JAGUAR X308 1998 2.G Workshop Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Workshop Manual

Page 1384 of 2490

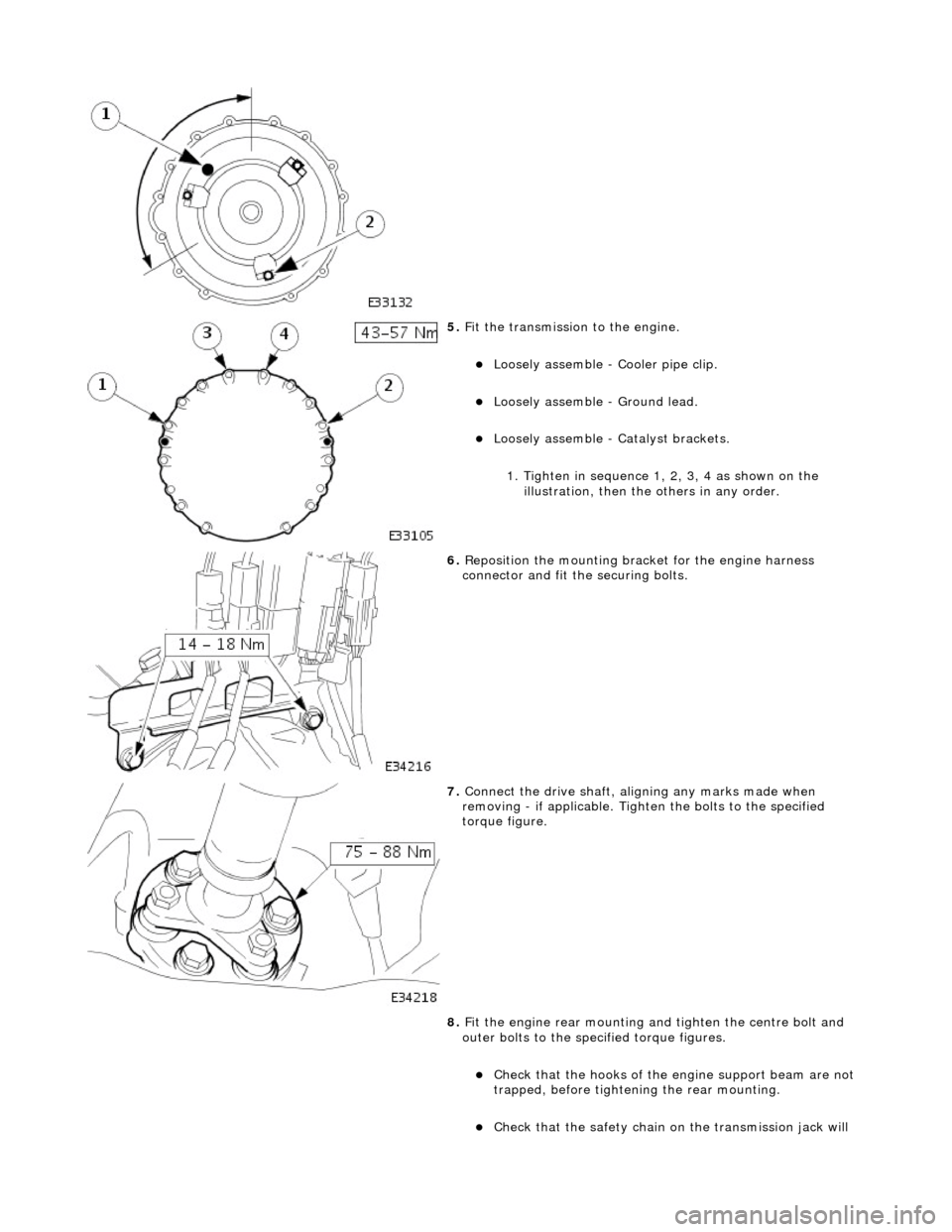

5. Fit the transmission to the engine.

пЃ¬Loosely assemble - Cooler pipe clip.

пЃ¬Loosely assemble - Ground lead.

пЃ¬Loosely assemble - Ca talyst brackets.

1. Tighten in sequence 1, 2, 3, 4 as shown on the illustration, then the others in any order.

6. Reposition the mounting brac ket for the engine harness

connector and fit the securing bolts.

7. Connect the drive shaft, aligning any marks made when

removing - if applicable. Tighten the bolts to the specified

torque figure.

8. Fit the engine rear mounting and tighten the centre bolt and

outer bolts to the specified torque figures.

пЃ¬Check that the hooks of the engine support beam are not

trapped, before tighteni ng the rear mounting.

