fuel injection JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 898 of 2490

ENSURE THAT ALL FIRE PREVENTION PROCEDURES ARE ACTIVE.

BEFORE PROCEEDING, IT IS ESSENTIAL THAT THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD.

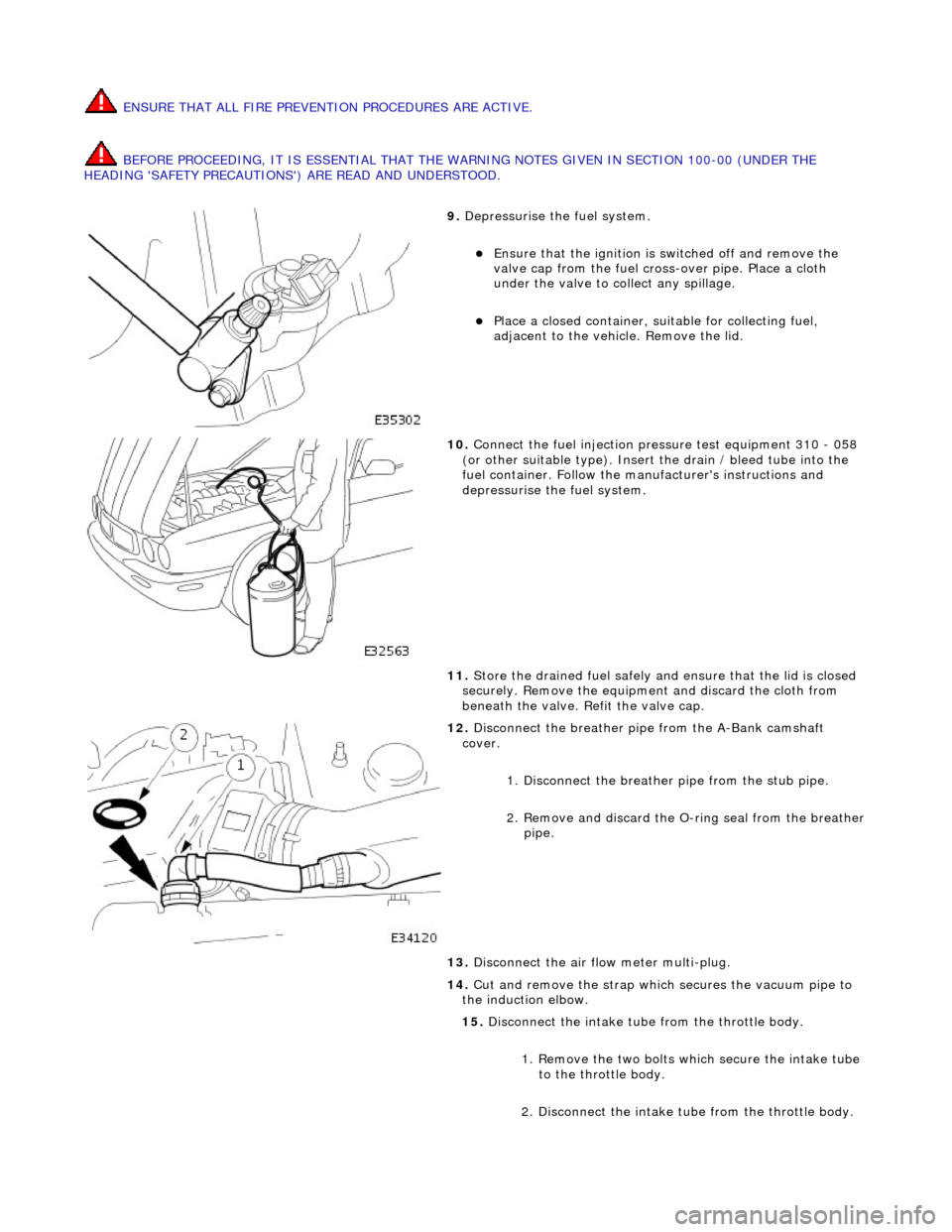

9. Depressurise the fuel system.

Ensure that the ignition is switched off and remove the

valve cap from the fuel cross-over pipe. Place a cloth

under the valve to collect any spillage.

Place a closed container, su itable for collecting fuel,

adjacent to the vehicle. Remove the lid.

