oil filter JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 14 of 2490

303‐07: En gine Ignition

Specification

Diagnosis and Testing

Engine Ignition

Diagnosis and Testing

Engine Ignition

Inspection and Verification

Driver Information Chart

Default mode Definitions

Diagnostic Trouble Code (DTC) index

Pinpoint Tests

Removal and Installation

Ignition Coil ‐On ‐Plug LH (18.20.44)

Ignition Coil ‐On ‐Plug RH (18.20.43)

Ignition Module (18.20.30)

Spark Plugs (18.20.02)

303‐08: En

gine Emission Control

Specification

Diagnosis and Testing

Engine Emission Control

Inspection and Verification

Diagnostic Trouble Code (DTC) Index

Pinpoint Tests

Removal and Installation

Exhaust Gas Recirculation (EGR) Valve (17.45.01)

Exhaust Manifold to Exhaust Gas Recirculation (E

GR) Valve Tube (17.45.11)

303‐12: Intake Air Distribution and Filtering

Removal and Installation

Air Cleaner (19.10.05)

Air Cleaner Element (19.10.08)

Charge Air Cooler LH (18.50.19)

Charge Air Cooler RH (18.50.18)

Charge Air Cooler Gasket LH (18.50.22)

Charge Air Cooler Gasket RH (18.50.21)

Supercharger (18.50.

15)

Page 16 of 2490

Knock Sensor (KS) RH (18.30.93)

Variable Camshaft Timing (VCT) Oil Co ntrol

Solenoid (18.30.90)

307: Automatic Transmission/Transaxle

307‐01A : Automatic Transmission/Transaxle ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Specification

Description and Operation

Transmission Description

Diagnosis and Testing

Diagnostic Strategy

General Procedures

Transmission Fluid Drain and Refill (44.24.02)

In‐Ve

hicle Repair

Electronic Pressure Control (EPC) Solenoid (44.15.51)

Extension Housing Seal (44.20.18)

Extension Housing O ‐Ring Seal (44.20.19)

Main Control Valve Body (44.40.01)

Output Shaft Speed (OSS) Sensor (44.15.41)

Shift Solenoids (SS) (44.15.50)

Transmission Control Module (TCM) (44.15.32)

Transmission Fluid Filter (44.24.07)

Transmission Fl

uid Pan (44.24.04)

Transmission Fluid Pan Gasket (44.24.05)

Transmission Internal Wiring Harness (44.15.35)

Transmission Internal Wiring Harness Electrical Connector O‐Ring Seals

(44.24.20)

Transmission Range (TR) Sensor

Transmission Support Insulator (12.45.04)

Turbine Shaft Speed (TSS) Sensor (44.15.40)

Removal

Transmission (44.20.01)

Disassembly and Assembly of Subassemblies

Input Sh

aft Seal (44.32.07)

Torque Converter (44.17.07)

Installation

Transmission (44.20.01)

Mass

Airflow

Sen s

or

Knock

Sensor

(KS)

LH

(18.30.92)

Page 20 of 2490

310‐01: Fu el Tank and Lines

Removal and Installation

Fuel Level Sensor (88.25.32)

Fuel Pump (19.45.08)

Fuel Tank (19.55.01)

310‐02

:

Acceleration Control

General Procedures

Accelerator Cable Adjustment (12.20.05)

Removal and Installation

Accelerator Cable (19.20.06)

310‐03: Speed Control

Diagnosis and Testing

Speed Con

trol

4: Electrical

412: Climate Control System

412‐00: Climate Control System ‐ General Information

Specification

Description and Operation

Climate Control System

Diagnosis and Testing

Climate Control System

General Procedures

Air Conditioning (A/C) System Check ‐ Retail Procedure

Air Conditioning (A/C) System Recovery, Evacuation and Charging (82.30.30)

Contaminated Refrigerant Ha

ndling

Manifold Gauge Set Connection

Refrigerant Adding (82.30.02)

Refrigerant Oil Adding

Refrigerant System Tests

412‐01: Air Distribution and Filtering

Description and Operation

Page 522 of 2490

diverter val

ve (if fitted) and oil filter.

Main

bearings

which are grooved in the upper positions and plain in

the lower positions. They are manufactured from

aluminium / tin material.

A c

rankshaft with under

cuts and rolled fillets for extra strength.

Fracture

-split connecting rods in sintered-forged steel.

Brackets

bolted to the front of

the cylinder

block are used to mo unt all accessories.

