sensor JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 7 of 2490

206‐07: Powe r Brake Actuation

Specif

ication

Description and Operation

Brake Booster

Removal and Installation

Brake Booster (70.50.17)

Brake Booster and Brake Master Cylinder (70.50.18)

206‐09: Anti ‐Lock Control

Specification

Description and Operation

Anti‐Lock Control

Diagnosis and Testing

Anti‐Lock Control

Removal and Installation

Anti‐Lock Brake System (ABS) Module (70.60.02)

Front Wheel Speed Sensor (70.60.03)

Hydraulic Cont

rol Unit (HCU)

Rear Wheel Speed Sensor (70.60.04)

Wheel Speed Sensor Ring (70.60.25)

211: Steering System

211‐00: Steering System ‐ General Information

Specification

Description and Operation

Steering System

Diagnosis and Testing

Steering Sy

stem

General Procedures

Power Steering System Filling and Bleeding

Power Steering System Flushing (57.15.08)

Power Steering System Vacuum Filling and Bleeding

Steering Gear Centralizing

Page 15 of 2490

Superchar

ger

Outlet Pipe (18.50.16)

Supercharger Outlet Pipe Gasket (18.50.17)

Throttle Body Elbow (19.70.28)

Throttle Body Elbow Gasket (19.70.29)

303‐13: Evaporative Emissions

Diagnosis and Testing

Evaporative Emissions

Preliminary

Inspection

Diagnostic

Drive Cycles

Diagnostic

Trouble Code (DTC) index/Symptom Chart

Pinpoint

Tests

Removal

and Installation

Evaporative

Emission Canister (17.15.13)

Evaporative

Emission Canister Purge Valve (17.15.30)

Fuel

Tank Press

ure Sensor (19.55.31)

Fuel

Vapor Vent Valve Housing (19.55.24)

Fuel

Vapor Vent Valve Housing Seal (19.55.25)

303

‐14: Electronic Engine Controls

Description

and

Diagnosis

and Testing

Electronic

Engine Con

trols

Inspection

and Verification

Driver

Information Chart

Default

mode Definitions

Diagnostic

Trouble Code (DTC) Index

Pinpoint

Tests

Removal

and Installation

Catalyst

Monitor Sensor LH (18.30.81)

Catalyst

Monitor Sensor RH (18.30.80)

Heated Oxygen Sensor (HO2S) LH (18.30.79)

Heated Oxygen Sensor (HO2S) RH (18.30.78)

Camshaft

Position

Sen s

or

ECM

Position

Sensor

Crankshaft

Removal

Engine

Coolant Temperature

Sensor

Operation

Intake Air Temperature (IAT) Sensor (18.

30.52)

Page 16 of 2490

Knock Sensor (KS) RH (18.30.93)

Variable Camshaft Timing (VCT) Oil Co ntrol

Solenoid (18.30.90)

307: Automatic Transmission/Transaxle

307‐01A : Automatic Transmission/Transaxle ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Specification

Description and Operation

Transmission Description

Diagnosis and Testing

Diagnostic Strategy

General Procedures

Transmission Fluid Drain and Refill (44.24.02)

In‐Ve

hicle Repair

Electronic Pressure Control (EPC) Solenoid (44.15.51)

Extension Housing Seal (44.20.18)

Extension Housing O ‐Ring Seal (44.20.19)

Main Control Valve Body (44.40.01)

Output Shaft Speed (OSS) Sensor (44.15.41)

Shift Solenoids (SS) (44.15.50)

Transmission Control Module (TCM) (44.15.32)

Transmission Fluid Filter (44.24.07)

Transmission Fl

uid Pan (44.24.04)

Transmission Fluid Pan Gasket (44.24.05)

Transmission Internal Wiring Harness (44.15.35)

Transmission Internal Wiring Harness Electrical Connector O‐Ring Seals

(44.24.20)

Transmission Range (TR) Sensor

Transmission Support Insulator (12.45.04)

Turbine Shaft Speed (TSS) Sensor (44.15.40)

Removal

Transmission (44.20.01)

Disassembly and Assembly of Subassemblies

Input Sh

aft Seal (44.32.07)

Torque Converter (44.17.07)

Installation

Transmission (44.20.01)

Mass

Airflow

Sen s

or

Knock

Sensor

(KS)

LH

(18.30.92)

Page 20 of 2490

310‐01: Fu el Tank and Lines

Removal and Installation

Fuel Level Sensor (88.25.32)

Fuel Pump (19.45.08)

Fuel Tank (19.55.01)

