fuel level JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1201 of 2490

leak

/blockage

EVAP valve failure

P0444Evaporati

ve emissions system

(EVAP) valve circuit open circuit

EVAP t

o ECM drive circuit open

circuit or high resistance

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0445Evaporati

ve emissions system

(EVAP) valve circuit short circuit

E

VAP to ECM drive circuit short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0447Cani

ster close valve (CCV) circuit

open circuit

CCV to ECM

drive circuit open

circuit, high resi stance or short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0448Cani

ster close valve (CCV) circuit

short circuit

CCV to

ECM drive circuit short

circuit to high voltage

CCV failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0452F

uel tank pressure (FTP) sensor

circuit low voltage

FTP

sensor disconnected

FTP

sensor to ECM sense circuit

open circuit or short circuit to

ground

FTP sen

sor to ECM power supply

circuit open circuit or short circuit

to ground

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0453F

uel tank pressure (FTP) sensor

circuit high voltage

FTP

sensor to ECM signal ground

circuit open circuit

F

TP sensor to ECM wiring (supply,

sense, signal, ground) short circuit

to each other

FTP

sensor to ECM sense circuit

short circuit to high voltage

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0460Fue

l level sense signal

performance

Fue

l level sensor

to instrument

cluster circuits in termittent short or

open circuit

F

uel level sensor failure

Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0506Idl

e rpm lower than expected

Ai

r intake blockage

Acce

ssory drive overload

(defective/siezed component)

Thr

ottle valve stuck closed

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check t

he accessory drive

components,

REFER to Section 303

-0

5 Accessory

Dr

ive

.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0507Idle rpm

higher than expected

Inta

ke air leak between MAF

sensor and throttle

Inta

ke air leak between throttle

and engine

Engine

breather leak

Cruis

e (speed) control vacuum

failure

Thr

ottle valve stuck open

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Chec

k the engine breather system,

REFER to Section 303

-08

Engine

Emissi

on Control

.

F

or cruise (speed) control information,

REFER to Section 310

-03

Speed

Control.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0560Vehicle voltage

malfunction

ECM battery

power supply open

circuit, high resistance

F

or ECM power supply circuit tests,

GO to Pinpoint Test AD.

.

