length JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 79 of 2490

1

11 and support on stands. Refer to Section 100-02.

5. Ins

tall Special Tool 204-111 in road spring.

Sl

acken tool adjuster to suit spring length.

Install adaptor

and thrust collar.

Posit

ion stem of tool in center of spring passing dowel

through slot in su spension turret.

6. R

otate stem of Special Tool to

position dowel across slot.

7. W

ARNING: WHEN TURNING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT ROTATE AND DISTURB POSITION

OF DOWEL IN SUSPENSION TURRET.

Rotate adjuster of Special Tool to tension spring.

8. R

emove spring pan to lower

wishbone securing bolts.

9. Rotate adjuster of Special Tool to release tension from spring.

Page 91 of 2490

1

11 and support on stands. Refer to Section 100-02.

5. Ins

tall Special Tool 204-111 in road spring.

Sl

acken tool adjuster to suit spring length.

Fit adaptor and th

rust collar.

Posit

ion stem of tool in center of spring passing dowel

through slot in su spension turret.

6. R

otate stem of Special Tool to

position dowel across slot.

7. W

ARNING: WHEN TURNING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT ROTATE AND DISTURB POSITION

OF DOWEL IN SUSPENSION TURRET.

Rotate adjuster of Special Tool to tension spring.

8. R

emove spring pan securing bolts.

9. Rotate adjuster of Special Tool to release tension from spring.

Page 97 of 2490

I

nstallation

CAUTI

ON: The wishbone front and rear arm bushes differ in length.

Ensure the correct bush is installed in each arm.

1.

Position arm on suitable supports on press bed.

2. Position Special Tool 204-214 on top of bush.

3. Operate press to remove bush from arm.

34. Remove wishbone front arm from press

35

.

NOTE: For assembly purposes, note orientation of bush.

• NOTE: Initial press action will cause tool to sh ear bush flange.

Using a hydraulic press, remove bush from rear wishbone arm.

1. Position arm on suitable supports on press bed.

2. Position special tool on top of bush.

3. Operate press to remove bush from arm.

1. Using a h

ydraulic press, install bu

sh in wishbone rear arm/ball

joint assembly.

1. Position arm on suitable supports on press bed.

2. Position bush on arm ensuring orientation is as noted during removal of old bush.

3. Position suitable flat steel plate on top of bush.

4. Operate press to install bush in arm.

2. Using a h

ydraulic press, install

bush in wishbone front arm.