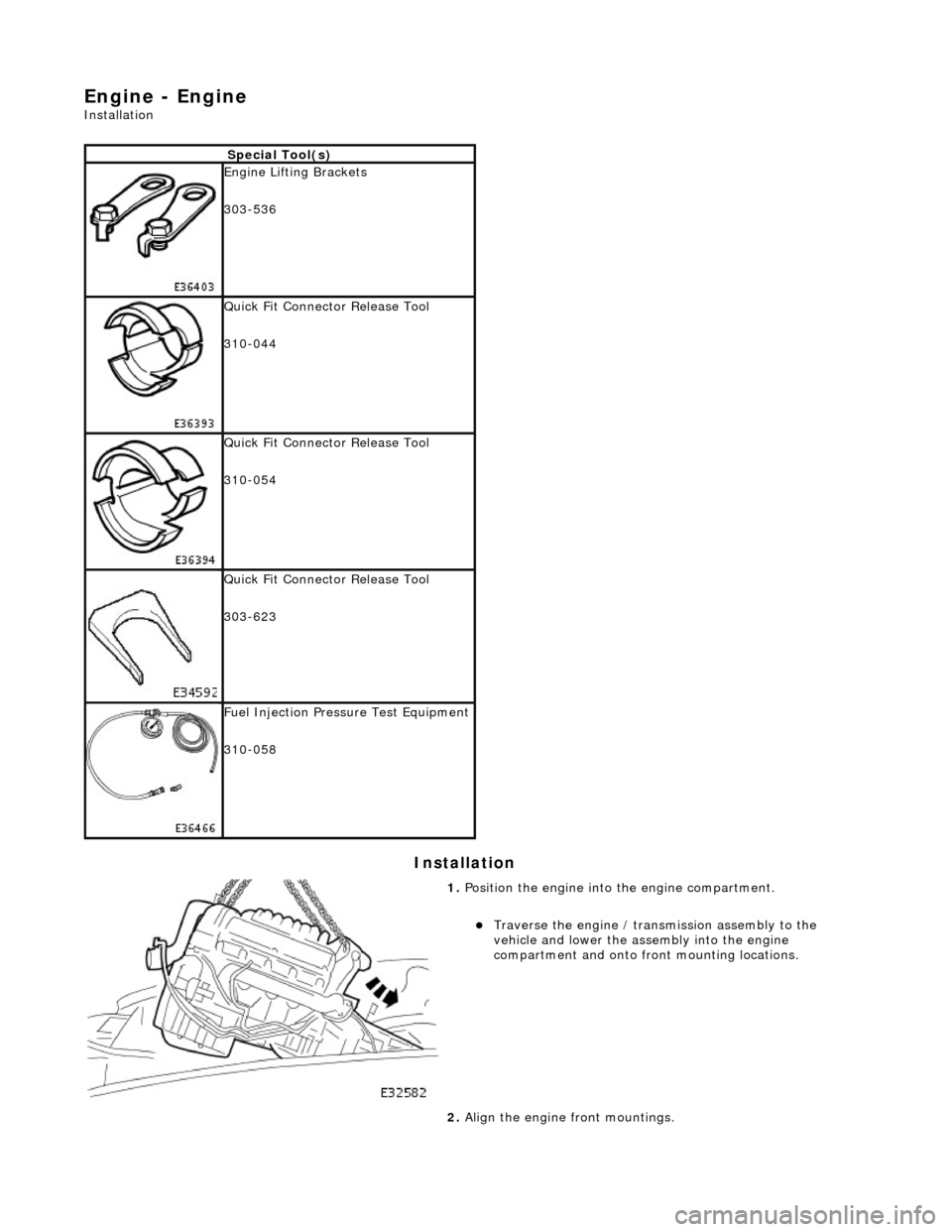

10. Connect the fuel injection pressure test equipment 310 - 058

(or other suitable type). Insert the drain / bleed tube into the

fuel container. Follow the ma nufacturer's instructions and

depressurise the fuel system.

11. Store the drained fuel safely and ensure that the lid is closed

securely. Remove the equipmen t and discard the cloth from

beneath the valve. Refit the valve cap.

