air condition JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 20 of 2490

В В В В В В В В В В В В 310‐01: В Fu elВ Tank В and В Lines В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В FuelВ Level В Sensor В (88.25.32) В

В В В В В В В В В В В В В В В В В В В В FuelВ Pump В (19.45.08) В

В В В В В В В В В В В В В В В В В В В В FuelВ Tank В (19.55.01) В

В

310‐02

:

В Acceleration В Control В

В В В В В В В В В В В В В В В В GeneralВ Procedures В

В В В В В В В В В В В В В В В В В В В В Accelerator В CableВ Adjustment В (12.20.05) В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В Accelerator В CableВ (19.20.06) В

В

В В В В В В В В В В В В 310‐03: В Speed В Control В

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В SpeedВ Con

trolВ

В

В В В В 4: В Electrical В

В

В В В В В В В В 412: В Climate В Control В System В

В

В В В В В В В В В В В В 412‐00: В Climate В Control В System  ‐ General В InformationВ

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В ClimateВ ControlВ System В

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В ClimateВ ControlВ System В

В В В В В В В В В В В В В В В В GeneralВ Procedures В

В В В В В В В В В В В В В В В В В В В В AirВ Conditioning В (A/C) В System В Check ‐ RetailВ Procedure В

В В В В В В В В В В В В В В В В В В В В AirВ Conditioning В (A/C) В System В Recovery, В Evacuation В and В ChargingВ (82.30.30) В

В В В В В В В В В В В В В В В В В В В В Contaminated В Refrigerant В Ha

ndling В

В В В В В В В В В В В В В В В В В В В В ManifoldВ GaugeВ SetВ Connection В

В В В В В В В В В В В В В В В В В В В В RefrigerantВ AddingВ (82.30.02) В

В В В В В В В В В В В В В В В В В В В В RefrigerantВ OilВ Adding В

В В В В В В В В В В В В В В В В В В В В RefrigerantВ SystemВ Tests В

В

В В В В В В В В В В В В 412‐01: В Air В Distribution В and В Filtering В

В В В В В В В В В В В В В В В В Description В and В Operation В

Page 21 of 2490

В В В В В В В В В В В В В В В В В В В В AirВ Distributio nВ and В Filt

ering

В

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В AirВ Distribution В and В Filtering В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В CenterВ Registers В (82.20.38) В

В В В В В В В В В В В В В В В В В В В В DriverВ Side В Blower В Motor В (82.25.56) В

В В В В В В В В В В В В В В В В В В В В PassengerВ Side В Blower В Motor В (82.25.55) В

В В В В В В В В В В В В В В В В В В В В PlenumВ Chamber В (82.20.87) В

В

В В В В В В В В В В В В 412‐02: В Heating В and В Ventilation В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В HeatingВ and В Ventilation В

В В В В В В В В В В В В В В В В В В В

В В В В В В В В В В В В В В В В В В В В В

В В

В В В В В В В В В В В В В В В В Removal

В and В Installation В

В В В В В В В В В В В В В В В В В В В В Heater

В Core В (80.20.29) В

В В В В В В В В В В В В В В В В В В В В Heater

В Core В and В Evaporator В Core В Housing В (82.25.21) В

В

В В В В В В В В В В В В 412

‐03: В Air В Conditioning В

В В В В В В В В В В В В В В В В Description

В and В Operation В

В В В В В В В В В В В В В В В В В В В В AirВ

Conditioning В

В В В В В В В В В В В В В В В В Diagnosis

В and В Testing В

В В В В В В В В В В В В В В В В В В В В AirВ

Conditioning В

В В В В В В В В В В В В В В В В Removal

В and В Installation В

В В В В В В В В В В В В В В В В В В В В AirВ

Conditioning В (A/C) В CompressorВ (82.10.20)В

В В В В В В В В В В В В В В В В В В В В Condenser

В Core В (82.15.07) В

В В В В В В В В В В В В В В В В В В В В Evaporator

В Core В (82.25.20) В

В В В В В В В В В В В В В В В В В В В В Press

ureВ Cutoff В Switch В (82.10.32) В

В В В В В В В В В В В В В В В В В В В В Receiver

В Drier В (82.17.01) В

В

В В В В В В В В В В В В 412

‐04: В Control В Components В

В В В В В В В В В В В В В В В В Description

В and В Operation В

В В В В В В В В В В В В В В В В В В В В ControlВ

Components В

В В В В В В В В В В В В В В В В Diagnosis

В and В Testing В

В В В В В В В В В В В В В В В В В В В В ControlВ

Components В

В В В В В В В В В В В В В В В В Removal

В and В Installation В

В В В В В В В В В В В В В В В В В В В В AirВ

Discharge В Temperature В Sensor В (82.20.64) В

Page 35 of 2490

General Infor

mation - Gene

ral Service Information

Description an

d Operation

Safety Notice

Appropri

ate service me

thods and proper repair procedures are essential for the safe, reliable operation of all motor vehicles,

as well as the safety of the person do ing the work. This manual provides genera l directions for accomplishing service and

repair work with tested, effect ive, techniques. Following them will help assure reliability.

There are numerous variations in procedures, techniques, tools, and parts for servicing vehicles, as well as in the skill of the

person doing the work. This manual cannot possibly anticipate all such variations and provide advice or cautions as to each.

Accordingly, anyone who depart s from the instructions provided in the manua l must first establish that neither personal

safety nor vehicle integrity is compromised from choices of methods, tools or parts.

Notes, Ca

utions and Warnings

Throughout

this manual, important inform

ation is highlighted by the use of notes, cautions and warnings. NOTES give

additional information on a topic or proc edure, CAUTIONS are given to prevent da mage to the vehicle, and WARNINGS are

given to prevent personal injury.

Worksh

op Manual Organization

This

manual incorporates descript

ive, diagnostic, and repair information to help trained Jaguar technicians complete service

and rectification procedures. The informat ion can be accessed by choosing the appropriate five digit section number. For

example, Section 412-03 covers air conditioning , which is part of the Climate Control System.