пЃ¬Check that the safety chain on the transmission jack will

Page 1397 of 2490

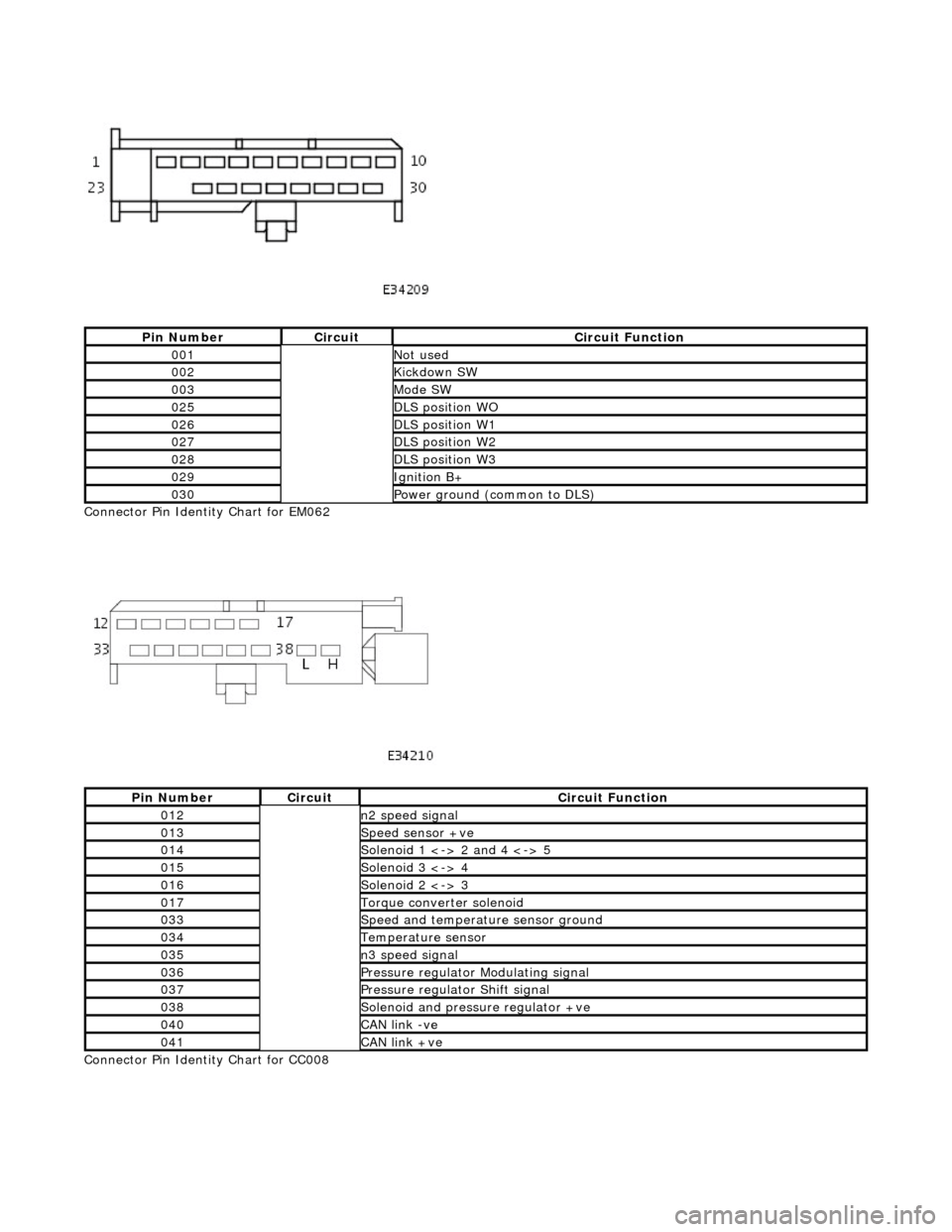

Connector Pin Identity Chart for EM062

Connector Pin Identity Chart for CC008

Pin NumberCircuitCircuit Function

001Not used

002Kickdown SW

003Mode SW

025DLS position WO

026DLS position W1

027DLS position W2

028DLS position W3

029Ignition B+

030Power ground (common to DLS)

