wheel JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 439 of 2490

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to E2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Rear Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

E2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Di

sconnect the ABS module connector, LF27.

2

Meas

ure the resistance between LF27

, pin 21 (U) and LA02, pin 01 (U).

3

I

s the resistance less than 5 ohms?

Yes GO to E3

.

No

Repair the high resistance circui t. This circuit includes intermediate connector, LA02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

E3

: CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure the resistance between LF27

, pin 22 (U) and LA02, pin 02 (U).

1

I

s the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, CA29. Refer to the

electrical guides. Clear the DTC, check for normal operation.

P

INPOINT TEST F : CONT

ROLLER AREA NETWORK (CAN) INTEGRITY TEST

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

F

1: CHECK THE NETWORK INTEGRITY

FROM THE DIAGNOSTIC SOCKET

M

easure the resistance between pins 06 (Y) and 14 (G) of the diagnostic socket.

1

I

s the resistance 60 ohms?

Yes The CAN system is OK. Check for DTCs indicating a fault elsewhere.

No Check the CAN system for open an d short circuits. Refer to the electrical guides. Clear the DTC,

check for normal operation.

Page 440 of 2490

Anti-Lock Control - Anti-Lock Brake System (ABS) Module

Remo

val and Installation

Remov

a

l

• C

A

UTIONS:

