instrument cluster JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1189 of 2490

E

lectronic Engine Controls -

Electronic Engine Controls

D

iagnosis and Testing

I

nspection and Verification

1.

1. Veri

fy the customer concern.

2. 2. Confirm which, if any, warning li ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

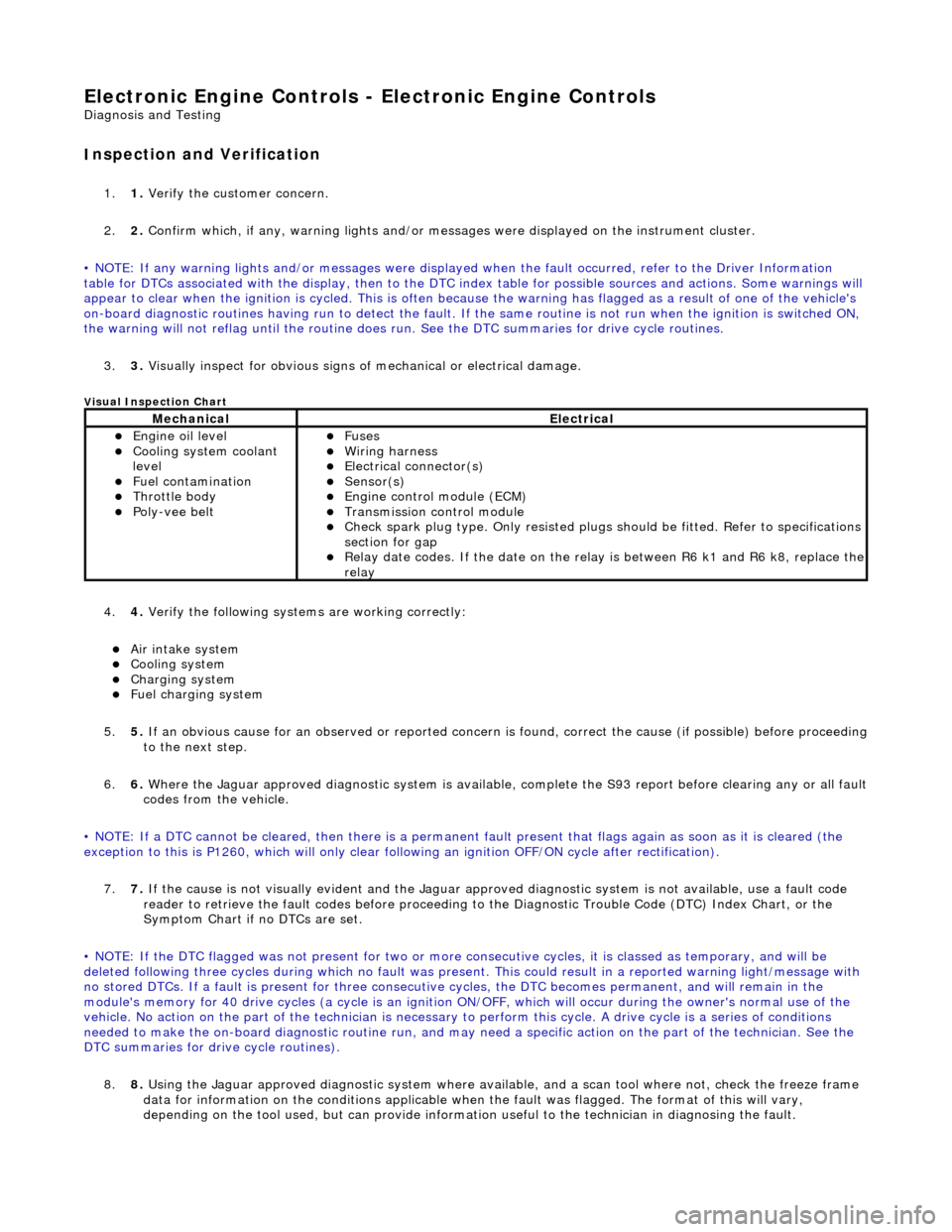

V

isual Inspection Chart

4.

4. Veri

fy the following syst

ems are working correctly:

Air in

take system

Coo

ling system

Charging system

F

uel charging system

5. 5. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycles (a cy cle is an ignition ON/OFF, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for driv e cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

dependin

g o

n the tool used, but can provide information useful to the technician in dia

gnos

in

g th

e fault.