The manual is organized into groups covering generic aspects of the vehicle systems; the first digit of the section

number represents a group se lected from the following:

1. General Information.

2. Chassis.

3. Powertrain.

4. Electrical.

5. Body and Paint.

Each of the groups comprises sections re lating to specific areas of the vehicle.

The second and third digits of the section number indicate the vehicle system.

The last two digits of the se ction number define the system covered, more specifically.

Each section comprises one or more of the following sub-sections:

Specification

Page 36 of 2490

пЃ¬Gener

al specifications (including setting-up information, capacities, lubricants, fluids, sealants and adhesives).

пЃ¬To

r

que specifications.

Description and Operation

пЃ¬A g

eneral illustration and part

s list to identify the components which comp rise a particular system or assembly.

пЃ¬A b

rief description of the system operating characteristics or description of the assembly.

пЃ¬A d

escription of each component and its function.

Diagnosis and Testing

пЃ¬D e

scriptions of how to iden

tify system problems.

пЃ¬Inspection and verifi

cation information.

пЃ¬S

y

mptom charts comprising fault conditions, possible sources and actions.

General Procedures

пЃ¬G e

neral maintenance procedures, including adjustment, alig

nment, bleeding and filling, with illustrated steps and

supporting text.

пЃ¬Tigh te

ning torque specifications, shown in the illustrations.

Removal and Installation

пЃ¬Com p

onent removal and installation maintenance proced

ures, with illustrated steps and supporting text.

пЃ¬Tighte

ning torque specifications, shown in the illustrations.

пЃ¬An i

llustrated tool

chart for each proced

ure requiring the use of special tools.

Disassembly and Assembly

пЃ¬Compon ent disassembly and

assembly

maintenance procedures, with illust rated steps and supporting text.

пЃ¬Tighte

ning torque specifications, shown in the illustrations.

пЃ¬An i

llustrated tool

chart for each proced

ure requiring the use of special tools.

Repairs and Replacem

ents

Wh

en s

ervice parts are required, it is essential that only genuine Jaguar/Daimler replacements are used.

Attention is drawn to the following points concerning repa irs and the fitting of replacement parts and accessories:

пЃ¬Safety feat

ures embodied in the vehicle

may be impaired if other than genuine parts are fitted. In certain territories,

legislation prohibits the fitting of pa rts which are not produced to the vehi cle manufacturer's specification.

пЃ¬Torque wrench setting figures given i

n this manual must be strictly adhered to. Locking devices, where specified,

must be fitted. If the efficiency of a locking device is impaired during removal it must be renewed.

пЃ¬O w

ners purchasing accessories

while travelling abroad should ensure that the accessory and its fitted location on the

vehicle conform to mandatory requirements existing in their country of origin.

пЃ¬The vehicle warranty may be invali

dated by the fitting

of other than genuine Ja guar/Daimler parts. All

Jaguar/Daimler replacements have the fu ll backing of the factory warranty.

пЃ¬Jaguar/Daimler dealers are obliged to

supply only genuine service parts.

Thread Locking Devices

P a

tched Fasteners

Two types

of

patched fastener are essentially used on certai

n suspension, steering and other critical components, where

operational movement of the component necessitates positive thread locking. Standard patched fasteners have part

numbers bearing the suffix le tter M. For identification of special patched fa steners, refer to the list of patched fasteners

below, or the relevant component drawings.

Jaguar Specification JFS 02.01.02 patched fasteners incorporate a micro-encapsulated adhesive which is released into the

mating threads during tightening. Following final tightening, the adhesive in this type of patched fastener must be allowed a

period to cure before the component/vehicle is used. On removal, this type of fastener must be discarded and a new

Page 39 of 2490

Before inspecting a component for wear or per

forming a dimensional check,

ensure that it is absolutely clean; a slight smear

of grease can conceal an incipient failure. When a component is to be checked dimensionally against figures quoted for it,

use the correct equipment (surface plates, micrometers, dial gauges etc.) in serviceable condition. The use of makeshift

equipment can be dangerous. Reject a component if its dimensio ns are outside the limits quoted, or if damage is apparent.

A part may be refitted if its critical di mension is exactly to the limit size and it is otherwise satisfactory. Use Plastigauge 12

Type PG-1 for checking bearing surface clearance, e.g. big end bearing shell to crank jour nal. Instructions for the use of

Plastigauge and a scale giving bearing clearances in steps of 0.0025 mm (0.0001 in) are supplied with the package.

Safety

Precautions

• WAR

NINGS:

WORKING ON THE FUEL SYSTEM RESULTS IN FUEL AND FUEL VAPOUR BEING PRESENT IN THE ATMOSPHERE. FUEL

VAPOUR IS EXTREMELY FLAMMABLE, HENCE GREAT CARE MUST BE TAKEN WHILST WORKING ON THE FUEL SYSTEM.

ADHERE STRICTLY TO THE FOLLOWING PRECAUTIONS:

пЃ¬DO

NOT SMOKE IN THE WORK AREA.

пЃ¬DISP

LAY 'NO SMOKING' SIGNS AROUND THE AREA.

пЃ¬DISCONNECT TH

E BATTERY BEFORE WORKING ON THE FUEL SYSTEM.

пЃ¬DO NOT CONNEC

T/DISCONNECT ELECTRICAL CIRCUITS

, USE ELECTRICAL EQUIPMENT OR OTHER TOOLS OR

ENGAGE IN WORKING PRACTICES WHICH IN ANY WAY MAY RESULT IN THE PRODUCTION OF SPARKS.

пЃ¬ENS

URE THAT A CO2 FIRE EXTINGUISHER IS CLOSE AT HAND.

пЃ¬ENS

URE THAT DRY SAND IS AVAILABLE TO SOAK UP ANY FUEL SPILLAGE.