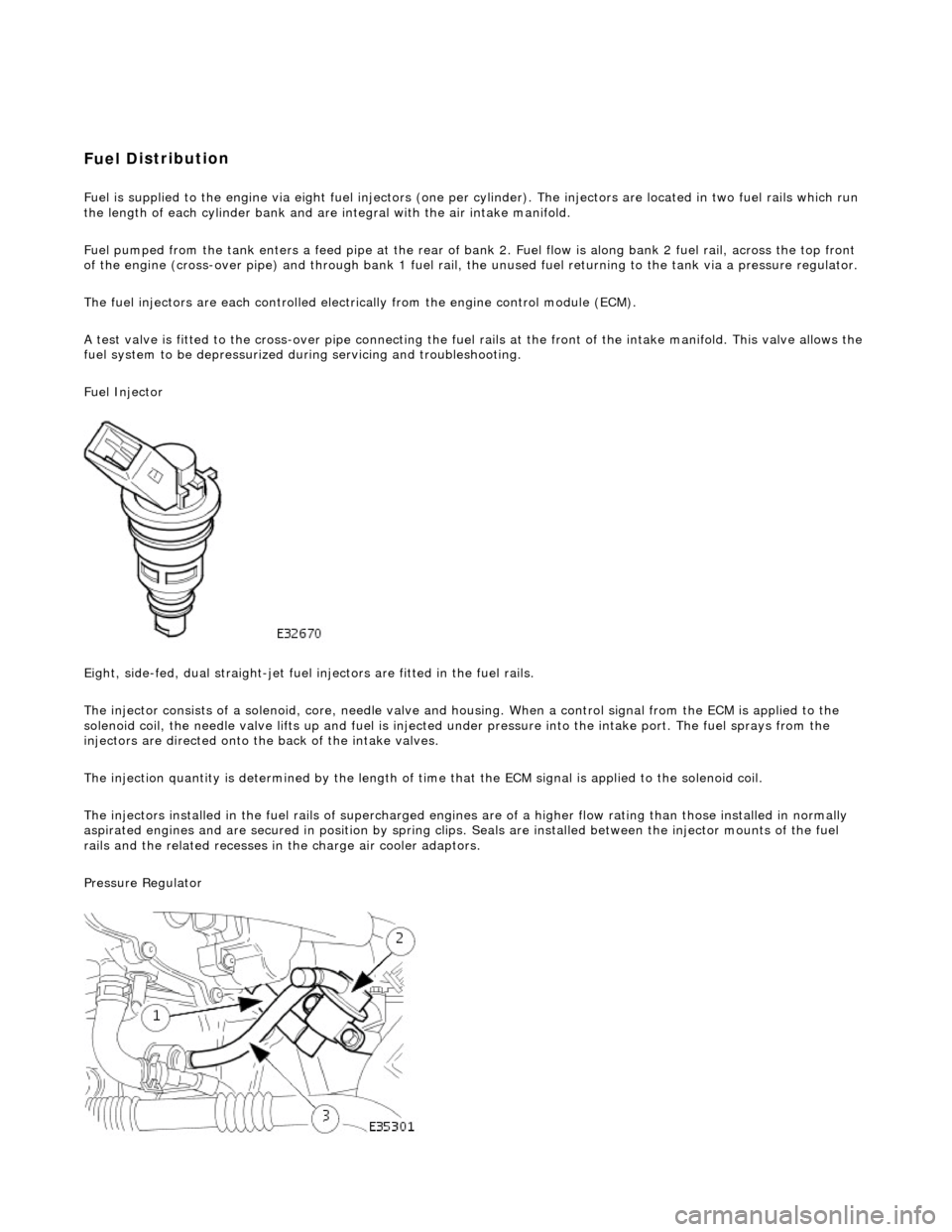

12. Disconnect the breather pipe from the A-Bank camshaft

cover.

1. Disconnect the breather pipe from the stub pipe.

2. Remove and discard the O-ring seal from the breather

pipe.

13. Disconnect the air flow meter multi-plug.

14. Cut and remove the strap which secures the vacuum pipe to

the induction elbow.

15. Disconnect the intake tube from the throttle body.

1. Remove the two bolts which secure the intake tube to the throttle body.

2. Disconnect the intake tube from the throttle body.

Page 911 of 2490

Engine - Engine

Installation

Installation

Special Tool(s)

Engine Lifting Brackets

303-536

Quick Fit Connector Release Tool

310-044

Quick Fit Connector Release Tool

310-054

Quick Fit Connector Release Tool

303-623

Fuel Injection Pressure Test Equipment

310-058

1. Position the engine into the engine compartment.

Traverse the engine / transmission assembly to the

vehicle and lower the assembly into the engine

compartment and onto front mounting locations.

2. Align the engine front mountings.

Page 1015 of 2490

Fuel D

istribution

Fuel is supplied to th

e engine

via eight fuel injectors (one pe r cylinder). The injectors are located in two fuel rails which r un

the length of each cylinder bank and ar e integral with the air intake manifold.

Fuel pumped from the tank enters a feed pipe at the rear of bank 2. Fuel flow is along bank 2 fuel rail, across the top front

of the engine (cross-over pipe) and through bank 1 fuel rail, the unused fuel re turning to the tank via a pressure regulator.

The fuel injectors are each controlled electrically from the engine control module (ECM).

A test valve is fitted to the cross-over pipe connecting the fu el rails at the front of the intake manifold. This valve allows the

fuel system to be depr essurized during servicin g and troubleshooting.

Fuel Injector

Eight, side-fed, dual straight-jet fuel injectors are fi tted in the fuel rails.

The injector consists of a solenoid, core, needle valve and ho using. When a control signal from the ECM is applied to the

solenoid coil, the needle valve lifts up and fuel is injected under pressure into the intake port. The fuel sprays from the

injectors are directed onto the back of the intake valves.

The injection quantity is determined by the length of time that the ECM signal is applied to the solenoid coil.

The injectors installed in the fuel rails of supercharged engines are of a higher flow rating than those installed in normally

aspirated engines and are secured in position by spring clips. Seals are instal led between the injector mounts of the fuel

rails and the related re cesses in the charge air cooler adaptors.

Pressure Regulator

Page 1016 of 2490

Pa

rts List

The pressure regulator is a diap hragm-operated valve that regula tes fuel-rail pressure at 3,0 bar above the intake manifold

pressure. A pipe connects the throttle induction elbow to the pressure regulator to provide the vacuum control signal. On

supercharged engines, the pressure regulator vacuum feed is taken from the top of the supercharger outlet duct.

The regulator is fitted between the rear end of the right-hand fuel rail (bank 1) and the fuel return line to the tank.

