low beam JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1386 of 2490

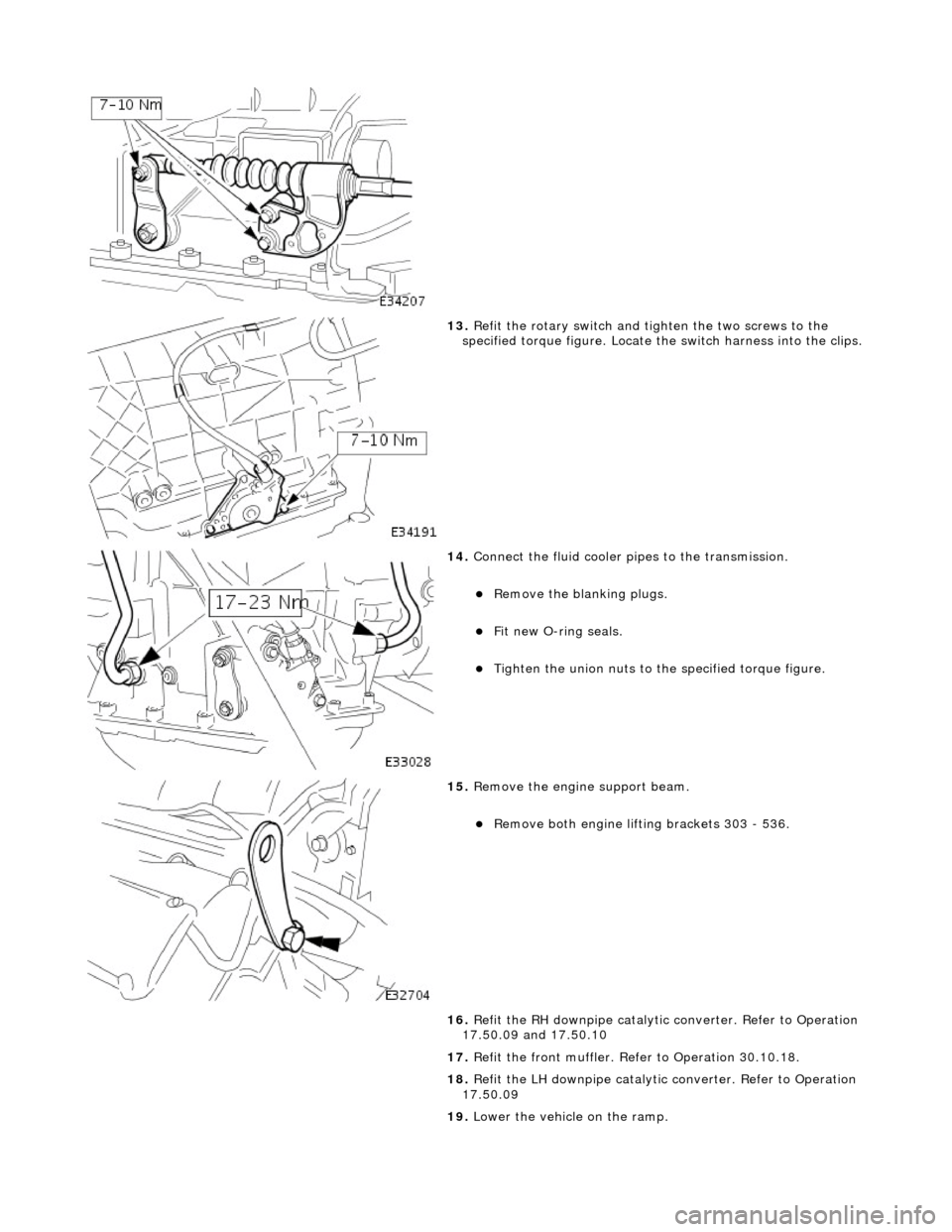

13. Refit the rotary switch and tighten the two screws to the

specified torque figure. Locate the switch harness into the clips.

14. Connect the fluid cooler pipes to the transmission.

Remove the blanking plugs.

Fit new O-ring seals.

Tighten the union nuts to the specified torque figure.

15. Remove the engine support beam.

Remove both engine lifting brackets 303 - 536.