пЃ¬EMP

TY FUEL USING SUITABLE FIRE PROOF EQUIPMENT IN

TO AN AUTHORIZED EXPLOSION PROOF CONTAINER.

пЃ¬DO NOT EMP

TY FUEL WHILE WORKING IN A WORKSHOP OR A PIT.

пЃ¬ENS

URE THAT WORKING AREA IS WELL VENTILATED.

пЃ¬ENS

URE THAT ANY WORK ON THE FUEL SYSTEM IS ON

LY CARRIED OUT BY EXPERIENCED AND WELL QUALIFIED

MAINTENANCE PERSONNEL.

пЃ¬ENS

URE THAT FUME EXTRACTION EQUIPMENT IS USED WHERE APPROPRIATE.

FUME EXTRACTION EQUIPMENT MUST BE IN OPERATION WHEN SOLVENTS ARE USED E.G. TRICHLOROETHANE,

WHITE SPIRIT, SBP3, METHYLENE CHLORIDE, PERCHLORETHY LENE. DO NOT SMOKE IN THE VICINITY OF VOLATILE

DEGREASING AGENTS.

General workshop practices:

пЃ¬Disc

onnect the grounded termin

al of the vehicle battery.

пЃ¬D

o not apply heat in an attempt to free seized nuts or fitt

ings; as well as causing damage to protective coatings,

there is a risk of damage from stray heat to electronic equipment and brake lines.

пЃ¬Keep oils and solven

ts away from naked flames and other sour

ces of ignition.

пЃ¬Adhere str

ictly to handling and safety inst

ructions given on containers and labels.

пЃ¬E

nsure that a suitab

le form of fire extinguisher is conveniently located.

пЃ¬Wh

en using electrical tools and equipment, inspect the power

lead for damage and check that it is properly earthed.

пЃ¬D

o not leave tools, equipment, spilt oil etc. around the work area.

Working beneath a vehicle:

пЃ¬Wh

enever possible, use a ramp or

pit in preference to jacking.

пЃ¬Posit

ion chocks at the wheels as we

ll as applying the parking brake.

пЃ¬N

ever rely on a jack alone to support a

vehicle; use axle stands, or blocks care fully placed at the jacking points, to

provide a rigid location.

пЃ¬Ch

eck that any lifting equipment used has adeq

uate capacity and is fully serviceable.

Working on air conditioning systems:

пЃ¬D

o not disconnect any pipes of the refrigeration system

unless you are trained and instructed to do so; a refrigerant

is used which can cause blindness if allowed to come into contact with the eyes.

Health Protection

P

rolonged and repeated contact with mineral oil will result in the removal of natural oils from the skin, leading to dryness,

