B pillar JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2211 of 2490

For additional information, refer to: C

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

15. Install the high mounted stoplamp.

For additional information, refer to: High Mounted Stoplamp

(417-01 Exterior Lighting, Removal and Installation).

Page 2212 of 2490

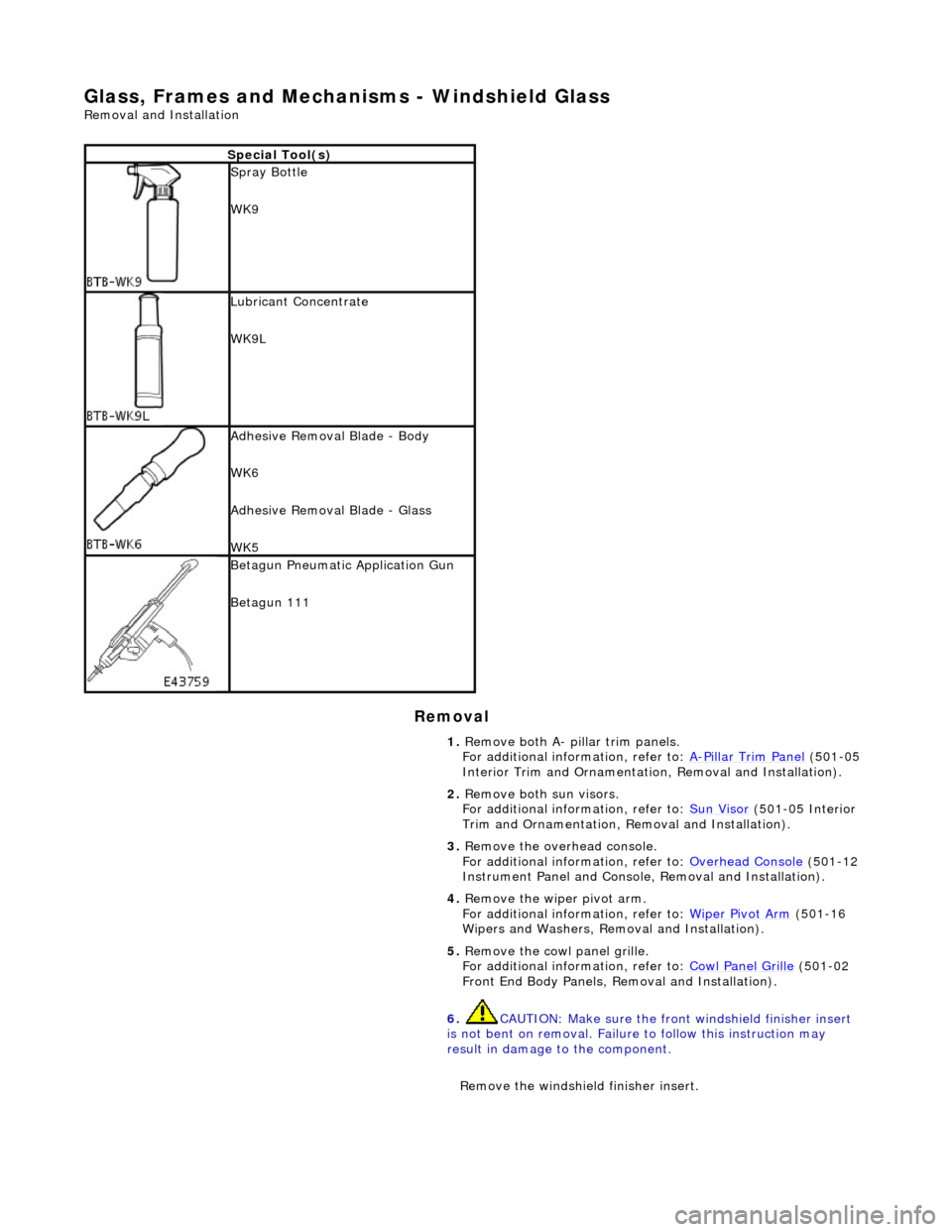

Glass, Frames and Mechanisms - Windshield Glass

Removal and Installation

Removal

Special Tool(s)