16. Refit the RH downpipe catalytic converter. Refer to Operation

17.50.09 and 17.50.10

17. Refit the front muffler. Refer to Operation 30.10.18.

18. Refit the LH downpipe catalytic converter. Refer to Operation

17.50.09

19. Lower the vehicle on the ramp.

Page 1855 of 2490

The In

strument Cluster is the primary electronic control module for the speedomete

r, tachometer, coolant temperature, fuel

level, driver information (Message Centre) and warning lamps.

The Instrument Cluster also:

- provides input / output informatio n signals for use by other modules.

- acts as a protocol converter (software language translator - the languages used on each network are very similar, but

neither can be directly interp reted by the opposite system) for communication between all modules on both the CAN and

SCP multiplexed networks. The Instrument Cluster is the only module on the vehicle which communicates between the two

networks.

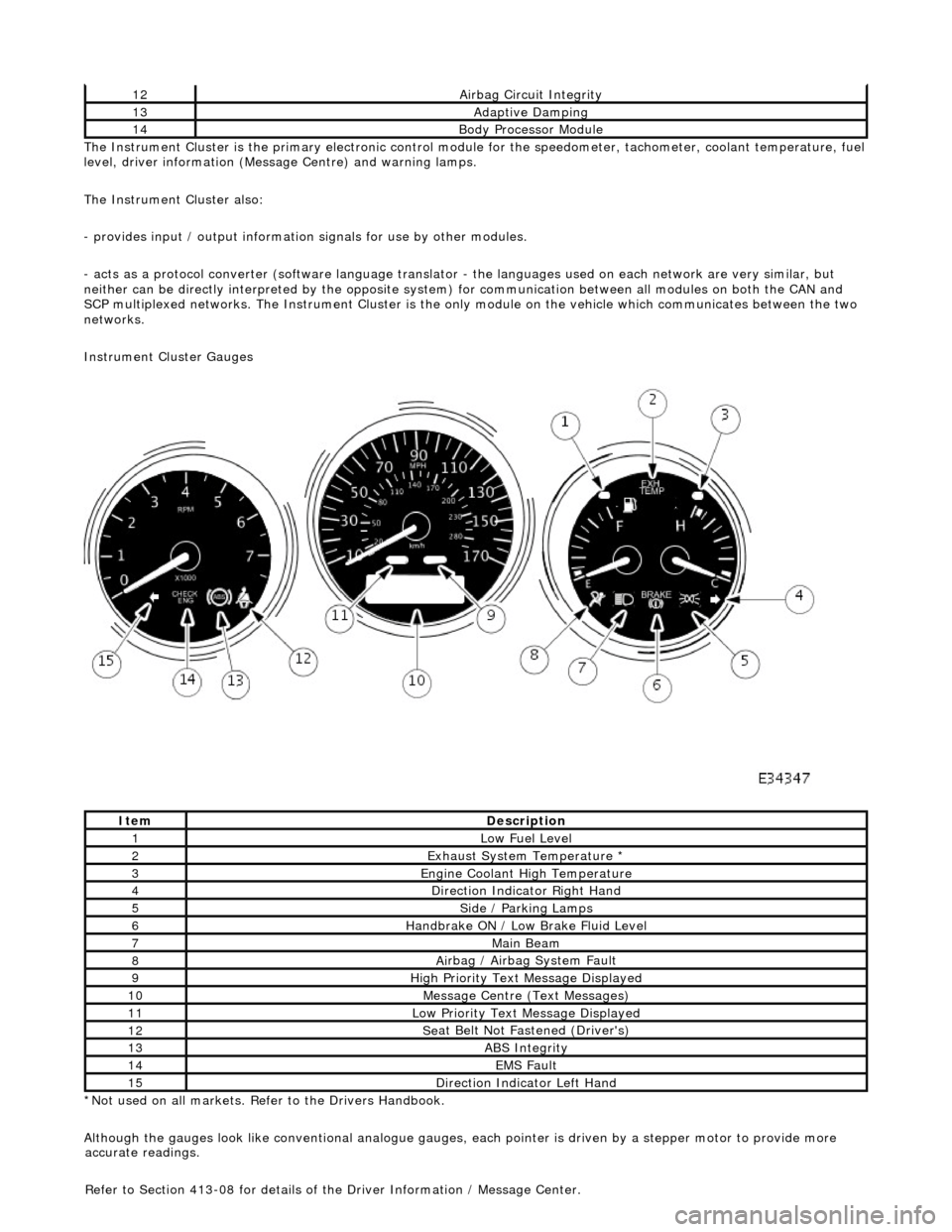

Instrument Cluster Gauges

*Not used on all markets. Refer to the Drivers Handbook.