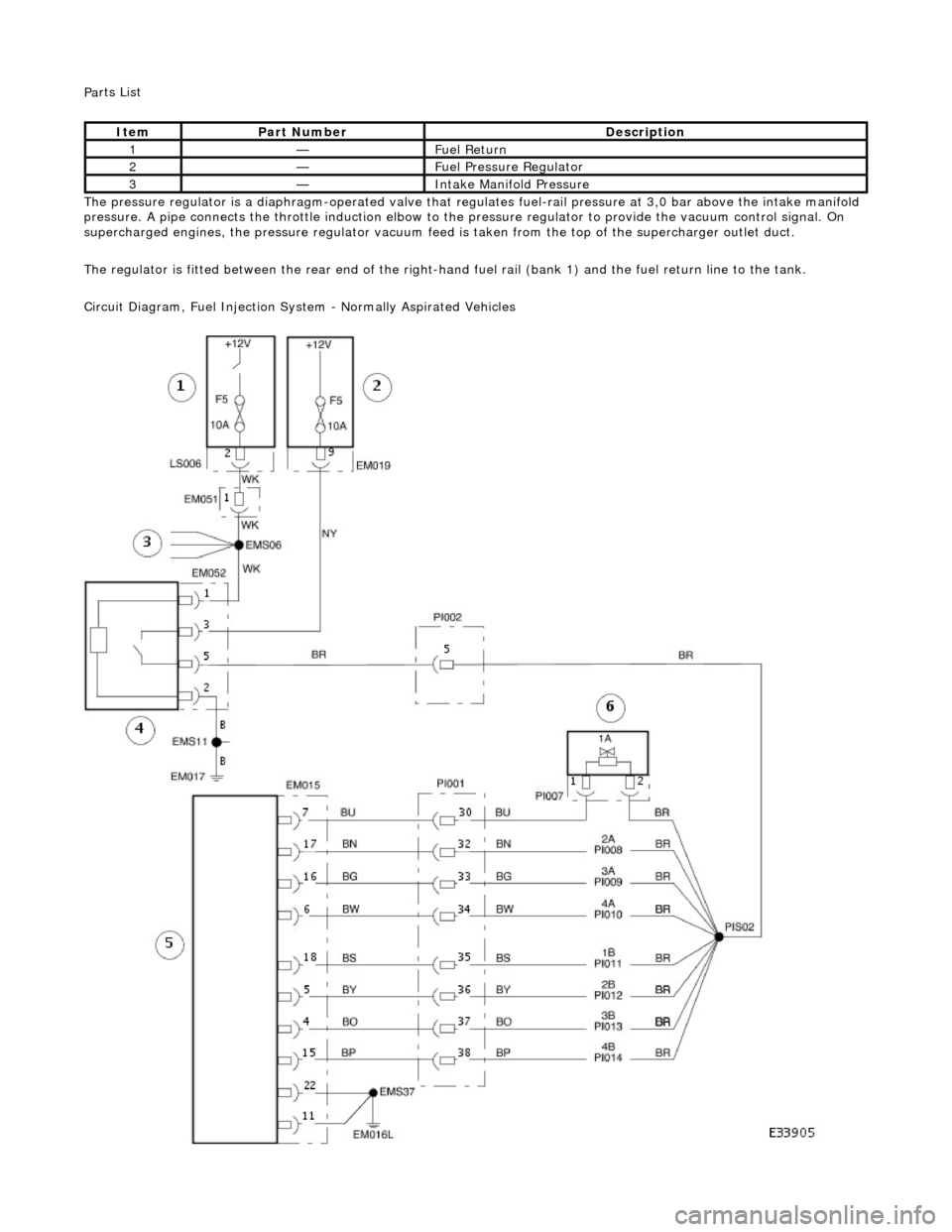

Circuit Diagram, Fuel Injection Syst em - Normally Aspirated Vehicles

Ite

m

Par

t

Number

De

scr

iption

1—F

u

el Return

2—F

u

el Pressure Regulator

3—Inta

k

e Manifold Pressure

Page 1017 of 2490

Ci

rcuit references to injectors:

'A' refers to bank 1;

'B' refers to bank 2.

Fuel C

harging and Controls - Supercharged Vehicles

Ci

rcuit Diagram, Fuel Injection

System - Supercharged Vehicles

It

em

Par

t Number

De

scription

1—E

ngine compartment fuse-box

2—Engine

management fuse-box

3—Splice

- 12V to

other circuits

4—PI m

ain relay

5—Engine

control module (ECM)

6—Fue

l injector 1A - other injectors similar

Page 1029 of 2490

ci

rcuit includes the EMS fuse box,

fuse 05, and the fuel injection relay. For additional information,

refer to the wiring diagrams. CLEAR DTC. TEST the system for normal operation.

