Drive shaft JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 293 of 2490

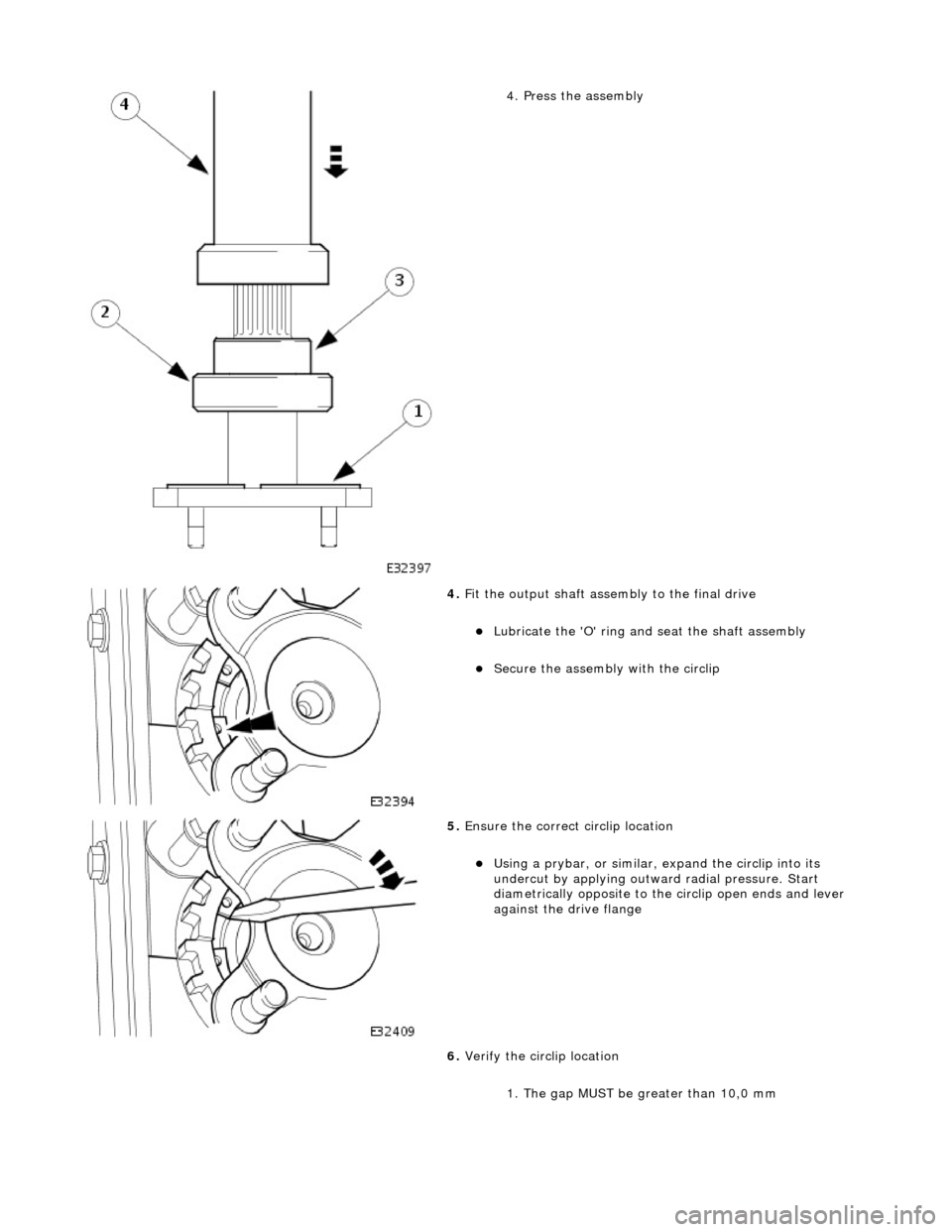

4.

