ignition switch JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 898 of 2490

ENSURE THAT ALL FIRE PREVENTION PROCEDURES ARE ACTIVE.

BEFORE PROCEEDING, IT IS ESSENTIAL THAT THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD.

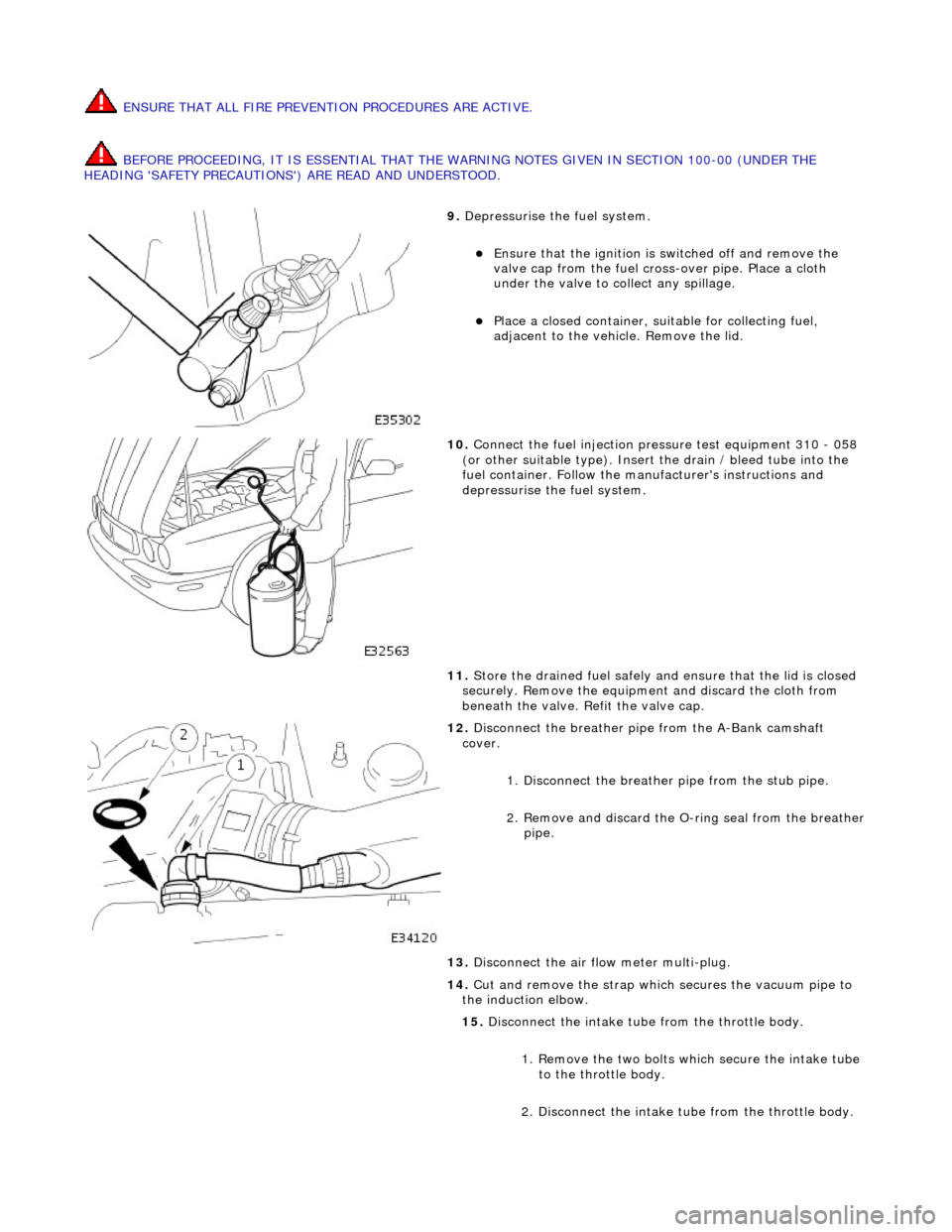

9. Depressurise the fuel system.

Ensure that the ignition is switched off and remove the

valve cap from the fuel cross-over pipe. Place a cloth

under the valve to collect any spillage.

Place a closed container, su itable for collecting fuel,

adjacent to the vehicle. Remove the lid.

10. Connect the fuel injection pressure test equipment 310 - 058

(or other suitable type). Insert the drain / bleed tube into the

fuel container. Follow the ma nufacturer's instructions and

depressurise the fuel system.

11. Store the drained fuel safely and ensure that the lid is closed

securely. Remove the equipmen t and discard the cloth from

beneath the valve. Refit the valve cap.

12. Disconnect the breather pipe from the A-Bank camshaft

cover.

1. Disconnect the breather pipe from the stub pipe.

2. Remove and discard the O-ring seal from the breather

pipe.

13. Disconnect the air flow meter multi-plug.

14. Cut and remove the strap which secures the vacuum pipe to

the induction elbow.