Although the gauges look like conventional analogue gauges, each pointer is driven by a stepper motor to provide more

12Ai

rbag Circuit Integrity

13Adaptive Damping

14Body Processor

Module

It

em

De

scription

1Low Fu

el Level

2Exhaus

t System Temperature *

3E

ngine Coolant High Temperature

4Di

rection Indicator Right Hand

5Side

/ Parking Lamps

6Handbrake ON / Low

Bra

ke Fluid Level

7Main

Beam

8Ai

rbag / Airbag System Fault

9Hi

gh Priority Text

Message Displayed

10M

essage Centre (Text Messages)

11Low Pri

ority Text Message Displayed

12Se

at Belt Not Fa

stened (Driver's)

13ABS Integrity

14EMS Fault

15D

irection Indicator Left Hand

accu

rate readings.

Refer to Section 413-08 for details of the Driver Information / Message Center.

Page 1919 of 2490

Exterior Lighting - Exterior Lighting

Description and Operation

A multi-function switch located on the left stalk of the steering column switch assembly permits selection of either parking

(side), headlamps, auto-headlamp or off. Selection of a particular mode provides the appropriate input to the body

processor module (BPM).

Where the auto headlamp function is incorporated, a light sensor in the interior rear view mirror monitors ambient light and

provides an input to the BPM. The BPM responds by switching the low beam headlamps on or off as appropriate for the

prevailing light conditions.

The front and rear fog lamp switch is located on the fascia outboard of the steering column.