Press the assembly

4. Fi

t the output shaft assembly to the final drive

Lubri

cate the 'O' ring and

seat the shaft assembly

Secu

re the assembly with the circlip

5. Ensure the correct circli

p location

U

sing a prybar, or similar, expand the circlip into its

undercut by applying outwar d radial pressure. Start

diametrically opposite to the circlip open ends and lever

against the drive flange

6. Verify the circlip location

1. The gap MUST be greater than 10,0 mm

Page 294 of 2490

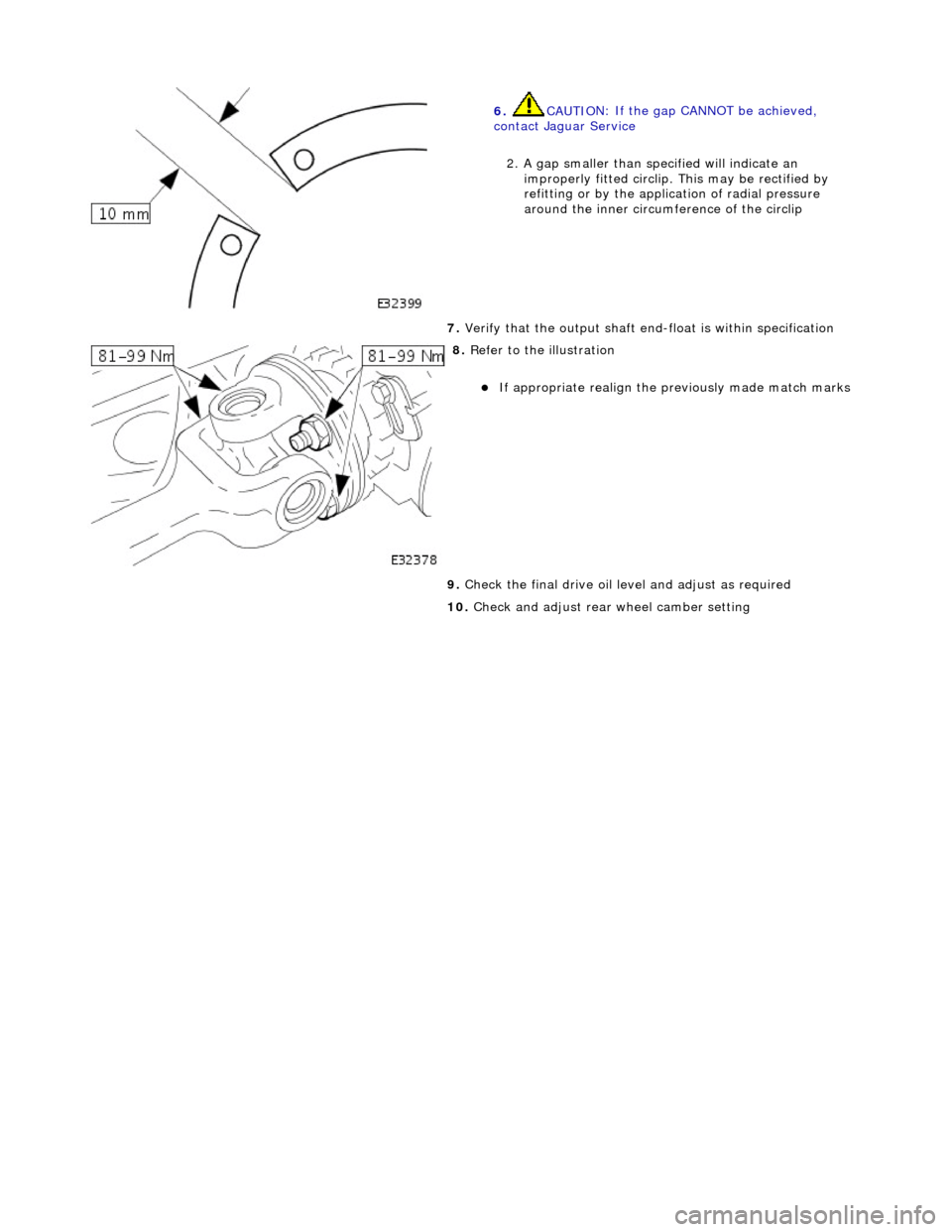

6.