15. Disconnect the intake tube from the throttle body.

1. Remove the two bolts which secure the intake tube to the throttle body.

2. Disconnect the intake tube from the throttle body.

Page 948 of 2490

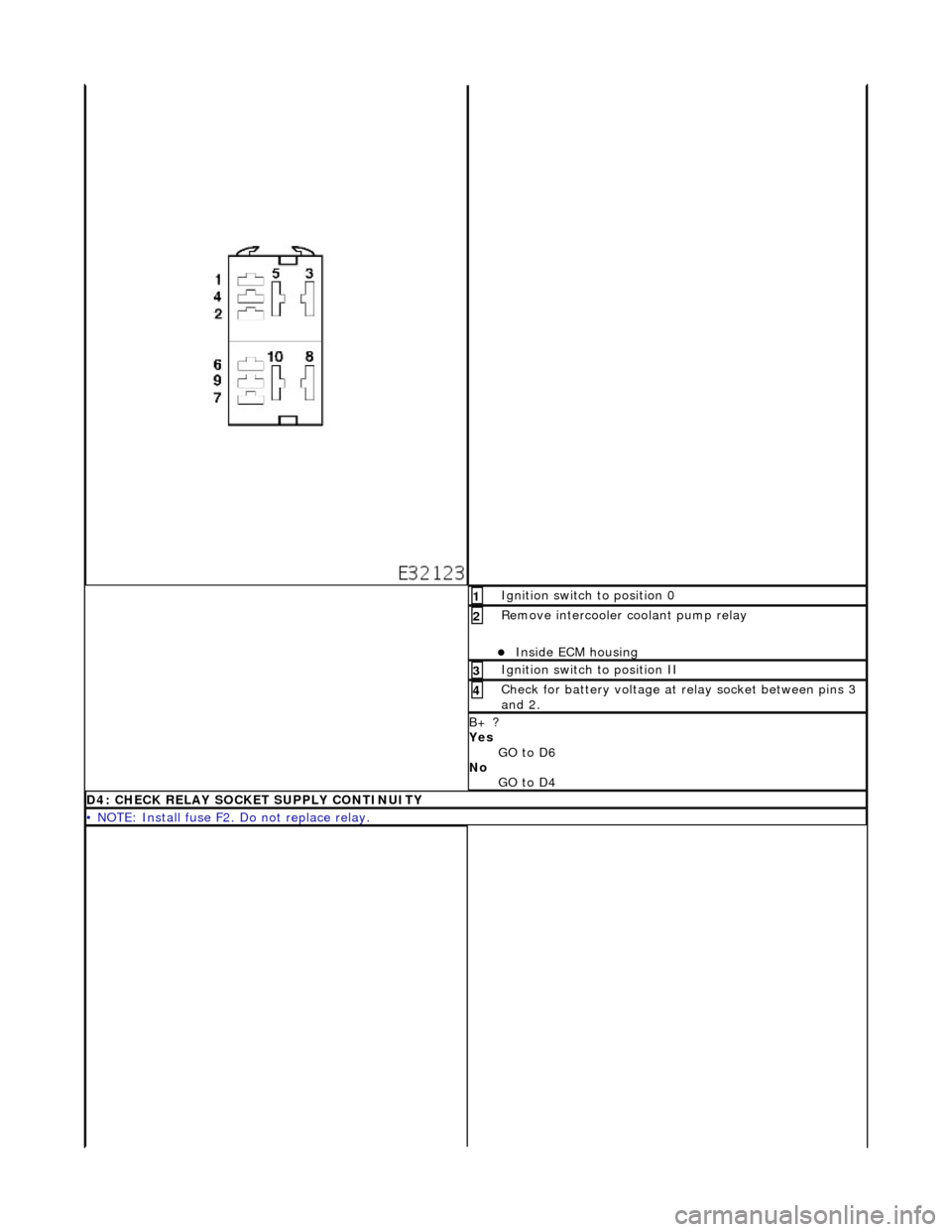

Ig

nition switch to position 0

1

R

e

move intercooler

coolant pump relay

Inside EC

M housing

2

Ignition switc

h

to position II

3

Ch

e

ck for battery voltage at relay socket between pins 3

and 2.

4

B+ ?

Yes

GO to D6

No GO to D4

D4: C H

ECK RELAY SOCKET SUPPLY CONTINUITY

•

NOTE: Install fuse F2.

Do not replace relay.

Page 954 of 2490

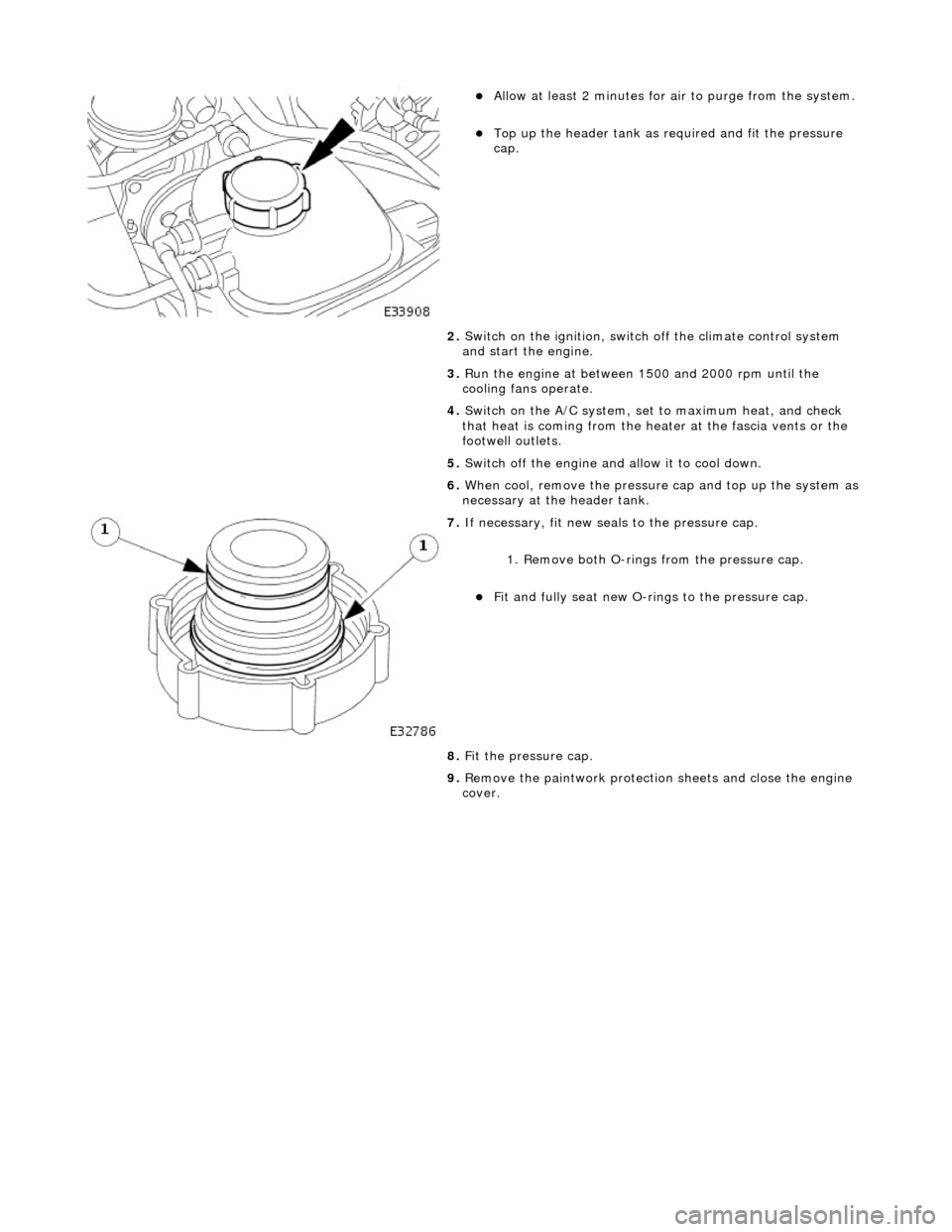

Allow at least 2 minutes f

or ai

r to purge from the system.