Pin NumberCircuitCircuit Function

012n2 speed signal

013Speed sensor +ve

014Solenoid 1 <-> 2 and 4 <-> 5

015Solenoid 3 <-> 4

016Solenoid 2 <-> 3

017Torque converter solenoid

033Speed and temperature sensor ground

034Temperature sensor

035n3 speed signal

036Pressure regulator Modulating signal

037Pressure regulator Shift signal

038Solenoid and pressure regulator +ve

040CAN link -ve

041CAN link +ve

Page 1398 of 2490

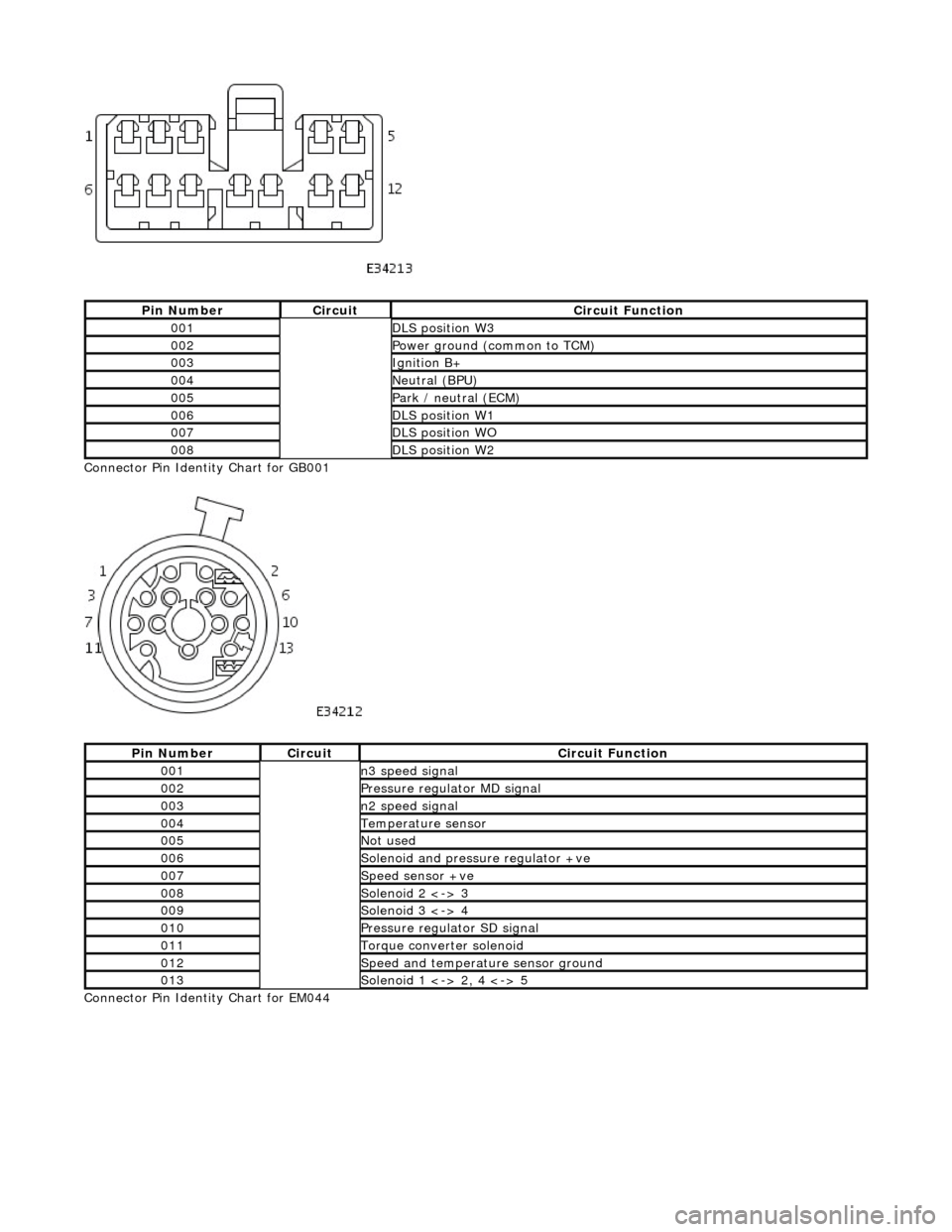

Connector Pin Identity Chart for GB001

Connector Pin Identity Chart for EM044

Pin NumberCircuitCircuit Function

001DLS position W3

002Power ground (common to TCM)

003Ignition B+

004Neutral (BPU)

005Park / neutral (ECM)