310‐02

:

Acceleration Control

General Procedures

Accelerator Cable Adjustment (12.20.05)

Removal and Installation

Accelerator Cable (19.20.06)

310‐03: Speed Control

Diagnosis and Testing

Speed Con

trol

4: Electrical

412: Climate Control System

412‐00: Climate Control System ‐ General Information

Specification

Description and Operation

Climate Control System

Diagnosis and Testing

Climate Control System

General Procedures

Air Conditioning (A/C) System Check ‐ Retail Procedure

Air Conditioning (A/C) System Recovery, Evacuation and Charging (82.30.30)

Contaminated Refrigerant Ha

ndling

Manifold Gauge Set Connection

Refrigerant Adding (82.30.02)

Refrigerant Oil Adding

Refrigerant System Tests

412‐01: Air Distribution and Filtering

Description and Operation

Page 21 of 2490

Air Distributio n and Filt

ering

Diagnosis and Testing

Air Distribution and Filtering

Removal and Installation

Center Registers (82.20.38)

Driver Side Blower Motor (82.25.56)

Passenger Side Blower Motor (82.25.55)

Plenum Chamber (82.20.87)

412‐02: Heating and Ventilation

Description and Operation

Heating and Ventilation

Removal

and Installation

Heater

Core (80.20.29)

Heater

Core and Evaporator Core Housing (82.25.21)

412

‐03: Air Conditioning

Description

and Operation

Air

Conditioning

Diagnosis

and Testing

Air

Conditioning

Removal

and Installation

Air

Conditioning (A/C) Compressor (82.10.20)

Condenser

Core (82.15.07)

Evaporator

Core (82.25.20)

Press

ure Cutoff Switch (82.10.32)

Receiver

Drier (82.17.01)

412

‐04: Control Components

Description

and Operation

Control

Components

Diagnosis

and Testing

Control

Components

Removal

and Installation

Air

Discharge Temperature Sensor (82.20.64)

Page 22 of 2490

Ambient Air Temperature Sensor (82.20. 02)

Cold Ai

r

Bypass Blend Door Actuator (82.20.86)

Defrost Vent/Register Blend Door Actuator (82.20.84)

Footwell Vent/Duct Blend Door Actuator (80.20.20 or 82.20.85)

Instrument Panel Blend Door Actuator (82.20.83)

Remote Climate Control Module LHD (82.20.65)

Remote Climate Control Module RHD (82.20.65)

413: Instrumentation and Warning Sy

stems

413‐00: Instrument Cluster and Panel Illumination

Description and Operation

Instrument Cluster and Panel Illumination

Removal and Installation

Instrument Panel Dimmer Switch (86.65.07)

413‐01: Instrument Cluster

Description and Operation

Instrument Cluster

Diagnosis and Testing

Instrument Cluster

Removal and Installation

Instrument Clust

er (88.20.01)

413‐06: Horn

Description and Operation

Horn

Diagnosis and Testing

Horn

413‐07: Clock

Description and Operation

Clock

Diagnosis and Testing

Clock

Removal and Installation

Clock (88.15.07)

Page 23 of 2490

413‐08: Information and Message Ce nter

Descriptio

n

and Operation

Information and Message Center

Diagnosis and Testing

Information and Message Center

Removal and Installation

Message Center Switch (86.66.11)

413‐13: Parking Aid

Description and Operation

Parking Aid

Diagnosis and Testing

Parking Aid

Removal and Installation

Parking Aid Module (86.80.39)

Rear Parking Aid Sensor (86.54.

14) (86.62.01)

Rear Parking Aid Speaker (86.54.19) (86.62.02)

414: Battery and Charging System

414‐00: Battery and Charging System ‐ General Information

Description and Operation

414

‐01: Battery, Mounting and Ca

bles

Description

and Operation

Battery

and Cables

General

Procedures

Battery

Connect (86.15.15)

Removal

and Installation

Battery

(86.15.01)

Battery

Ground Cable (86.15.19)

Battery

Positive Cable (86.15.17)

Battery

Retaining Bracket (86.15.12)

Page 32 of 2490

Rear Cup Holder (76.25.27)

Steering Col u

mn

Lower Shroud (76.46.03)

Steering Column Upper Shroud (76.46.02)

501‐14: Handles, Locks, Latches and Entry Systems

Description and Operation

Handles, Locks, Latches and Entry Systems

Removal and Installation

Exterior Driver Door Handle (76.58.07)

Driver Door Latch (76.37.74)

Glove Compartment Lid Ha

ndle (76.52.08)