Top up the he

ader tank as re

quired and fit the pressure

cap.

2. Switch on the ignition, switch off the climate control system

and start the engine.

3. Run the engine at between 1500 and 2000 rpm until the

cooling fans operate.

4. Switch on the A/C system, set to maximum heat, and check

that heat is coming from the heat er at the fascia vents or the

footwell outlets.

5. Switch off the engine and allow it to cool down.

6. When cool, remove the pressure cap and top up the system as

necessary at the header tank.

7. If n e

cessary, fit new seals to the pressure cap.

1. Remove both O-rings from the pressure cap.

Fit and

fully seat new O-rings to the pressure cap.

8. Fit the pressure cap.

9. Remove the paintwork protection sheets and close the engine

cover.

Page 956 of 2490

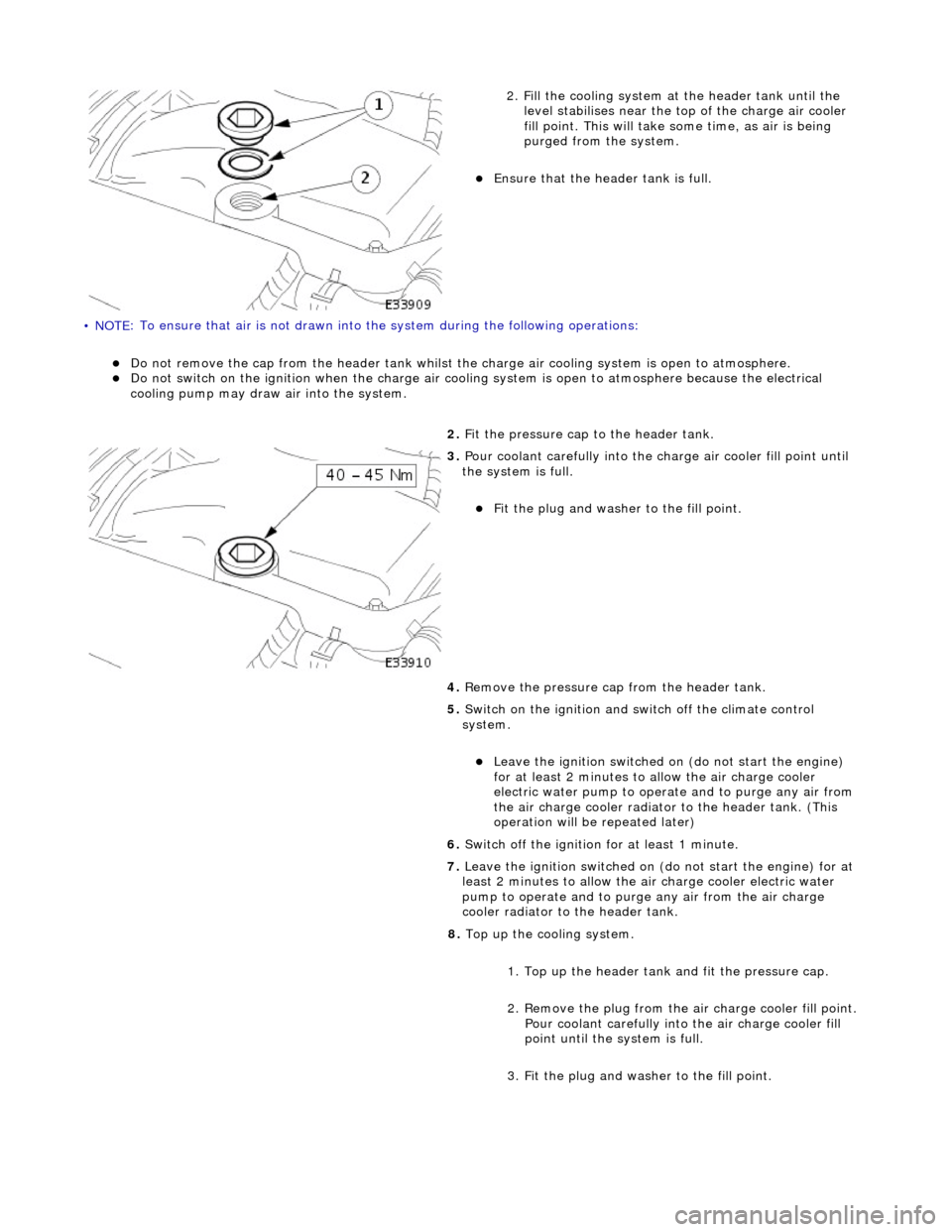

• NOTE

: To ensure that

air is not drawn into the system during the following operations:

Do

not remove the cap from the header tank whilst the

charge air cooling system is open to atmosphere.

Do

not switch on the ignition when th

e charge air cooling system is open to atmosphere because the electrical

cooling pump may draw air into the system.

2. Fi

ll the cooling system at the header tank until the

level stabilises near the to p of the charge air cooler

fill point. This will take some time, as air is being

purged from the system.

Ensure that the head

er tank is full.

2. Fit the pressure cap to the header tank.

3. Pour coolant careful l

y into the charge air cooler fill point until

the system is full.

Fi t t

he plug and washer to the fill point.

4. Remove the pressure cap from the header tank.

5. Switch on the ignition and switch off the climate control

system.

Le ave

the ignition switched on (do not start the engine)

for at least 2 minutes to allow the air charge cooler

electric water pump to oper ate and to purge any air from

the air charge cooler radiator to the header tank. (This

operation will be repeated later)

6. Switch off the ignition for at least 1 minute.

7. Leave the ignition switched on (do not start the engine) for at

least 2 minutes to allow the air charge cooler electric water

pump to operate and to purg e any air from the air charge

cooler radiator to the header tank.

8. Top up the cooling system.

1. Top up the header tank and fit the pressure cap.

2. Remove the plug from the air charge cooler fill point. Pour coolant carefully into the air charge cooler fill

point until the system is full.