MechanicalElectrical

Engi

ne oil level

Coo

ling system coolant

level

Fuel contamination

Throttle body Poly

-vee belt

F

uses

W

iring harness

E

lectrical connector(s)

Sens

or(s)

Engine

control module (ECM)

Tran

smission control module

Check spark plu

g type. Only re

sisted plugs should be fitted. Refer to specifications

section for gap

Relay date codes.

If the date on the rela

y is between R6 k1 and R6 k8, replace the

relay

Page 1201 of 2490

leak

/blockage

EVAP valve failure

P0444Evaporati

ve emissions system

(EVAP) valve circuit open circuit

EVAP t

o ECM drive circuit open

circuit or high resistance

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0445Evaporati

ve emissions system

(EVAP) valve circuit short circuit

E

VAP to ECM drive circuit short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0447Cani

ster close valve (CCV) circuit

open circuit

CCV to ECM

drive circuit open

circuit, high resi stance or short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0448Cani

ster close valve (CCV) circuit

short circuit

CCV to

ECM drive circuit short

circuit to high voltage

CCV failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0452F

uel tank pressure (FTP) sensor

circuit low voltage

FTP

sensor disconnected

FTP

sensor to ECM sense circuit

open circuit or short circuit to

ground

FTP sen

sor to ECM power supply

circuit open circuit or short circuit

to ground

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0453F

uel tank pressure (FTP) sensor

circuit high voltage

FTP

sensor to ECM signal ground

circuit open circuit

F

TP sensor to ECM wiring (supply,

sense, signal, ground) short circuit

to each other

FTP

sensor to ECM sense circuit

short circuit to high voltage

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0460Fue

l level sense signal

performance

Fue

l level sensor

to instrument

cluster circuits in termittent short or

open circuit

F

uel level sensor failure

Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0506Idl

e rpm lower than expected

Ai

r intake blockage

Acce

ssory drive overload

(defective/siezed component)

Thr

ottle valve stuck closed

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check t

he accessory drive

components,

REFER to Section 303

-0

5 Accessory

Dr

ive

.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0507Idle rpm

higher than expected

Inta

ke air leak between MAF

sensor and throttle

Inta

ke air leak between throttle

and engine

Engine

breather leak

Cruis

e (speed) control vacuum

failure

Thr

ottle valve stuck open

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Chec

k the engine breather system,

REFER to Section 303

-08

Engine

Emissi

on Control

.

F

or cruise (speed) control information,

REFER to Section 310

-03

Speed

Control.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0560Vehicle voltage

malfunction

ECM battery

power supply open

circuit, high resistance

F

or ECM power supply circuit tests,

GO to Pinpoint Test AD.

.

P0566Cruise (speed) contr

ol

CANCEL

switch ON fault

Cru

ise (speed) control switches

internal steering wheel short circuit

to ground

For cru

ise (speed) control circuit tests,

REFER to Section 310

-03

Speed

Page 1393 of 2490

2.2. Switch OFF the ignition.

3. 3. Wait 10 seconds.

4. 4. Start the engine.

5. 5. Select R (reverse will be selected).

6. 6. Select D ( 2 will be selected).

The limp-home mode will be retained until the fault is remedied or the fault code has been erased. Intermittent faults may

be cleared by cycling the ignition OFF/ON. In certain cases the component may need to be operated before the fault code is

cleared eg. a shift solenoid.

Emergency Running (mechanica l/hydraulic limp-home mode)

Should slip be detected, due to a mechanical failure or loss of pressure, the transmission will either shift to, and hold 3 or

shift to, and hold, the last gear which was known to be alright. This condition may be cleared by cycling the ignition OFF/ON

following mechanical repair.

The operator will be made aware of certain faults by a warning message on th e instrument cluster.

Data concerning OBDII related transmission failures is stored in the ECM for access via the J1962 socket.

Safety Functions

These functions are designed to safeguard against inappropriate actions by the operator as well as system malfunctions.

The electrical and diagnostic system has been designed such that system integrity is protected at all times, the safety

concept being based on th e following three points.

1. 1. The hydraulic system has 'fail-safe' characteristics regardin g its electrical operation, such that should the power

supply be lost to the electro-hydraulic actuators the transmission will initiate a limp-home mode.

2. 2. Recognition of critical shift operation by monitoring the last element in the signal path, ie the solenoid valve, and

checking by means of redundant me asured variables relative to engine, transmission and road speeds.

3. 3. Each time the vehicle is started there is a check on the entire safety hardware and the associated program parts

and signal paths. A malfunction in this part of the system, or triggering of the safety circuit, is communicated to

the operator by a warning messag e on the instrument cluster.