In

spection

Page 42 of 2490

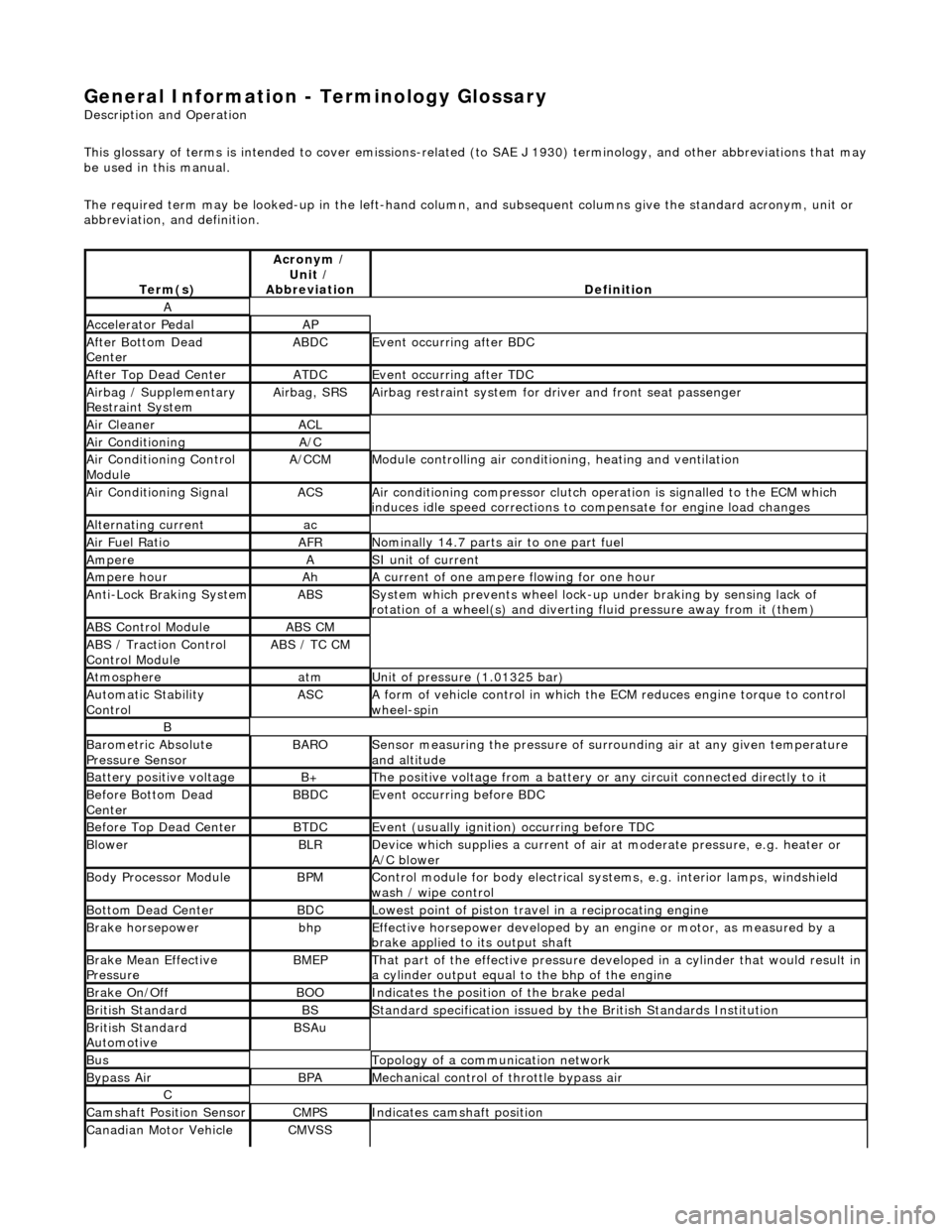

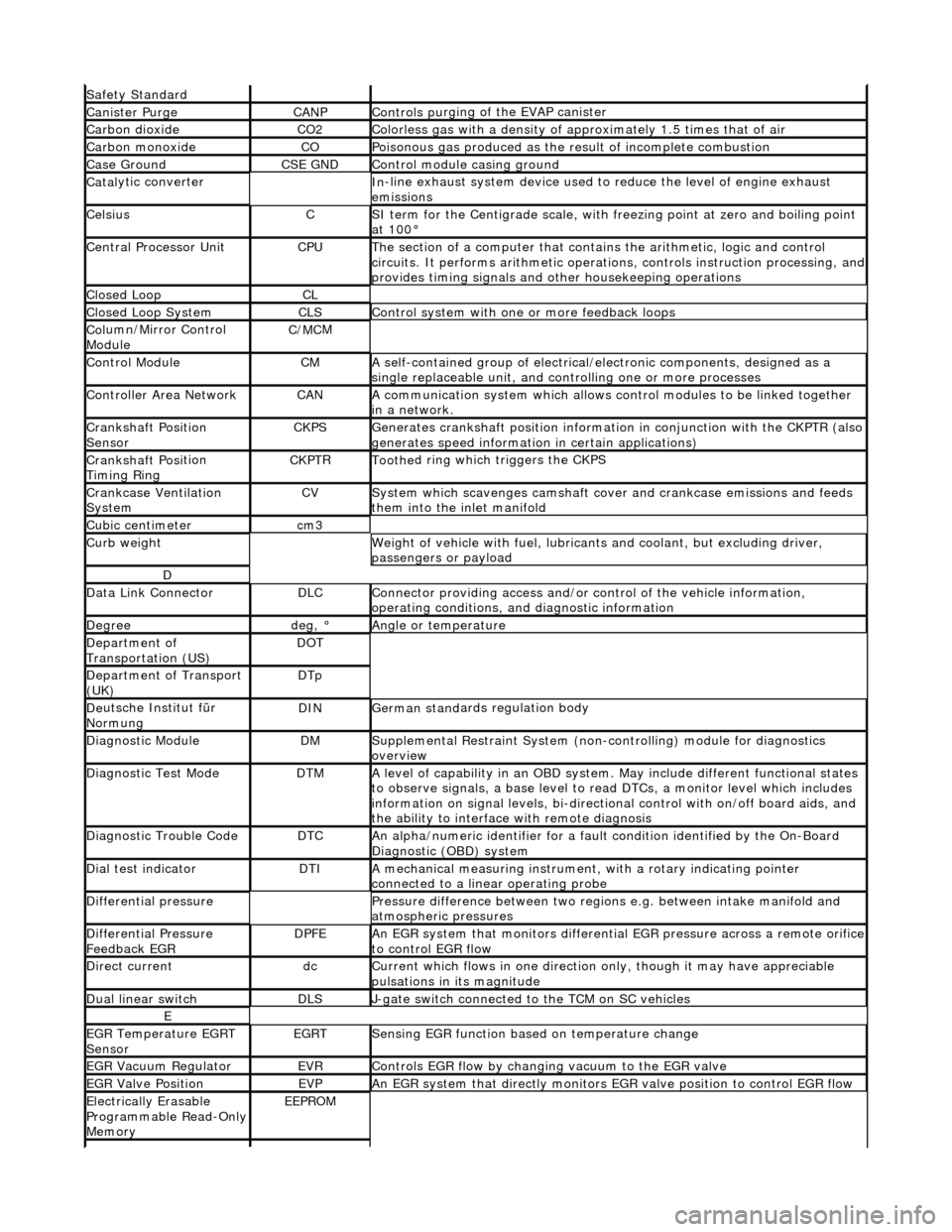

General Information - Terminology Glossary

Description an

d Operation

This glossary of terms is intended to cover emissions-related (to SAE J 1930) term inology, and other abbreviations that may

be used in this manual.

The required term may be looked-up in th e left-hand column, and subsequent columns give the standard acronym, unit or

abbreviation, and definition.

Te rm

(s)

Acr

ony

m /

Unit /

Abbreviation

De fi

nition

A

Accel

e

rator Pedal

AP

Af

ter Botto

m Dead

Center

ABDCEvent occurri ng after

BDC

Af

ter Top Dead CenterATDCEvent occurri ng after

TDC

Ai

rbag /

Supplementary

Restraint System

Airbag, SRSAi rbag restraint system for

dr

iver and front seat passenger

Air Cleane rACL

Air ConditioningA/C

Air Conditioning Con t

rol

Module

A/CCMModule c

ontrolling air conditioning, heating and ventilation

Air Conditioning SignalACSA

i

r conditioning compressor clutch operation is signalled to the ECM which

induces idle speed corrections to co mpensate for engine load changes

Alternating cu

rrent

ac

Ai

r Fuel R

atio

AFRN

omi

nally 14.7 parts air to one part fuel

Ampe

reASI unit of current

Ampere hourAhA current of one ampere

fl

owing for one hour

Anti-Lock Braking SystemABSS

y

stem which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and divertin g fluid pressure away from it (them)

ABS Control Mo

dule

ABS CM

ABS /

T

raction Control

Control Module

ABS / T

C CM

Atmosph

e

re

atmU

n

it of pressure (1.01325 bar)