CAUTIO

N: If the gap CANNOT be achieved,

contact Jaguar Service

2. A gap smaller than specified will indicate an improperly fitted circlip. This may be rectified by

refitting or by the application of radial pressure

around the inner circum ference of the circlip

7. Verify t

hat the output shaft end-float is within specification

8. Re

fer to the illustration

If

app

ropriate realign the pr

eviously made match marks

9. Check the final drive oil level and adjust as required

10. Check and adjust rear wheel camber setting

Page 295 of 2490

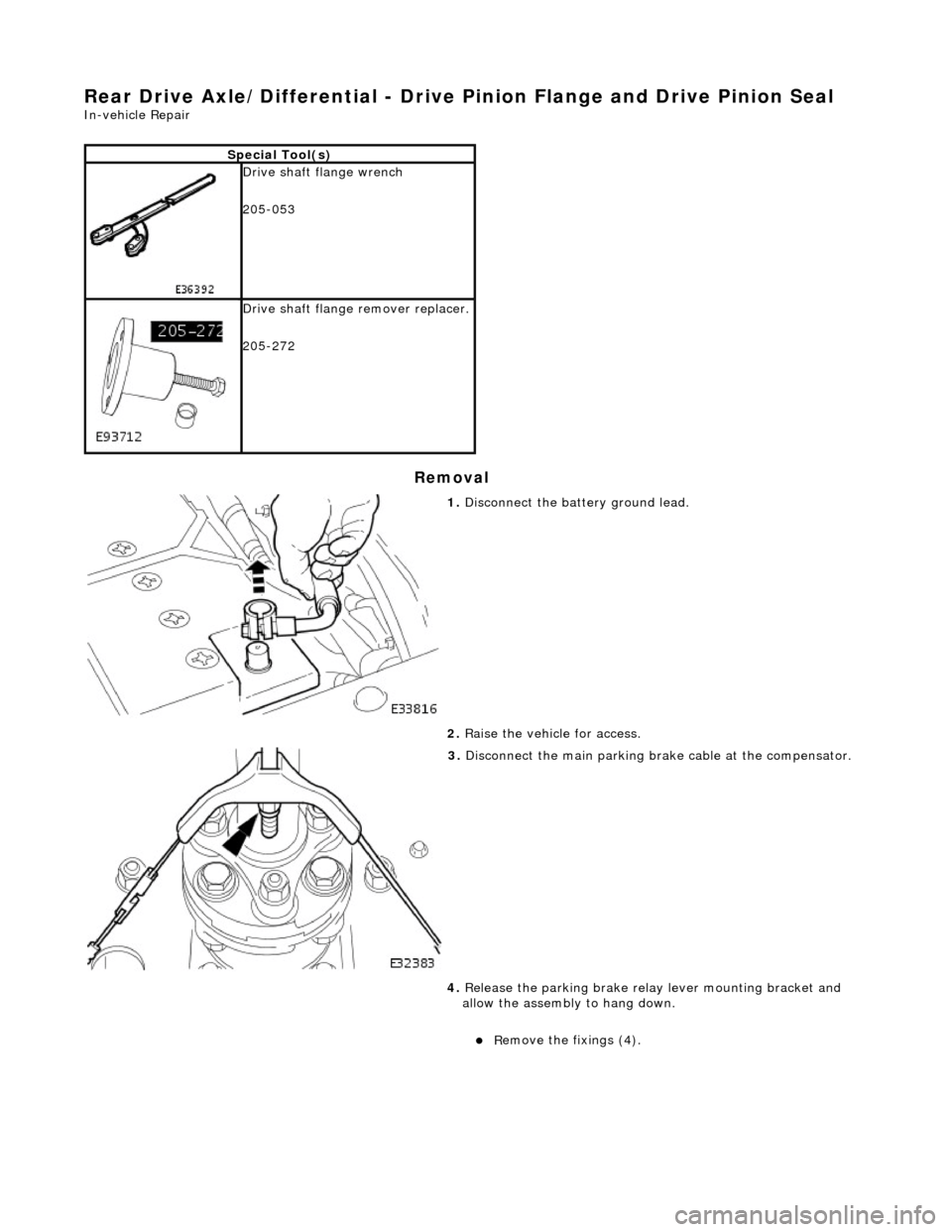

R

ear Drive Axle/Differential - Drive Pinion Flange and Drive Pinion Seal

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Drive sh

aft flange wrench

205-053

D

rive shaft flange remover replacer.

205-272

1. Di

sconnect the battery ground lead.

2. Raise the vehicle for access.

3. Disconnect the main parking br ake c

able at the compensator.

4. Release the parking brake relay lever mounting bracket and

allow the assembly to hang down.

R

emove the fixings (4).