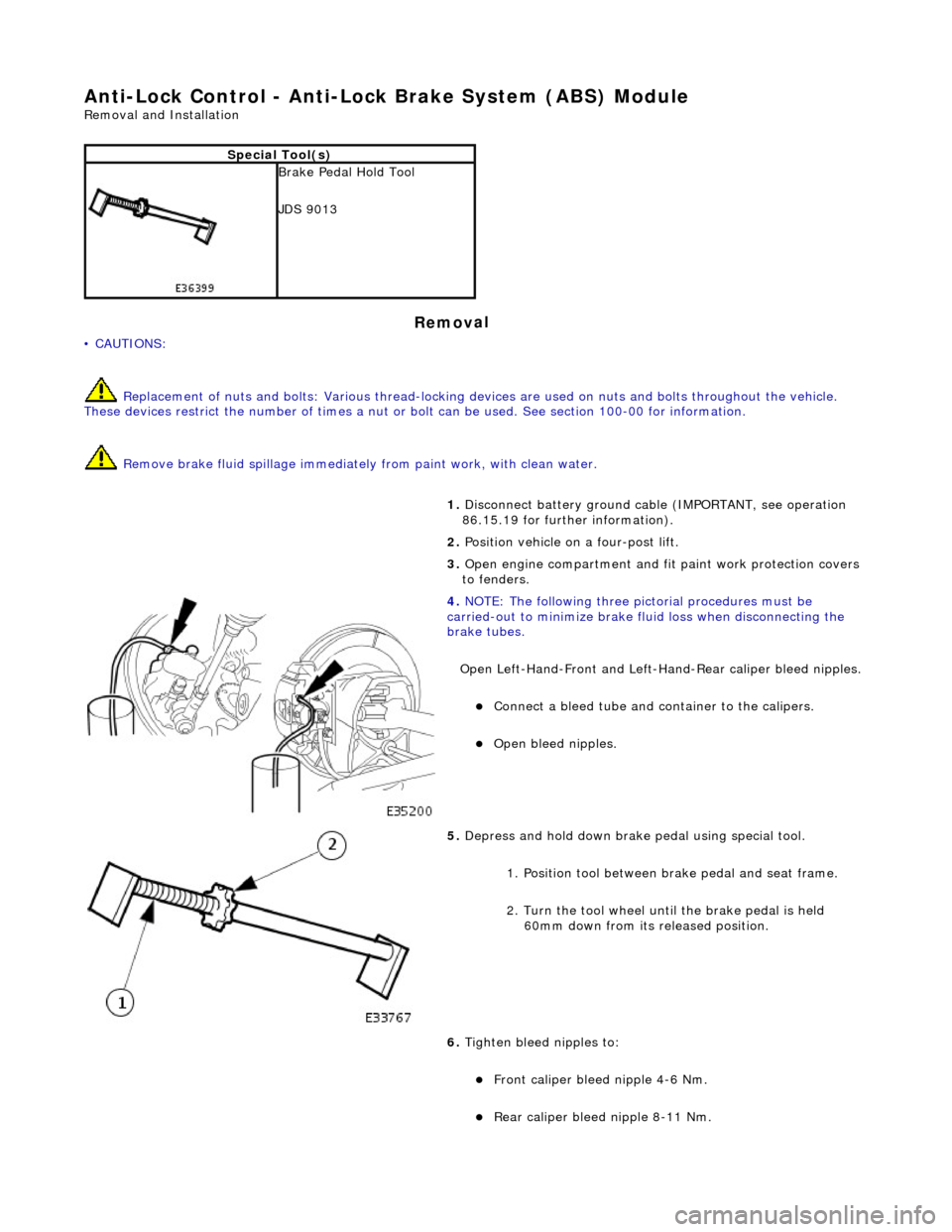

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

Sp

ecial Tool(s)

Brake Pedal

H

old Tool

JDS 9013

1. Disc onne

ct battery ground cable (IMPORTANT, see operation

86.15.19 for further information).

2. Position vehicle on a four-post lift.

3. Open engine compartment and fit paint work protection covers

to fenders.

4. NOTE : Th

e following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake tubes.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect a

bleed tube and co

ntainer to the calipers.

Op

en bleed nipples.

5. Depress and hold down brake pedal u s

ing special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

60mm down from its released position.

6. Tighten bleed nipples to:

Front caliper blee d nipple 4-6 Nm.

Rear

caliper bleed nip

ple 8-11 Nm.

Page 444 of 2490

Anti-Lock Control - Front Wheel Speed Sensor

Remo

val and Installation

Remov

a

l

Installation

1.

Ra

ise front of vehicle and support

on stands. Refer to section

100-02.

2. Remove wh

eel speed sensor.

Di

sc

onnect harness connector.

Re

mo

ve bolt.

3. Clean components and mating surfaces.

1. Inst al

l wheel speed sensor.

Posit

i

on sensor.

Install and tigh

ten bolt to 8-1

0 Nm.

Conne

ct

harness connector.

2. Remove stands an d lower vehicle.

Page 445 of 2490

Anti-Lock Control - Hydraulic Contro

l Unit (HCU)

Re

moval and Installation

Remov

al

• C

AUTIONS:

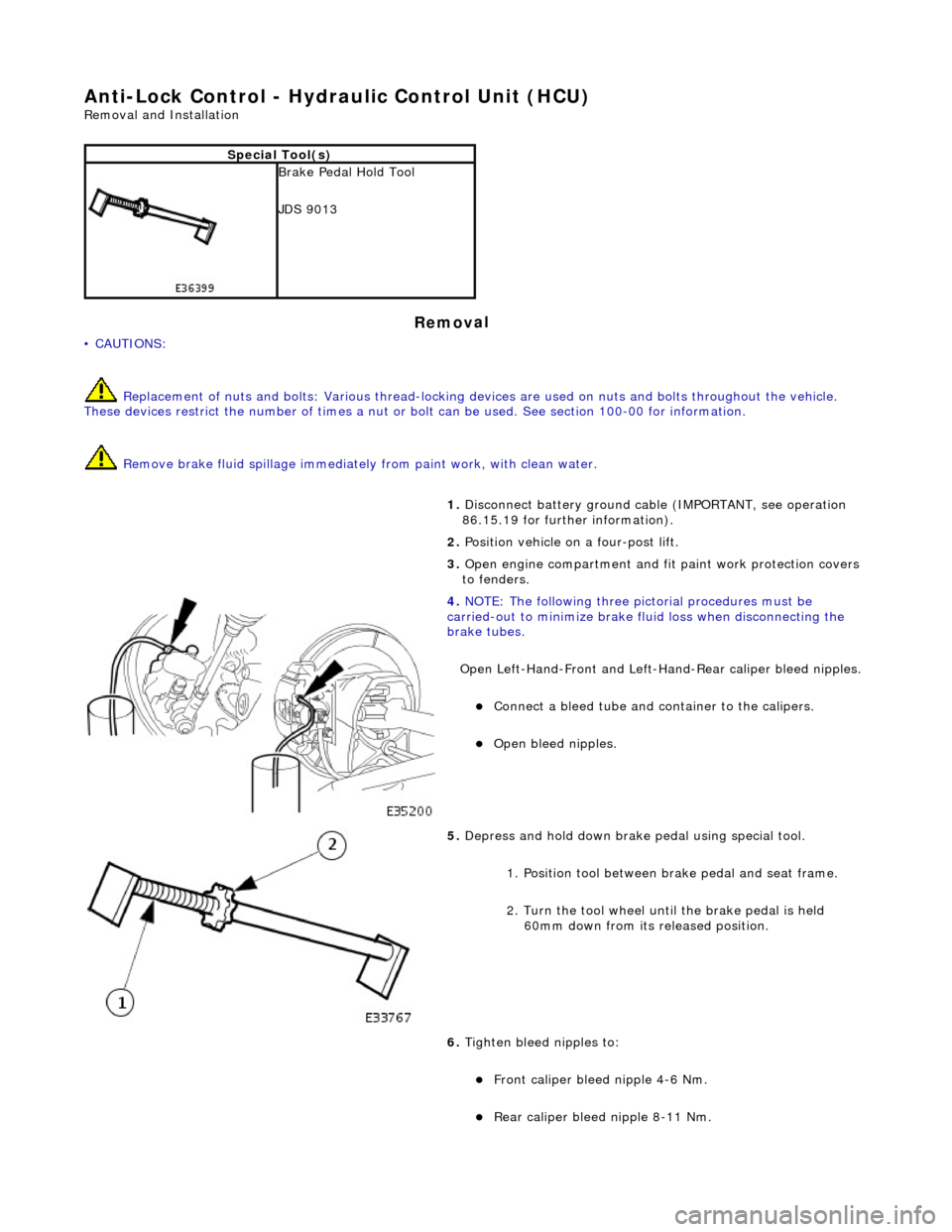

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

S

pecial Tool(s)

Brake Pedal

Hold Tool

JDS 9013

1. Disc

onnect battery ground cable (IMPORTANT, see operation

86.15.19 for further information).

2. Position vehicle on a four-post lift.

3. Open engine compartment and fit paint work protection covers

to fenders.

4. NOTE

: The following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake tubes.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect

a bleed tube and co

ntainer to the calipers.

O

pen bleed nipples.

5. Depress and hold down brake pedal u

sing special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

60mm down from its released position.

6. Tighten bleed nipples to:

Front caliper blee d nipple 4-6

Nm.

Rear

caliper bleed nipple 8-11 Nm.

Page 449 of 2490

Anti-Lock Control - Rear Wheel Speed Sensor

Re

moval and Installation

Remov

al

Installation

1.

R

aise rear of vehicle and support

on stands. Refer to section

100-02.

2. Re

move wheel speed sensor.

Di

sconnect harness connector.

Re

move bolt.

3. Clean components and mating surfaces.

1. Inst

all wheel speed sensor.

Posit

ion sensor.

Install and tigh

ten bolt to 8-10 Nm.

Conne

ct harness connector.

2. Remove stands an d lower vehicle.

Page 450 of 2490

Anti-Lock Control - Wheel Speed Se

nsor Ring

Re

mo

val and Installation

Remov

a

l

CAUTI

O

N: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

S p

ecial Tool(s)

Hub Holdin

g Tool

2

04-195 (JD 227)

ABS Rotor Nut Socket

2

06-

066A

1.

Op

en engine compartment and

fit paintwork protectors to

fenders.

2. Raise front of vehicle and support on stands. Refer to section

100-02.

3. Remove front wheel. Re fer to section 204-04.

4. Remove front brake disc. Refer to operation 70.10.12.

5. Remove vertical link and hub assembly. Refer to operation

60.25.38.90.

6. Re

move brake-disc shield from vertical link.