CAUTION: Do not engage R or P with the vehicle in motion.

Should R be engaged with the vehicle in forward motion, the transmission will default to neutral until either the vehicle

speed decreases to 4 mph or D is selected.

Towing

The vehicle may be towed provided that:

Selector in position N Speed < 50 kph Distance < 50 km

System Functions

'J' Gate Layout

Page 1465 of 2490

The Drive-to-fourth switch:

Detects when the gear selector lever is moved from Drive to Fourth. Is hard-wired to the transmission control module.

The Neutral position switch:

Is hard-wired to the body processor module. Detects when the gear selector lever is moved to the Neutral position.

The Park position switch:

Is hard-wired to the body processor module. Detects when the gear selector leve r is moved to the Park position.

The gear selector module:

Provides illumination of the gear sele ctor surround, which is dimmable via a CA N signal from the instrument cluster. Provides red illumination, on the gear selector surround, of the gear selected, by CAN signals from the instrument

cluster.

Illuminates the security system Active LED on the gear se lector surround, in response to an input from the body

processor module.

Is connected to the fascia harness via a 12-way connector. Refer to Connec tor Pins Identification, 307-01A.

The gear selector interlock solenoid:

Prevents the gear selector lever from be ing moved from the Park position, unless th e ignition switch is in position II,

and the brake pedal is depressed.

Is controlled by an input from the body processor module.

The seven gear selector positions are:

P : The transmission is mechanically locked (starting available). R : Reverse gear. N : No power to the rear wh eels (starting available). D : All 5 forward gears available. 4 : Upshift to 4th gear only. 3 : Upshift to 3rd gear only. 2 : Upshift to 2nd gear only.

Performance Mode Pushbutton

The performance mode pushbutton:

Is mounted on the gear selector surround. Selects Normal or Sport mode when pressed by the driver. Is illuminated when Sport mode is selected.