A sin

gle, seven ribbed vee belt

drives the accessories.

An au

tomatic belt tensioner for the front accessory drive,

incorporating a wear indicator.

An advanced en

gine management system inco

rporating electronic throttle control.

The un

it meets the requirements of the CARB OBDII USA legislation.

Ancillary Systems

The an

ci

llary systems, driven by the engine, each have a

detailed Description and Operation along with Diagnostic

Procedures, and Removal and Installation instructions ; refer to the following sections of this manual:

Power Steeri

ng Pump - Section 211-02

Ai

r Conditioning Compressor - Sectio

n 412-03

Engine

C

ooling Pump - Section 303-03

Generator

- Sectio

n 414-02

The drive belt, idler pulley and automatic tensioner are described in Section 303-05.

The engine starting system is described in Section 303-06.

En

gine Management and Emission Control System

Engine Control Modu

le (ECM)

Engine

management and exhaust emissions are controlled by the ECM, which has the

following main functions:

Fu

el injection

Idle

s

peed

Ignition Ev

aporative loss system

Engine

cooling fans Clim

ate control compressor clutch demand

The microprocessor within the ECM receiv es signals from various sensors and other modules and uses a pre-determined

program to compute engine management functions.

Adaptive functions are incorporated in the ECM to cater for co ntinuous adjustments to its computations to suit prevailing

conditions. Because the system also controls emissions to suit all modes, neither CO levels nor idle speed require service

attention or adjustment, except if an error should occur.

On Board Diagnostics are controlled by the ECM with the continuous monitoring of incoming signals and the subsequent

verification against what the module expects to 'see'. Should a si gnal be incorrect or missing, the ECM will substitute a fixed

value to provide the 'limp home mode' and alert the driver of the problem. Fixed values may be adopted for:

Transmission oil

temperature

Mechanica

l

guar

d position

Throttle blade angle Camshaft position

Inta

k

e air temperature

Diagnostic trouble codes (DTC), including OBD II codes, are stored in the ECM memo ry and can be read by an appropriate

retrieval tool.

Should either the ECM or TCM fa il, ensure that the control housing cooling fan is operating correctly. Failure of the cooling

fan MUST be rectified before renewing a control module and details of a fa n failure should accompany a returned control

module.

Page 555 of 2490

I

nstallation

Tigh

ten each bolt to 8 to 12 Nm initial torque value.

Ti

ghten to a final torque of 57 to 63 Nm.

27. Check that the cranks haft turns freely.

28. Repeat the previous operations for each connecting rod

bearing as necessary.

1. Install the oil pan bo dy assembly. Refer to Operation 12.60.48.

2. Po

sition and align the oil pan gasket to the oil pan body

assembly.

Inse

rt the seal into the locating positions in the groove,

working around from a corner.

Press in the remai

nder of th

e seal, following the same

procedure.

3. Install th

e oil pan to the oil pan body.

1. Position and align the oil pan.

2. Install, but do not tighte n, all eighteen bolts which

secure the oil pan.