P0566Cruise (speed) contr

ol

CANCEL

switch ON fault

Cru

ise (speed) control switches

internal steering wheel short circuit

to ground

For cru

ise (speed) control circuit tests,

REFER to Section 310

-03

Speed

Page 1241 of 2490

E

lectronic Engine Controls - Engine

Control Module (ECM) Adaptation

Gen

eral Procedures

When to car

ry out adaptations

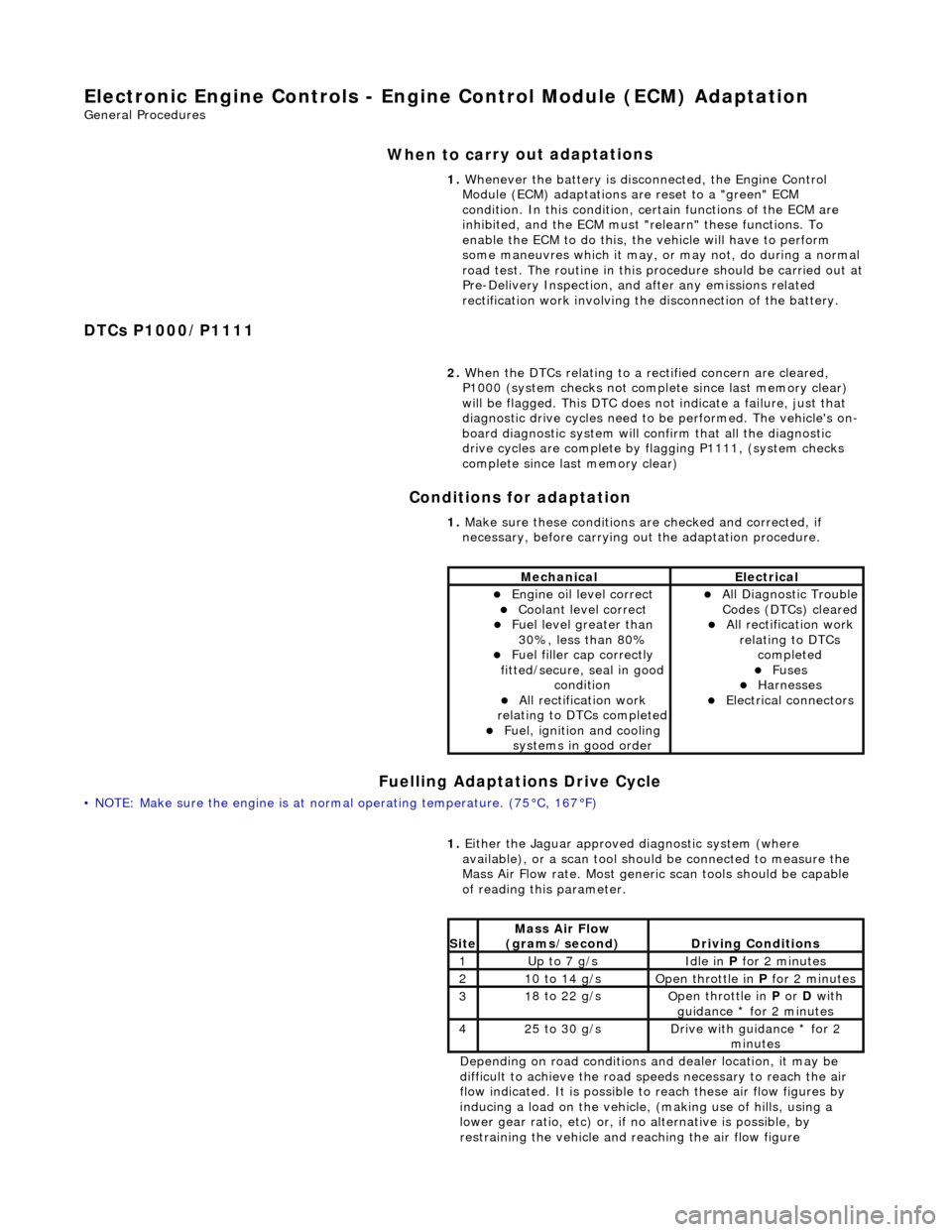

DTCs P1000/P1111 Conditions for adaptation

Fuelling Adaptations Drive Cycle

•

NOTE: Make sure the engine is at normal operating

temperature. (75°C, 167°F) 1.

Whenever the battery is disconnected, the Engine Control

Module (ECM) adaptations are reset to a "green" ECM

condition. In this condition, certain functions of the ECM are

inhibited, and the ECM must "r elearn" these functions. To

enable the ECM to do this, the vehicle will have to perform

some maneuvres which it may, or may not, do during a normal

road test. The routine in this pr ocedure should be carried out at

Pre-Delivery Inspection, and after any emissions related

rectification work involving the disconnection of the battery.

2. When the DTCs relating to a rectified concern are cleared,

P1000 (system checks not complete since last memory clear)

will be flagged. This DTC does no t indicate a failure, just that

diagnostic drive cycles need to be performed. The vehicle's on-

board diagnostic system will confirm that all the diagnostic

drive cycles are complete by flagging P1111, (system checks

complete since last memory clear)

1. Make sure these conditions are checked and corrected, if

necessary, before carrying ou t the adaptation procedure.

MechanicalElectrical

Engi

ne oil level correct

Coo

lant level correct

F

uel level greater than

30%, less than 80%

F

uel filler cap correctly

fitted/secure, seal in good condition

Al

l rectification work

relating to DTCs completed

F

uel, ignition and cooling

systems in good order

Al

l Diagnostic Trouble

Codes (DTCs) cleared

Al

l rectification work

relating to DTCs completed

F

uses

Harnes

ses

E

lectrical connectors

1.

Either

the Jaguar approved diagnostic system (where

available), or a scan tool should be connected to measure the

Mass Air Flow rate. Most generi c scan tools should be capable

of reading this parameter.