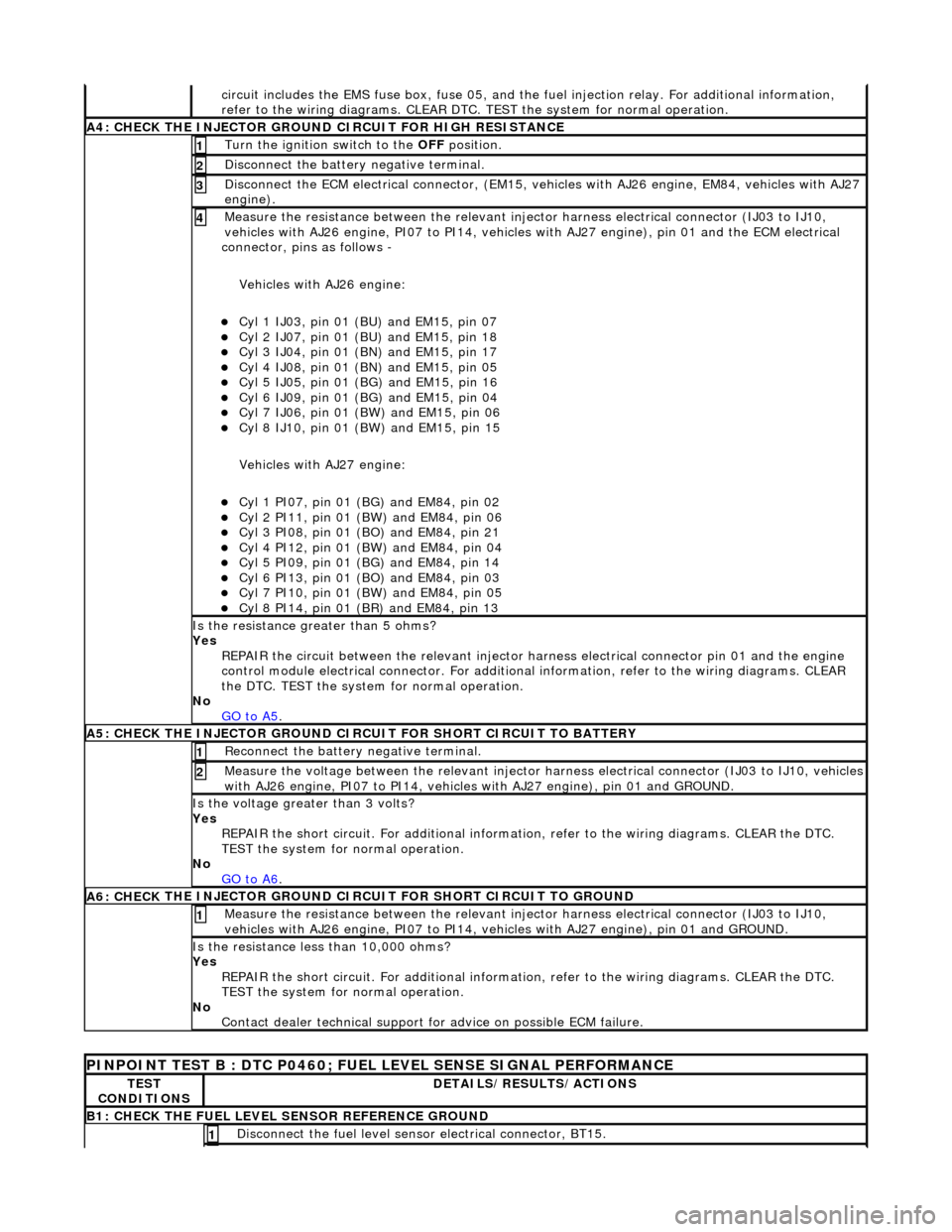

A4: CHECK

THE INJECTOR GROUND

CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

Di

sconnect the battery negative terminal.

2

D

isconnect the ECM electrical connector, (EM15, vehi

cles with AJ26 engine, EM84, vehicles with AJ27

engine).

3

Meas

ure the resistance between the relevant injector harness electrical connector (IJ03 to IJ10,

vehicles with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and the ECM electrical

connector, pins as follows -

Vehicles with AJ26 engine:

Cy

l 1 IJ03, pin 01 (BU) and EM15, pin 07

Cy

l 2 IJ07, pin 01 (BU) and EM15, pin 18

Cy

l 3 IJ04, pin 01 (BN) and EM15, pin 17

Cy

l 4 IJ08, pin 01 (BN) and EM15, pin 05

Cy

l 5 IJ05, pin 01 (BG) and EM15, pin 16

Cy

l 6 IJ09, pin 01 (BG) and EM15, pin 04

Cy

l 7 IJ06, pin 01 (BW) and EM15, pin 06

Cy

l 8 IJ10, pin 01 (BW) and EM15, pin 15

Vehicles with AJ27 engine:

Cy

l 1 PI07, pin 01 (B

G) and EM84, pin 02

Cy

l 2 PI11, pin 01 (BW) and EM84, pin 06

Cy

l 3 PI08, pin 01 (BO) and EM84, pin 21

Cy

l 4 PI12, pin 01 (BW) and EM84, pin 04

Cy

l 5 PI09, pin 01 (B

G) and EM84, pin 14

Cy

l 6 PI13, pin 01 (BO) and EM84, pin 03

Cy

l 7 PI10, pin 01 (BW) and EM84, pin 05

Cy

l 8 PI14, pin 01 (BR) and EM84, pin 13

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the circuit between the relevant injector harness electrical connector pin 01 and the engine

control module electrical connecto r. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to A5

.

A5: CHECK

THE INJECTOR GROUND CI

RCUIT FOR SHORT CIRCUIT TO BATTERY

R

econnect the battery negative terminal.

1

Meas

ure the voltage between the relevant injector harness electrical connector (IJ03 to IJ10, vehicles

with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and GROUND.

2

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A6

.

A6: CHECK

THE INJECTOR GROUND CI

RCUIT FOR SHORT CIRCUIT TO GROUND

Meas

ure the resistance between the relevant injector harness electrical connector (IJ03 to IJ10,

vehicles with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and GROUND.

1

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No Contact dealer technical support for advice on possible ECM failure.

P

INPOINT TEST B : DTC P0460; FUEL

LEVEL SENSE SIGNAL PERFORMANCE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE FUEL LEVEL SENSOR REFERENCE GROUND

Di

sconnect the fuel level sensor electrical connector, BT15.