Au

to

matic Stability

Control

ASCA form of vehicle

control

in which the ECM reduces en gine torque to control

wheel-spin

B

Baro me

tric Absolute

Pressure Sensor

BAR OSensor measuring the pressure of surr ou

nding air at any given temperature

and altitude

Bat t

ery positive voltage

B+The posi

ti

ve voltage from a battery or

any circuit connected directly to it

Before Bottom Dead

CenterBBDCEvent occurri ng before BD

C

Before Top Dead

Center

BTD

CEvent (usual ly

ignition) occurring before TDC

Blowe

rBLRDe

vice which supplies a current of air at

moderate pressure, e.g. heater or

A/C blower

Body Processor M

odule

BPMControl modu

le

for body electrical systems, e.g. interior lamps, windshield

wash / wipe control

Bott om D

ead Center

BD

CLowest poin t of piston

travel in a reciprocating engine

Brake hors

epowe

r

bhpEffecti

ve horsepower devel

oped by an

engine or motor, as measured by a

brake applied to its output shaft

Brake Mean Effective

Pres sureBME PThat p

art of the effective

pressure developed in a cyli nder that would result in

a cylinder output equal to the bhp of the engine

Brake On/ O

ff

BOOIn

dic

ates the position of the brake pedal

Br

it

ish Standard

BSStan

dar

d specification issued by the British Standards Institution

Br

it

ish Standard

Automotive

BSAu

BusTopology of a commu n

ication network

Bypass

AirBPAMechanica l

control of throttle bypass air

C

Camshaft Posit

i

on Sensor

CMPSIndi

cat

es camshaft position

Canadian Motor

V

ehicle

CMVSS

Page 43 of 2490

Safety Standard

Canister PurgeCANPControls pu

rging of the EVAP canister

Carbon dioxideCO2Colorless gas with

a density of a

pproximately 1.5 ti mes that of air

Carbon mon

oxide

COPoi

sonous gas produced as the re

sult of incomplete combustion

Case G

round

CSE GNDControl modu

le casing ground

Catal

ytic converter

In

-line exhaust system device used to reduce the level of engine exhaust

emissions

Ce

lsius

CSI ter

m for the Centigrade scale, with

freezing point at zero and boiling point

at 100В°

Central

Processor Unit

CPUTh

e section of a computer that contai

ns the arithmetic, logic and control

circuits. It performs arithm etic operations, controls instruction processing, and

provides timing signals and other housekeeping operations

Cl

osed Loop

CL

Cl

osed Loop System

CLSControl

system with one

or more feedback loops

Col

umn/Mirror Control

Module

C/MC

M

Control ModuleCMA

self-contained group of electrical/electronic components, designed as a

single replaceable un it, and controlling one or more processes

Controll

er Area Network

CANA

communication system which allows control modules to be linked together

in a network.

Crankshaft Posi

tion

Sensor

CKPSGenerates crankshaft positi on informa

tion in conjunct

ion with the CKPTR (also

generates speed information in certain applications)

Crankshaft Posi

tion

Timing Ring

CKPT

R

Toothe

d ring which

triggers the CKPS

Crankcase Ventila

tion

System

CVSys

tem which scavenges camshaft cover and crankcase emissions and feeds

them into the inlet manifold

Cubic ce nt

imeter

cm

3

Curb weightWe

ight of vehicle with fuel, lubrican

ts and coolant, but excluding driver,

passengers or payload

D

Dat

a Link Connector

DLCConne

ctor providing access and/or control of the vehicle information,

operating conditions, and diagnostic information

De

gree

deg, В°Angle or tempe

rature

D

epartment of

Transportation (US)

DO

T

D

epartment of Transport

(UK)

DTp

De

utsche In

stitut fГјr

Normung

DINGerman stand

ards regulation body

Di

agnostic Module

DMSuppl

emental Restraint System (non-c

ontrolling) module for diagnostics

overview

Di

agnostic Test Mode

DTMA le

vel of capability in an OBD system.

May include different functional states

to observe signals, a base level to re ad DTCs, a monitor level which includes

information on signal levels, bi-directional control with on /off board aids, and