Depending on road conditions and dealer location, it may be

difficult to achieve the road sp eeds necessary to reach the air

flow indicated. It is possible to reach these air flow figures by

inducing a load on the vehicle, (making use of hills, using a

lower gear ratio, etc) or, if no alternative is possible, by

restraining the vehicle and re aching the air flow figure

Si

te

Mass Air Flow

(gra

ms/second)

D

riving Conditions

1Up t

o 7 g/s

Idle

in

P for 2 minutes

21

0 to 14 g/s

O

pen throttle in

P for 2 minutes

31

8 to 22 g/s

O

pen throttle in

P or D with

guidance * for 2 minutes

42

5 to 30 g/s

D

rive with guidance * for 2

minutes

Page 1242 of 2490

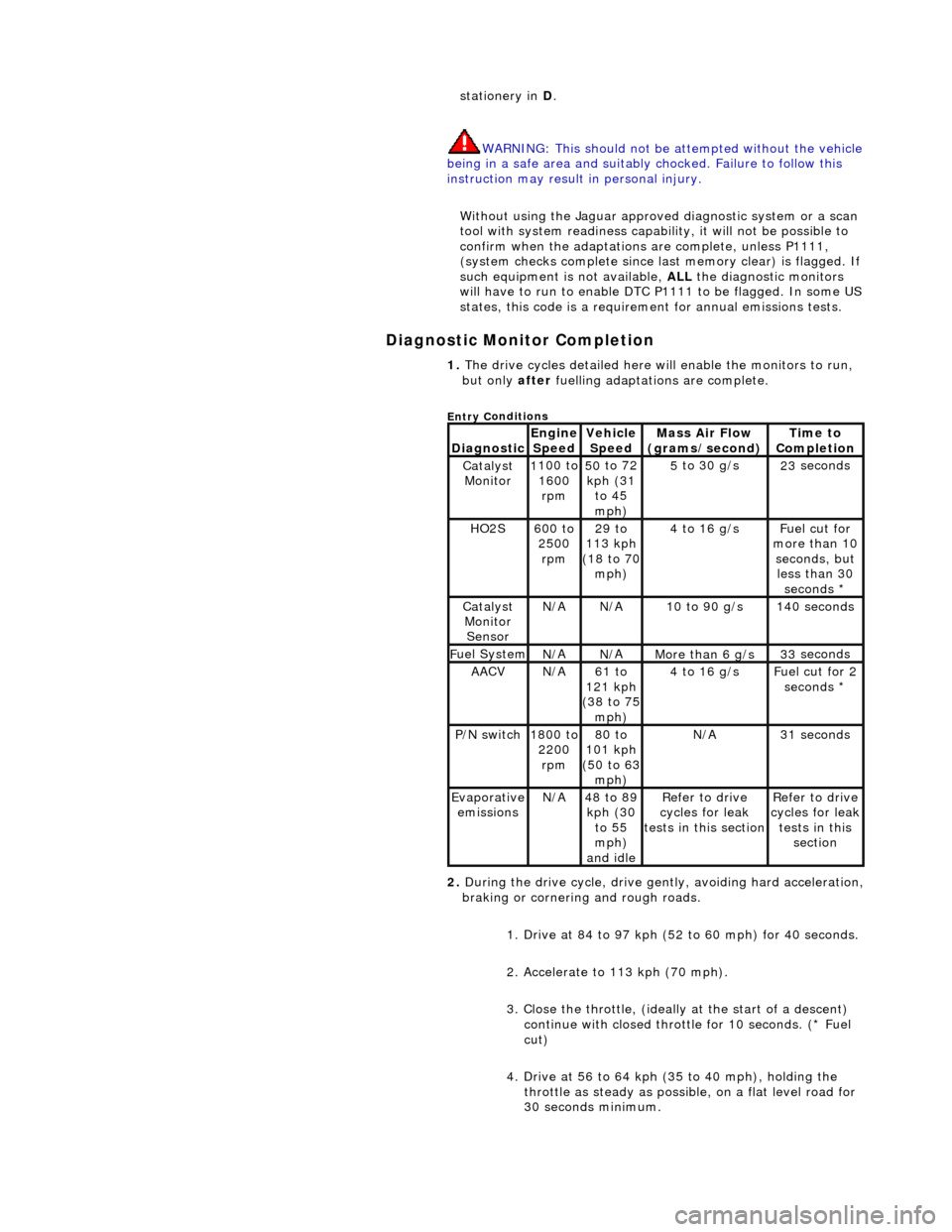

Diagnostic Monitor Comp

letion

stat

ionery in

D.