1. Remove screws.

2. Remove disc shield.

7. Using special tool, secure vertical link and hub assembly in a

vice.

Secure special tool

in a vice.

Posit

i

on hub in tool.

Fit and

tighten wheel nuts.

Page 452 of 2490

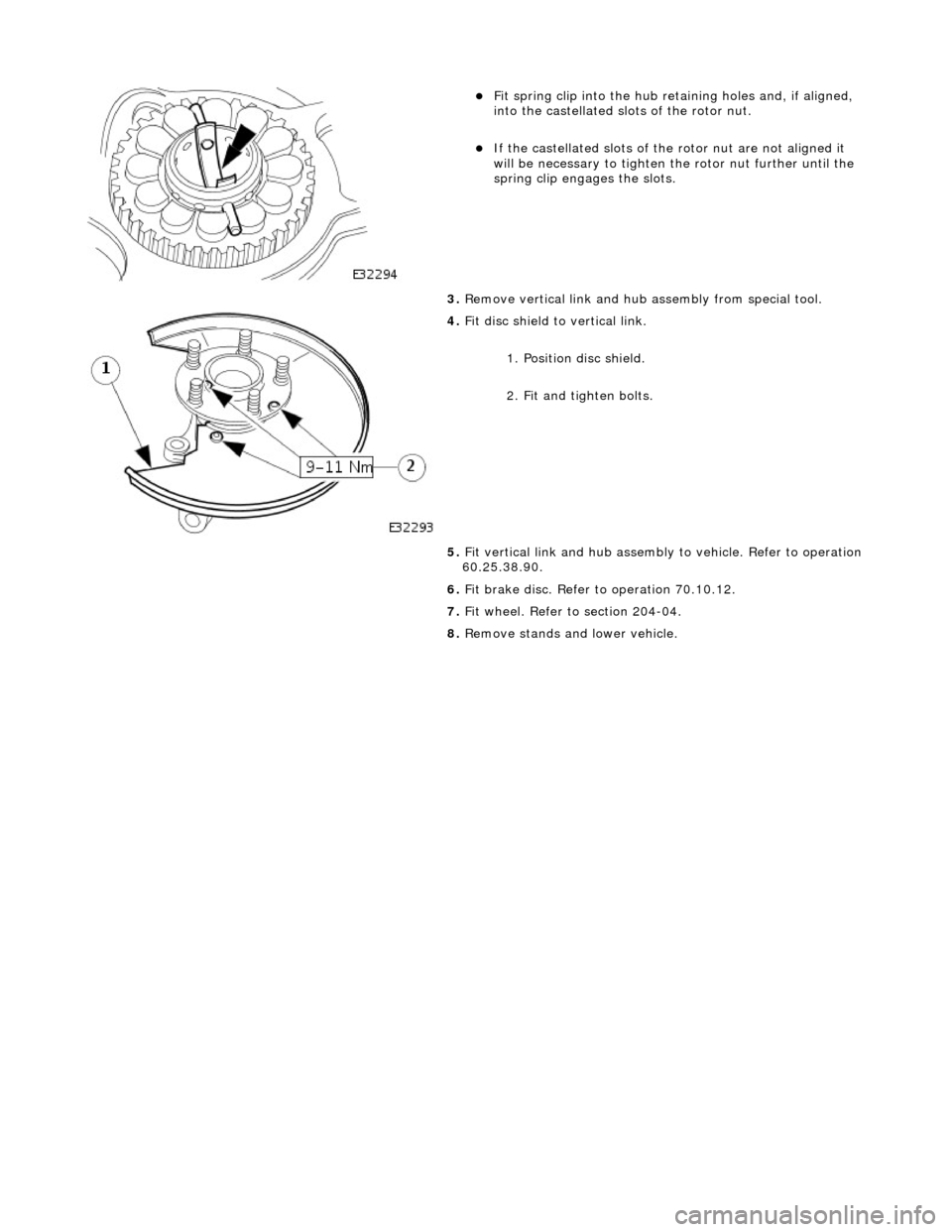

Fit sp

ring clip into the hub retaining holes and, if aligned,

into the castellated slots of the rotor nut.