006DLS position W1

007DLS position WO

008DLS position W2

Pin NumberCircuitCircuit Function

001n3 speed signal

002Pressure regulator MD signal

003n2 speed signal

004Temperature sensor

005Not used

006Solenoid and pressure regulator +ve

007Speed sensor +ve

008Solenoid 2 <-> 3

009Solenoid 3 <-> 4

010Pressure regulator SD signal

011Torque converter solenoid

012Speed and temperature sensor ground

013Solenoid 1 <-> 2, 4 <-> 5

Page 1399 of 2490

Pin NumberCircuitCircuit Function

001n3 speed signal

002Pressure regulator MD signal

003n2 speed signal

004Temperature sensor

005Solenoid 1 <-> 2, 4 <-> 5

006Solenoid and pressure regulator +ve

007Speed sensor +ve

008Solenoid 2 <-> 3

009Solenoid 3 <-> 4

010Pressure regulator SD signal

011Torque converter solenoid

012Speed and temperature sensor ground

Page 1407 of 2490

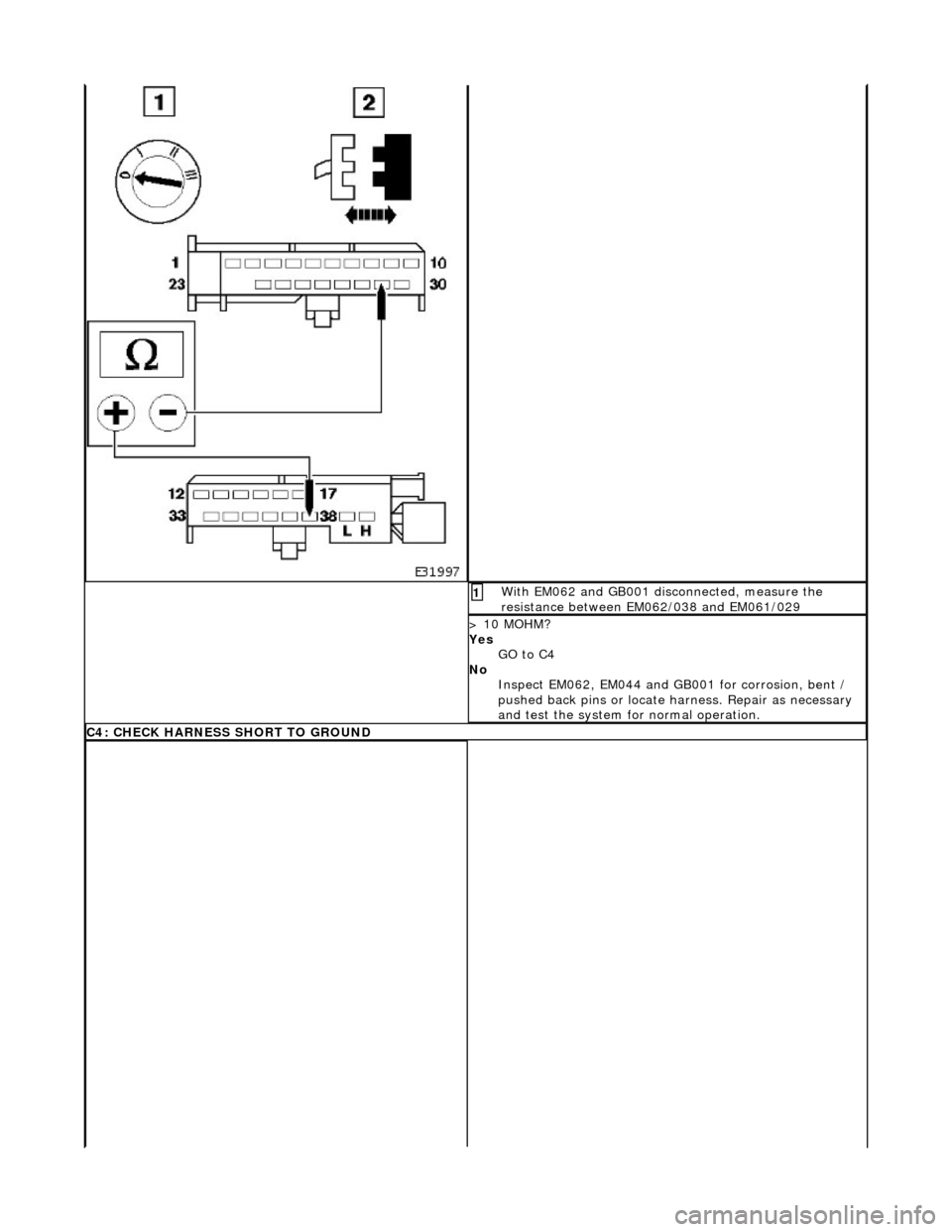

With EM062 and GB001 disconnected, measure the

resistance between EM062/038 and EM061/029 1

> 10 MOHM?

Yes GO to C4

No Inspect EM062, EM044 and GB001 for corrosion, bent /

pushed back pins or locate harness. Repair as necessary

and test the system for normal operation.