WARNING: This should not be attempted without the vehicle

being in a safe area and suitably chocked. Failure to follow this

instruction may result in personal injury.

Without using the Jaguar approved diagnostic system or a scan

tool with system readiness capability, it will not be possible to

confirm when the adaptations are complete, unless P1111,

(system checks complete since last memory clear) is flagged. If

such equipment is not available, ALL the diagnostic monitors

will have to run to enable DTC P1111 to be flagged. In some US

states, this code is a requirem ent for annual emissions tests.

1. The dri v

e cycles detailed here w

ill enable the monitors to run,

but only after fuelling adaptations are complete.

Entry C

onditions

Di

agno

stic

Engine

S p

eed

Ve

h

icle

Speed

Mass Air Flow

(gra ms/sec

ond)

Ti

m

e to

Completion

Catalyst Monitor1 100

to

1600 rpm

50 to

72

kph (31 to 45

mph)

5 to

30 g/s

23

se

conds

HO2S6

00 t

o

2500 rpm

29 to

113 kph

(18 to 70

mph)

4 to

16 g/s

F

u

el cut for

more than 10 seconds, but less than 30 seconds *

Catalyst Monitor SensorN/ AN/A10

to 90 g/s

14

0

seconds

F

u

el System

N/

AN/AMore than 6 g/s33 se

conds

AACVN/

A61 to

121 kph

(38 to 75

mph)

4 to

16 g/s

F

u

el cut for 2

seconds *

P /

N switch

1

800

to

2200 rpm

80 to

101 kph

(50 to 63

mph)

N/ A31 se

conds

Evaporative

em is

sions

N/

A48 to

89

kph (30 to 55

mph)

and idle

R e

fer to drive

cycles for leak

tests in this section

Re

fer to drive

cycles for leak

tests in this section

2. During the drive cycle, drive gent ly, avoiding hard acceleration,

braking or cornering and rough roads.

1. Drive at 84 to 97 kph (52 to 60 mph) for 40 seconds.

2. Accelerate to 113 kph (70 mph).

3. Close the throttle, (ideally at the start of a descent)

continue with closed throttle for 10 seconds. (* Fuel

cut)

4. Drive at 56 to 64 kph (35 to 40 mph), holding the throttle as steady as possib le, on a flat level road for

30 seconds minimum.

Page 1688 of 2490

Fuel System - General Inform

ation - Fuel System

Description an

d Operation

The fuel tank is mounted across the vehicle behind the passenger compartment bulkhead.

Fuel is drawn by the fuel pump from the tank and then supplied to the two fuel rails, via a filter.

Fuel injectors are installed in the fuel ra ils on each side of the intake manifold.

The amount of fuel injected into th e engine is controlled by the ECM.

A cross-over pipe connects the two fuel ra ils together at the front of the manifold.

A test valve in the cross-over pipe allo ws the fuel rail to be pressurized and de-pressurized during the servicing and

troubleshooting procedures.

A pressure regulator on the rear of the right fuel rail controls the pressure in the fuel rails.

A return line directs excess fuel from the pressure regulator back to the fuel tank.

Operation and service procedures

The fuel injector

s, rails, pres

sure regulator and, wher e fitted, supercharger are described in greater detail in Section 303-04

together with servicing procedures.

The fuel tank, pump, fuel level senders and fuel lines are similarly covered in Section 310-01.

Page 1692 of 2490

Fuel Tank and Lines - Fuel Tank and Li

nes

Description an

d Operation

Fuel Tank

Parts List

The steel fuel tank is located inside the trunk and mounted across the vehicle behind the passenger compartment bulkhead.

The fuel tank is held in posi tion by two retaining straps fi tted to body-mounted brackets.

The fuel tank has an integral non-adjustable fill er pipe and integral breather and vapor pipework.

A single fuel pump is mounted inside the tank on vehicles with normally aspirated engines. For vehicles with supercharged

engines, two pumps are fitted in the tank. Fuel is drawn by the pump(s) from the fuel tank and supplied via the fuel lines

and 70 micron filter to the fuel rails.