the ability to interface with remote diagnosis

Diagnostic Trouble CodeDTCAn al

pha/numeric identifier for a fault

condition identified by the On-Board

Diagnostic (OBD) system

D

ial test indicator

DTIA mechan

ical measuring

instrument, with a rotary indicating pointer

connected to a linear operating probe

D

ifferential pressure

Pressure di

fference betwee

n two regions e.g. between intake manifold and

atmospheric pressures

D

ifferential Pressure

Feedback EGR

DP

FE

An

EGR system that monito

rs differential EGR pressure across a remote orifice

to control EGR flow

D

irect current

dcCurrent which f

lows in on

e direction only, though it may have appreciable

pulsations in its magnitude

Du

al linear switch

DLSJ

-gate switch connected to the TCM on SC vehicles

E

EGR

Temperature EGRT

Sensor

EGRTSens

ing EGR function based on temperature change

EGR Vacu

um Regulator

EVRControls EGR

flow by changi

ng vacuum to the EGR valve

EGR Valve

Position

EVPAn EGR

system that direct

ly monitors EGR valve position to control EGR flow

Electrically E

rasable

Programmable Read-Only

Memory

EEP

ROM

Page 267 of 2490

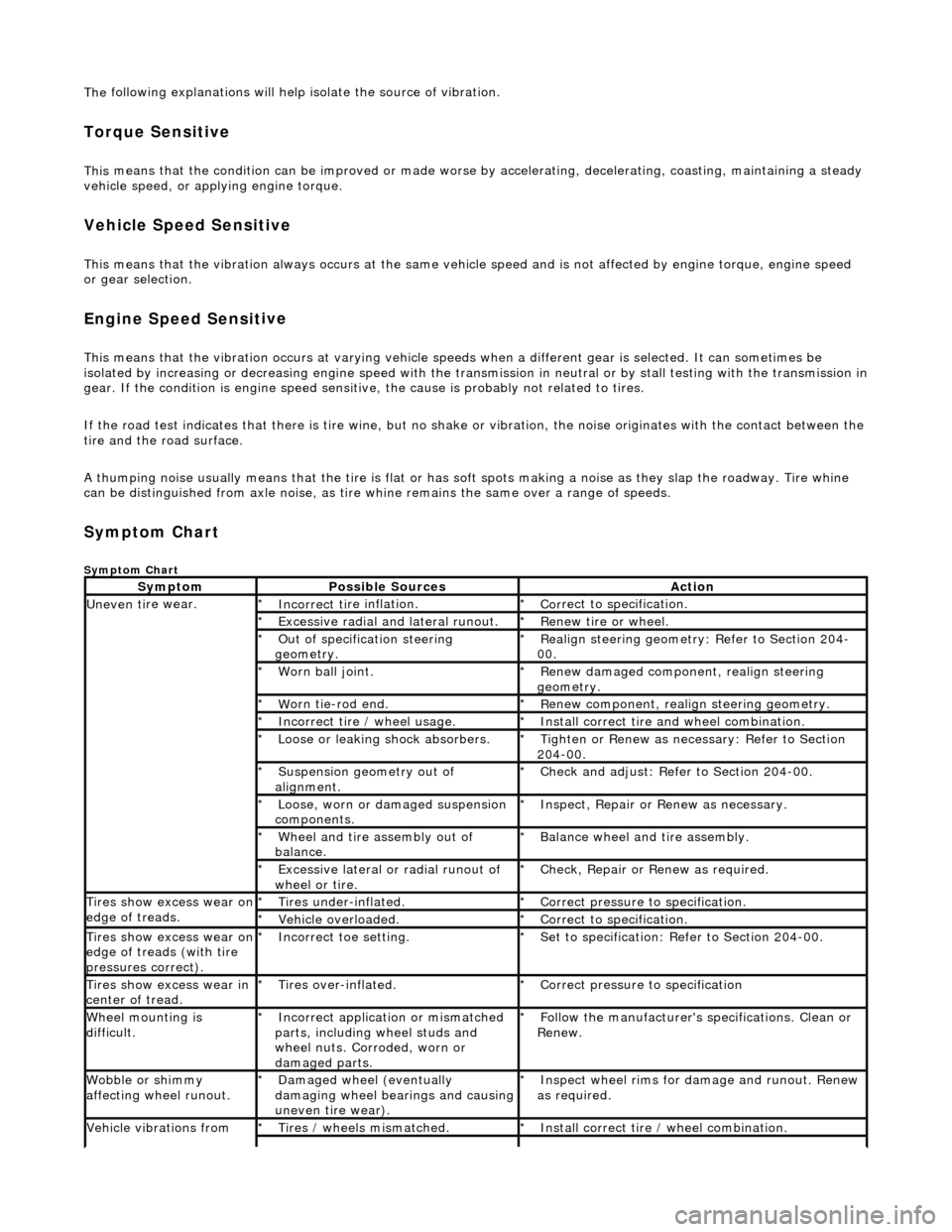

The

following explanations will help isolate the source of vibration.

Torque Sensitive

This

means that the condition can be impr

oved or made worse by accelerating, dece lerating, coasting, maintaining a steady

vehicle speed, or applying engine torque.

Ve

hicle Speed Sensitive

This means th

at the vibration al

ways occurs at the same vehicle speed and is not affected by engine torque, engine speed

or gear selection.

Engine Speed Sensit

ive

This means th

at the vibration

occurs at varying vehicle spee ds when a different gear is selected. It can sometimes be

isolated by increasing or decreasing engine speed with the tran smission in neutral or by stall testing with the transmission in

gear. If the condition is engine speed sensitive, the cause is probably not related to tires.

If the road test indicates that there is tire wine, but no shake or vibration, the noise originates with the contact between th e

tire and the road surface.

A thumping noise usually means that the tire is flat or has soft spots making a noise as they slap the roadway. Tire whine

can be distinguished from axle no ise, as tire whine remains the same over a range of speeds.

Sym

ptom Chart

Sy

mptom Chart

Sy

mptom

Possib

le Sources

Acti

on

Uneven ti

re wear.

Incorrect ti

re inflation.

*

Cor

rect to specification.

*

Exce

ssive radial an

d lateral runout.

*

Renew tire

or wheel.

*

O

ut of specification steering

geometry.

*

R

ealign steering geometry: Refer to Section 204-

00.

*

W

orn ball joint.

*

Renew

damaged component, realign steering

geometry.

*

W

orn tie-rod end.

*

R

enew component, realign steering geometry.

*

Incorrect

tire / wheel usage.

*

Inst

all correct tire and wheel combination.

*

Loose or leaki

ng shock absorbers.

*

Tigh

ten or Renew as nece

ssary: Refer to Section

204-00.

*

Suspensi

on geometry out of

alignment.

*

Che

ck and adjust: Refer to Section 204-00.

*

Loose, worn or da mage

d suspension

components.

*

In

spect, Repair or Renew as necessary.

*

Wh

eel and tire assembly out of

balance.

*

Balance wheel an

d tire assembly.

*

Excessive later

al or radial runout of

wheel or tire.

*

Check, Repair o

r

Renew as required.

*

Tire

s show excess wear on

edge of treads.

Ti

res under-inflated.

*

Cor

rect pressure to specification.

*

Vehi

cle overloaded.

*

Cor

rect to specification.

*

Tire

s show excess wear on

edge of treads (with tire

pressures correct).

Incorre

ct toe setting.

*

Se

t to specification: Refer to Section 204-00.

*

Tire

s show excess wear in

center of tread.

Tire

s over-inflated.

*

Cor

rect pressure to specification

*

W

heel mounting is

difficult.

Incorrect app

lication or mismatched

parts, including wheel studs and

wheel nuts. Corroded, worn or

damaged parts.

*

Fol

low the manufacturer's specifications. Clean or

Renew.

*

Wobble or sh

immy

affecting wheel runout.

Damaged wh

eel (eventually

damaging wheel bearings and causing

uneven tire wear).

*

Inspect wheel rims for

damage and runout. Renew

as required.