C4: CHECK HARNESS SHORT TO GROUND

Page 1410 of 2490

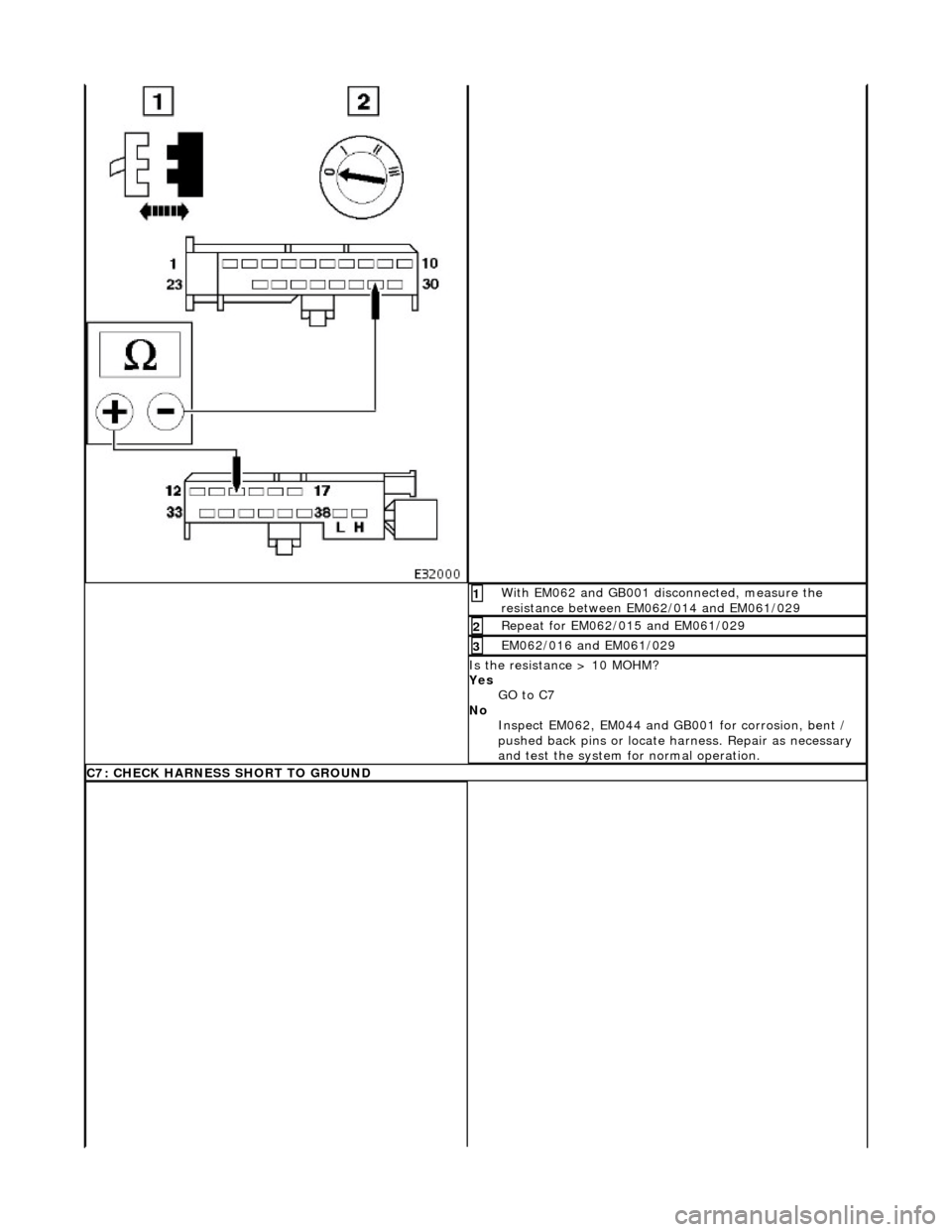

With EM062 and GB001 disconnected, measure the

resistance between EM062/014 and EM061/029 1

Repeat for EM062/015 and EM061/029 2

EM062/016 and EM061/029 3

Is the resistance > 10 MOHM?

Yes GO to C7

No Inspect EM062, EM044 and GB001 for corrosion, bent /

pushed back pins or locate harness. Repair as necessary

and test the system for normal operation.

C7: CHECK HARNESS SHORT TO GROUND

Page 1414 of 2490

No Inspect EM062, EM044 and GB001 for corrosion, bent /

pushed back pins or locate harness. Repair as necessary

and test the system for normal operation.