Page 296 of 2490

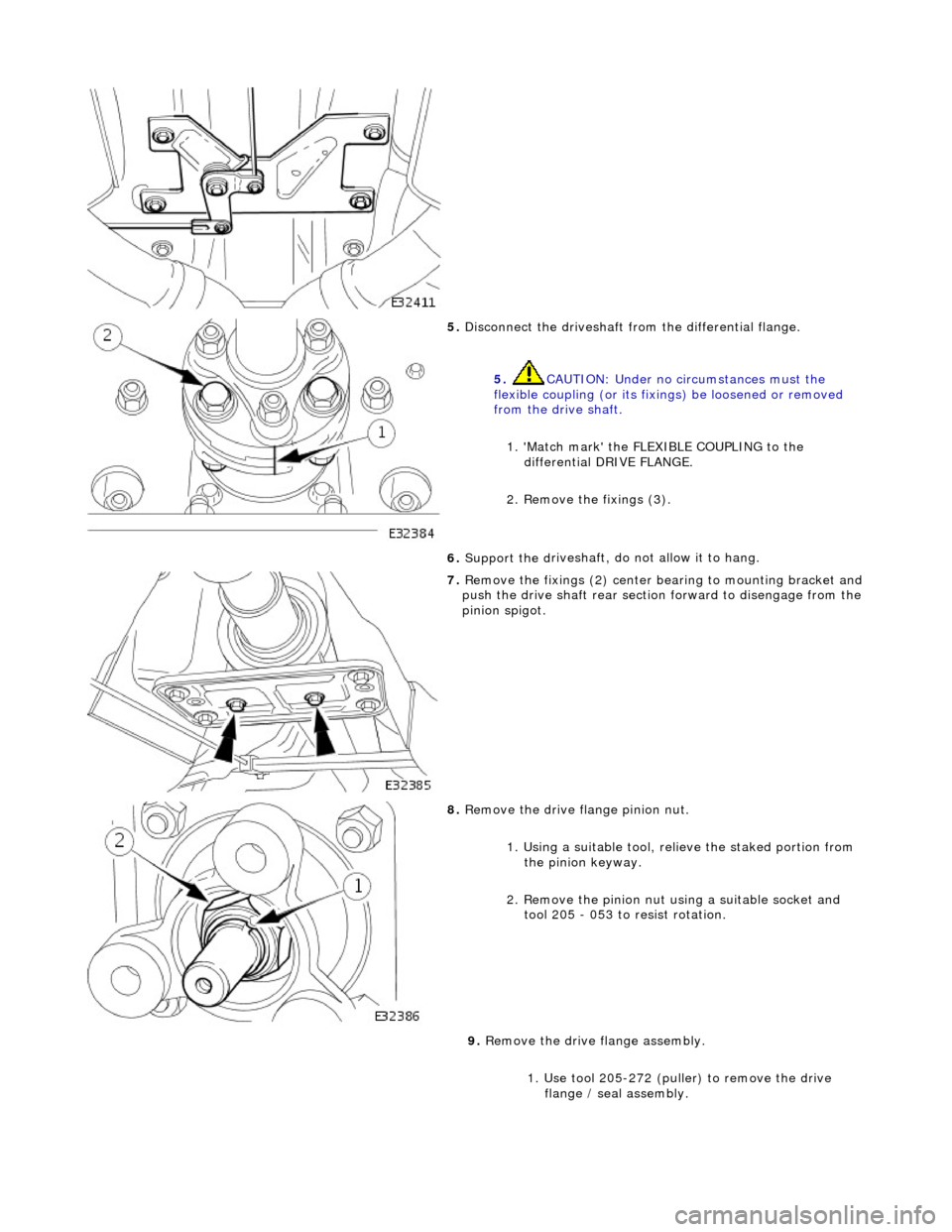

5. Disconne

ct the driveshaft fr

om the differential flange.

5. CAUTION: Under no circumstances must the

flexible coupling (or its fixings) be loosened or removed

from the drive shaft.

1. 'Match mark' the FLEX IBLE COUPLING to the

differential DRIVE FLANGE.

2. Remove the fixings (3).

6. Support the d

riveshaft, do not allow it to hang.

7. Re

move the fixings (2) center

bearing to mounting bracket and

push the drive shaft rear sectio n forward to disengage from the

pinion spigot.

8. Remove the drive flange pinion nu

t.

1. Using a suitable tool, re lieve the staked portion from

the pinion keyway.

2. Remove the pinion nut using a suitable socket and tool 205 - 053 to resist rotation.

9. Remove the drive flange assembly.

1. Use tool 205-272 (puller) to remove the drive flange / seal assembly.

Page 298 of 2490

7. Chec k

that the pinion sp

igot radial run-out.

0,08

mm MAX TIR.

If t

hi

s specification is exceeded, contact Jaguar Service.

8. Re

fer to the illustration.

R

e

new the driveshaft fixings.

9. Re

fer to the illustration.

E

n

sure that the bear

ing is central.