1

Page 1032 of 2490

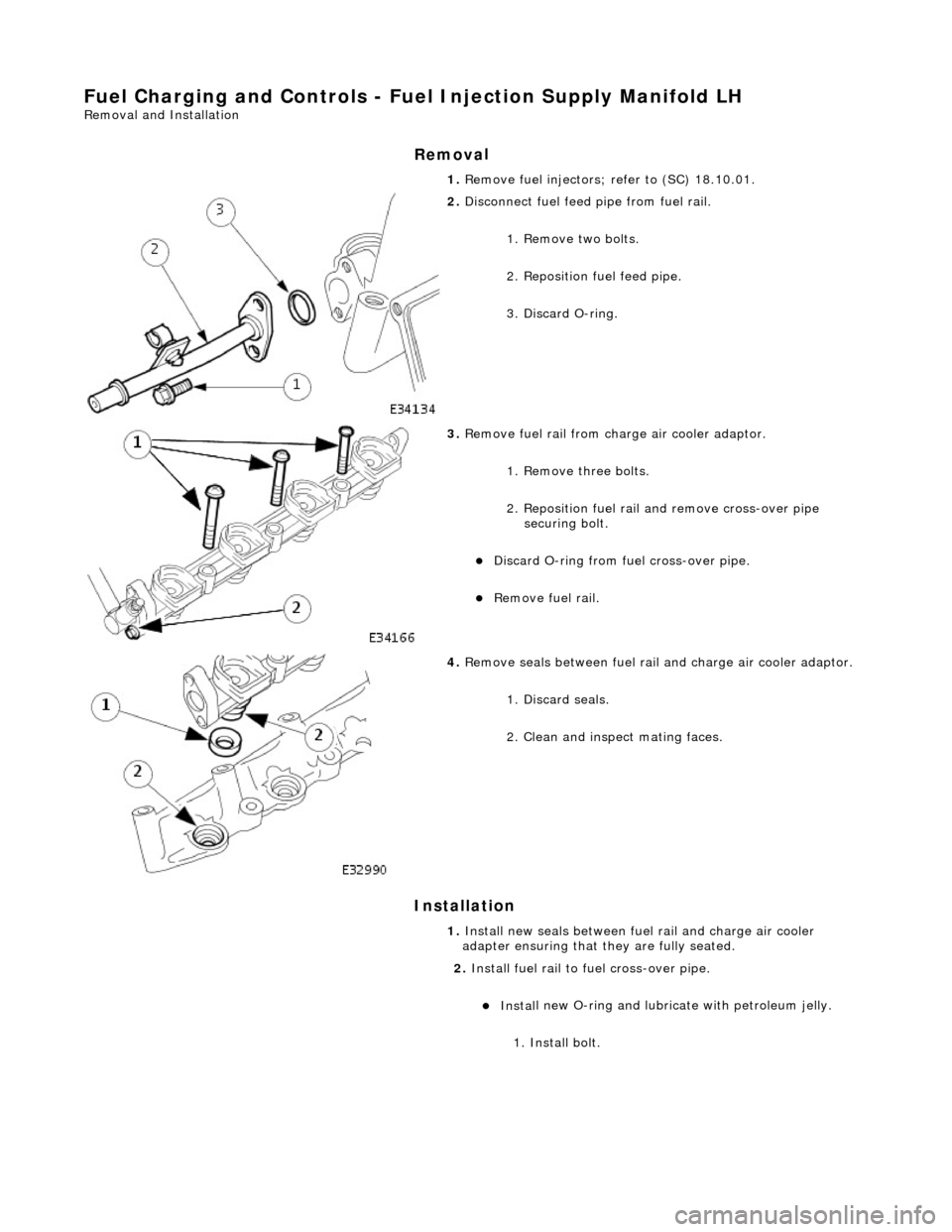

Fuel Char

ging and Controls - Fu

el Injection Supply Manifold LH

Remo

val and Installation

Remov

a

l

Installation

1. Re

move fuel injectors; refer to (SC) 18.10.01.

2. Disc

onnect fuel feed

pipe from fuel rail.

1. Remove two bolts.

2. Reposition fuel feed pipe.

3. Discard O-ring.

3. Re

move fuel rail from charge air cooler adaptor.

1. Remove three bolts.

2. Reposition fuel rail and remove cross-over pipe securing bolt.

Di

scard O-ring from fuel cross-over pipe.

R

e

move fuel rail.

4. Re

move seals between fuel rail

and charge air cooler adaptor.

1. Discard seals.

2. Clean and inspect mating faces.

1. Install new seals between fuel rail and charge air cooler

adapter ensuring that they are fully seated.

2. Install fuel rail to fuel cross-over pipe.

Inst al

l new O-ring and lubricate with petroleum jelly.