If t he

castellated slots of the rotor nut are not aligned it

will be necessary to tighten the rotor nut further until the

spring clip engages the slots.

3. Remove vertical link and hub assembly from special tool.

4. Fi

t disc shield to vertical link.

1. Position disc shield.

2. Fit and tighten bolts.

5. Fit vertical link and hub assembly to vehicle. Refer to operation

60.25.38.90.

6. Fit brake disc. Refer to operation 70.10.12.

7. Fit wheel. Refer to section 204-04.

8. Remove stands an d lower vehicle.

Page 453 of 2490

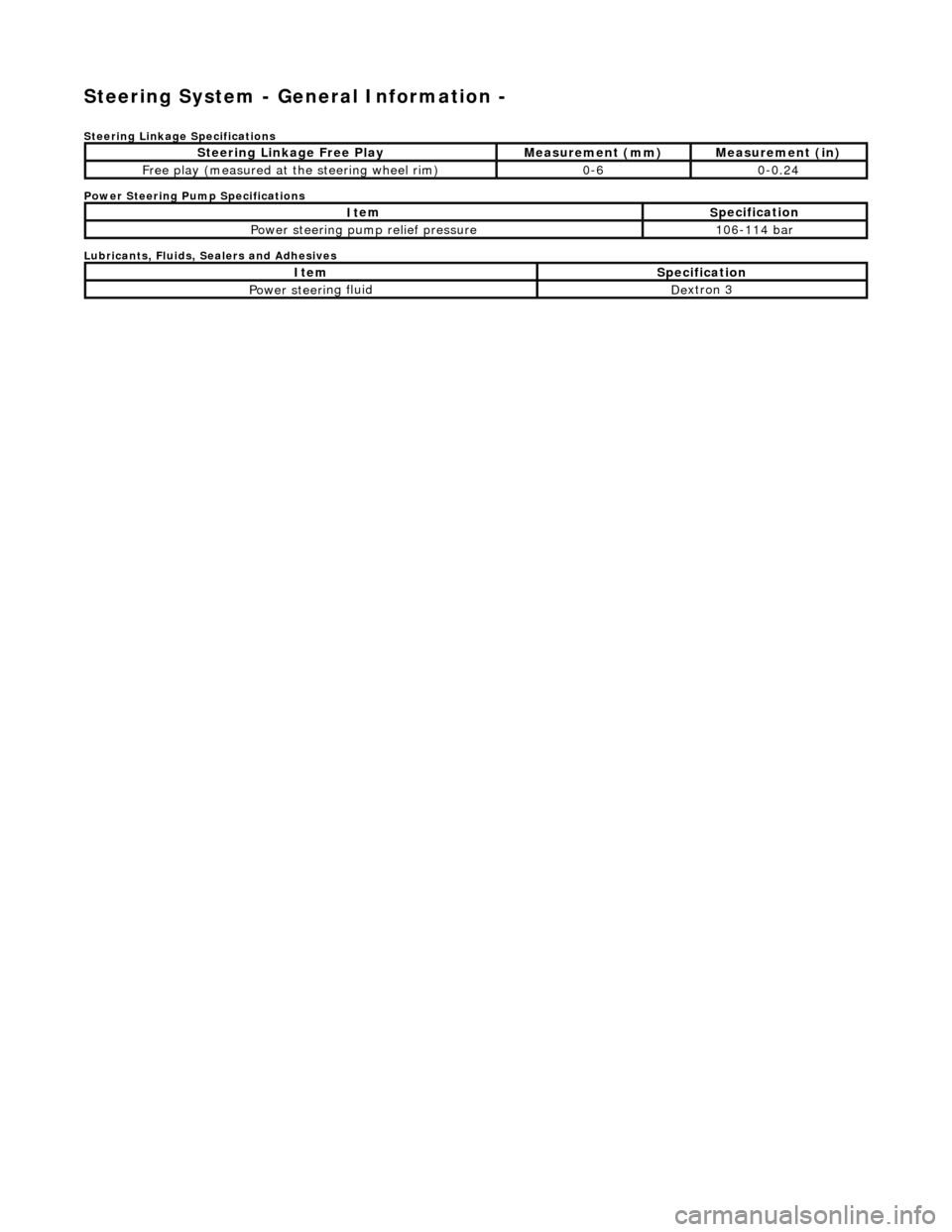

Stee

ring System - General Information -

S

teering Linkage Specifications

Power Steering Pump Specifications

Lubricants, Fluids, Sealers and Adhesives

S

teering Linkage Free Play

Meas

urement (mm)