Spray Bottle

WK9

Lubricant Concentrate

WK9L

Adhesive Removal Blade - Body

WK6

Adhesive Removal Blade - Glass

WK5

Betagun Pneumatic Application Gun

Betagun 111

1. Remove both A- pill ar trim panels.

For additional information, refer to: A

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

2. Remove both sun visors.

For additional information, refer to: Sun Visor

(501-05 Interior

Trim and Ornamentation, Re moval and Installation).

3. Remove the overhead console.

For additional information, refer to: Overhead Console

(501-12

Instrument Panel and Console, Removal and Installation).

4. Remove the wiper pivot arm.

For additional information, refer to: Wiper Pivot Arm

(501-16

Wipers and Washers, Remo val and Installation).

5. Remove the cowl panel grille.

For additional information, refer to: Cowl Panel Grille

(501-02

Front End Body Panels, Removal and Installation).

6. CAUTION: Make sure the front windshield finisher insert

is not bent on removal. Failure to follow this instruction may

result in damage to the component.

Remove the windshield finisher insert.

Page 2214 of 2490

пЃ¬Cut a suitable length of cheese wire and pass one end

through handle tube and locating aperture.

пЃ¬Move cutting handle central tube downwards to secure

cheese wire.

12. Using a suitable long bladed tool, penetrate Betaseal

approximately 150mm from the top of one A pillar.

13. Pass free end of cheese wire through penetration and install

second cutting handle.

14. WARNING: When removing the windshield glass,

personal protection must be worn. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Make sure the ch eese wire cannot contact the paintwork

while the the windshield adhesive is being cut. Failure to follow

this instruction may result in damage to the vehicle.

Make sure the cheese wire cannot contact the instrument

panel while the the windshield adhesive is being cut. Failure to

follow this instruction may result in damage to the vehicle.

Make sure the cheese wire passes the Vehicle Identification

Number (VIN) plate on the correct side. Failure to follow this

instruction may result in damage to the component.

When cutting, do not allow ch eese wire to contact edge of

windshield glass as this will crack the windshield glass.

• NOTE: Apply cutting lubricant to the cheese wire frequently

through out the cutting process.