Page 1744 of 2490

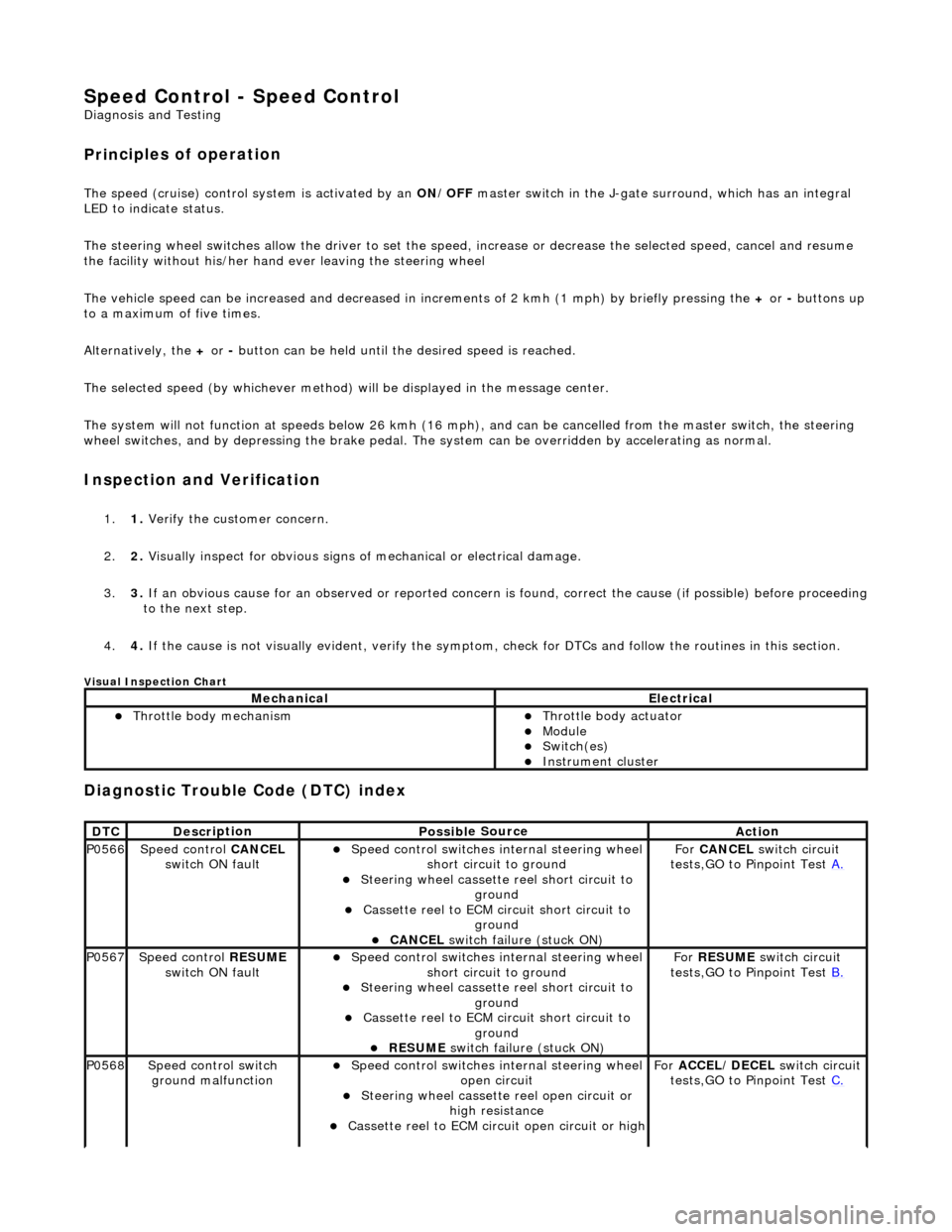

Speed Control - Speed

Control

D

iagn

osis and Testing

Pri

n

ciples of operation

The s

p

eed (cruise) control sy

stem is activated by an ON/OFF master switch in the J-gate surround, which has an integral

LED to indicate status.

The steering wheel switches allow the driver to set the speed, increase or decrease the selected speed, cancel and resume

the facility without his/her hand ever leaving the steering wheel

The vehicle speed can be increased an d decreased in increments of 2 kmh (1 mph) by briefly pressing the + or - buttons up

to a maximum of five times.

Alternatively, the + or - button can be held until th e desired speed is reached.

The selected speed (by whichever method) w ill be displayed in the message center.

The system will not function at speeds below 26 kmh (16 mph), and can be cancelled from the master switch, the steering

wheel switches, and by depressing th e brake pedal. The system can be overridden by accelerating as normal.

In

spection and Verification

1.

1. Veri fy the customer concern.

2. 2. Vis

ually inspect for obvious signs of mechanical or electrical damage.

3. 3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step.

4. 4. If the cause is not visually evident, verify the symptom, check for DTCs and follow the routines in this section.

Vi

sual Inspection Chart

Diagnostic Trouble Code (D

TC) index

MechanicalElectrical

Throttle body mechan

ism

Throttle body actuator

Module Switch(es) Instrument cluster

DTC

De

scr

iption

Possib

l

e Source

Acti

o

n

P0566Speed

c

ontrol

CANCEL

switch ON fault

Speed

control switches internal steering wheel

short circuit to ground

St

eering wheel cassette reel short circuit to

ground

Cassette reel to ECM circ

uit short circuit to

ground

CANCEL

switch failure (stuck ON)

Fo

r

CANCEL switch circuit

tests,GO to Pinpoint Test A.

P0567Speed c

ontrol

RESUME

switch ON fault

Speed

control switches internal steering wheel

short circuit to ground

St

eering wheel cassette reel short circuit to

ground

Cassette reel to ECM circ

uit short circuit to

ground

RESUME swit

ch failure (stuck ON)

For

RESUME switch circuit

tests,GO to Pinpoint Test B.

P0568Spee

d control switch

ground malfunction

Speed

control switches internal steering wheel

open circuit

St

eering wheel cassette reel open circuit or

high resistance

Cassette reel to ECM ci

rcuit open circuit or high

For

ACCEL/DECEL switch circuit

tests,GO to Pinpoint Test C.