Meas

urement (in)

F

ree play (measured at

the steering wheel rim)

0-

6

0

-0.24

It

em

S

pecification

Power steeri

ng pump relief pressure

10

6-114 bar

It

em

S

pecification

Power steeri

ng fluid

De

xtron 3

Page 455 of 2490

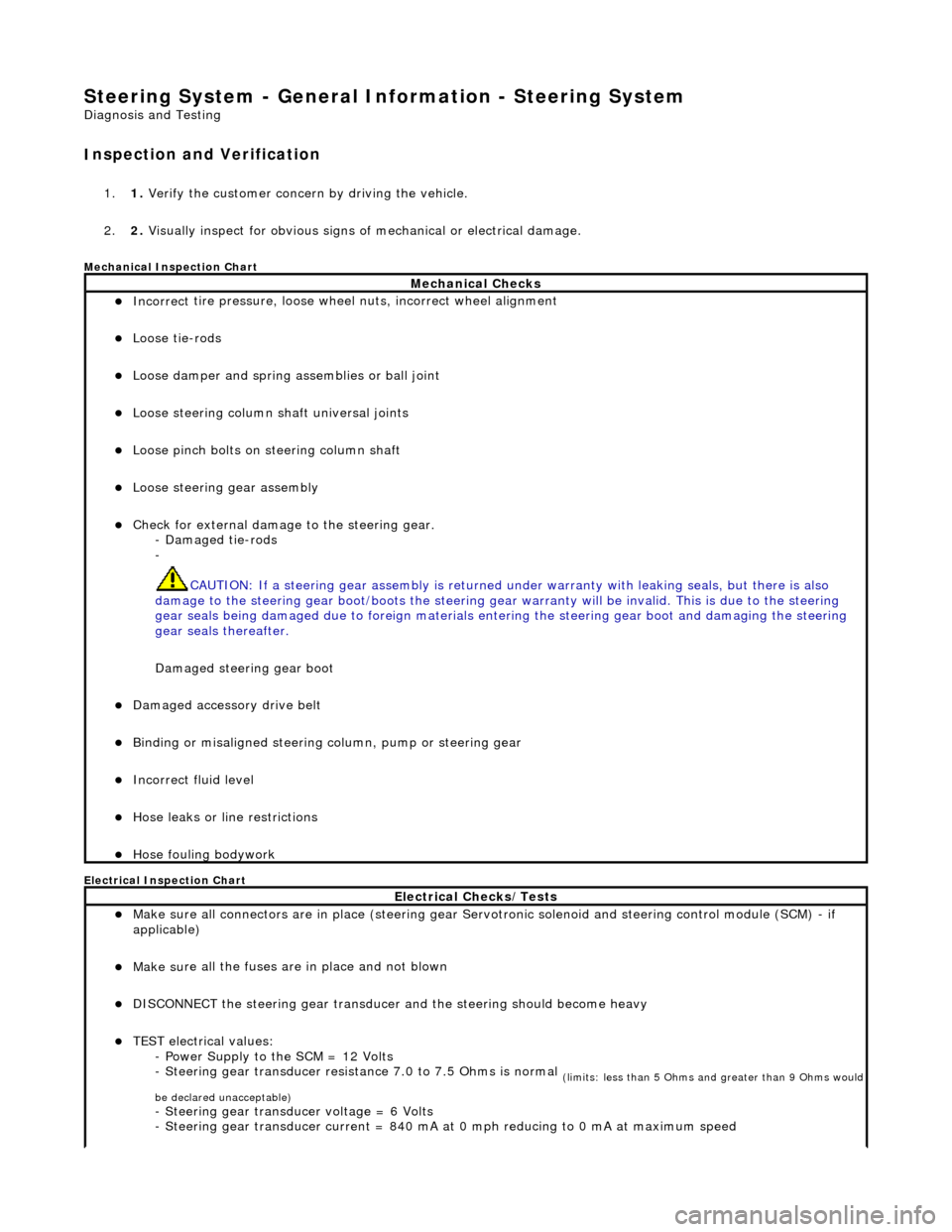

Steering System - General Inform

ation - Steering System

D

iagnosis and Testing

I

nspection and Verification

1.

1. Verify t

he customer concern by driving the vehicle.

2. 2. Visually inspect for obvious signs of mechanical or electrical damage.

Mec

hanical Inspection Chart

Electrical Inspection Chart

Mechanical Checks

Incorrect

tire pressure, loose whee

l nuts, incorrect wheel alignment

Loose ti

e-rods

Loose dam

per and spring assemblies or ball joint

Loose s

teering column shaft universal joints

Loose pinc

h bolts on steering column shaft

Loose steeri

ng gear assembly

Check f

or external damage to the steering gear.

- Damaged tie-rods

-

CAUTION: If a steering gear assemb ly is returned under warranty with leaking seals, but there is also

damage to the steering gear boot/boots the steering gear warranty will be invalid. This is due to the steering

gear seals being damaged due to fore ign materials entering the steering gear boot and damaging the steering

gear seals thereafter.

Damaged steering gear boot

Damaged accessory driv

e belt

Bin

ding or misaligned steering co

lumn, pump or steering gear

Incorrect fluid

level

Hose leaks o

r line restrictions

Hose fou

ling bodywork

El

ectrical Checks/Tests

Make sure all

connectors are in plac

e (steering gear Servotronic solenoid and steering control module (SCM) - if

applicable)

Make su

re all the fuses are in place and not blown

D

ISCONNECT the steering gear transducer

and the steering should become heavy

TEST e

lectrical values:

- Power Supply to the SCM = 12 Volts

- Steering gear transducer resist ance 7.0 to 7.5 Ohms is normal

(

limits: less than 5 Ohms and greater than 9 Ohms would

be declared unacceptable)

- Steeri

ng gear transducer voltage = 6 Volts

- Steering gear transducer cu rrent = 840 mA at 0 mph reducing to 0 mA at maximum speed