1. Position arm on suitable supports on press bed.

2. Position bush on arm ensuring orientation is as noted during removal of old bush.

3. Position suitable flat steel plate on top of bush.

4. Operate press to install bush in arm.

3. Position wishbone rear arm on crossbeam and install but do

Page 109 of 2490

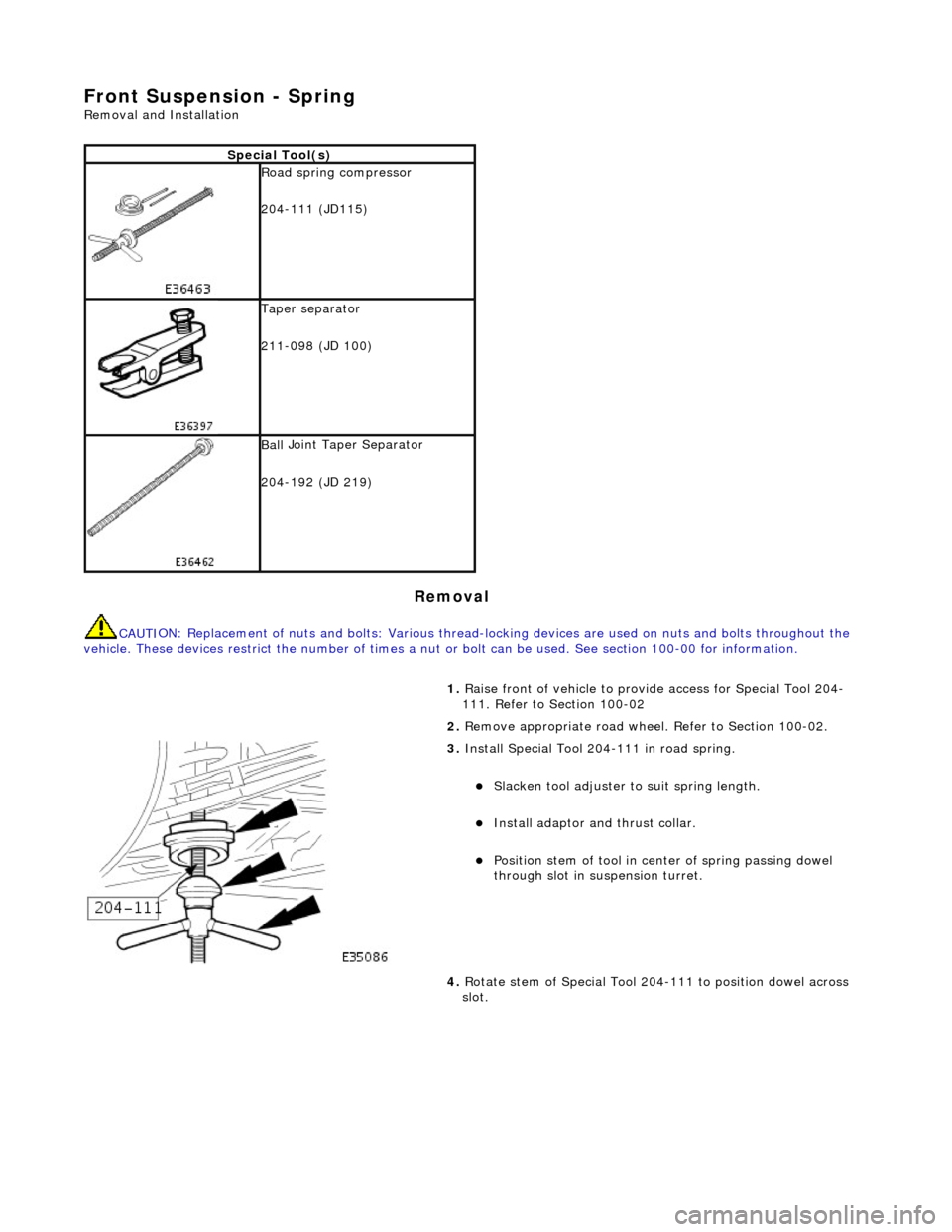

Front Suspension - Spring

Re

moval and Installation

Remov

al

CAUTI

ON: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

S

pecial Tool(s)

R

oad spring compressor

204-111 (JD115)

Taper separator

211-098 (JD 100)

Ball

Joint Taper Separator

204-192 (JD 219)

1. R

aise front of vehicle to provid

e access for Special Tool 204-

111. Refer to Section 100-02

2. Remove appropriate road wheel. Refer to Section 100-02.

3. Ins

tall Special Tool 204-111 in road spring.

Sl

acken tool adjuster to suit spring length.

Install adaptor

and thrust collar.

Posit

ion stem of tool in center of spring passing dowel

through slot in su spension turret.

4. Rotate stem of Special Tool 204-111 to position dowel across

slot.