Page 1828 of 2490

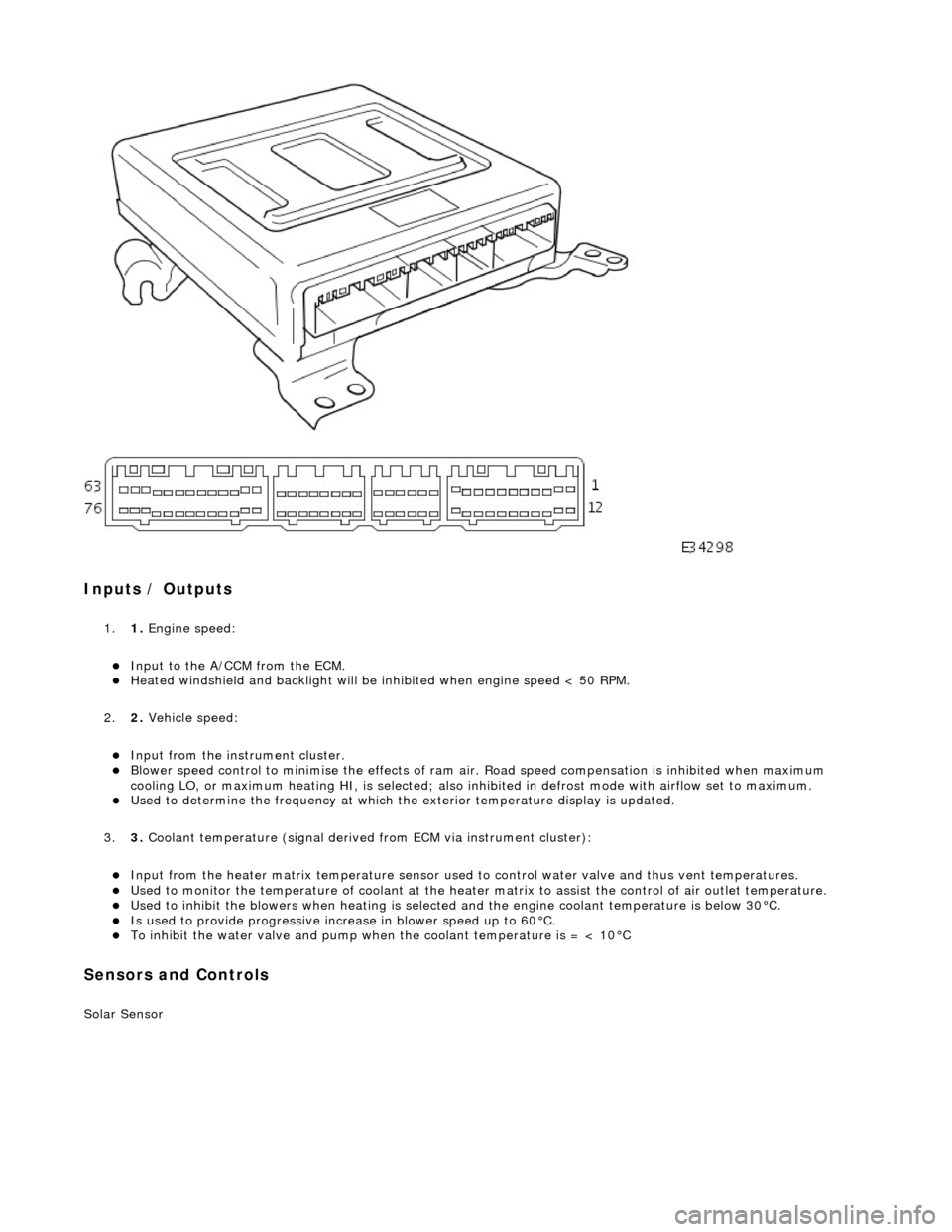

Inputs / Outputs

1.1. Engine speed:

Input to the A/CCM from the ECM. Heated windshield and backli ght will be inhibited when engine speed < 50 RPM.

2. 2. Vehicle speed:

Input from the instru ment cluster. Blower speed control to minimise the effects of ram ai r. Road speed compensation is inhibited when maximum

cooling LO, or maximum heating HI, is selected; also inhi bited in defrost mode with airflow set to maximum.

Used to determine the frequency at which the exterior temperature display is updated.

3. 3. Coolant temperature (signal derived from ECM via instrument cluster):

Input from the heater matrix temperature sensor used to control water valve and thus vent temperatures. Used to monitor the temperature of coolant at the heater matrix to assist the control of air outlet temperature. Used to inhibit the blowers when heating is selected and the engine coolant temperature is below 30°C. Is used to provide progressive increase in blower speed up to 60°C. To inhibit the water valve and pump when the coolant temperature is = < 10°C

Sensors and Controls

Solar Sensor

Page 1831 of 2490

other sensors. This feature prevents the effects of sudden changes in air outlet temperatures due to factors such as:

Recirculating air from the engine cooling pack at low vehicle speeds Sudden changes in ambient temperature The effects of water splash