3. Fit the plug and washer to the fill point.

Page 962 of 2490

All vehicles

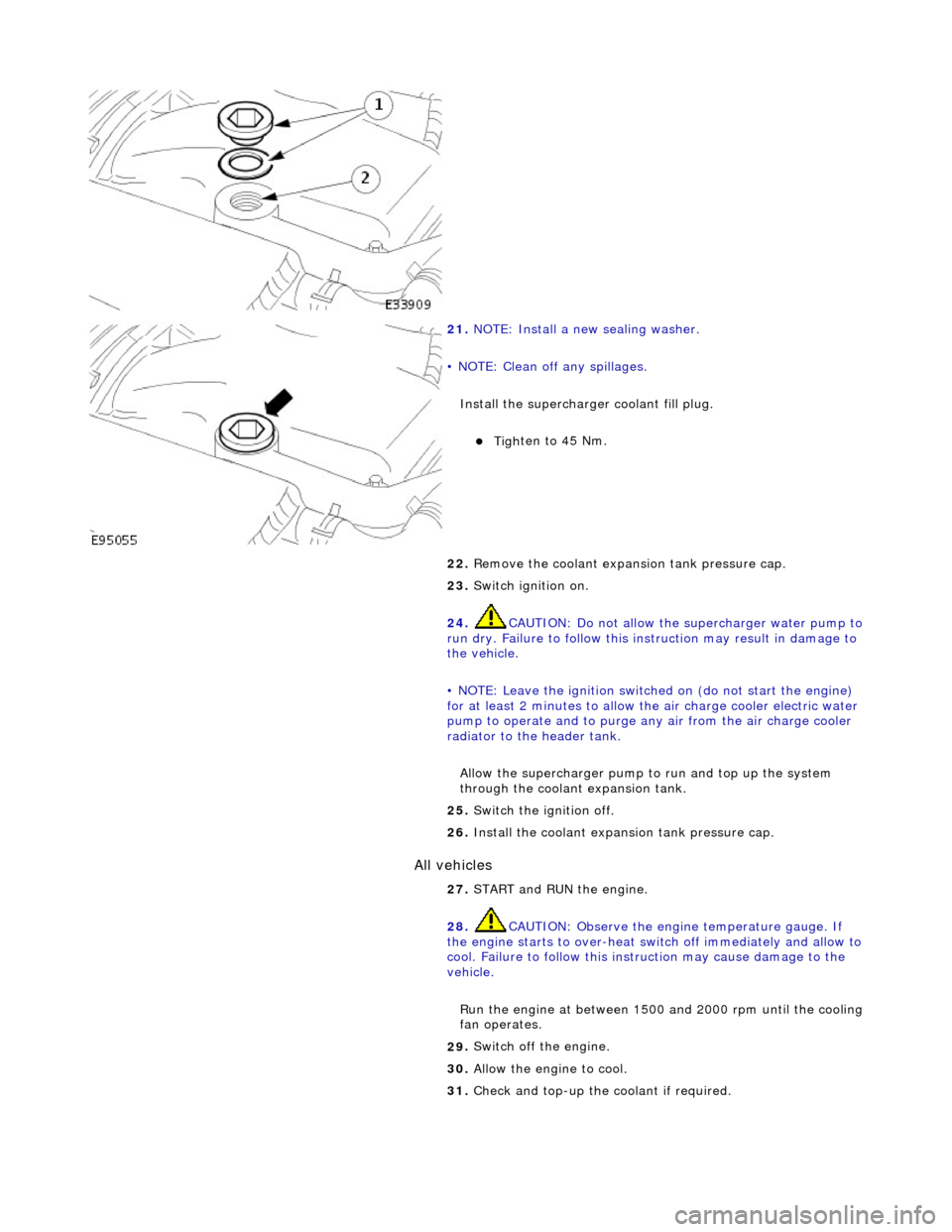

21.

N

OTE: Install a new sealing washer.

• NOTE: Clean off any spillages.

Install the supercharger coolant fill plug.

Tighte

n to 45 Nm.

22. Remove the coolant expans ion tank pressure cap.

23. Switch ignition on.

24. CAUTION: Do not allow the supercharger water pump to

run dry. Failure to follow this instruction may result in damage to

the vehicle.

• NOTE: Leave the ignition switched on (do not start the engine)

for at least 2 minutes to allow the air charge cooler electric water

pump to operate and to purge an y air from the air charge cooler

radiator to the header tank.

Allow the supercharger pump to run and top up the system

through the coolant expansion tank.

25 . Swit

ch the ignition off.

26. Install the coolant expansion tank pressure cap.

27. START and RUN the engine.

28. CAUTION: Observe the engine temperature gauge. If

the engine starts to over-heat switch off immediately and allow to

cool. Failure to follow this inst ruction may cause damage to the

vehicle.

Run the engine at between 1500 and 2000 rpm until the cooling

fan operates.

29 .

Swi

tch off the engine.