Page 113 of 2490

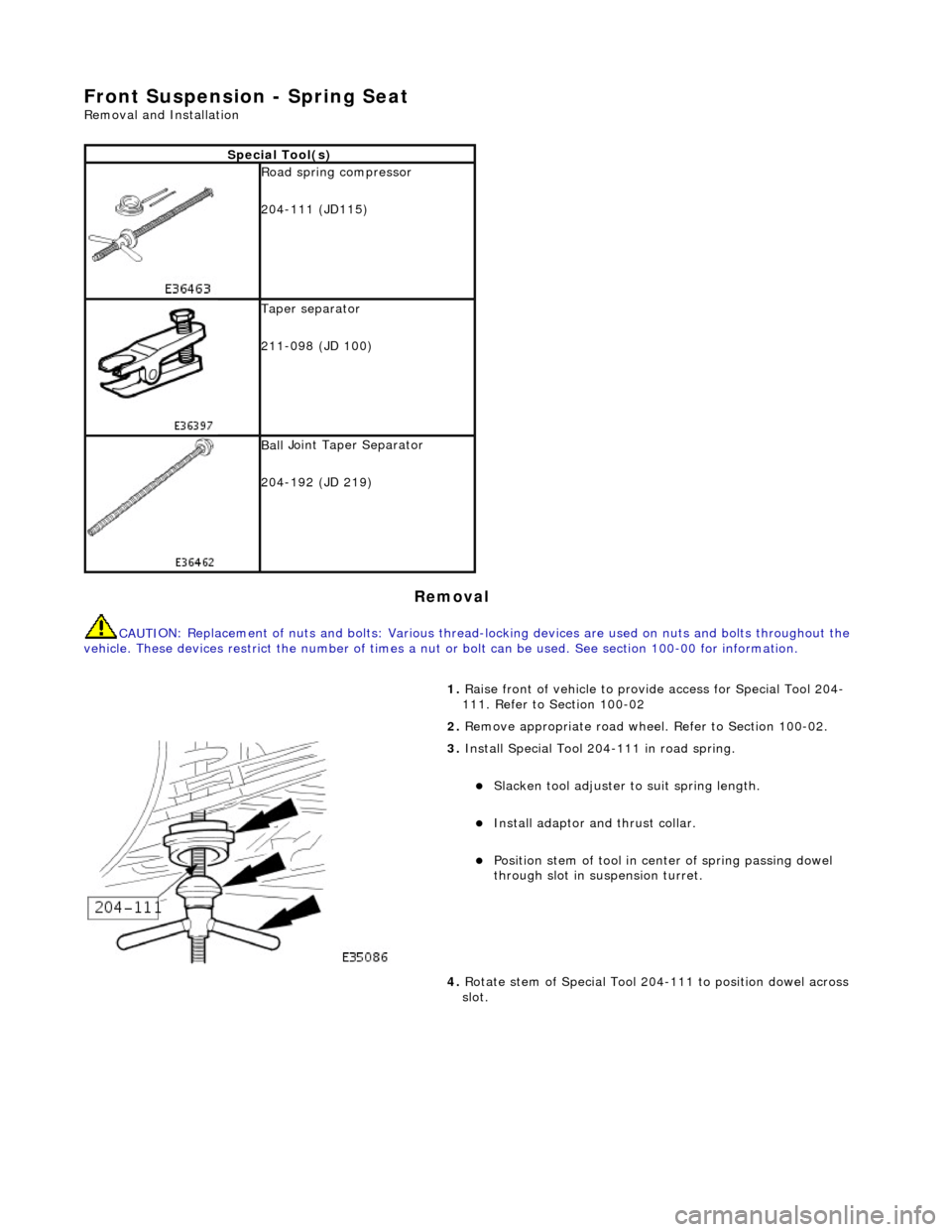

Front Suspension - Spring Seat

Re

moval and Installation

Remov

al

CAUTI

ON: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

S

pecial Tool(s)

R

oad spring compressor

204-111 (JD115)

Taper separator

211-098 (JD 100)

Ball

Joint Taper Separator

204-192 (JD 219)

1. R

aise front of vehicle to provid

e access for Special Tool 204-

111. Refer to Section 100-02

2. Remove appropriate road wheel. Refer to Section 100-02.

3. Ins

tall Special Tool 204-111 in road spring.

Sl

acken tool adjuster to suit spring length.

Install adaptor

and thrust collar.

Posit

ion stem of tool in center of spring passing dowel

through slot in su spension turret.

4. Rotate stem of Special Tool 204-111 to position dowel across

slot.