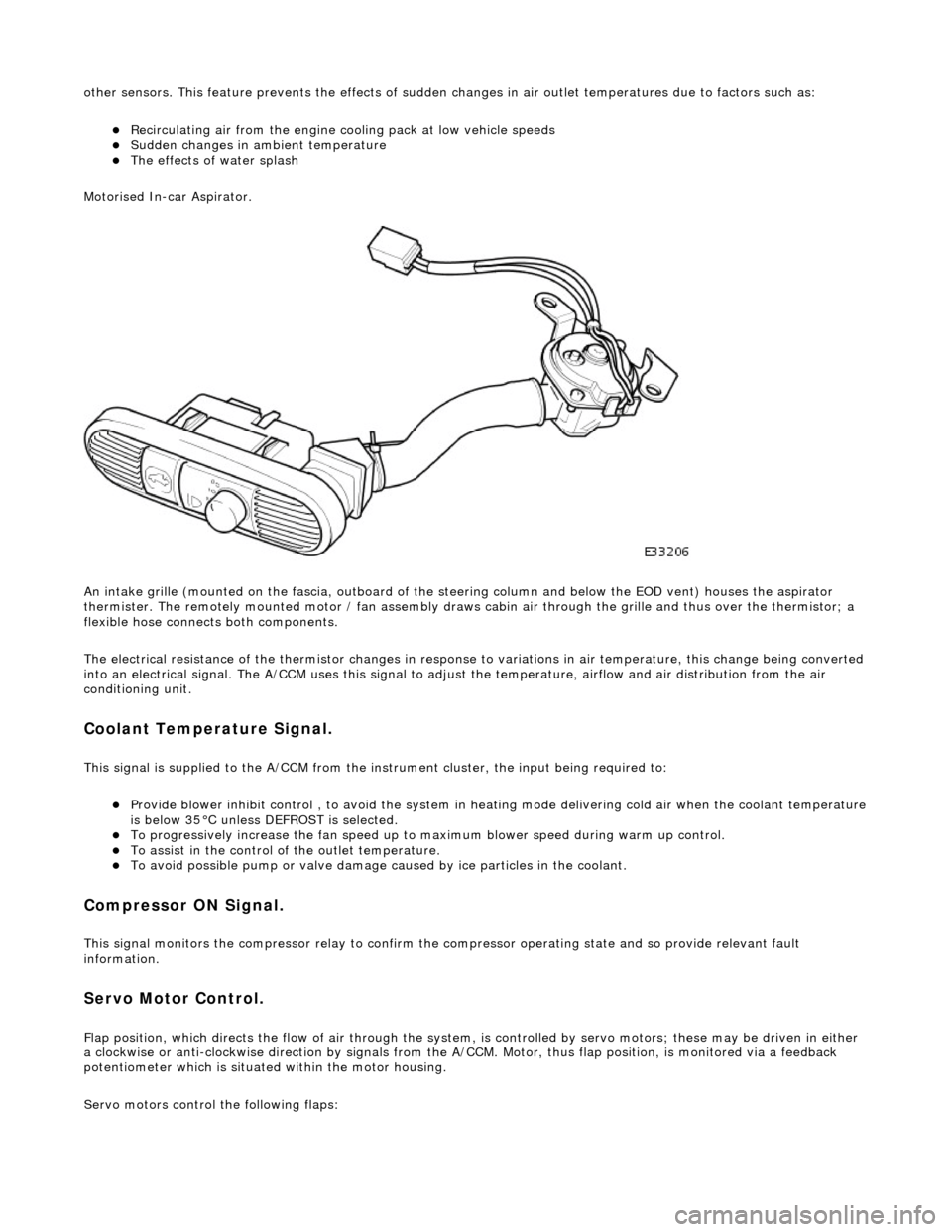

Motorised In-car Aspirator.

An intake grille (mounted on the fascia , outboard of the steering column and below the EOD vent) houses the aspirator

thermister. The remotely mounted motor / fan assembly draws ca bin air through the grille and thus over the thermistor; a

flexible hose connects both components.

The electrical resistance of the thermistor changes in response to variations in air temperatur e, this change being converted

into an electrical signal. The A/CCM uses this signal to adjust the temperature, airflow and air distribution from the air

conditioning unit.

Coolant Temperature Signal.

This signal is supplied to the A/CCM from the instrument cluster, the input being required to:

Provide blower inhibit control , to avoid the system in heat ing mode delivering cold air when the coolant temperature is below 35°C unless DEFROST is selected. To progressively increase the fan speed up to maximum blower speed during warm up control. To assist in the control of the outlet temperature. To avoid possible pump or valve damage ca used by ice particles in the coolant.

Compressor ON Signal.

This signal monitors the compressor relay to confirm the compressor operating state and so provide relevant fault

information.

Servo Motor Control.

Flap position, which directs the flow of air through the system, is controlled by servo motors; these may be driven in either

a clockwise or anti-clockwise direction by signals from the A/ CCM. Motor, thus flap position, is monitored via a feedback

potentiometer which is situated within the motor housing.