The fuel lines run from front-to-rear down the vehicle's left-hand-side.

Ite

m

Part

Number

Descr

iption

1—Fu

el filler latch box

2—Pressure reli

ef pipe, ORVR

(shown) / tank breather pipe on non-ORVR systems

3—Tank grounding

cable

4—Evaporative flan

ge assembly

(ORVR type shown)

5—Trunk elec

trical harne

ss (part of)

6—Fue

l

level sensor

flange/connector

7—Fu

el tank retaining straps

8—F

u

el tank retaining stra

ps adjustable clamps

9—Fu

el tank retaining straps lower brackets

10—Tank vapor outlet pipe to un

derflo

or pipe quick-fit connector

11—F

u

el filler latch bo

x water drain pipe

Page 1694 of 2490

P a

rts List

The fuel level sensor is mounte d on the fuel tank vertical face and reacts to level changes via a float and pivot which is

connected to a potentiometer. As the fuel level drops the resistance increases.

The fuel level sensor can be serviced without removing the tank.

It e

m

Par

t

Number

De

scr

iption

1—Lockin

g rin

g

2—Fue

l

level sensor

3—Seal

Fuel

Level Sensor

Page 1698 of 2490

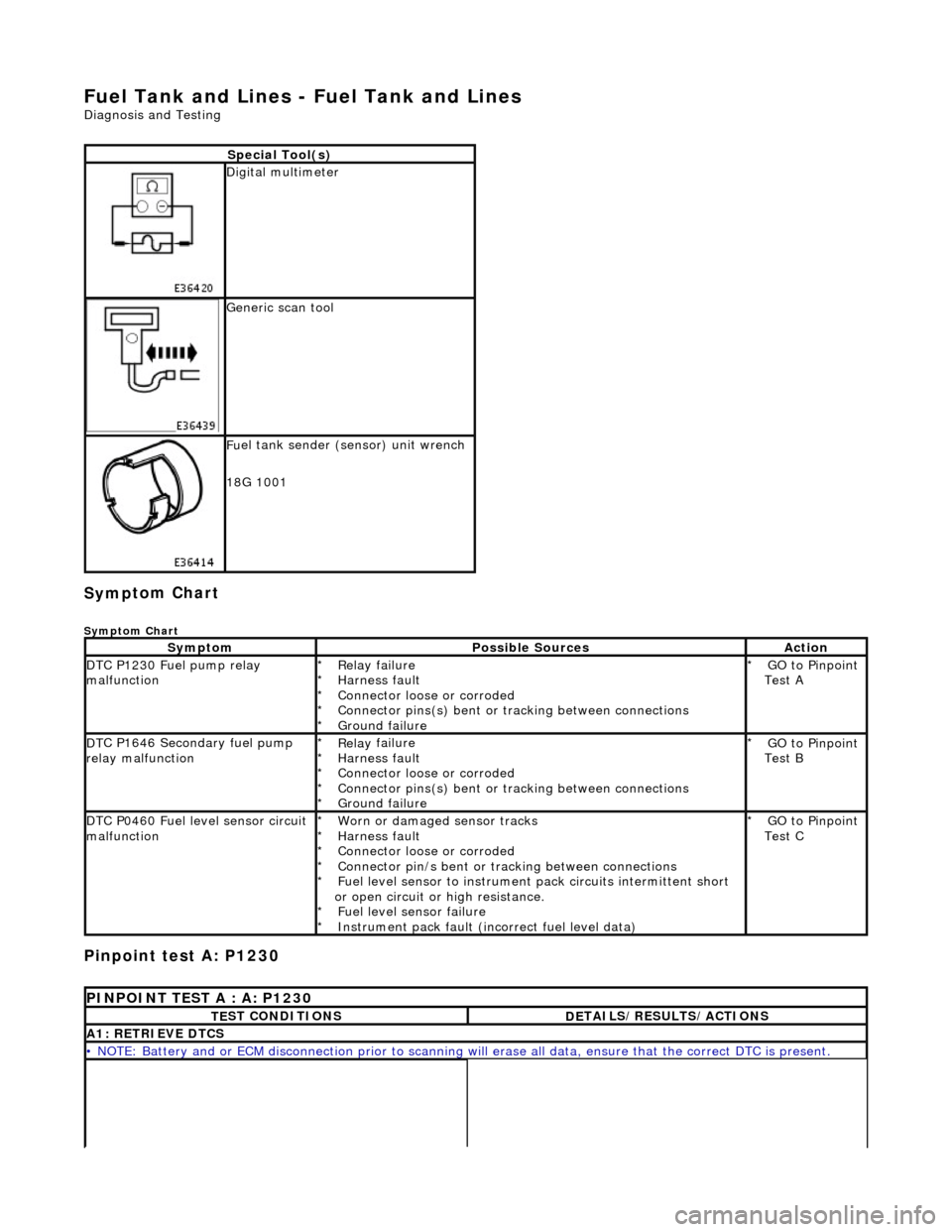

Fuel Tank and Lines - Fuel Tank and Li

nes

D

iagn

osis and Testing

Sym

p

tom Chart

Sy

m

ptom Chart

Pinpoint test A: P1230

S

p

ecial Tool(s)

D

i

gital multimeter

Generi

c scan tool

F

u

el tank sender (sensor) unit wrench

18G 1001

Sy m

ptom

Possib

l