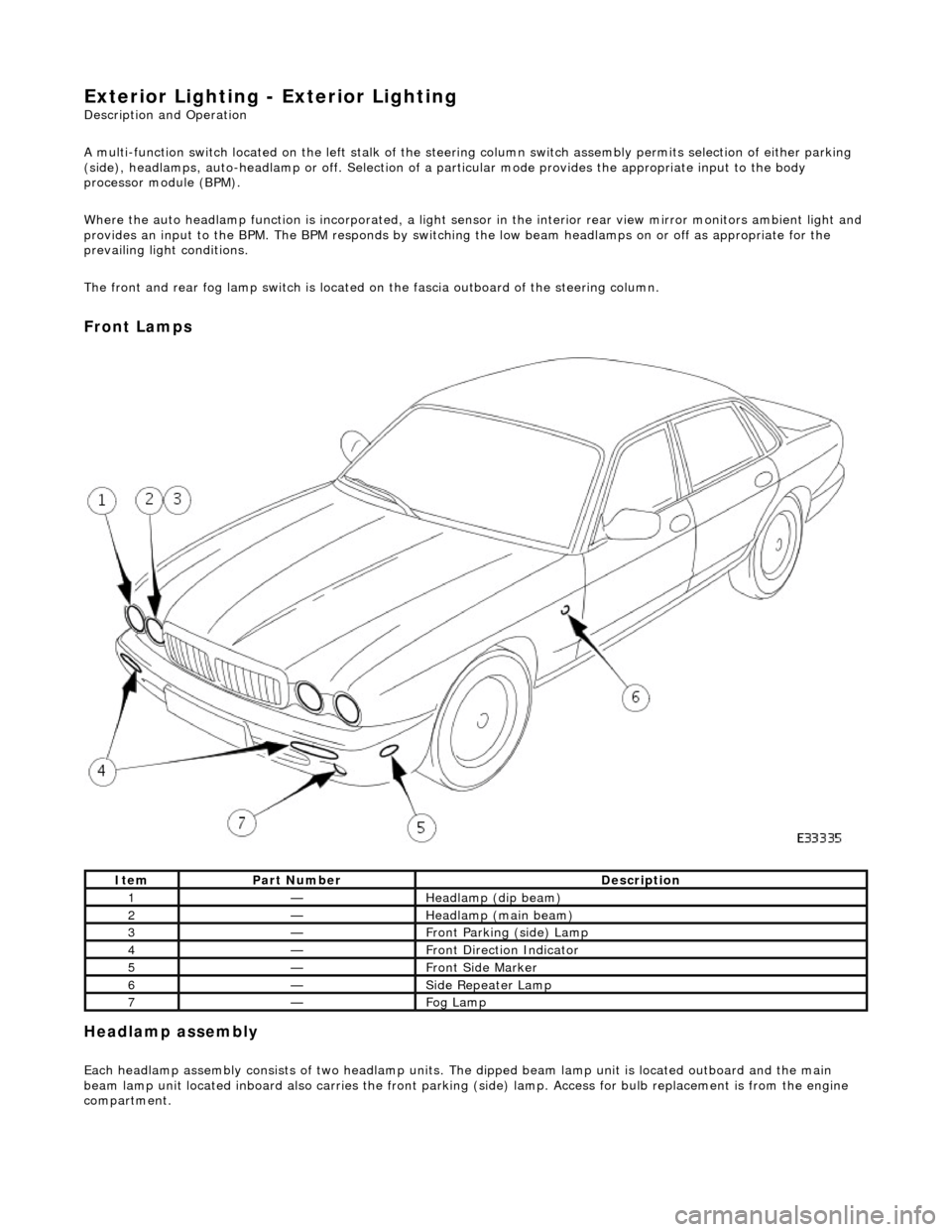

Front Lamps

Headlamp assembly

Each headlamp assembly consists of tw o headlamp units. The dipped beam lamp unit is located outboard and the main

beam lamp unit located inboard also carries the front parking (side) lamp. Access for bulb replacement is from the engine

compartment.

ItemPart NumberDescription

1—Headlamp (dip beam)

2—Headlamp (main beam)

3—Front Parking (side) Lamp

4—Front Direction Indicator

5—Front Side Marker

6—Side Repeater Lamp

7—Fog Lamp

Page 1920 of 2490

Direction indicator and side marker lamps

Each front direction indicator and side marker lamp is retained in the bumper cover by a lug at one end and a spring clip at

the other end. The side marker lamps are not electrically connected for certain markets.

The side repeater lamps are secured by sp ring clips on the lower edge of the lamp unit. In certain markets Jaguar leaper

badges are substituted for side repeater lamps.

Fog lamps

The fog lamps are located in recesses in the front bump er and secured by three screws. The la mps which are not

interchangeable left to right, are accessed from the rear of the bumper.

Operation

All lamps are controlled by the BPM which provides an appropriate output in response to an input received when a selected

switch is operated.

All lamps receive an input direct from th e BPM with the exception of the main be am, dip beam and front fog lamps which

receive an input from the BPM vi a the respective relays and fuses; refer to section 418-01.

Fault analysis must be undertaken using the PDU. Refer to Diagnosis and Testing.

Consult the relevant Electrical Guid e for details of circuit operation.