10. Refer to the illustration.

Page 300 of 2490

Rea

r Drive Axle/Differential - Axle Assembly

Re

mo

val and Installation

Remov

a

l

•

NOTE: The pinion flange shown in this procedure is NOT intended to be a true representation

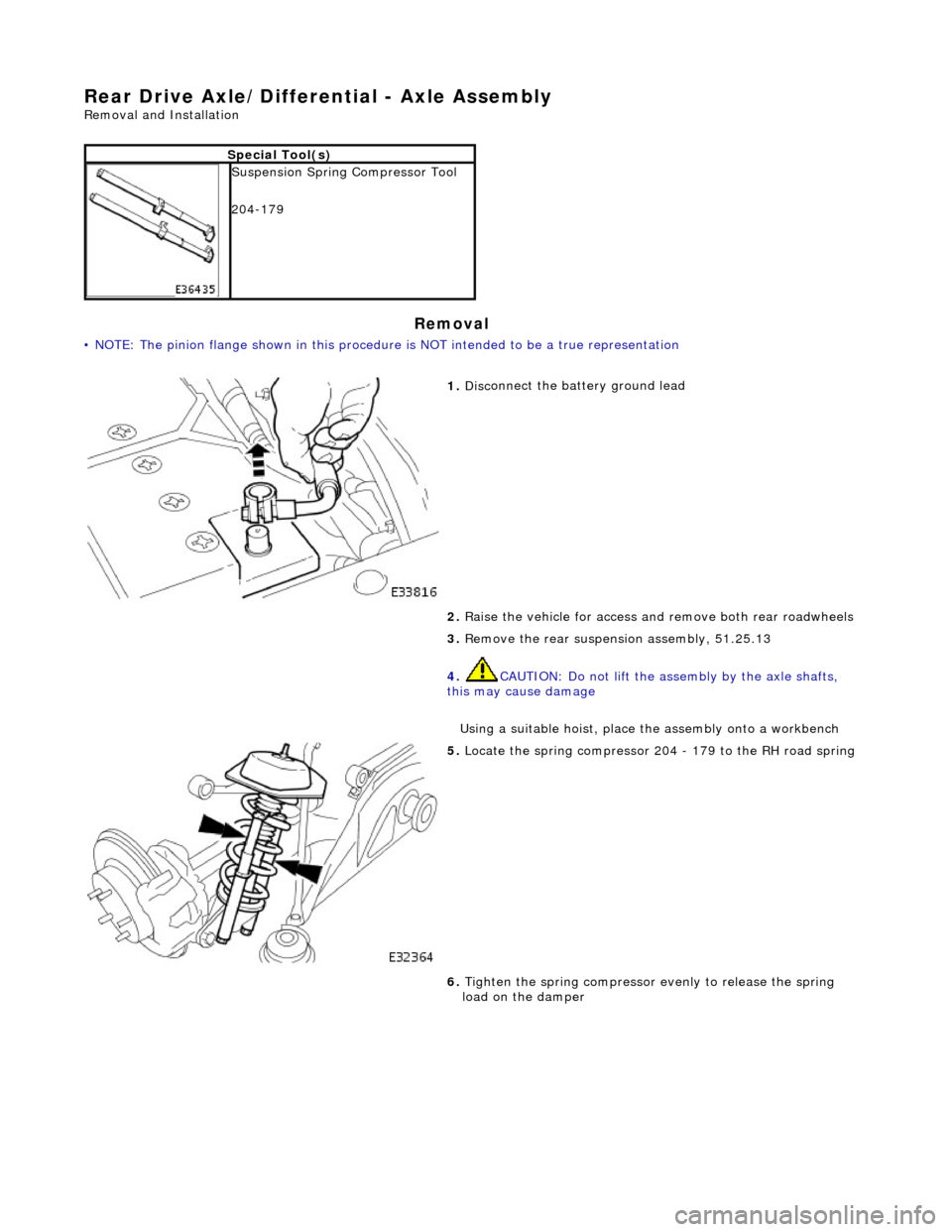

S

p

ecial Tool(s)