e Sources

Acti

o

n

D

T

C P1230 Fuel pump relay

malfunction

Re lay

failure

Harness fault

Connector loose or corroded

Connector pins(s) bent or tracking between connections

Ground failure

*

*

*

*

*

GO to Pinpoint

Test A

*

D

T

C P1646 Secondary fuel pump

relay malfunction

Re lay

failure

Harness fault

Connector loose or corroded

Connector pins(s) bent or tracking between connections

Ground failure

*

*

*

*

*

GO to Pinpoint

Test B

*

D

T

C P0460 Fuel level sensor circuit

malfunction

Worn

or damaged sensor tracks

Harness fault

Connector loose or corroded

Connector pin/s bent or tracking between connections

Fuel level sensor to instrument pack circui ts intermittent short

or open circuit or high resistance. Fuel level sensor failure

Instrument pack fault (inc orrect fuel level data)

*

*

*

*

*

*

*

GO to Pinpoint

Test C

*

P

INPOINT TES

T A : A: P1230

T

E

ST CONDITIONS

D

E

TAILS/RESULTS/ACTIONS

A1

: RETRIEV

E DTCS

•

NOTE

: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Page 1727 of 2490

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to C2

C2

: CHECK CONTINUITY FUEL SENSOR

W

ith connectors BT014 and BT015 disconnected check

the resistance between the fuel level sensor pins.

1

Is

the resistance >70 and <1000 OHM?

Yes GO to C3

No Renew the level sensor and test the system for normal

operation.