30. Allow the engine to cool.

31. Check and top-up the coolant if required.

Page 1012 of 2490

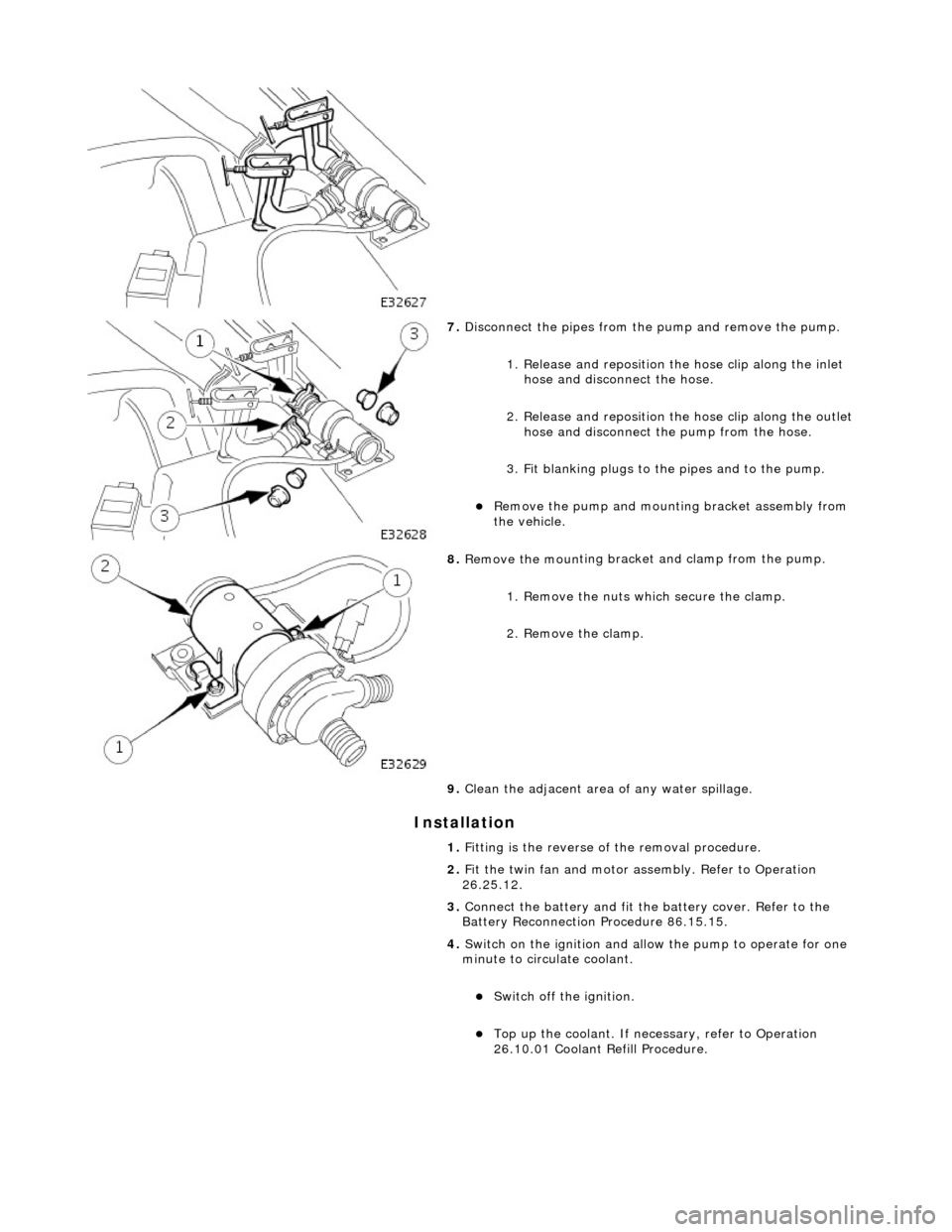

In

stallation

7.

Disc

onnect the pipes from the

pump and remove the pump.

1. Release and reposition th e hose clip along the inlet

hose and discon nect the hose.

2. Release and reposition the hose clip along the outlet

hose and disconnect th e pump from the hose.

3. Fit blanking plugs to the pipes and to the pump.

Remove t

he pump and mounting bracket assembly from

the vehicle.

8. Remove the moun

ting bracket and clamp from the pump.

1. Remove the nuts which secure the clamp.

2. Remove the clamp.

9. Clean the adjacent area of any water spillage.

1. Fitting is the reverse of the removal procedure.

2. Fit the twin fan and motor assembly. Refer to Operation

26.25.12.

3. Connect the battery and fit the battery cover. Refer to the

Battery Reconnection Procedure 86.15.15.

4. Switch on the ignition and allow the pump to operate for one

minute to circulate coolant.

Swit ch

off the ignition.

Top up th

e coolant

. If ne

cessary, refer to Operation

26.10.01 Coolant Refill Procedure.

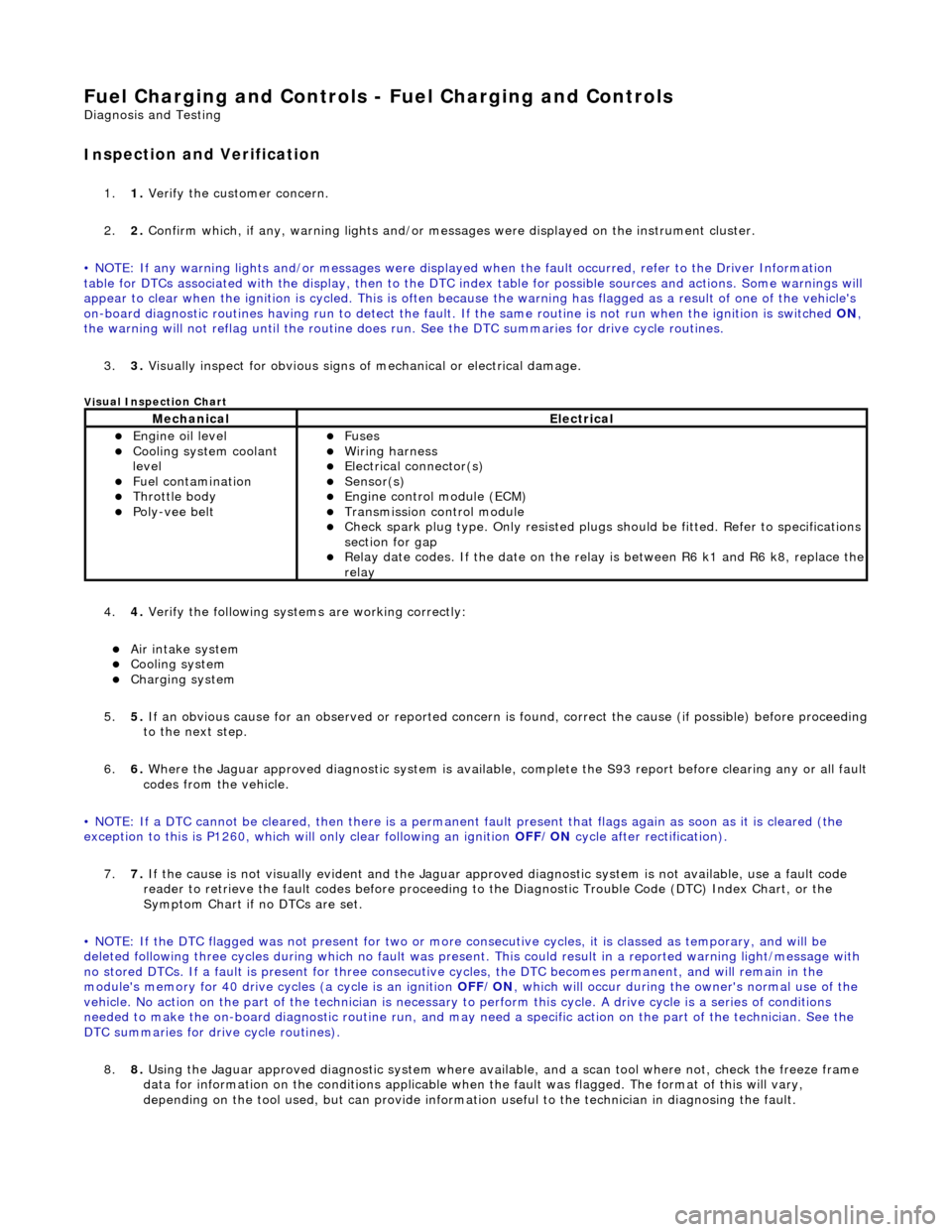

Page 1020 of 2490

Fuel Char

ging and Controls - Fuel Charging and Controls

D

iagn

osis and Testing

I

n

spection and Verification

1.