Page 153 of 2490

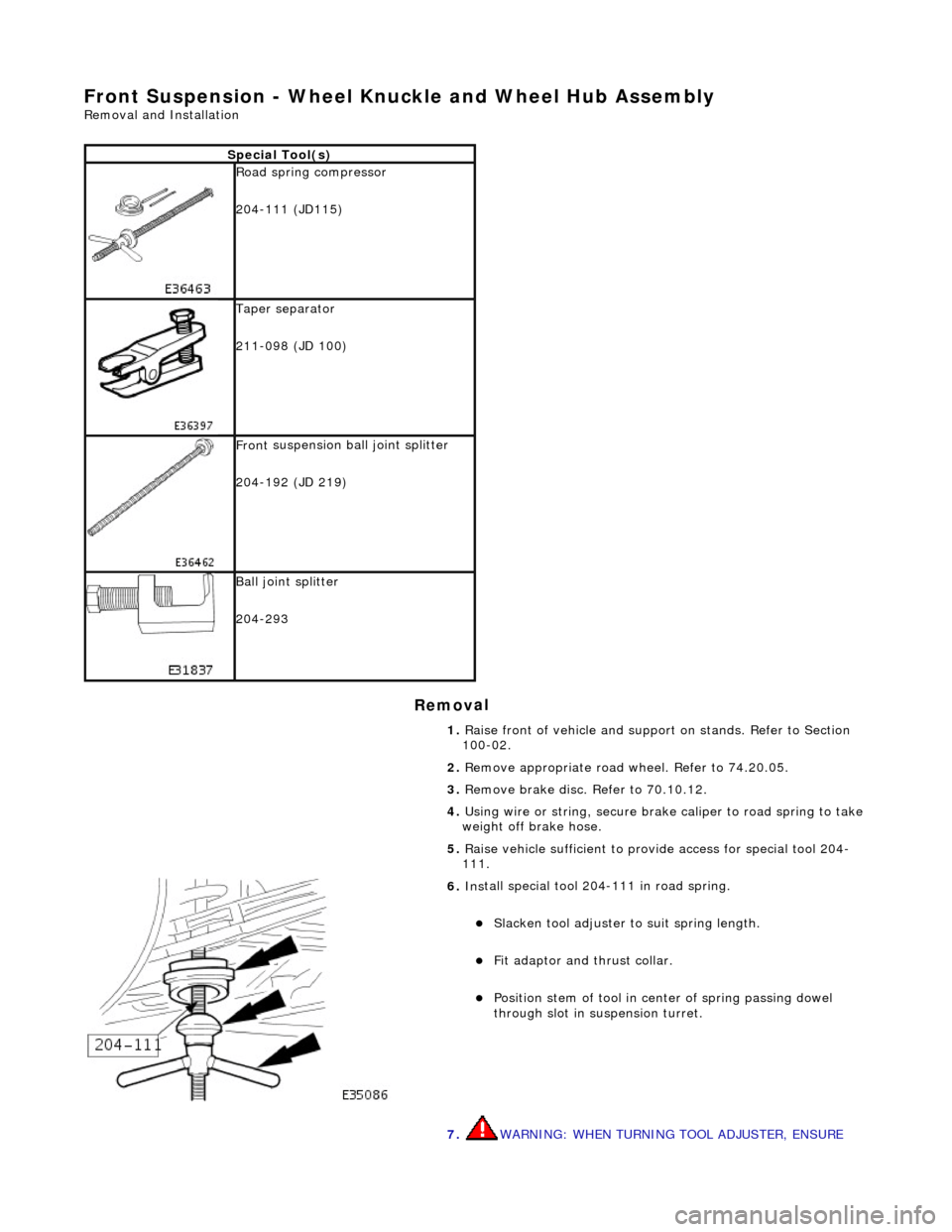

Front Susp

ension - Wheel Knuckle and Wheel Hub Assembly

Re

moval and Installation

Remov

al

S

pecial Tool(s)

R

oad spring compressor

204-111 (JD115)

Taper separator

211-098 (JD 100)

Front

suspension ball joint splitter

204-192 (JD 219)

Bal

l joint splitter

204-293

1. Raise front of vehicle and support on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to 74.20.05.

3. Remove brake disc. Refer to 70.10.12.

4. Using wire or string, secure brak e caliper to road spring to take

weight off brake hose.