With assistance and exercising care at the corners to avoid

damaging paintwork, cut around the windshield glass

Page 2218 of 2490

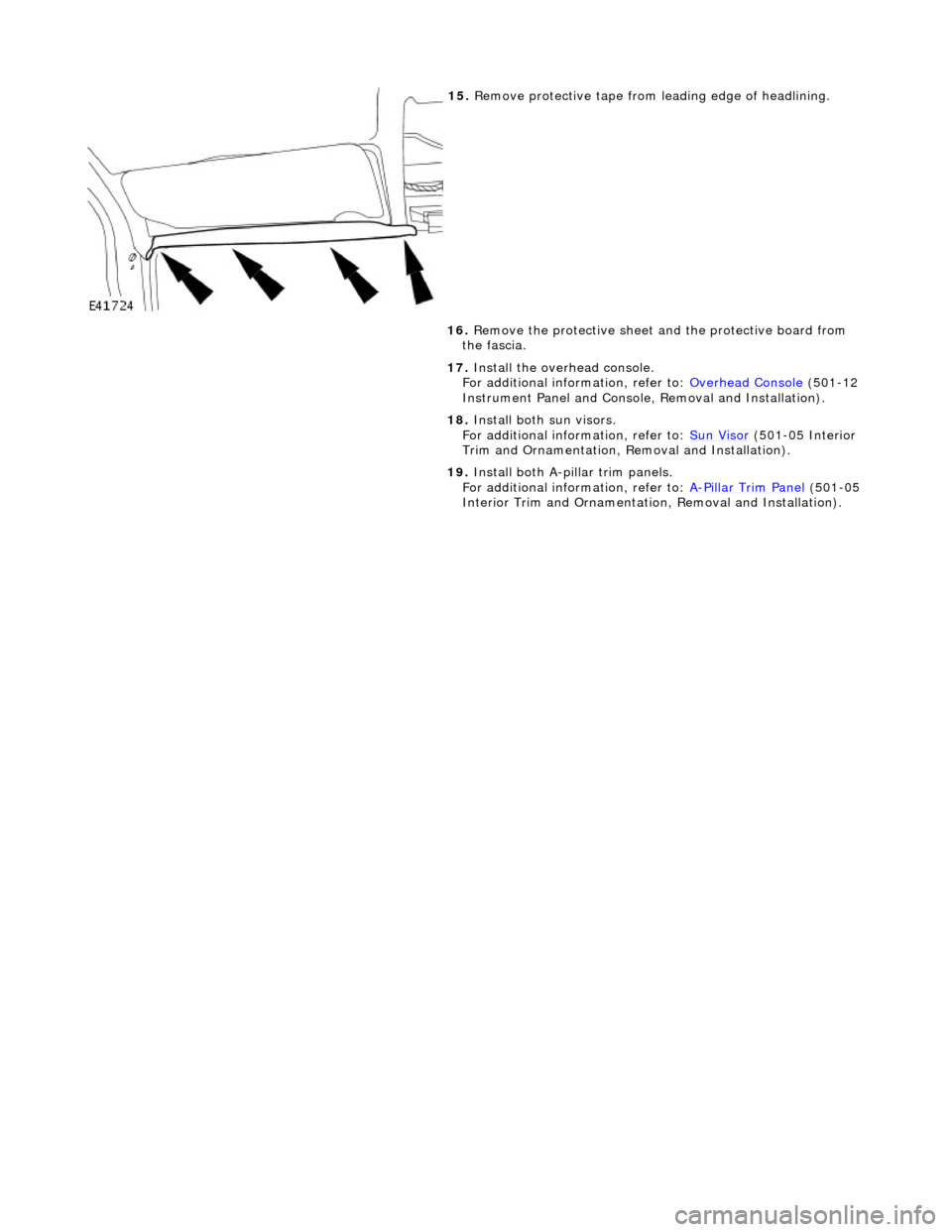

15. Remove protective tape from leading edge of headlining.

16. Remove the protective sheet and the protective board from

the fascia.

17. Install the overhead console.

For additional information, refer to: Overhead Console

(501-12

Instrument Panel and Console, Removal and Installation).

18. Install both sun visors.

For additional information, refer to: Sun Visor

(501-05 Interior

Trim and Ornamentation, Re moval and Installation).

19. Install both A-pillar trim panels.

For additional information, refer to: A

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

Page 2286 of 2490

6.

Fit bias spring to operating arm ensuring it is fully seated and

tensioned, with ends positioned each side of pillar.

7. Fit operating arm and bias spring assembly to barrel and

secure with 'C' clip.

8. Fit lock barrel assembly to housing.

9. Position lock assembly in handle and fit and tighten securing

screw.

10. Fit key and check lock function.

11. Remove key from lock.

12. Fit handle and lock assembly to glovebox lid.. Refer to 76.52

08.