1. Veri fy the customer concern.

2. 2. Confi

rm which, if any, warning li

ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

Vi

sual Inspection Chart

4.

4. Veri fy the foll

owing syst

ems are working correctly:

Air intake

system

Cooling system

Charging system

5. 5. If

an obvious cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycl es (a cycle is an ignition OFF/ON, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for drive cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

MechanicalElectrical

Engine

oil level

Coo

ling system coolant

lev

el

Fuel contamination

Throttle body Poly-ve

e belt

Fu

ses

W

i

ring harness

E

l

ectrical connector(s)

Sens

o

r(s)

Engine

control module (E

CM)

Tran

s

mission control module

Check spark plu

g type. Only r

e

sisted plugs should be fitted. Refer to specifications

section for gap

Relay date codes. I

f the date on the rela

y is between R6 k1 and R6 k8, replace the

relay

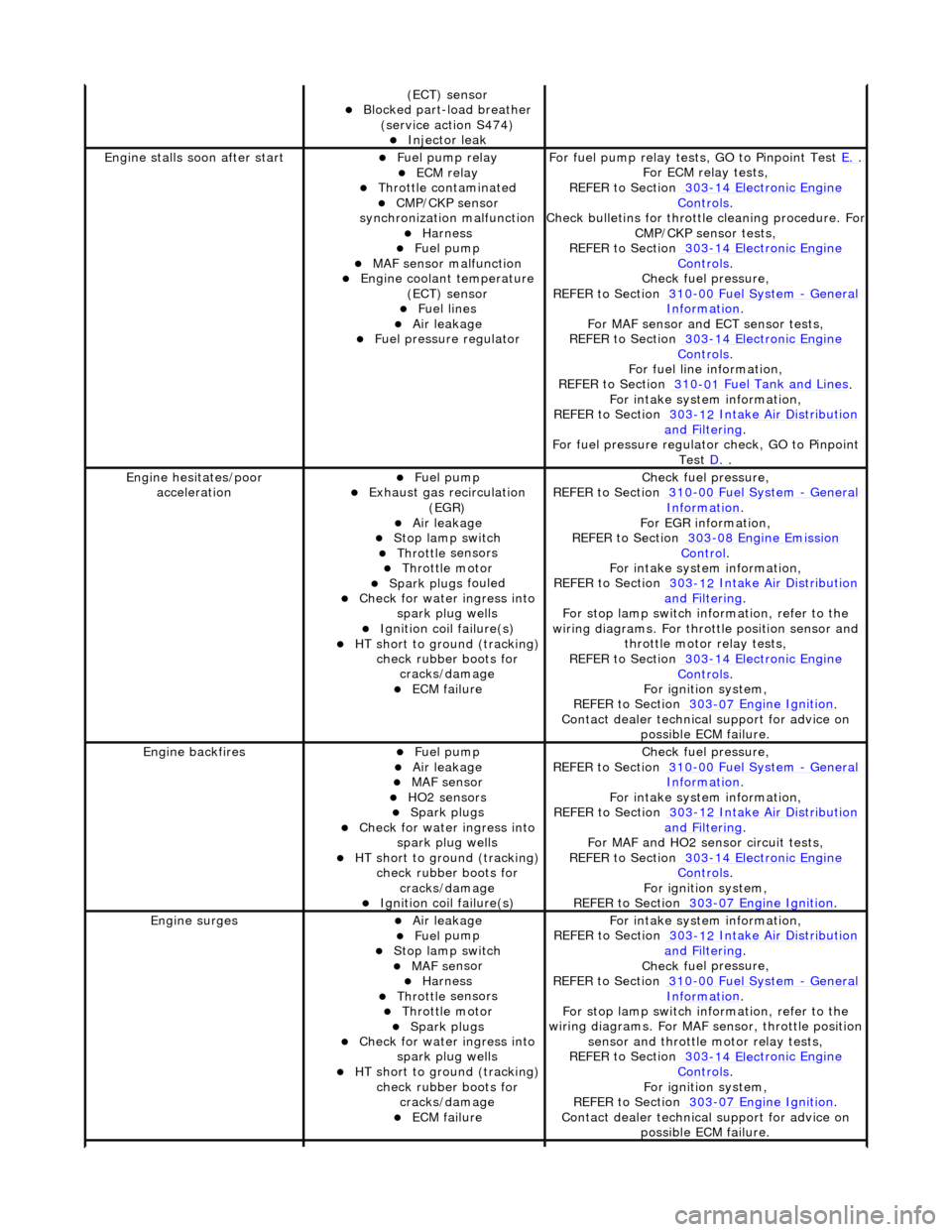

Page 1022 of 2490

(ECT) se

nsor

Blocked part-load breather

(s

ervice action S474)

Injec

t

or leak

Engine stalls

soon

after start

F

u

el pump relay

ECM relay Thr

o

ttle contaminated

CMP/CKP sen

s

or

synchronization malfunction

Harness Fuel

pump

MAF

s

ensor malfunction

Engine coolan

t

temperature

(ECT) sensor

Fue l

lines

Air leakage Fu

el pressure regulator

F

o

r fuel pump relay tests,

GO to Pinpoint Test E.

.

F or ECM

relay tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

Check bull etins for throttl

e cleaning procedure. For

CMP/CKP sensor tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

Chec k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Ge

n

eral

Informati

o

n

.

F or MAF sensor and

ECT sensor tests,

REFER to Section 303

-14 Electronic En

gine

Controls.

For fuel l

ine information,

REFER to Section 310

-01

Fuel Tank and Lines

.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

F o

r fuel pressure regulato

r check, GO to Pinpoint

Test D.

.

Engine h e

sitates/poor

acceleration

Fue l

pump

Exhaus

t gas

recirculation

(EGR)

Air leakage Stop lamp swi t

ch

Throttl

e

sensors

Throttl

e

motor

Spark plugs

fouled

Check f

o

r water ingress into

spark plug wells

Ignition coil fail

ure(s)

HT sho

rt to ground (tracking)

check rubber

boots for

cracks/damage

ECM failu r

e

Chec

k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Ge

n

eral

Informati

o

n

.