Suspensi

on

Spring Compressor Tool

204-179

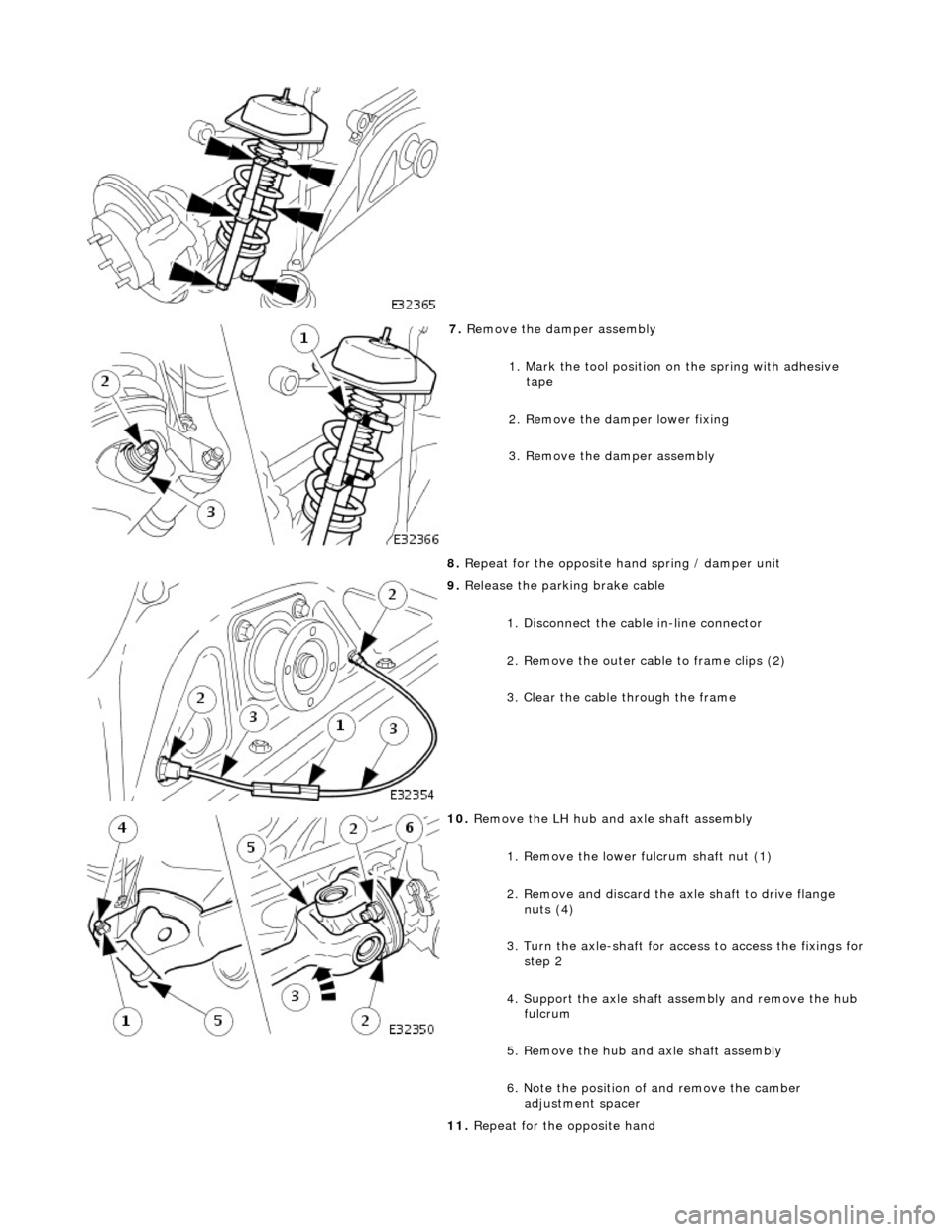

1. Disc

onnect the battery ground lead

2. Raise the vehicle for access and remove both rear roadwheels

3. Remove the rear suspensi on assembly, 51.25.13

4. CAUTION: Do not lift the assembly by the axle shafts,

this may cause damage

Using a suitable hoist, place the assembly onto a workbench

5. Locat e

the spring compressor 204

- 179 to the RH road spring

6. Tighten the spring compressor evenly to release the spring

load on the damper

Page 301 of 2490

7. Re

move the damper assembly

1. Mark the tool position on the spring with adhesive

tape

2. Remove the damper lower fixing

3. Remove the damper assembly

8. Repeat for the opposite hand spring / damper unit

9. Relea

se the parking brake cable

1. Disconnect the cable in-line connector

2. Remove the outer cable to frame clips (2)

3. Clear the cable through the frame

10

.

Remove the LH hub and axle shaft assembly

1. Remove the lower fulcrum shaft nut (1)

2. Remove and discard the axle shaft to drive flange nuts (4)

3. Turn the axle-shaft for ac cess to access the fixings for

step 2

4. Support the axle shaft a ssembly and remove the hub

fulcrum

5. Remove the hub and axle shaft assembly

6. Note the position of and remove the camber adjustment spacer

11. Repeat for the opposite hand

Page 461 of 2490

sus

pension components

and for damaged coil springs in the front suspension.

as necessary. For addi tional information,

REF

ER to Section 204

-0

2 Rear Suspension

. I

NSTALL new front suspension components

as necessary. For addi tional information,

REFER to Section 204

-01

Front Suspension

.