Page 2317 of 2490

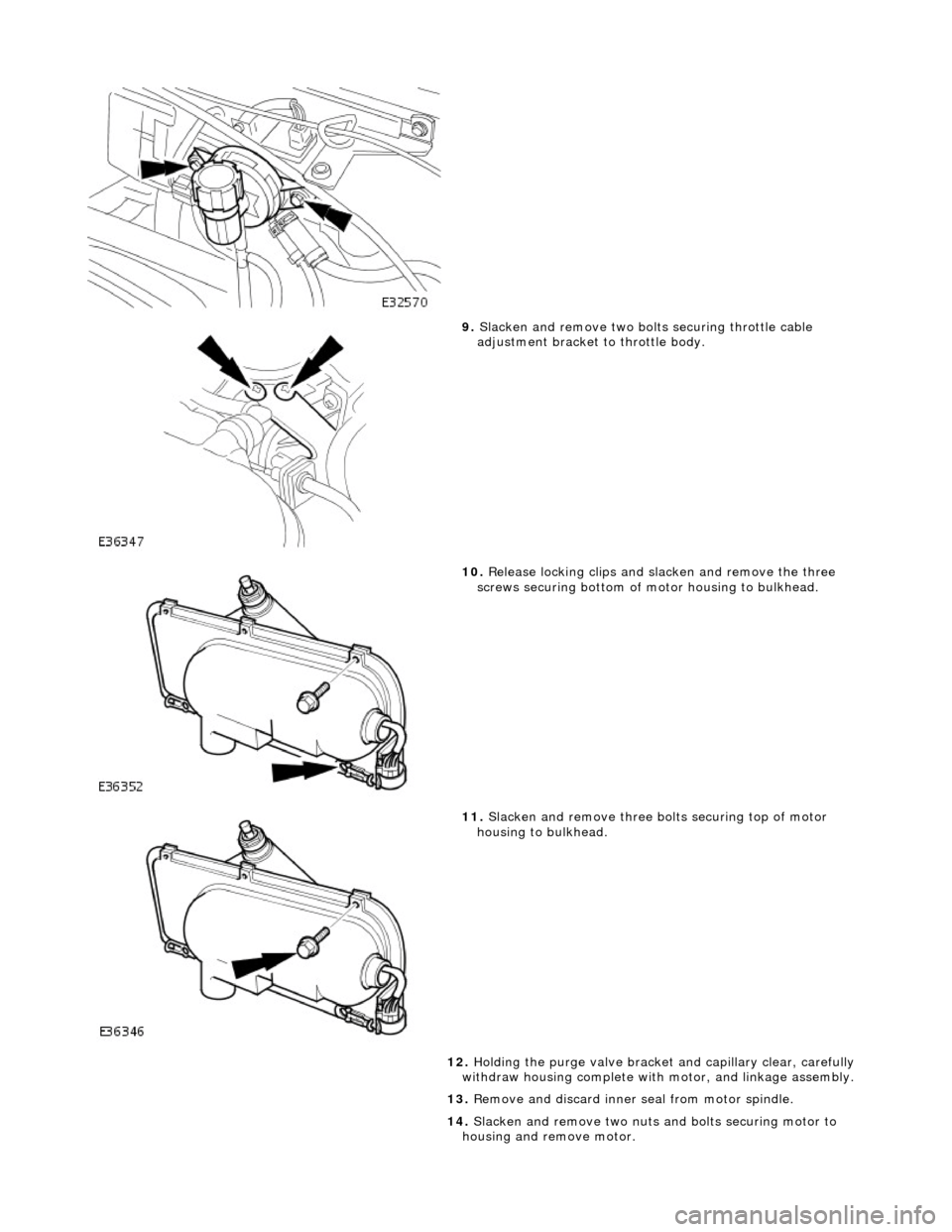

9. Slacken and remove two bolts securing throttle cable

adjustment bracket to throttle body.

10. Release locking clips and sl acken and remove the three

screws securing bottom of motor housing to bulkhead.

11. Slacken and remove three bo lts securing top of motor

housing to bulkhead.

12. Holding the purge valve bracket and capillary clear, carefully

withdraw housing complete with motor, and linkage assembly.

13. Remove and discard inner seal from motor spindle.

14. Slacken and remove two nuts and bolts securing motor to

housing and remove motor.

Page 2318 of 2490

Installation

1.

Position motor in housing and fi t and tighten securing nuts and

bolts.

2. Apply suitable lubricant to bore of new spindle inner seal and

fit seal over motor spindle.