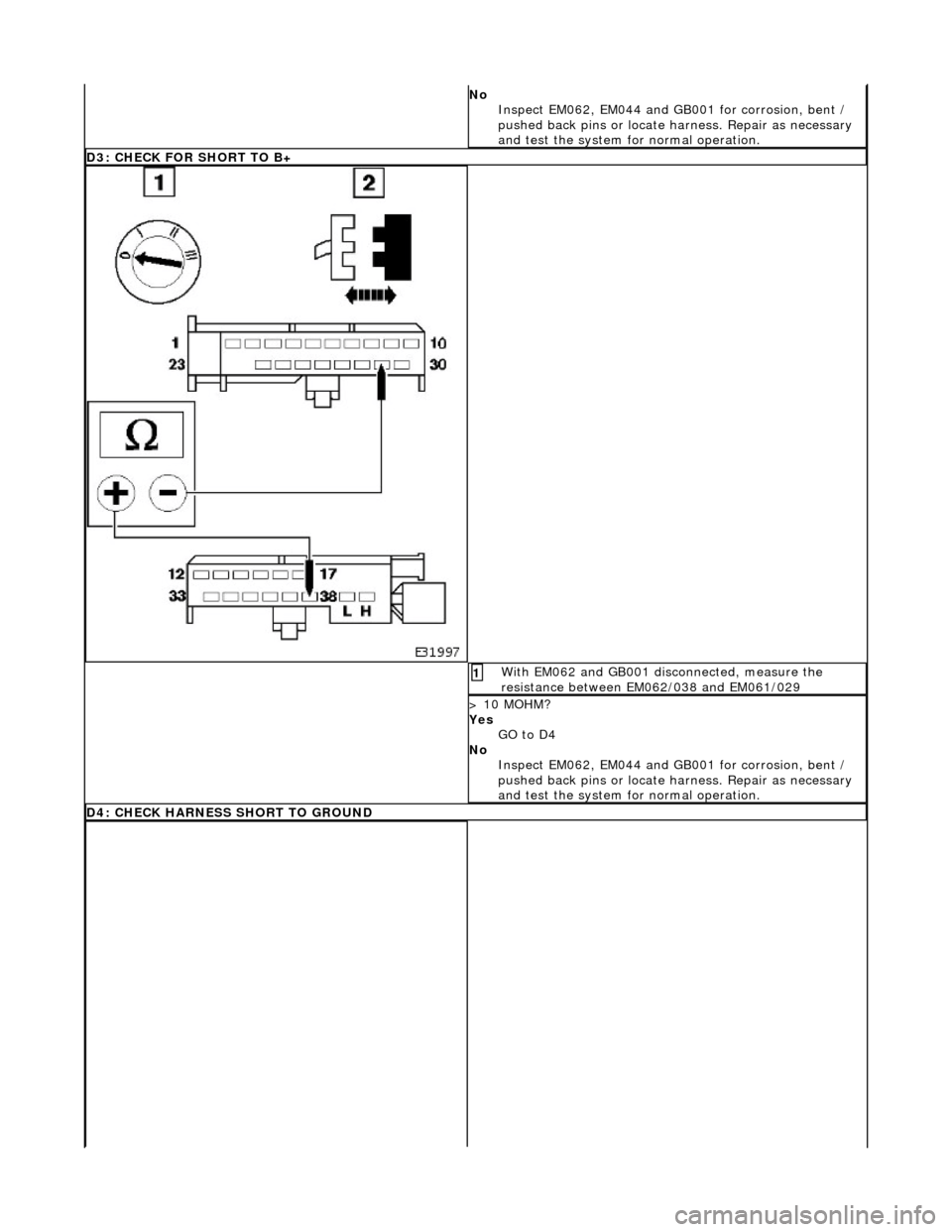

D3: CHECK FOR SHORT TO B+

With EM062 and GB001 disconnected, measure the

resistance between EM062/038 and EM061/029 1

> 10 MOHM?

Yes GO to D4

No Inspect EM062, EM044 and GB001 for corrosion, bent /

pushed back pins or locate harness. Repair as necessary

and test the system for normal operation.