*

Vehicle vibrations from

Tire

s / wheels mismatched.

*

Inst

all correct tire / wheel combination.

*

Page 291 of 2490

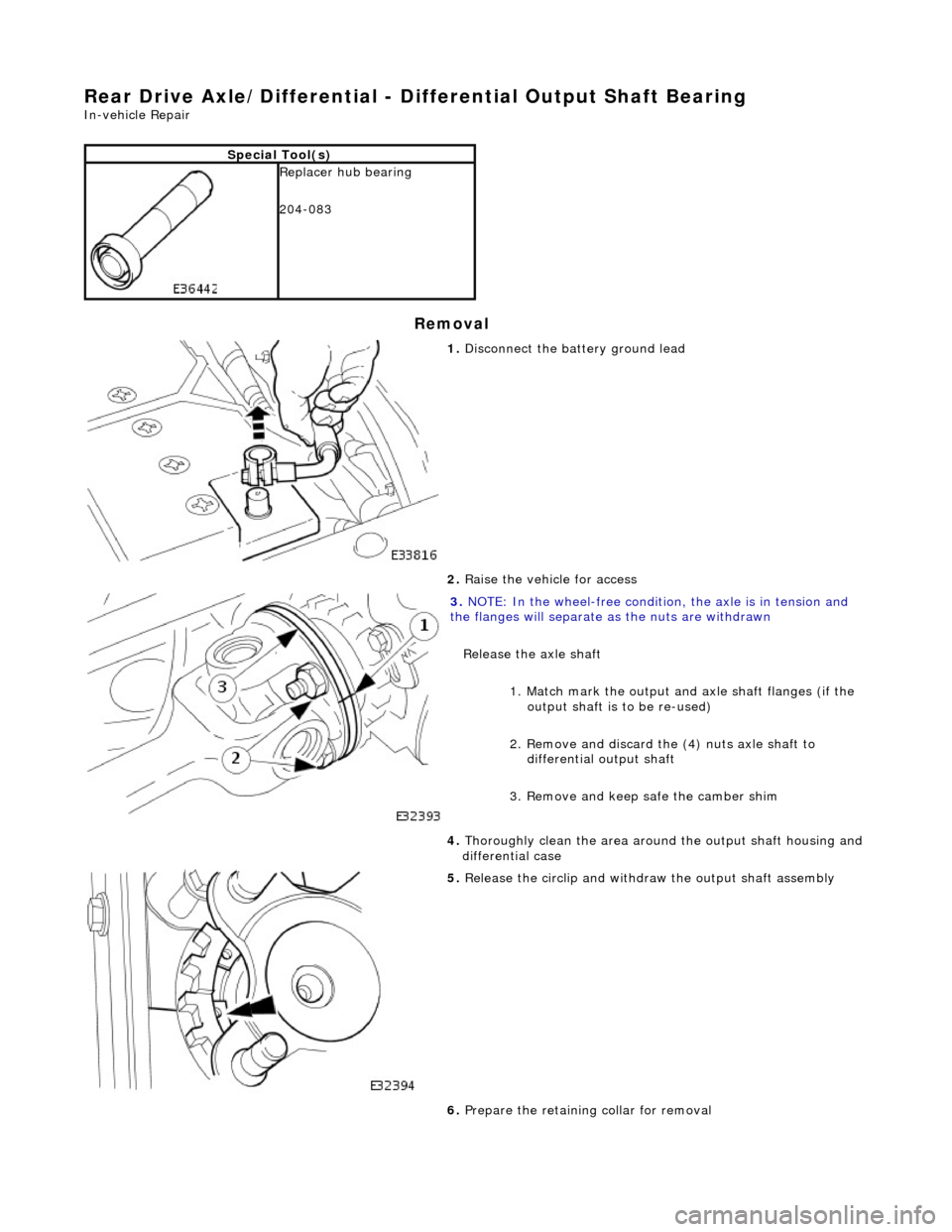

R

ear Drive Axle/Differential - Differential Output Shaft Bearing

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Replacer hu

b bearing

204-083

1. Di

sconnect the battery ground lead

2. Raise the vehicle for access

3. NO

TE: In the wheel-free condition, the axle is in tension and

the flanges will separate as the nuts are withdrawn

Release the axle shaft

1. Match mark the output an d axle shaft flanges (if the

output shaft is to be re-used)