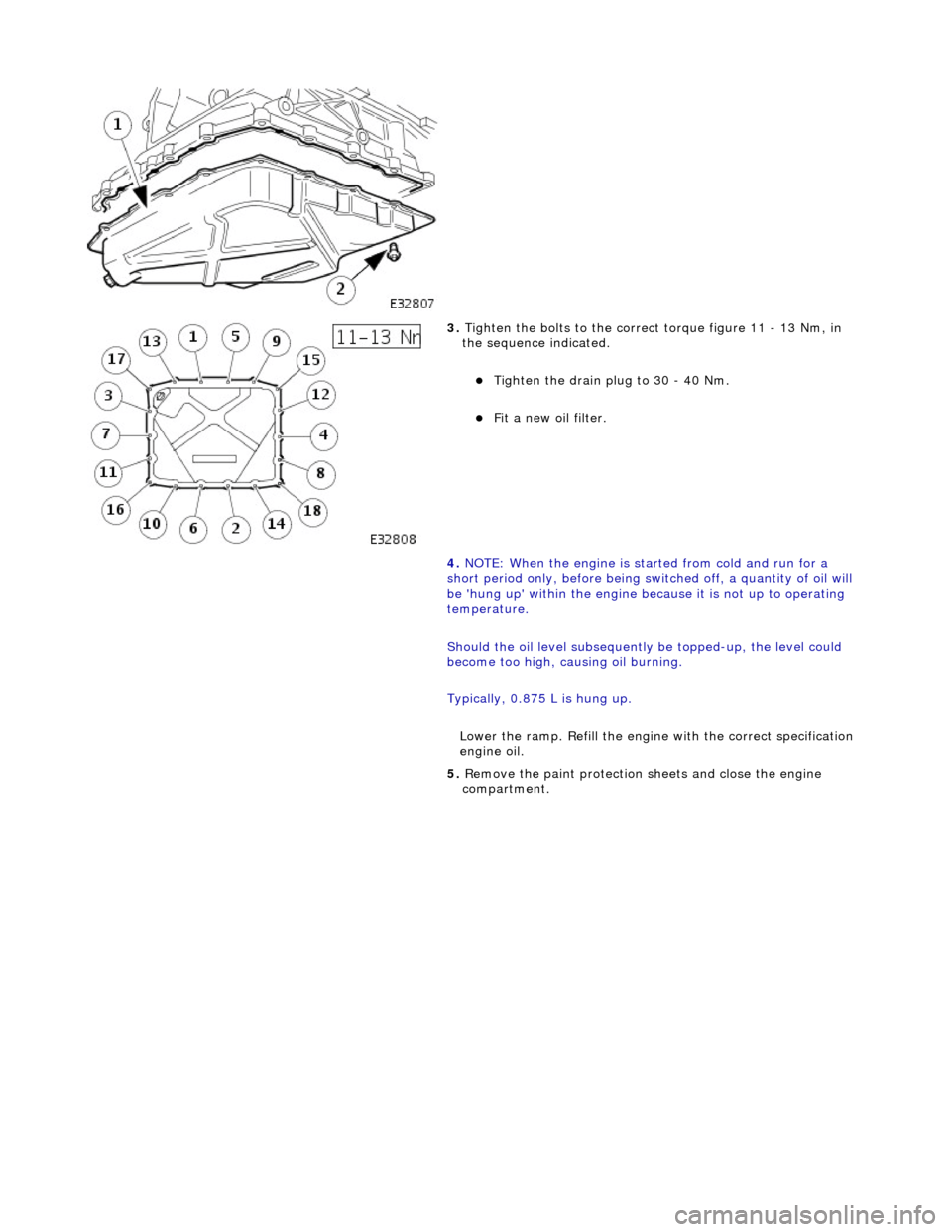

4. Tigh

ten the bolts to the correct

torque figure 11-13 Nm, in the

sequence indicated.

Tigh

ten the drain plug to 30-40 Nm.

Install a new oil

filter.

Page 753 of 2490

3. Tighten the bolts to the correct torque figure 11 - 13 Nm, in

the sequence indicated.

Tighten the drain plug to 30 - 40 Nm.

Fit a new oil filter.

4. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will

be 'hung up' within the engine because it is not up to operating

temperature.

Should the oil level subsequently be topped-up, the level could

become too high, causing oil burning.

Typically, 0.875 L is hung up.

Lower the ramp. Refill the engine with the correct specification

engine oil.

5. Remove the paint protection sheets and close the engine

compartment.

Page 754 of 2490

Engine - Oil Pressure Switch

In-vehicle Repair

Removal

Installation

1.

Raise vehicle on four post ramp.

2. Remove oil pressure switch.

Disconnect connector.

Remove oil pressure switch from oil filter head.

1. NOTE: Fit new sealing washer to oil pressure switch.

Installation is reverse of removal.

Page 830 of 2490

Engine - Upper Oil Pan3.2L NA V8 - AJ26

In-vehicle Repair

Removal

Special Tool(s)

Installer/remover, Oil Filter

303-752

1. Disconnect the batt ery ground cable.

Remove the battery cover.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Set the engine compartment cover to the service access

position.

4. Remove the timing cover and al l associated components, as

detailed in Operation 12.65.01.

5. Remove both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

6. Remove the undertray. Re fer to Operation 76.22.90.

7. Remove the two bolts which secu re the generator cooling duct

to the oil pan body and remove the duct.

8. Remove the front cross member for access. Refer to Operation

76.10.05.