3. Holding the capillary and purge valve clear, position

motor/housing assembly on bulkhead.

4. Seat motor spindle seal correctly in upper plenum aperture and

ensure that housing lo cates on lower studs.

5. Fit and tighten the housin g upper securing bolts.

6. Fit and tighten the housing lower securing screws and slide

locking clips inwards.

7. Position throttle cable adjustment bracket on throttle body and

fit and tighten securing bolts.

8. Position purge valve bracket at bulkhead and fit and tighten

securing bolt and nuts.

9. Position engine harness multiplu g on mounting bracket and fit

and tighten securing nut.

10. Connect motor harness multiplug and locate in retaining clip.

11. Apply suitable lubricant to bore of new outer seal and fit with

washer to motor spindle.

12. Fit and fully tighten collar nut on motor spindle.

13. Fit plenum cover. Refer to 76.10.01.

14. Fit wiper arm and blade. Refer to 84.15.44.90.

15. Fit top covers to LH and RH bulkheads and rear of engine

compartment. refer to 76.11.33 and 76.11.35.

16. Fit ground cable to battery te rminal and cover to battery.

Refer to 86.15.15.

Page 2384 of 2490

Generally, resistance spot welding equipment used in the motor vehicle repair industry does not produce welds of equivalent strength to those achieved during manufactu re. The expression 'single row of resistance spot welds' indicates that the spots

should be spaced on a pitch of 19mm to 25mm, which normally results in mo re spot welds than those produced in the

original factory joint.

Resistance spot welds should be removed using a resistance spot weld cutter. If the new joint is to be MIG plug welded, old

resistance spot welds should be cut from the panel to be reta ined and the resulting holes used for plug welding. Suitable

holes may also be drilled or punched; 8,0 mm dia for sect ions up to 1,6 mm, and 10,0 mm dia for thicker sections.