2. Remove and discard the (4) nuts axle shaft to differential output shaft

3. Remove and keep safe the camber shim

4. T

horoughly clean the area around the output shaft housing and

differential case

5. Relea

se the circlip and withdraw the output shaft assembly

6. Prepare the retaining collar for removal

Page 310 of 2490

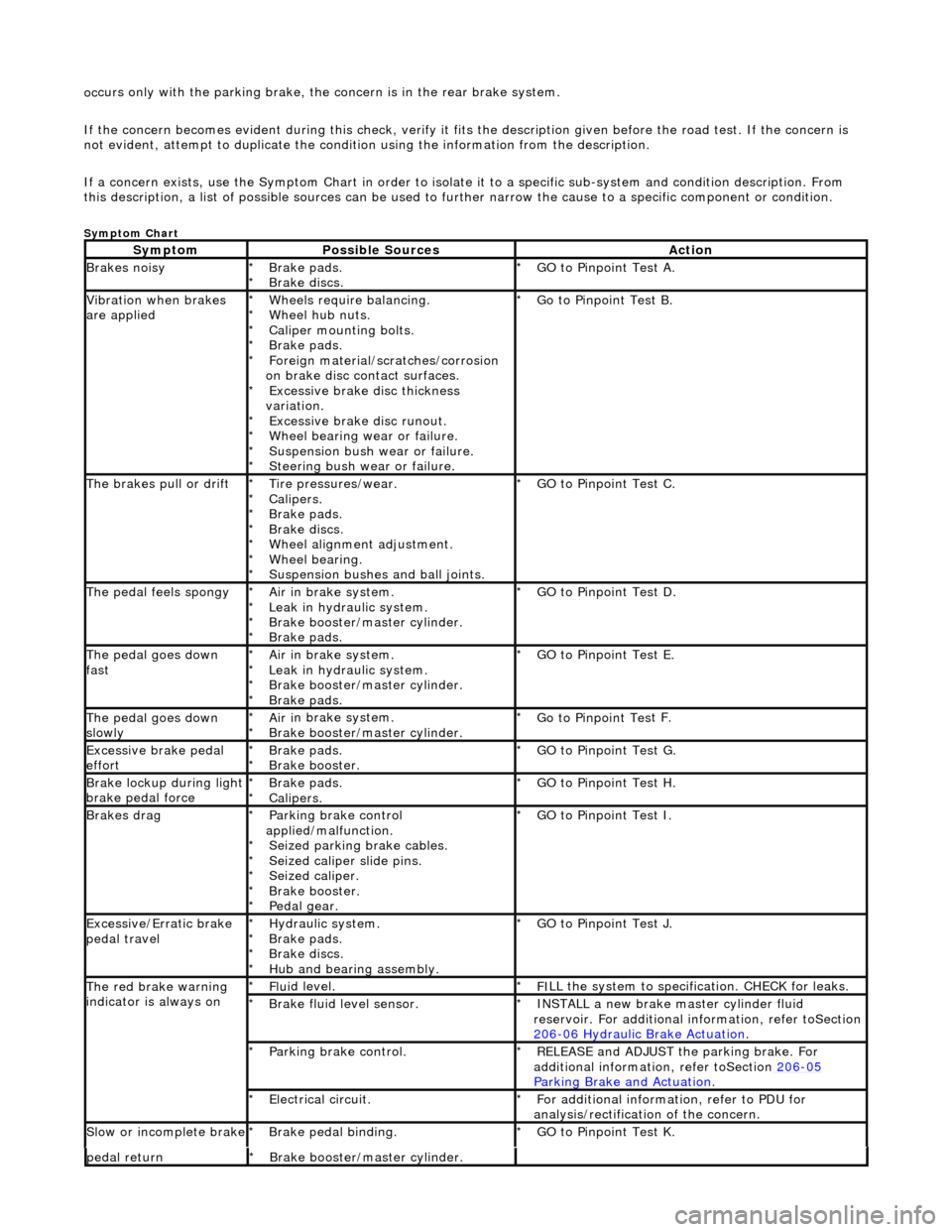

oc

curs only with the parking brake, th

e concern is in the rear brake system.

If the concern becomes evident during this check, verify it fits the description given before the road test. If the concern is

not evident, attempt to duplicate the condition using the information from the description.

If a concern exists, use the Symptom Chart in order to isolate it to a specific sub-system and condition description. From

this description, a list of possible sources can be used to further narrow the cause to a specific component or condition.

Sym

ptom Chart

Sy

m

ptom

Possib

l

e Sources

Acti

o

n

Brakes

n

oisy

Brake pads.

Brake di

scs

.

*

*

GO to Pinpoint

Tes

t A.

*

Vibration wh

en brakes

are applied

Wh eels require bala

ncing.

Wheel hub nuts.

Caliper mounting bolts.

Brake pads.

Foreign material/scr atches/corrosion

on brake disc contact surfaces. Excessive brake disc thickness

variation. Excessive brake disc runout.

Wheel bearing wear or failure.

Suspension bush wear or failure.

Steering bush wear or failure.

*

*

*

*

*

*

*

*

*

*

Go to Pinpoint

Tes

t B.

*

The brakes pull or drif tTire pressures/wear.

Calipers.

Brake pads.

Brake di

scs.

Wheel alignment adjustment.

Wheel bearing.

Suspension bushes and ball joints.

*

*

*

*

*

*

*

GO to Pinpoint

Tes

t C.

*

The pedal feels spongyAir i

n brake system.

Leak in hydraulic system.

Brake booster/master cylinder.

Brake pads.

*

*

*

*

GO to Pinpoint Tes

t D.

*

The pedal goes down

fa s

t

Ai

r i

n brake system.

Leak in hydraulic system.

Brake booster/master cylinder.

Brake pads.

*

*

*

*

GO to Pinpoint

Tes

t E.

*

The pedal goes down

slowl yAir i

n brake system.

Brake booster/master cylinder.

*

*

Go to Pinpoint

Tes

t F.

*

Excessive brake pedal

effor tBrake pads.

Brake booster.

*

*GO to Pinpoint

Tes

t G.

*

Brake lockup du ring ligh

t

brake pedal force

Brake pads.

Calipers.

*

*GO to Pinpoint

Tes

t H.

*

Brakes d r

ag

Parkin

g brake con

trol

applied/malfunction. Seized parking brake cables.

Seized caliper slide pins.

Seized caliper.

Brake booster.

Pedal gear.

*

*

*

*

*

*

GO to Pinpoint

Tes

t I.

*

Exce ssi

ve/Erratic brake

pedal travel

Hydrau li

c system.

Brake pads.

Brake discs.

Hub and bearing assembly.

*

*

*

*

GO to Pinpoint

Tes

t J.

*

The red brak e warning

indi

cator is always on

Fl

ui

d level.

*

F I

LL the system to specification. CHECK for leaks.

*

Brake flu i

d level sensor.

*

I N

STALL a new brake master cylinder fluid

reservoir. For additional in formation, refer toSection

206

-0 6

Hydraulic Brake Actuation

.

*

Parkin

g brake con

trol.

*

REL

E

ASE and ADJUST the parking brake. For

additional information, refer toSection 206

-05

Parkin g Brake an

d Actuation

.

*

E

l

ectrical circuit.

*

F or additional

information, refer to PDU for

analysis/rectification of the concern.

*

Sl

ow or i

ncomplete brake

Brake peda

l binding.

*

GO to Pinpoint Tes

t K.

*

pedal retu rnBr

ake booster/master cylinder.

*