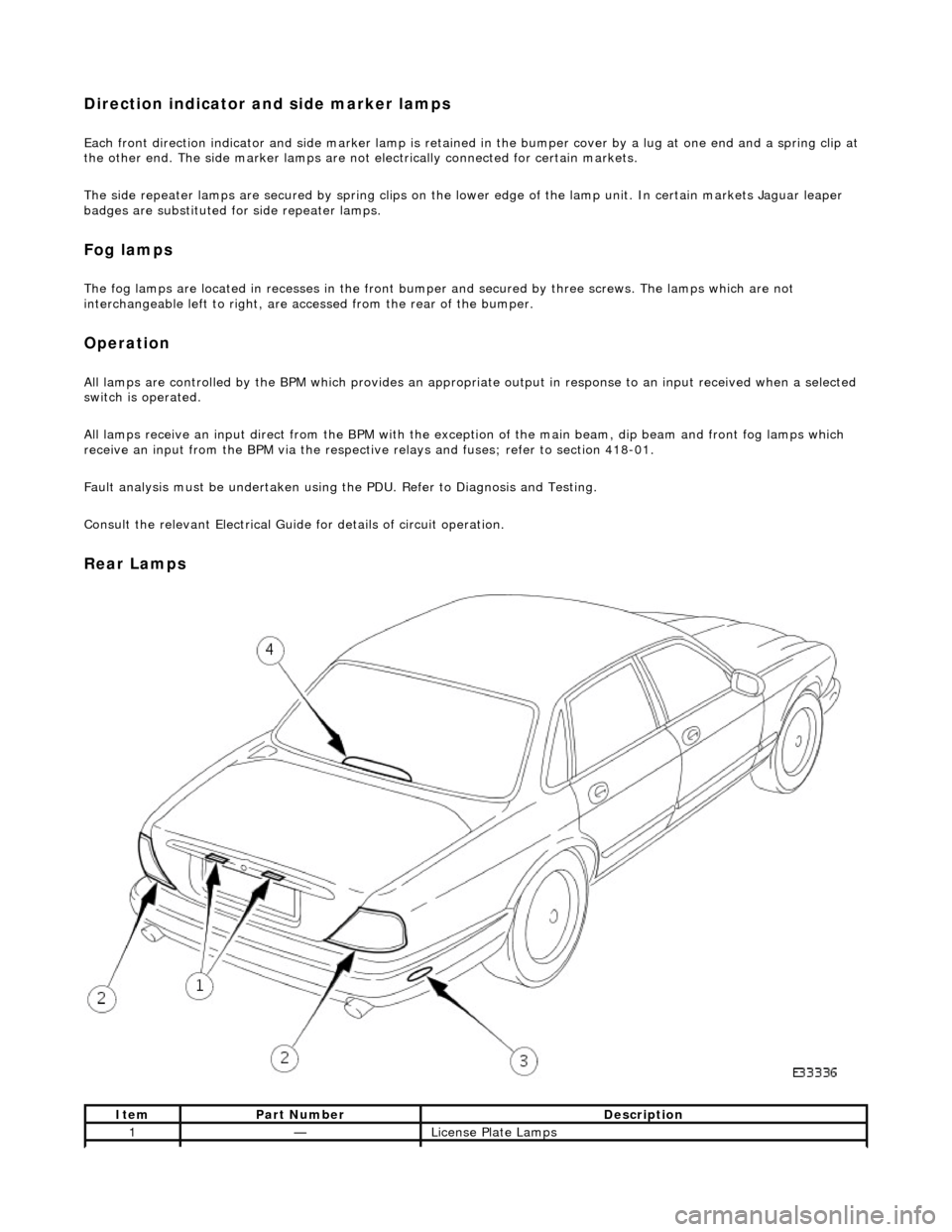

Rear Lamps

ItemPart NumberDescription

1—License Plate Lamps

Page 1947 of 2490

Exterior Lighting - Low Beam HeadlampVehicles Without: Headlamp

Leveling

Removal and Installation

Removal

Installation

1. Remove headlamp assembly fo r access. Refer to 86.41.33.

2. Release bulb holder securing tangs and withdraw holder for

access.

3. Invert headlamp assembly.

4. Release headlamp unit adju sting screws and pivot.

1. Install headlamp unit adjusting screws and pivot in locating

seats.

2. Invert headlamp assembly.

3. Install headlamp assembly bulb holder.

Page 1949 of 2490

Exterior Lighting - Low Beam HeadlampVehicles With: Headlamp Leveling

Removal and Installation

Removal

Installation

1.

Remove headlamp assembly for access. Refer to 86.41.33.

2. Release bulb holder securing tangs and withdraw holder for

access.

3. Invert headlamp assembly.

4. Release headlamp unit adjusting screws and pivot.

5. Remove actuator.

1. Release headlamp unit from leveling actuator adjusting screw.

2. Rotate actuator 1/4 turn inward, tilt forward end

downward and withdraw assembly from headlamp.

1. Install headlamp unit adjusting screws and pivot in locating

seats.

2. Invert headlamp assembly and install bulb holder.

3. With forward end tilted downward, position actuator assembly on

headlamp mounting.

4. Align actuator with headlamp and rotate it 1/4 turn outwards to

engage and fully seat in mounting.