Page 457 of 2490

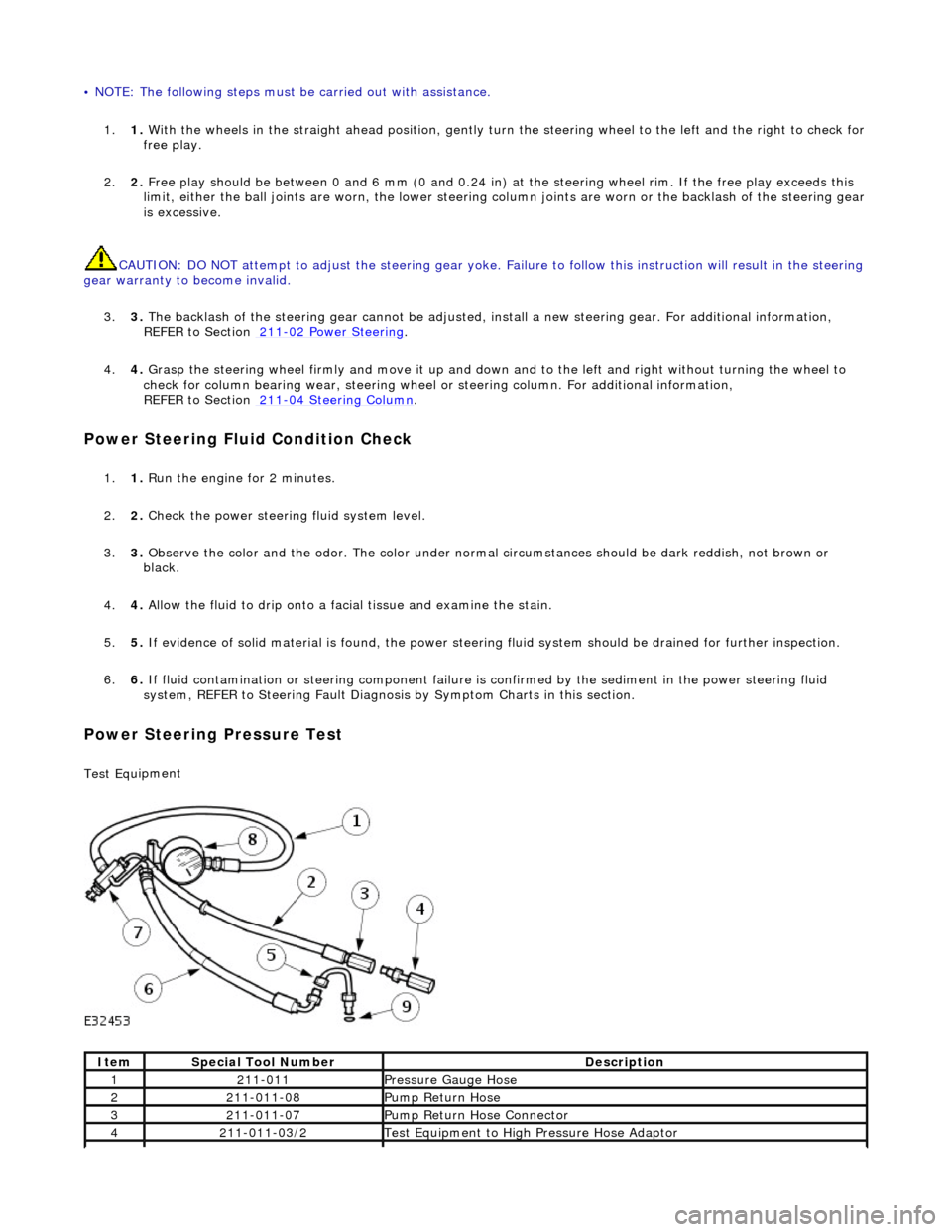

•

NOTE: The following steps must be carried out with assistance.

1. 1. With the wheels in the straight ahead po sition, gently turn the steering wheel to the left and the right to check for

free play.

2. 2. Free play should be between 0 and 6 mm (0 and 0.24 in) at the steering wheel rim. If the free play exceeds this

limit, either the ball joints are worn, the lower steering column joints are worn or the backlash of the steering gear

is excessive.

CAUTION: DO NOT attempt to adjust the stee ring gear yoke. Failure to follow this instruction will result in the steering

gear warranty to become invalid.

3. 3. The backlash of the steering gear cannot be adjusted, in stall a new steering gear. For additional information,

REFER to Section 211

-0

2 Power Steering

.

4. 4. Grasp the steering wheel

firm

ly and move it up and down and to the left and right without turning the wheel to

check for column bearing wear, steering wheel or steering column. For additional information,

REFER to Section 211

-0

4 Steering Column

.

Power Steering Fluid Condition Check

1.

1. R

un the engine for 2 minutes.

2. 2. Check the power steering fluid system level.

3. 3. Observe the color and the odor. The color under normal circumstances should be dark reddish, not brown or

black.

4. 4. Allow the fluid to drip onto a faci al tissue and examine the stain.

5. 5. If evidence of solid material is foun d, the power steering fluid system should be drained for further inspection.

6. 6. If fluid contamination or steering co mponent failure is confirmed by the se diment in the power steering fluid

system, REFER to Steering Fault Diagnosis by Symptom Charts in this section.

Power Steer

ing Pressure Test

Test Equ

ipment

It

em

S

pecial Tool Number

De

scription

12

11-011

Pres

sure Gauge Hose

221

1-011-08

Pump Return Hose

321

1-011-07

Pump Return Hose Connector

42

11-011-03/2

Test Equ

ipment to High

Pressure Hose Adaptor