Glove Compartment Lid Lock Cylinder (76.52.23)

Luggage Compartment Lid Latch (76.19.25)

Luggage Compartment Lid Latch Actuator (76.19.25)

Luggage Compartment Lid Release Switch (86.25.56)

Luggage Compartment Lid Warning Indicator Switch (86.65.93)

Exterior Passenger Door Handle (76.58.08)

Passenger Door Latch (76.37.75)

Exterior Rear Door Handle (76.58.02)

Rear Door Latch (76.37.09)

501‐16: Wipers and Washers

Descriptio

n and Operation

Wipers and Washers

Removal and Installation

Headlamp Washer Jet (84.20.08)

Headlamp Washer Pump (84.20.21)

Rain Sensor (84.12.10) (86.56.62)

Windshield Washer Pump (84.10.21)

Windshield Washer Reservoir (84.10.01) (84.10.03)

Windshield Wiper Motor (84.15.13)

Windshield Wiper/

Washer Switch (86.65.42)

Wiper Pivot Arm (84.15.03)

Page 34 of 2490

501‐20B : Supp l

emental

Restraint System

Specification

Description and Operation

Air Bag Supplemental Restraint System (SRS)

Removal and Installation

Air Bag Control Module (76.73.41)

Driver Air Bag Module (76.73.39)

Passenger Air Bag Module (76.73.37)

Side Air Bag Module (76.73.47)

Side Impact Sensor (76.73.53)

501‐25: Body Repairs ‐ Genera

l Information

Description and Operation

Body Repairs

502: Frame and Mounting

502‐00: Uni ‐Body, Subframe and Mounting System

Removal and Installation

Front Axle Crossmember

Front Axle Crossmember Front Bushing (60.35.24)

Front Axle Crossmember Front Bushing Heat Shield (60.35.37)

Front Axle Crossmember Rear Bushing (

60.35.26)

Rear Axle Crossmember (64.25.16)

Rear Axle Crossmember Bushing (64.25.02)