Servo motors control the following flaps:

Page 1852 of 2490

Instrument Cluster and Panel Illumination - Instrument Cluster and Panel

Illumination

Description and Operation

Details on the Instrument Cluster and Panel Illumination can be found in sections 413-01, 413-06, 413-07 and 413-08.

Page 1853 of 2490

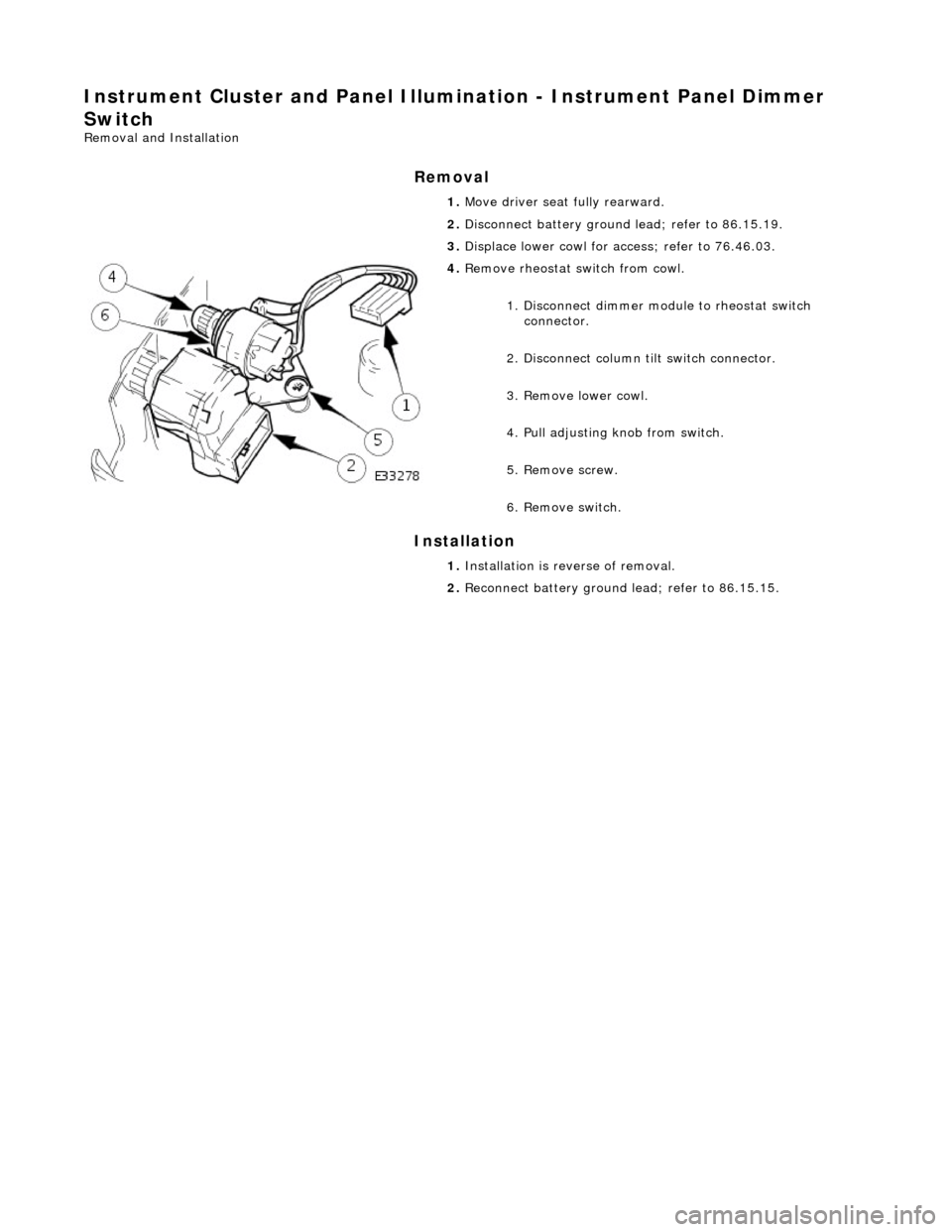

Instrument Cluster and Panel Illumination - Instrument Panel Dimmer

Switch

Removal and Installation

Removal

Installation

1.

Move driver seat fully rearward.