C3

: CHECK FOR SHORT TO GROUND

Page 1732 of 2490

Fu

el Tank and Lines - Fuel Level Sensor

Remov

a

l and Installation

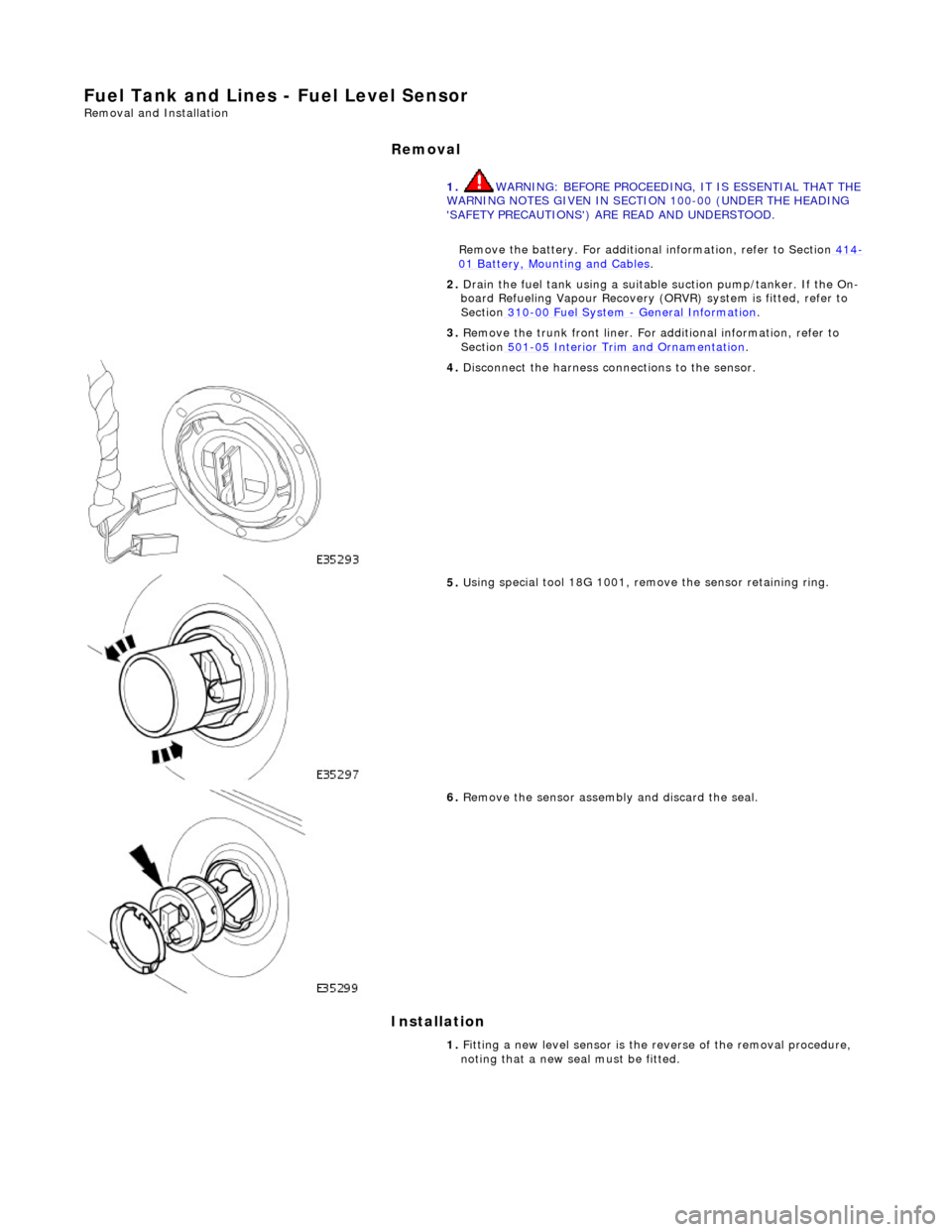

Removal

Ins

tallation

1.

WA

RNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT THE

WARNING NOTES GIVEN IN SECTIO N 100-00 (UNDER THE HEADING

'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD.

Remove the battery. For additional information, refer to Section 414

-01

Battery, Mounting and Cables

.

2.

Drain

the fuel tank using a suitable suction pump/tanker. If the On-

board Refueling Vapour Recovery (ORVR) system is fitted, refer to

Section 310

-00 Fu

el System

- Gen

e

ral Information

.

3. Remov

e the trunk front liner. For additional information, refer to

Section 501

-05 Interior Trim

and Ornamentation

.

4. D

isconnect the harness co

nnections to the sensor.

5. U

sing special tool 18G 1001, remo

ve the sensor retaining ring.

6.

Remov

e the sensor assembly and discard the seal.

1. Fitting a new level sensor is the reverse of the removal procedure,

noting that a new seal must be fitted.