1. Install bolt.

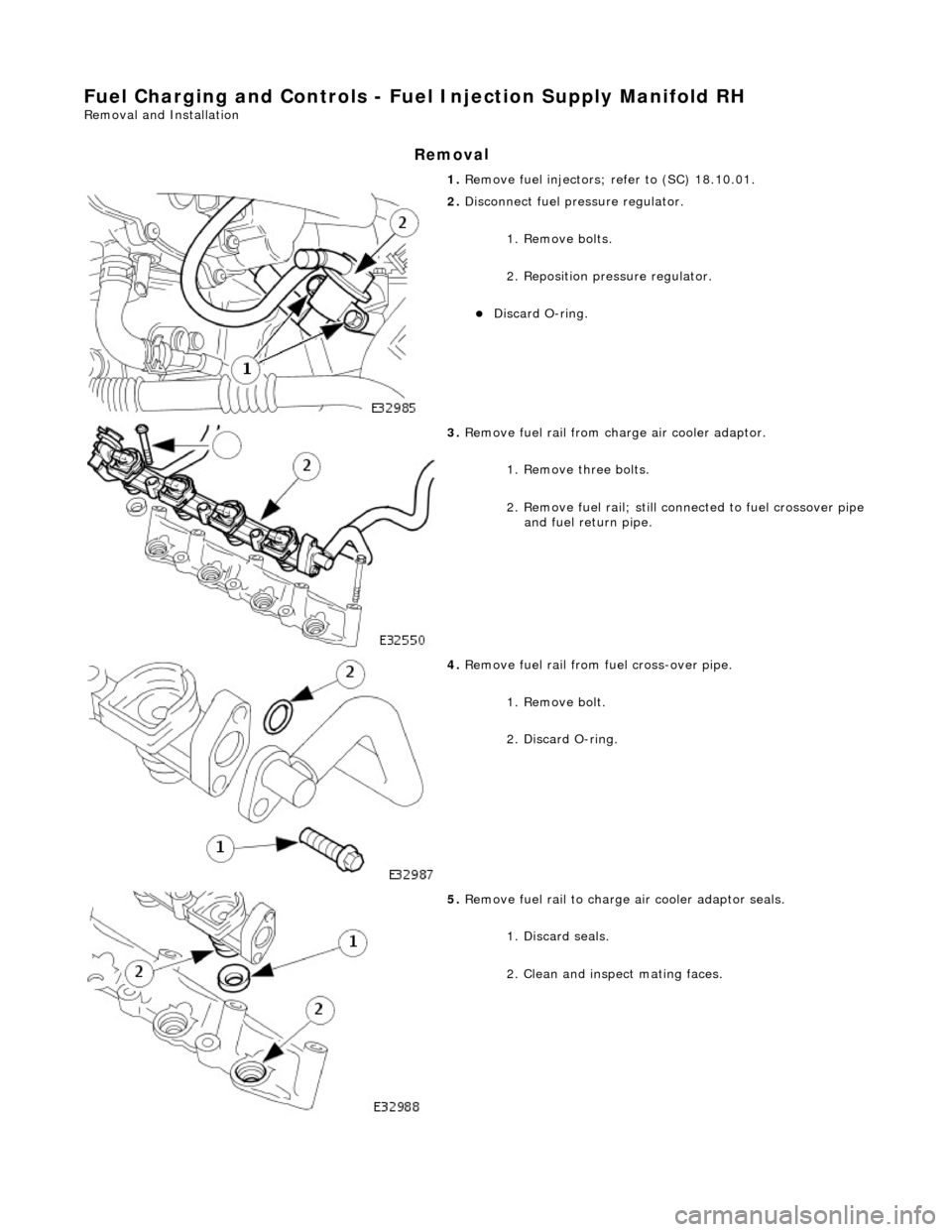

Page 1034 of 2490

Fuel Char

ging and Controls - Fu

el Injection Supply Manifold RH

Remo

val and Installation

Remov

a

l

1.

Re

move fuel injectors; refer to (SC) 18.10.01.

2. Disc

onnect fuel pressure regulator.

1. Remove bolts.

2. Reposition pres sure regulator.

Disc

ard O-ring.

3. Re

move fuel rail from charge air cooler adaptor.

1. Remove three bolts.

2. Remove fuel rail; still co nnected to fuel crossover pipe

and fuel return pipe.

4. Re

move fuel rail from fuel cross-over pipe.

1. Remove bolt.

2. Discard O-ring.

5. Re

move fuel rail to charge air cooler adaptor seals.

1. Discard seals.

2. Clean and inspect mating faces.

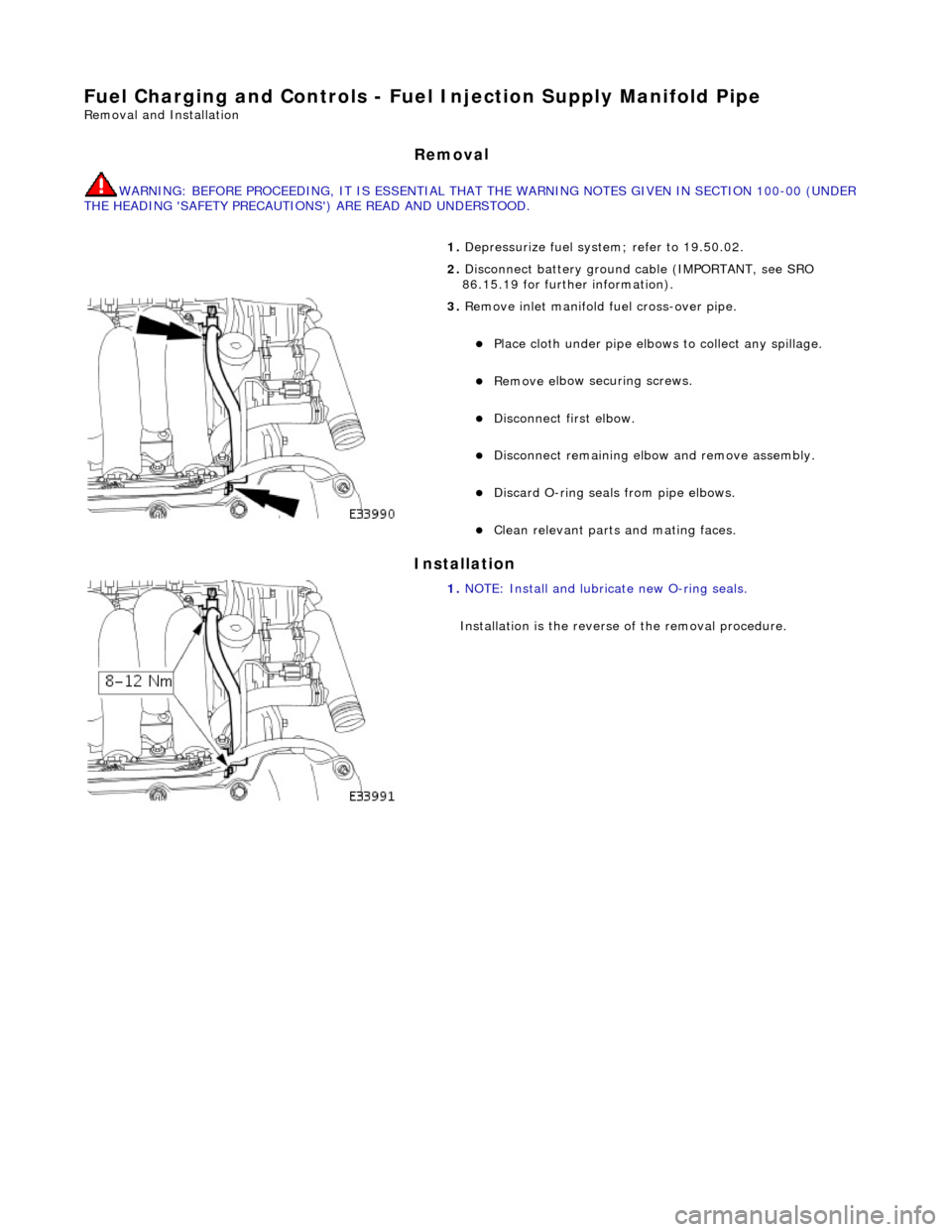

Page 1036 of 2490

Fuel Char

ging and Controls - Fuel

Injection Supply Manifold Pipe

Remo

val and Installation

Remov

a

l

WARNING: B

E

FORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER

THE HEADING 'SAFETY PRECAUTION S') ARE READ AND UNDERSTOOD.