2. Disconnect battery ground lead; refer to 86.15.19.

3. Displace lower cowl for access; refer to 76.46.03.

4. Remove rheostat sw itch from cowl.

1. Disconnect dimmer module to rheostat switch connector.

2. Disconnect column tilt switch connector.

3. Remove lower cowl.

4. Pull adjusting knob from switch.

5. Remove screw.

6. Remove switch.

1. Installation is reverse of removal.

2. Reconnect battery ground lead; refer to 86.15.15.

Page 1854 of 2490

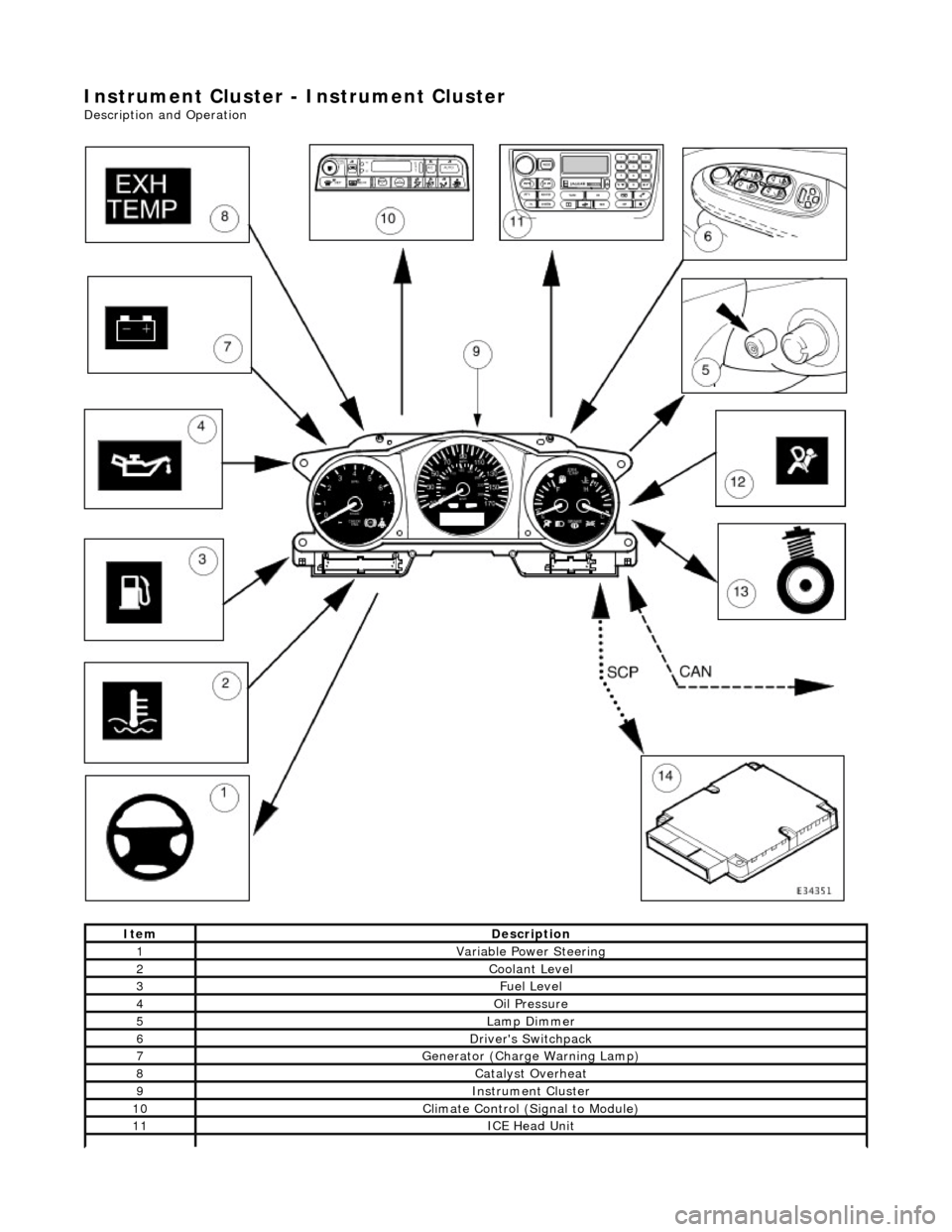

Instrument Cluster - Instrument Cluster

Description and Operation

ItemDescription

1Variable Power Steering

2Coolant Level

3Fuel Level

4Oil Pressure

5Lamp Dimmer

6Driver's Switchpack

7Generator (Charge Warning Lamp)

8Catalyst Overheat

9Instrument Cluster

10Climate Control (Signal to Module)

11ICE Head Unit