Chec

k the rear suspension

for loose or worn

suspension components.

TIGHTE

N or INSTALL new components as

necessary. For additi onal information,

REFER to Section 204

-0

2 Rear Suspension

.

Incorre

ct underbody

alignment.

CHECK

underbody alignment. For additional

information,

REFER to Section 502

-00

Uni

-Body, Subframe and M

ounting System

.

Poor r

eturnability of the

steering

Lower steeri

ng column

interference.

CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

Incorrect

tire pressure.

CHECK

and ADJUST the tire pressure. For

additional information,

REFER to Section 204

-0

4 Wheels and Tires

.

Incorrect

tire size or type.

IN

STALL a new tire as necessary. For

additional information,

REFER to Section 204

-0

4 Wheels and Tires

.

Steeri

ng column upper

shroud fouling on the steering wheel.

CHECK

steering column upper shroud for

fouling. ADJUST as necessary.

Steeri

ng column universal

joints binding.

IN

STALL a new steering column. For

additional information,

REFER to Section 211

-0

4 Steering Column

.

Steeri

ng column shaft floor

seal binding.

CHE

CK the steering column shaft floor seal

for correct fitm ent and REFIT as necessary.

Steeri

ng column shaft floor

seal may be torn.

IN

STALL a new steering column shaft floor

seal as necessary.

Bin

ding or damaged tie-

rods.

CHECK

tie-rod end for excessive wear or

tightness in ball joint. INSTALL a new tie- rod end. For additional information,

REFER to Section 211

-0

3 Steering Linkage

.

D

amaged or worn front

suspension components.

I

NSTALL new front suspension components

as necessary. For addi tional information,

REFER to Section 204

-01

Front Suspension

.

Incorre

ct toe adjustment.

AD

JUST as necessary. For additional

information,

REFER to Section 204

-00

Suspension

Sy

stem

- General

Information

.

Excessive steeri

ng efforts

required during low speed

manoeuvring and/or during parking manoeuvres

Low power steer

ing fluid.

CHE

CK steering system

for signs of steering

fluid loss.

BLEE

D the power steering system. For

additional information,

REFER to Section 211

-0

0 Steering System

- General Informati

on

.

Damaged accessory driv

e

belt tensioner.

INST

ALL a new accessory drive belt

tensioner.

Hose or cooler li

ne

restriction.

CHECK

hose or cooler lines for correct

routing.

INST

ALL a new hose as necessary.

Fl

uid aeration.

BLEE

D the system. For additional

information,

REFER to Power Steering System Bleeding

in t

his section.

Steeri

ng transducer not

closed - no feed voltage.

CHECK

the steering transducer circuit. For

additional information, REFER to the wiring diagrams.

Carry ou

t the electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

Steeri

ng transducer not

closed - cable fault.

CHECK

the steering transducer circuit. For

additional information, REFER to the wiring diagrams.

Carry ou

t the electrical checks and tests.

Page 463 of 2490

No

ise

S

teering heavy operation in

one direction

F

aulty rotary valve/seal.

addi

tional information, REFER to the Power

Steering Pressure Test in this section.

INST

ALL a new steering

gear as necessary.

For additional information,

REFER to Section 211

-0

2 Power Steering

.

Ti

re fouling on the wheel

arch liner.

CHECK for

clearance be

tween the tire and

the wheel arch liner.

R

emove and refit the wheel arch liner or

INSTALL a new wheel arch liner as necessary.

S

teering heavy operation in

both directions

Low power steer

ing fluid.

CHE

CK steering system

for signs of steering

fluid loss.

BLEE

D the power steering system. For

additional information,

REFER to Section 211

-0

0 Steering System

- General Informati

on

.

Ai

r in power steering

system.

CHECK

the power steering pump for signs o

f steering fl

uid loss.

INST

ALL a new power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0

2 Power Steering

.

Fluid loss at the power

steering pump shaft seal.

CHECK

the power steering pump for signs o

f steering fl

uid loss.

INST

ALL a new power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0

2 Power Steering

.

Power steeri

ng fluid

delivery pressure or flow too low.

CHECK

the power steering pump for signs o

f steering fl

uid loss.

CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

INST

ALL a new power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0

2 Power Steering

.

Steeri

ng operation varies

from heavy to light when

driving at constant speed

Lower steeri

ng column

interference.

CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

Incorre

ct sp

eedometer

signal.

CHECK

the speedo circ

uit. For additional

information, refer to the wiring diagrams.

Steeri

ng transducer

cable/connection faulty or grounded.

CHECK

the steering transducer circuit. For

additional information, refer to the wiring diagrams.

Carry ou

t the electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

Steeri

ng wheel varies from

light to heavy two times per revolution

Lower steeri

ng column

interference.

CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

Steeri

ng column universal

joints binding.

IN

STALL a new steering column. For

additional information,

REFER to Section 211

-0

4 Steering Column

.

Seized or damaged

ste

ering components.

CHECK

for wear or failure of suspension

bushes and ball join ts. For additional

information,

REFER to Section 204

-00

Suspension

Sy

stem

- General

Information

.

Cond

ition

Possib

le Sources

Acti

on

Acce

ssory drive

belt squeal

Incorre

ct accessory drive belt

tension or accessory drive belt glazed.

CHECK

accessory drive belt condition and INSTALL a

new accessory drive belt as necessary. For additional

information,

REFER to Section 303

-0

5 Accessory Drive

.

Chir

p noise in

the steering pump

Loose or worn accessory dr

ive belt.

CHECK

accessory drive belt condition and INSTALL a

new accessory drive belt as necessary. For additional

information,

REFER to Section 303

-0

5 Accessory Drive

.

Page 468 of 2490

Hiss (Swish)

Hiss or Val

ve Hiss is a high-frequency so

und coming from the steering gear when the system is loaded. It is a rushing or

"swish" noise that doesn't change frequency with RPM. Hiss is the general noise generated by the flow of hydraulic fluid

through restrictions in the steer ing system. Restrictions include the rotary stee ring valve, power steering tubes, connectors,

tuning orifices, etc. Hiss can be air- borne and structure-borne, but the structure-borne path through the steering

intermediate shaft is usually dominant.

Moan (Groan)

Moan is the general structu r

e-borne noise of the steering system. Moan is primarily transmitted to the driver via the body

structure through the pump mount, engine mounts, power steering lines and power steering brackets. On some vehicles,

moan is a load humming noise, often present when the wheel is turned and the system is loaded. It may change frequency

with engine RPM and if the sy stem is loaded or unloaded.

Rack Knock (R

ack Slap)

CAU

T

ION: DO NOT attempt to adjust the stee

ring gear yoke. Failure to follow this instruction will result in the steering

gear warranty to become invalid.

Rack Knock is a rattle sound an d steering wheel vibration caused by separation of the steering gear and pinion while driving

over bumps. It is a structure-borne noise transmitted throug h the intermediate shaft and column. Rack knock can also be

heard as a "thump" or impact noise that occurs with the vehicle stationary when the steering wheel is released from a

loaded position and allowed to return to rest . Noise occurs with the engine on or off.

Rattles

Ra

ttles are noises caused by knocking or hitting with components in the steering system. Steering rattles can occur in the

engine compartment, the suspension, or the passenger compartment . Rattles can be caused by loose parts, movable and

flexible parts, and improper clearances.

Squea k

s/Scrapes

Squeaks/Scrapes are noises due

to fri

ction or component rubbi

ng anywhere in the steering system. Squeaks/Scrapes have

appeared in steering linkages and jo ints, in column components and in co lumn and steering wheel trim parts.

Weep

We

ep is an air-borne noise, occasionally

generated when turning the steering across lock at a constant rate. When present

on a vehicle the noise, once initiated can often be maintained across a large proportion of the available steering movement.

Whistle

Wh

istle is similar to hiss but is louder and of a higher frequency. It is also more

of a pure tone noise than hiss. Whistle is

air-borne and is generated by a high flow rate of hydraulic fluid through a small restriction.

Zip

Zip n

o

ise is the air-borne noise

generated by power steerin g pump cavitation when power steering fluid does not flow freely

through the suction hose from the rese rvoir to the pump. Zip primarily occurs during cold weather at start-up.

Steering System Vibrations and Harshne

ss

Buzz

Buzz is a tactile rotary vi

bration felt in

the steering wheel for slow steering inputs. Buzz can also be called a grinding feel

and it is closely related to grunt and is caused by high system gain with low damping. Buzz is generally excited during

parking manoeuvres with low to medium speed steering input.