D4: CHECK HARNESS SHORT TO GROUND

Page 1417 of 2490

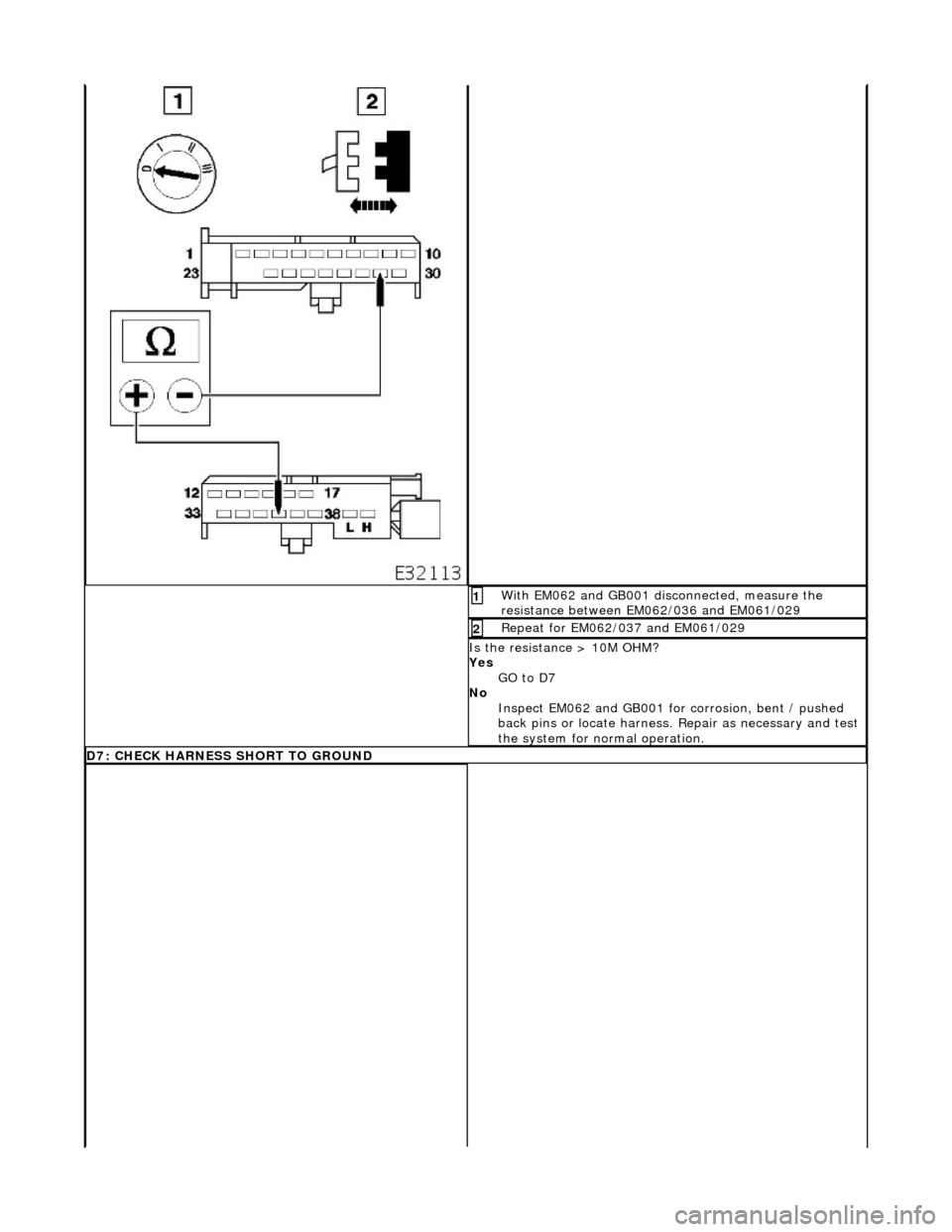

With EM062 and GB001 disconnected, measure the

resistance between EM062/036 and EM061/029 1

Repeat for EM062/037 and EM061/029 2

Is the resistance > 10M OHM?

Yes GO to D7

No Inspect EM062 and GB001 for corrosion, bent / pushed

back pins or locate harness. Repair as necessary and test

the system for normal operation.