5. Raise vehicle sufficient to provide access for special tool 204-

111.

6. Ins

tall special tool 204-111 in road spring.

Sl

acken tool adjuster to suit spring length.

Fit adaptor and th

rust collar.

Posit

ion stem of tool in center of spring passing dowel

through slot in su spension turret.

7. WARNING: WHEN TURNING TOOL ADJUSTER, ENSURE

Page 160 of 2490

8. Inst

all special tool 204-111 in road spring.

Slacken tool

adjuster to suit spring length.

Fit adaptor and th

rust collar.

Positi

on stem of tool in center of spring passing dowel

through slot in su spension turret.

9. WA

RNING: WHEN TURNING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT ROTATE AND DISTURB POSITION

OF DOWEL IN SUSPENSION TURRET.

Engage dowel of special tool 204-111 in suspension turret and

rotate to position across slot.

10 . Lower veh

icle onto stands.

11 . R

otate tool adjuster to tension spring.

12. Remove wheel speed sensor se curing screw and withdraw

sensor from vertical link.

Page 616 of 2490

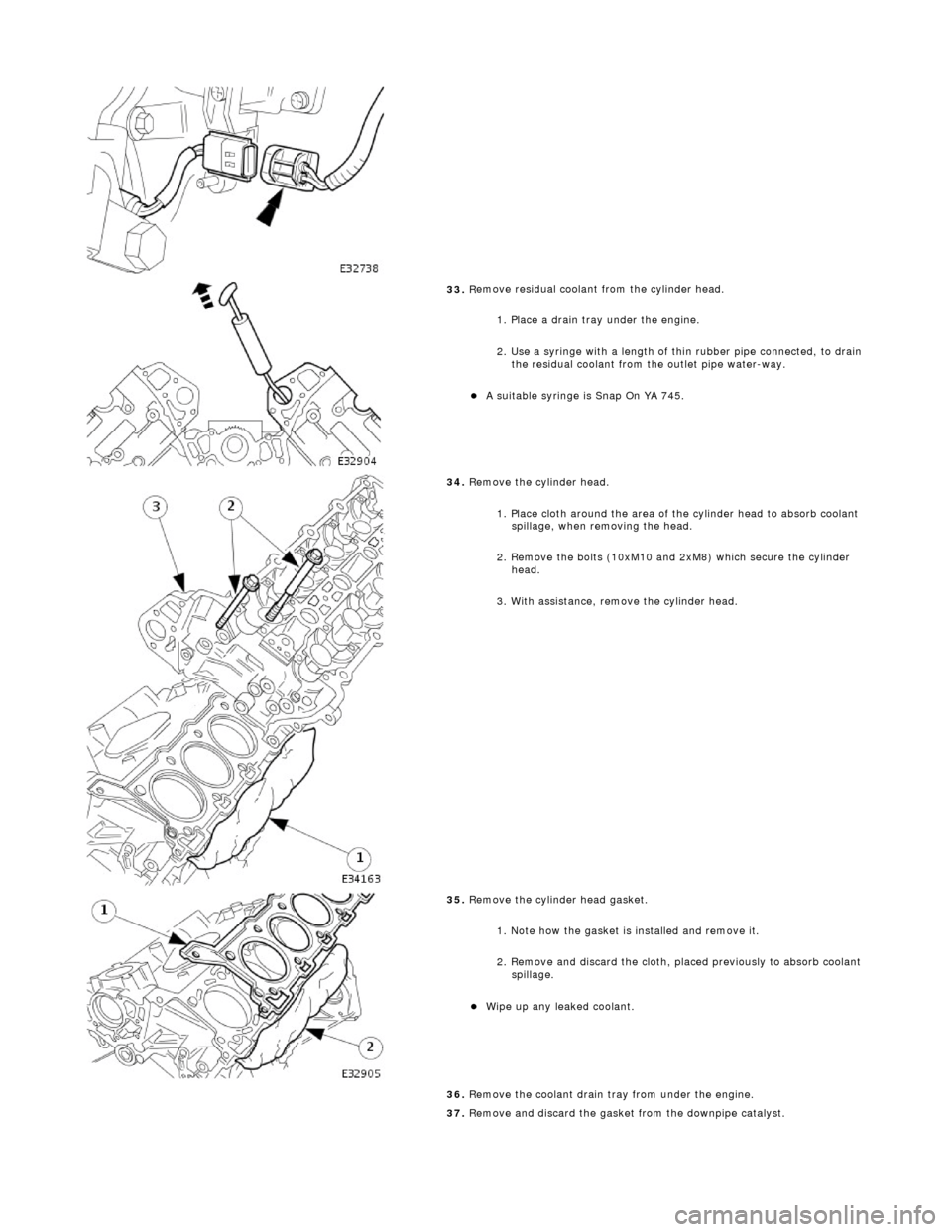

33. R

emove residual coolant from the cylinder head.

1. Place a drain tray under the engine.

2. Use a syringe with a length of thin rubber pipe connected, to drain the residual coolant from the outlet pipe water-way.

A s u

itable syringe is Snap On YA 745.

34 . R

emove the cylinder head.

1. Place cloth around the area of th e cylinder head to absorb coolant

spillage, when removing the head.

2. Remove the bolts (10xM10 and 2xM8) which secure the cylinder head.

3. With assistance, remove the cylinder head.

35 . R

emove the cylinder head gasket.

1. Note how the gasket is installed and remove it.

2. Remove and discard the cloth, placed previously to absorb coolant spillage.

Wipe up any l e

aked coolant.