9. Drain the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Fit a new sealing washer to the drain plug.

Page 831 of 2490

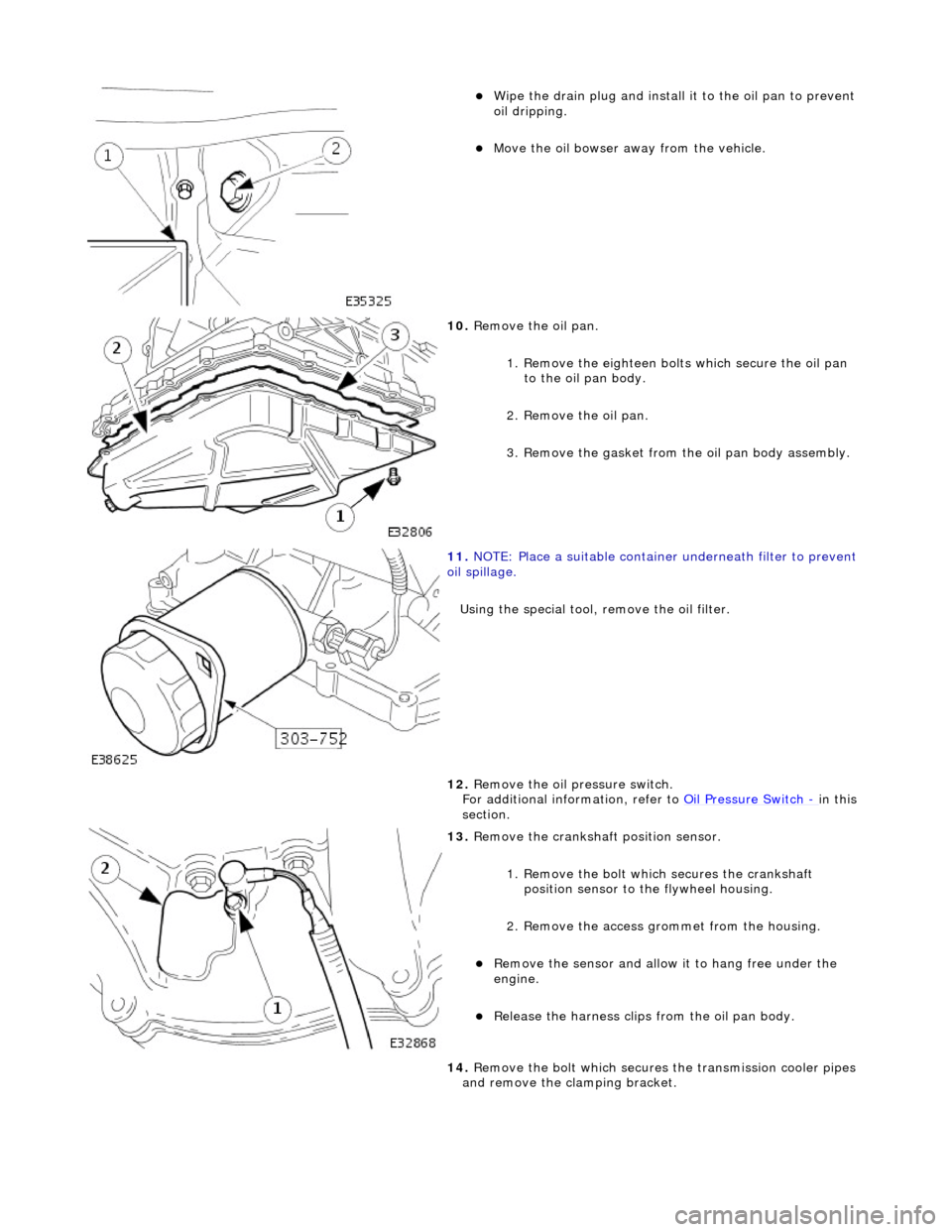

Wipe the drain plug and install it to the oil pan to prevent

oil dripping.

Move the oil bowser away from the vehicle.

10. Remove the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

11. NOTE: Place a suitable container underneath filter to prevent

oil spillage.

Using the special tool, remove the oil filter.

12. Remove the oil pressure switch.

For additional information, refer to Oil Pressure Switch

- in this

section.

13. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

2. Remove the access grommet from the housing.

Remove the sensor and allow it to hang free under the

engine.

Release the harness clips from the oil pan body.

14. Remove the bolt which secures the transmission cooler pipes

and remove the clamping bracket.

Page 833 of 2490

Installation

19. Remove the eight screws an d release the windage tray.

20. Remove the oil filter adaptor.

21. Clean all components and releva nt mating faces; cylinder

block, oil pan, oil pan body, wi ndage tray, oil pick-up pipe and

timing cover.

1. Reposition the windage tray and install the eight screws,