Page 42 of 2490

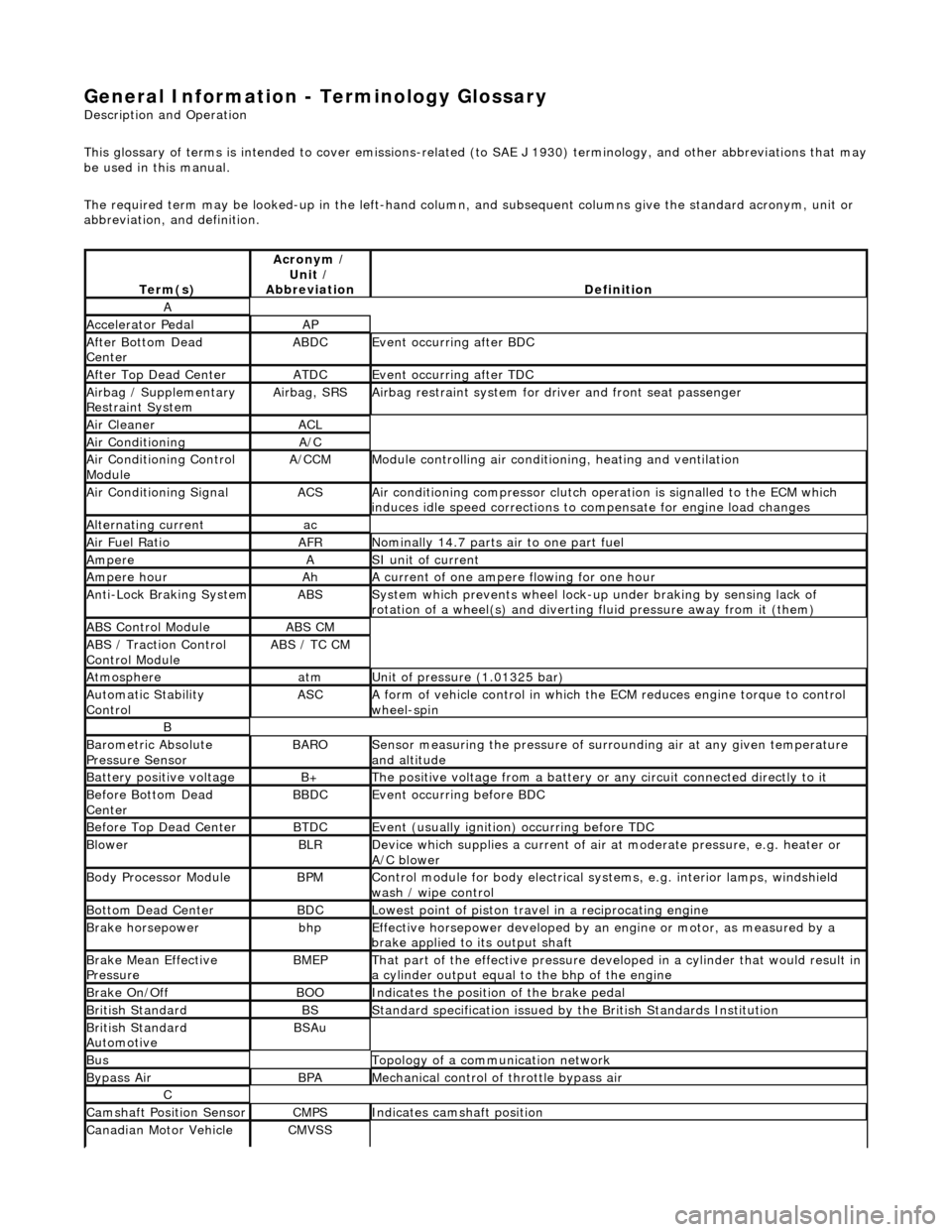

General Information - Terminology Glossary

Description an

d Operation

This glossary of terms is intended to cover emissions-related (to SAE J 1930) term inology, and other abbreviations that may

be used in this manual.

The required term may be looked-up in th e left-hand column, and subsequent columns give the standard acronym, unit or

abbreviation, and definition.

Te rm

(s)

Acr

ony

m /

Unit /

Abbreviation

De fi

nition

A

Accel

e

rator Pedal

AP

Af

ter Botto

m Dead

Center

ABDCEvent occurri ng after

BDC

Af

ter Top Dead CenterATDCEvent occurri ng after

TDC

Ai

rbag /

Supplementary

Restraint System

Airbag, SRSAi rbag restraint system for

dr

iver and front seat passenger

Air Cleane rACL

Air ConditioningA/C

Air Conditioning Con t

rol

Module

A/CCMModule c

ontrolling air conditioning, heating and ventilation

Air Conditioning SignalACSA

i

r conditioning compressor clutch operation is signalled to the ECM which

induces idle speed corrections to co mpensate for engine load changes

Alternating cu

rrent

ac

Ai

r Fuel R

atio

AFRN

omi

nally 14.7 parts air to one part fuel

Ampe

reASI unit of current

Ampere hourAhA current of one ampere

fl

owing for one hour

Anti-Lock Braking SystemABSS

y

stem which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and divertin g fluid pressure away from it (them)

ABS Control Mo

dule

ABS CM

ABS /

T

raction Control

Control Module

ABS / T

C CM

Atmosph

e

re

atmU

n

it of pressure (1.01325 bar)

Au

to

matic Stability

Control

ASCA form of vehicle

control

in which the ECM reduces en gine torque to control

wheel-spin

B

Baro me

tric Absolute

Pressure Sensor

BAR OSensor measuring the pressure of surr ou

nding air at any given temperature

and altitude

Bat t

ery positive voltage

B+The posi

ti

ve voltage from a battery or

any circuit connected directly to it

Before Bottom Dead

CenterBBDCEvent occurri ng before BD

C

Before Top Dead

Center

BTD

CEvent (usual ly

ignition) occurring before TDC

Blowe

rBLRDe

vice which supplies a current of air at

moderate pressure, e.g. heater or

A/C blower

Body Processor M

odule

BPMControl modu

le

for body electrical systems, e.g. interior lamps, windshield

wash / wipe control

Bott om D

ead Center

BD

CLowest poin t of piston

travel in a reciprocating engine

Brake hors

epowe

r

bhpEffecti

ve horsepower devel

oped by an

engine or motor, as measured by a

brake applied to its output shaft

Brake Mean Effective

Pres sureBME PThat p

art of the effective

pressure developed in a cyli nder that would result in

a cylinder output equal to the bhp of the engine

Brake On/ O

ff

BOOIn

dic

ates the position of the brake pedal

Br

it

ish Standard

BSStan

dar

d specification issued by the British Standards Institution

Br

it

ish Standard

Automotive

BSAu

BusTopology of a commu n

ication network

Bypass

AirBPAMechanica l

control of throttle bypass air

C

Camshaft Posit

i

on Sensor

CMPSIndi

cat

es camshaft position

Canadian Motor

V

ehicle

CMVSS