In

stallation

1.

De

pressurize fuel syst

em; refer to 19.50.02.

2. Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

3. Re

move inlet manifold

fuel cross-over pipe.

Plac

e cloth under pipe elbows

to collect any spillage.

Remove e

lbow securing screws.

Di

sc

onnect first elbow.

Disc

onnect remaining elbow and remove assembly.

Discard O

-

ring seals

from pipe elbows.

Clean relevant parts and mating faces.

1. NOTE : Install

and lubricate new O-ring seals.

Installation is th e reverse of the removal procedure.

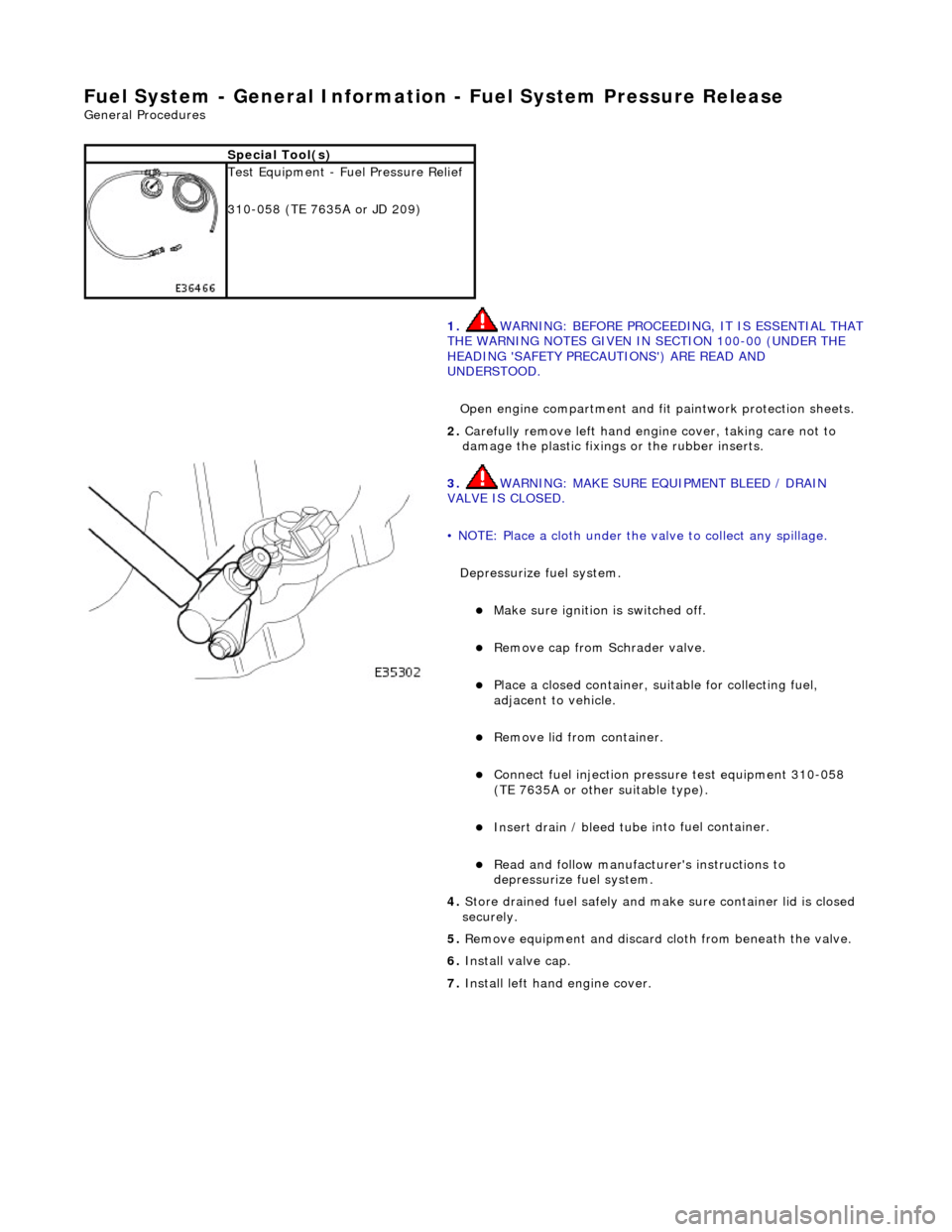

Page 1690 of 2490

Fuel System - General Information - Fuel System Pressure Rele

ase

Gen

e

ral Procedures

S p

ecial Tool(s)

Tes

t

Equipment - Fuel Pressure Relief

310-058 (TE 7635A or JD 209)

1. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Open engine compartment and fi t paintwork protection sheets.

2. Carefull

y remove left

hand engine cover, taking care not to

damage the plasti c fixings or the rubber inserts.

3. WA

RNING: MAKE SURE EQUIPMENT BLEED / DRAIN

VALVE IS CLOSED.

• NOTE: Place a cloth under the valve to collect any spillage.

Depressurize fuel system.

Make sure ignition i s

switched off.

R

e

move cap from Schrader valve.

Pla

c

e a closed container, su

itable for collecting fuel,

adjacent to vehicle.

R e

move lid from container.

Conne

ct

fuel injection pressu

re test equipment 310-058

(TE 7635A or other suitable type).

Insert drain / bleed tu be i

nto fuel container.

R

e

ad and follow manufacturer's instructions to

depressurize fuel system.

4. Store drained f u

el safely and make

sure container lid is closed

securely.

5. Remove equipment and discard cloth from beneath the valve.

6. Install valve cap.

7. Install left hand engine cover.