D7: CHECK HARNESS SHORT TO GROUND

Page 1429 of 2490

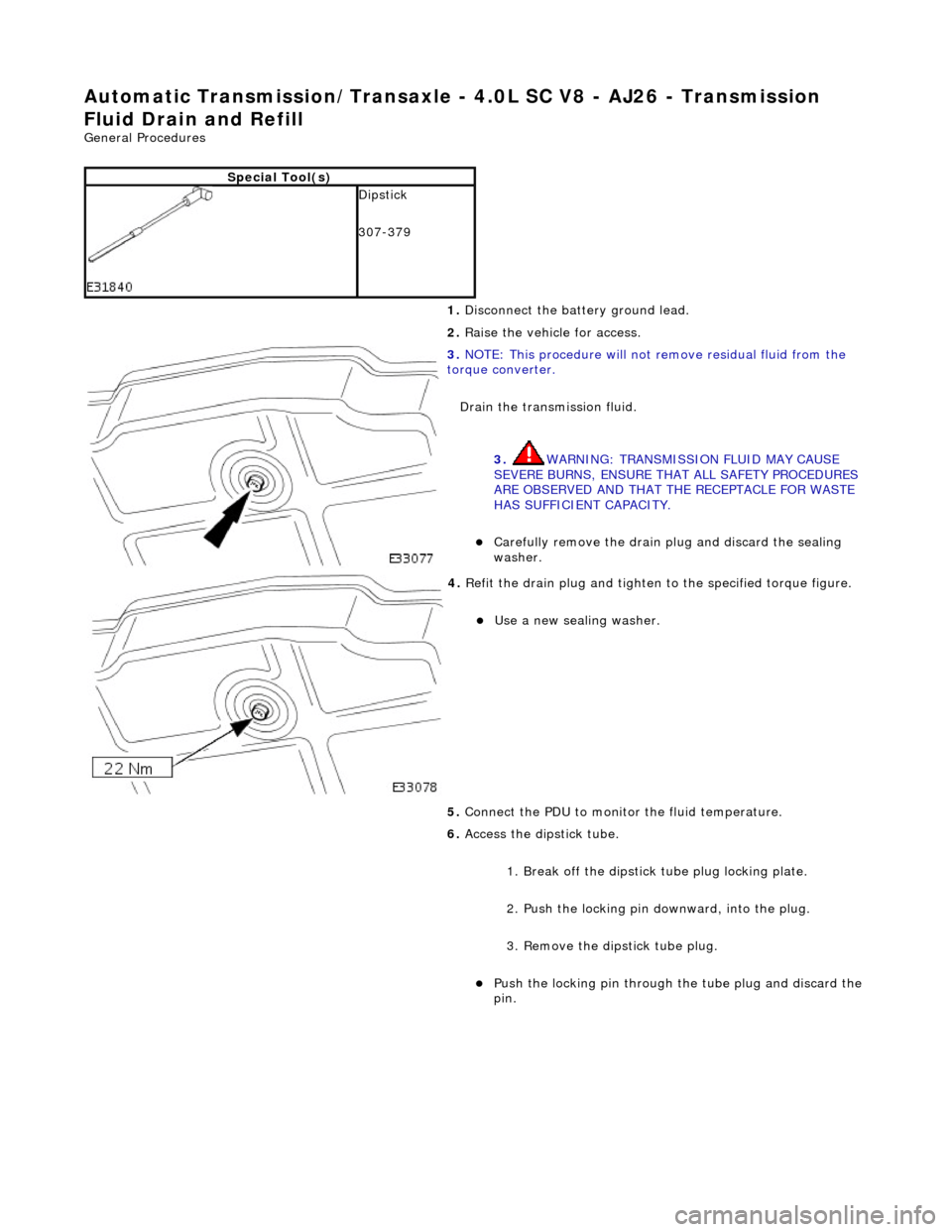

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Fluid Drain and Refill

General Procedures

Special Tool(s)

Dipstick

307-379

1. Disconnect the battery ground lead.

2. Raise the vehicle for access.

3. NOTE: This procedure will not re move residual fluid from the

torque converter.

Drain the transmission fluid.

3. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED AND THAT THE RECEPTACLE FOR WASTE

HAS SUFFICIENT CAPACITY.

пЃ¬Carefully remove the drain pl ug and discard the sealing

washer.

4. Refit the drain plug and tighten to the specified torque figure.

пЃ¬Use a new sealing washer.

5. Connect the PDU to monitor the fluid temperature.

6. Access the dipstick tube.

1. Break off the dipstick tube plug locking plate.

2. Push the locking pin downward, into the plug.

3. Remove the dipstick tube plug.

пЃ¬Push the locking pin through the tube plug and discard the

pin.

Page 1433 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Extension

Housing Seal

In-vehicle Repair

Removal

Special Tool(s)

Oil seal replacer

307-378

Driveshaft wrench

205-053

1. Disconnect the battery ground lead.

2. Select N and choc the road wheels.

3. Remove the front muffler, re fer to Operation 30.10.18.

4. Remove the engine rear mounting bracket.

1. Support the transmission.

2. Remove the bolt, engine rear mounting to transmission.

3. Remove the four bolts which secure the mounting

cross member to the body.

5. Detach the driveshaft from th e transmission drive flange.

1. If the transmission is to be refitted, mark the position of the coupling relative to the drive flange.

5. CAUTION: Under no circ umstances remove the

driveshaft to flexible coupling fixings.

2. Remove the three bolts, tr ansmission drive flange to

flexible coupling.

6. Secure the driveshaft wrench 205 - 053 to the output shaft

flange.