Page 1736 of 2490

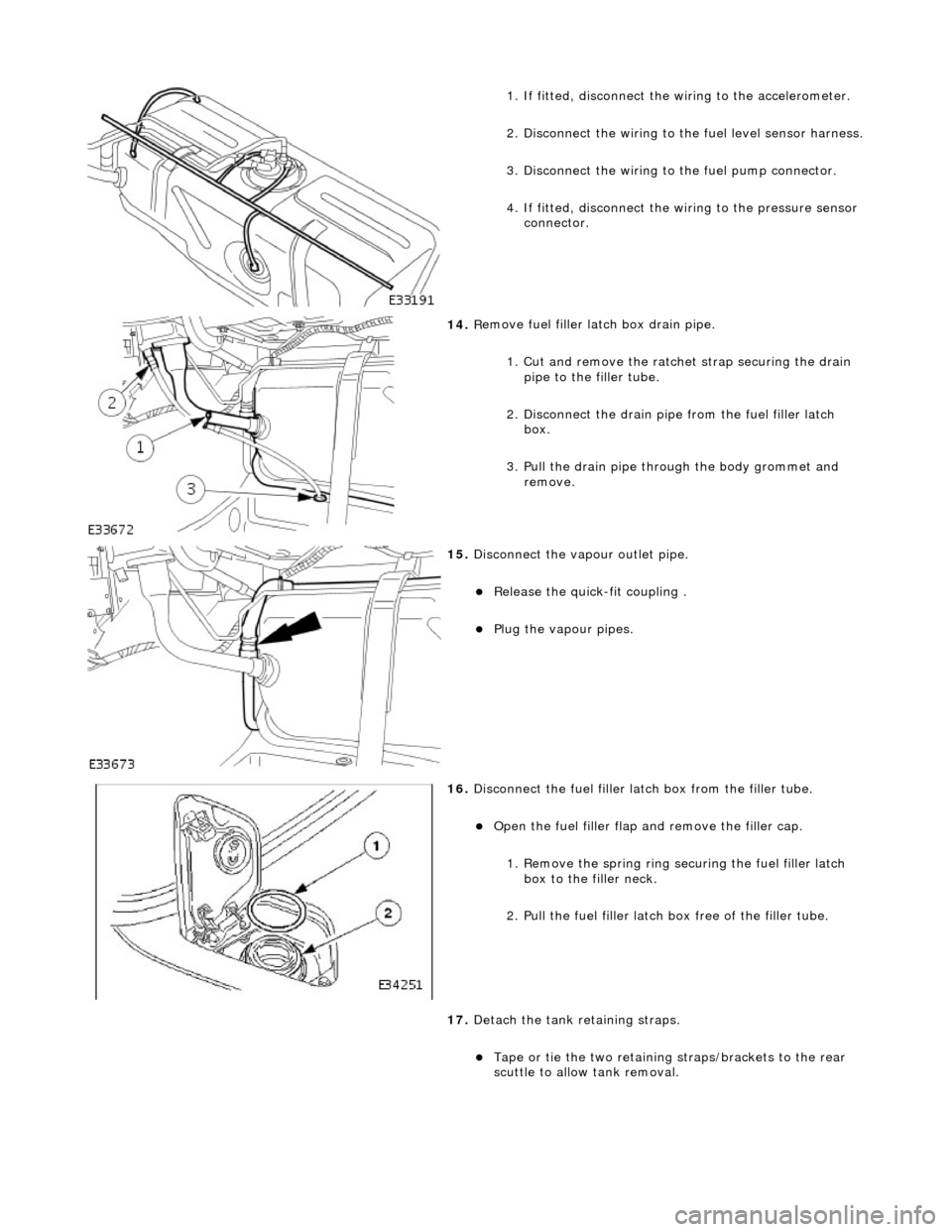

1.

If fitted, disconnect the

wiring to the accelerometer.

2. Disconnect the wiring to the fuel level sensor harness.

3.

Disc

onnect the wiring to

the fuel pump connector.

4. If fitted, disconnect the wi ring to the pressure sensor

connector.

14 . R

emove fuel filler

latch box drain pipe.

1. Cut and remove the ratche t strap securing the drain

pipe to the filler tube.

2. Disconnect the drain pipe from the fuel filler latch box.

3. Pull the drain pipe th rough the body grommet and

remove.

15 . Di

sconnect the vapo

ur outlet pipe.

Relea

se the quick-fit coupling .

Plu

g

the vapour pipes.

16 . D

isconnect the fuel filler la

tch box from the filler tube.

Open t

he fuel filler flap

and remove the filler cap.

1. Remove the spring ring se curing the fuel filler latch

box to the filler neck.

2. Pull the fuel filler latch box free of the filler tube.

17. Detach the tank retaining straps.

Tape or tie the two reta i

ning straps/brackets to the rear

scuttle to allow tank removal.