36. Remove the coolant drain tray from under the engine.

37. Remove and discard the gasket from the downpipe catalyst.

Page 631 of 2490

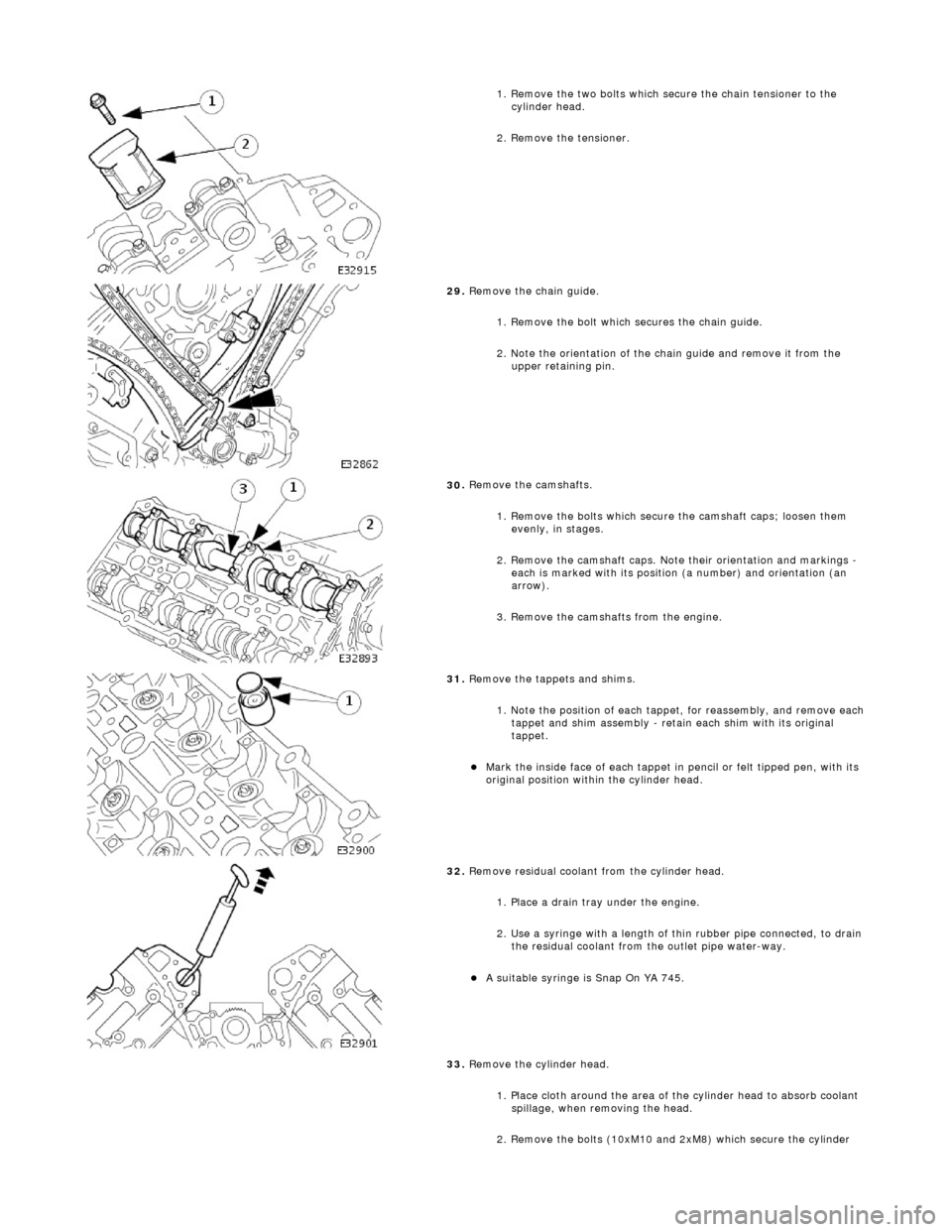

1.

Remove the two bolts which secure the chain tensioner to the

cylinder head.

2. Remove the tensioner.

29

.

Remove the chain guide.

1. Remove the bolt which secures the chain guide.

2. Note the orientation of the chain guide and remove it from the upper retaining pin.

30

.

Remove the camshafts.

1. Remove the bolts which secure the camshaft caps; loosen them evenly, in stages.

2. Remove the camshaft caps. Note their orientation and markings -

each is marked with its position (a number) and orientation (an

arrow).

3. Remove the camshafts from the engine.

31

.

Remove the tappets and shims.

1. Note the position of each tappet, for reassembly, and remove each

tappet and shim assembly - retain each shim with its original

tappet.

Mark

the inside face of each tappet in pencil or felt tipped pen, with its

original position within the cylinder head.

32

.

Remove residual coolant from the cylinder head.

1. Place a drain tray under the engine.

2. Use a syringe with a length of thin rubber pipe connected, to drain the residual coolant from the outlet pipe water-way.

A s

uitable syringe is Snap On YA 745.

33. Remove the cylinder head.

1. Place cloth around the area of th e cylinder head to absorb coolant

spillage, when removing the head.

2. Remove the bolts (10xM10 and 2xM8) which secure the cylinder

Page 665 of 2490

6. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

7. Install the crankshaft setting peg 303-531 to the crankshaft

position sensor location.

1. Install the crankshaft setting peg 303-531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Install and tighten the bolt to secure the setting peg.

8. Lower the vehicle on the ramp.

9. Install the camshaft locking tool 303-530 to Bank 2 camshafts,

aligning the shafts sl ightly as necessary.

10. CAUTION: Use a length of steel strip that will not fall

into the timing cover.

Protect the upper face of the ti ming cover from scratches, when

removing the bolt which secures the sprocket.

1. Place a flat piece of stee l strip along the timing cover

horizontal jointing face, adjacent to the exhaust

camshaft sprocket.

2. Secure the steel strip in place with adhesive tape.

11. A ball-ended hexagon drive bit is required to remove the

sprocket securing bolt. A suitable tool is available from Snap On as (FABLM10E) Long Series 10mm AF.