F o

r EGR information,

REFER to Section 303

-08 En gin

e Emission

Control.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

F or stop l

amp switch in

formation, refer to the

wiring diagrams. For throttle position sensor and throttle motor relay tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

For ign i

tion system,

REFER to Section 303

-07 En

gine Ignition

.

Contact dealer techn i

cal

support for advice on

possible ECM failure.

Engine ba ckfiresFuel

pump

Air leakage MAF s

e

nsor

HO2 sensors Spark plugs

Check fo

r water ingress into

spark plug wells

HT short to ground (tracking) check rubber

boots for

cracks/damage

Ignition coil fail

ure(s)

Chec

k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Ge

n

eral

Informati

o

n

.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

For MAF and HO2

sensor circuit tests,

REFER to Section 303

-14 Electronic En

gine

Controls.

For igni

tion system,

REFER to Section 303

-07 En

gine Ignition

.

Engine

s

urges

Air leakage Fue

l

pump

Stop lamp swi

t

ch

MAF s

e

nsor

Harness Throttl

e

sensors

Throttl

e

motor

Spark plugs

Check fo

r water ingress into

spark plug wells

HT sho rt to ground (tracking)

check rubber

boots for

cracks/damage

ECM failu r

e

F

or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

Chec k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Gen

e

ral

Informati

o

n

.

F or stop l

amp switch in

formation, refer to the

wiring diagrams. For MAF se nsor, throttle position

sensor and throttle motor relay tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

For ign i

tion system,

REFER to Section 303

-07 En

gine Ignition

.

Contact dealer techn i

cal

support for advice on

possible ECM failure.

Page 1031 of 2490

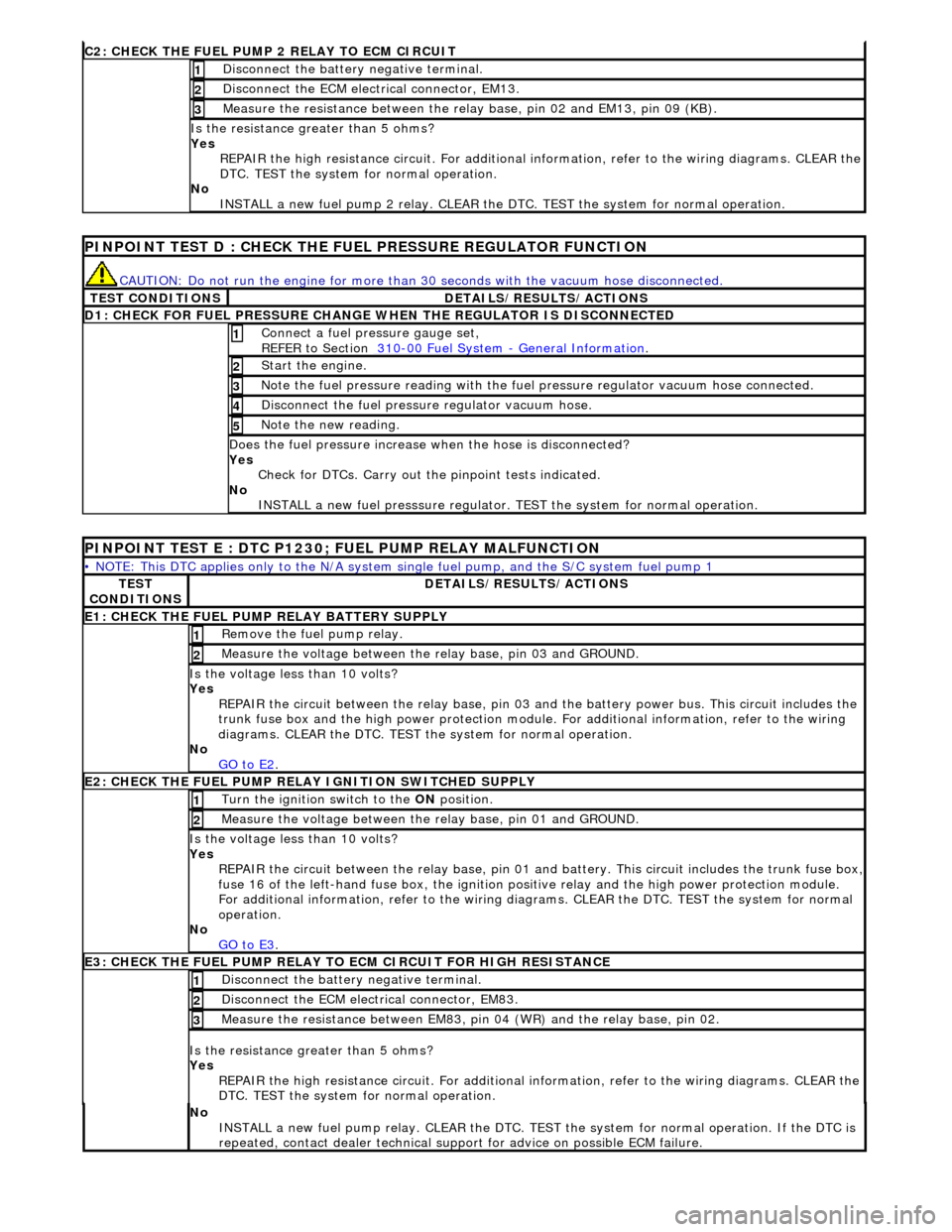

C2: CHECK THE FUEL

PUMP 2 RELAY TO ECM CIRCUIT

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM13.

2

Meas

ure the resistance between the rela

y base, pin 02 and EM13, pin 09 (KB).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No INSTALL a new fuel pump 2 relay. CLEAR the DT C. TEST the system for normal operation.

P

INPOINT TEST D : CHECK THE FUEL PRESSURE REGULATOR FUNCTION

CAUTI

ON: Do not run the engine for more than

30 seconds with the vacuum hose disconnected.

T

EST CONDITIONS

D

ETAILS/RESULTS/ACTIONS

D

1: CHECK FOR FUEL PRESSURE CHANGE

WHEN THE REGULATOR IS DISCONNECTED

Connect a

fuel pressure gauge set,

REFER to Section 310

-00

Fuel System

-

General Informati

on

. 1

St

art the engine.

2

N

ote the fuel pressure readin

g with the fuel pressure regu lator vacuum hose connected.

3

Di

sconnect the fuel pressu

re regulator vacuum hose.

4

N

ote the new reading.

5

Doe

s the fuel pressure increase when the hose is disconnected?

Yes Check for DTCs. Carry out the pinpoint tests indicated.

No INSTALL a new fuel presssure regulator. TEST the system for normal operation.

