB AND BEARING ASSEMBLY

Check the fr

ont hub and bearing assembly. Fo

r additional information, refer toSection 204

-01

Front

Suspe

nsion

. 1

Are th

e front wheel bearings loose?

Yes INSTALL a new front wheel bearin g if damaged. For additional information, refer toSection 204

-01

F

ront Suspension

. TEST

the system for normal operation.

No CHECK the front brake discs for thickness variances. For additional information, refer to General

Procedures in this section.

PINPO

INT TEST K : SLOW OR INCOMPLETE BRAKE PEDAL RETURN

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

K1: C

HECK FOR BRAKE PEDAL RETURN

Ru

n the engine at fast idle while

making several brake applications.

1

Pull the

brake pedal rearward with approximately 44.5 N (10lb) force.

2

Relea

se the brake pedal and measure

the distance to the toe board.

3

Make a hard brake

application.

4

Relea

se the brake pedal and measure the brake

pedal to toe board distance. The brake pedal

should return to its original position.

5

Does th

e brake pedal return

to its original position?

Yes Vehicle is OK.

No GO to K2

.

K

2: CHECK FOR BRAKE PEDAL BINDING

Check the brake pedal to make

s

ure it is operating freely.

1

Is th

e brake pedal operating freely?

Yes INSTALL a new brake booster. For addi tional information, refer toSection 206

-0

7 Power Brake

Actuation. TEST

the system for normal operation.

No REPAIR or INSTALL new brake pedal. TE ST the system for normal operation.