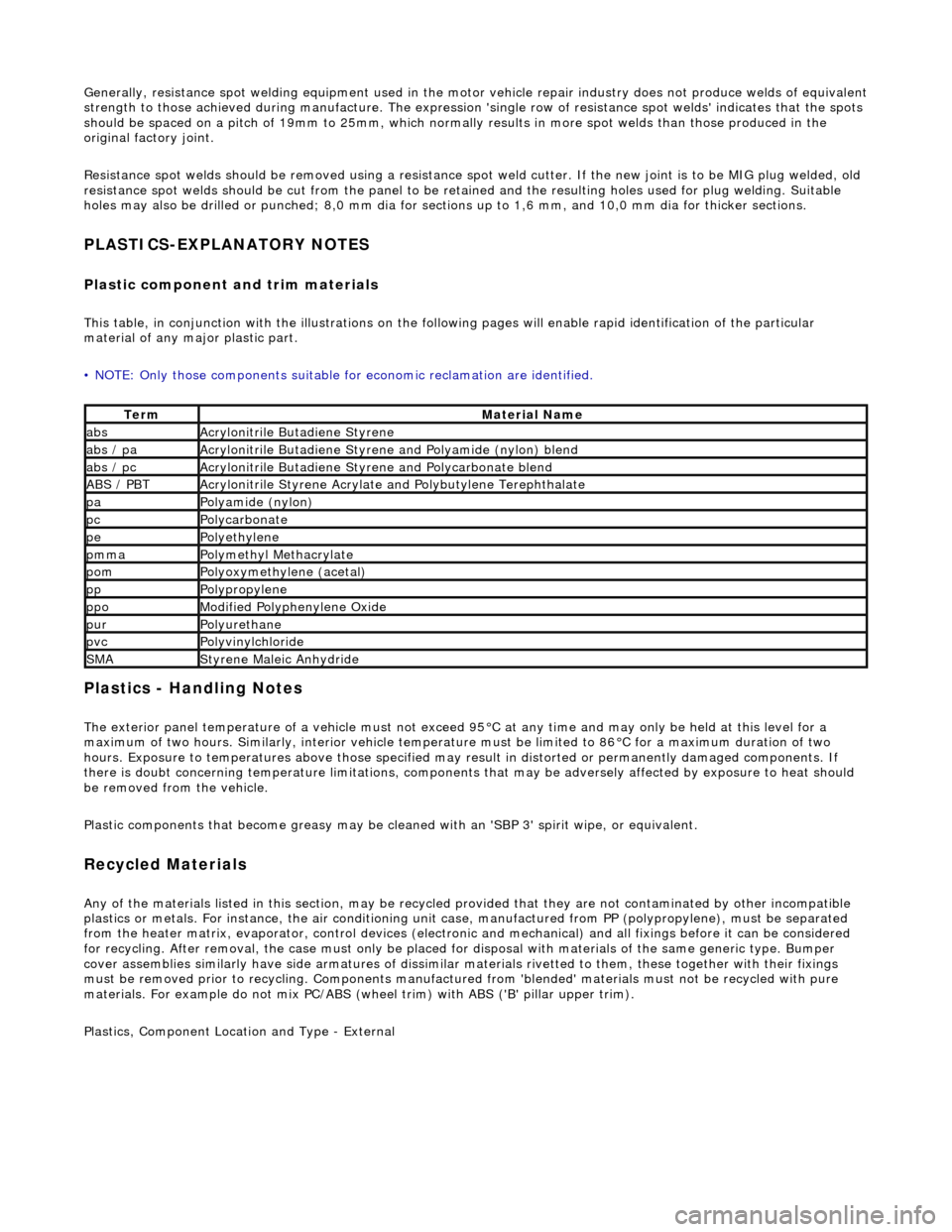

PLASTICS-EXPLANATORY NOTES

Plastic component and trim materials

This table, in conjunction with the illu strations on the following pages will enable rapid identification of the particular

material of any major plastic part.

• NOTE: Only those components suitable for economic reclamation are identified.

Plastics - Handling Notes

The exterior panel temperature of a vehicle must not exceed 95В°C at any time and may only be held at this level for a

maximum of two hours. Similarly, interior vehicle temperatur e must be limited to 86В°C for a maximum duration of two

hours. Exposure to temperatures above those specified may result in distorted or permanently damaged components. If

there is doubt concerning temperature limitations, components that may be adversel y affected by exposure to heat should

be removed from the vehicle.

Plastic components that become greasy may be clea ned with an 'SBP 3' spirit wipe, or equivalent.

Recycled Materials

Any of the materials listed in this section, may be recycled provided that they ar e not contaminated by other incompatible

plastics or metals. For instan ce, the air conditioning unit case, manufactur ed from PP (polypropylene), must be separated

from the heater matrix, evaporator, contro l devices (electronic and mechanical) and all fixings before it can be considered

for recycling. After removal, the case mu st only be placed for disposal with materials of the same generic type. Bumper

cover assemblies similarly have side arma tures of dissimilar materials rivetted to them, these together with their fixings

must be removed prior to recy cling. Components manufactured from 'blended' materials must not be recycled with pure

materials. For example do not mix PC/ABS (wheel trim) with ABS ('B' pillar upper trim).

Plastics, Component Location and Type - External

TermMaterial Name

absAcrylonitrile Butadiene Styrene

abs / paAcrylonitrile Butadiene Styrene and Polyamide (nylon) blend

abs / pcAcrylonitrile Butadiene Styrene and Polycarbonate blend

ABS / PBTAcrylonitrile Styrene Acrylate and Polybutylene Terephthalate

paPolyamide (nylon)

pcPolycarbonate

pePolyethylene

pmmaPolymethyl Methacrylate

pomPolyoxymethylene (acetal)

ppPolypropylene

ppoModified Polyphenylene Oxide

purPolyurethane

pvcPolyvinylchloride

SMAStyrene Maleic Anhydride