P

INPOINT TEST E : DTC P1230;

FUEL PUMP RELAY MALFUNCTION

•

NOTE: This DTC applies only to the N/A system si

ngle fuel pump, and the S/C system fuel pump 1

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

E1

: CHECK THE FUEL PUMP

RELAY BATTERY SUPPLY

R

emove the fuel pump relay.

1

Meas

ure the voltage between the

relay base, pin 03 and GROUND.

2

Is th

e voltage less than 10 volts?

Yes REPAIR the circuit between the rela y base, pin 03 and the battery power bus. This circuit includes the

trunk fuse box and the high power protection module . For additional information, refer to the wiring

diagrams. CLEAR the DTC. TEST th e system for normal operation.

No GO to E2

.

E2

: CHECK THE FUEL PUMP RELAY IGNITION SWITCHED SUPPLY

Turn the ignition swi

tch to the

ON position.

1

Meas

ure the voltage between the

relay base, pin 01 and GROUND.

2

Is th

e voltage less than 10 volts?

Yes REPAIR the circuit between the rela y base, pin 01 and battery. This circuit includes the trunk fuse box,

fuse 16 of the left-hand fuse box, the ignition po

sitive relay and the high power protection module.

For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST the system for normal

operation.

No GO to E3

.

E3

: CHECK THE FUEL PUMP RELAY TO

ECM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM83.

2

Meas

ure the resistance between EM83, pi

n 04 (WR) and the relay base, pin 02.

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No

INSTALL a new fuel pump relay. CLEAR the DTC. TEST the system for normal operation. If the DTC is

repeated, contact dealer technical support for advice on possible ECM failure.

Page 1064 of 2490

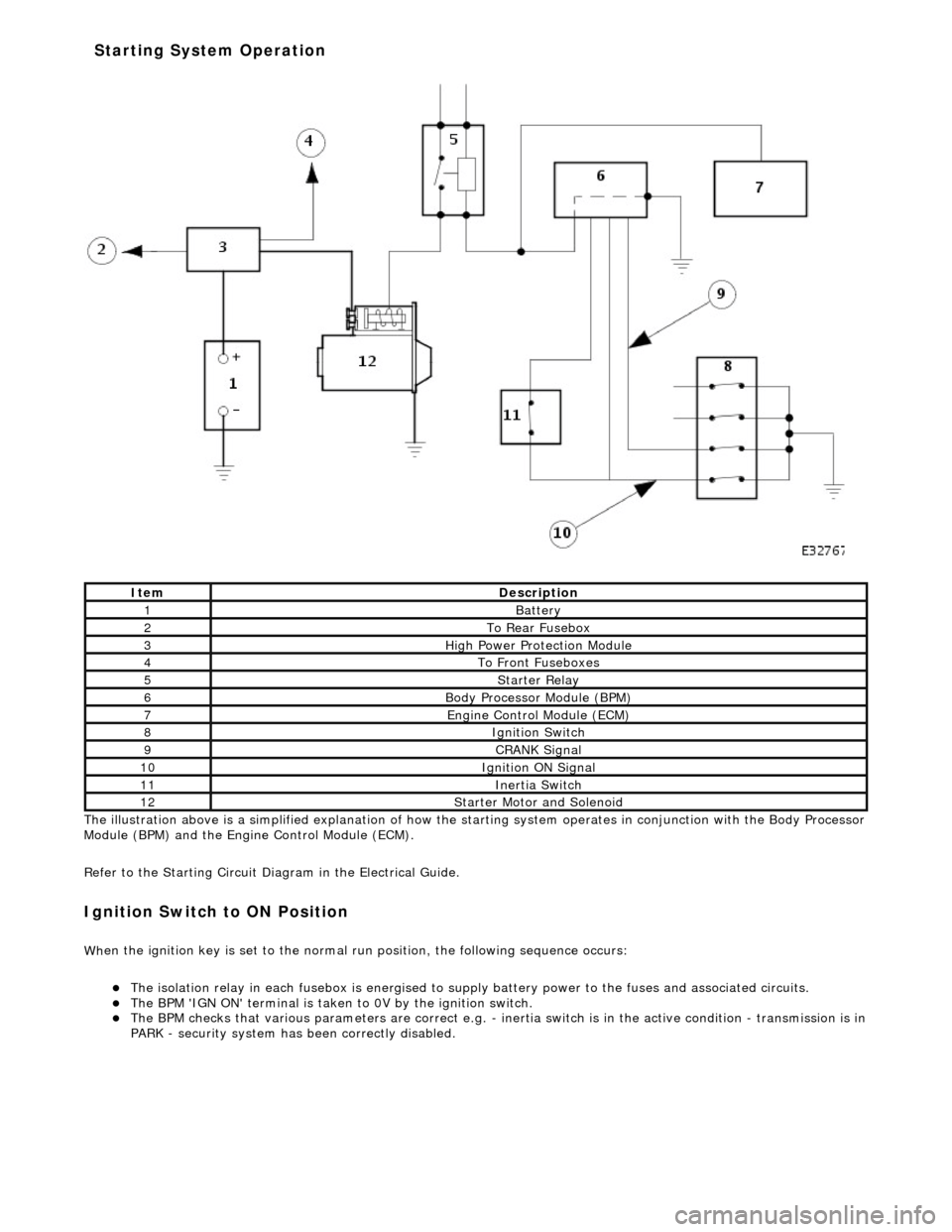

The il

lustration above is a simplified expl

anation of how the starting system operates in conjunction with the Body Processor

Module (BPM) and the Engine Control Module (ECM).

Refer to the Starting Circuit Diagram in the Electrical Guide.

I g

nition Switch to ON Position

W

h

en the ignition key is set to the normal run position, the following sequence occurs:

The

is

olation relay in each fusebox is

energised to supply battery power to the fuses and associated circuits.

The BPM 'IGN

ON' terminal

is taken to 0V by the ignition switch.

The BPM

checks that various parameters are correct e.g. -

inertia switch is in the active condition - transmission is in

PARK - security system has been correctly disabled.

It e

m

De

scr

iption

1Batt

ery

2To Re ar

Fusebox

3Hi

gh Power Pr

otection Module

4To Front

Fu

seboxes

5Starter Re

lay

6Body Processor M

odule (BPM)

7Engine

C

ontrol Module (ECM)

8Ignition Switch

9CRANK Signal

10Ignition ON Signal

11Inertia Switch

12St

arte

r Motor and Solenoid

Starting System Operation