5. Install headlamp assembly. Refer to 86.41.33.

6. Align headlamp beams.

Page 1950 of 2490

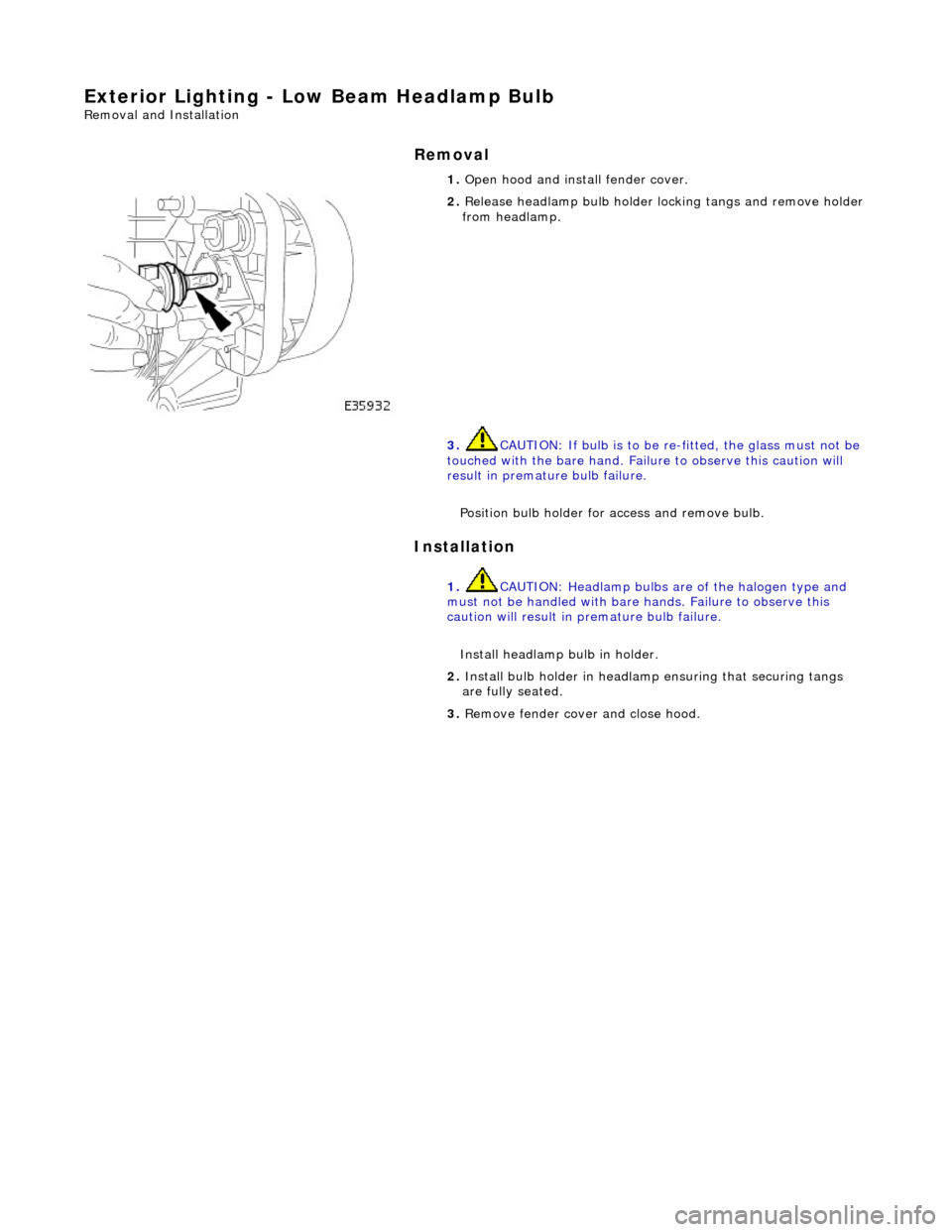

Exterior Lighting - Low Beam Headlamp Bulb

Removal and Installation

Removal

Installation

1.

Open hood and install fender cover.

2. Release headlamp bulb holder locking tangs and remove holder from headlamp.

3. CAUTION: If bulb is to be re -fitted, the glass must not be

touched with the bare hand. Failure to observe this caution will

result in premature bulb failure.

Position bulb holder for access and remove bulb.

1. CAUTION: Headlamp bulbs are of the halogen type and

must not be handled with bare hands. Failure to observe this

caution will result in premature bulb failure.

Install headlamp bulb in holder.

2. Install bulb holder in headlamp ensuring that securing tangs

are fully seated.

3. Remove fender cover and close hood.

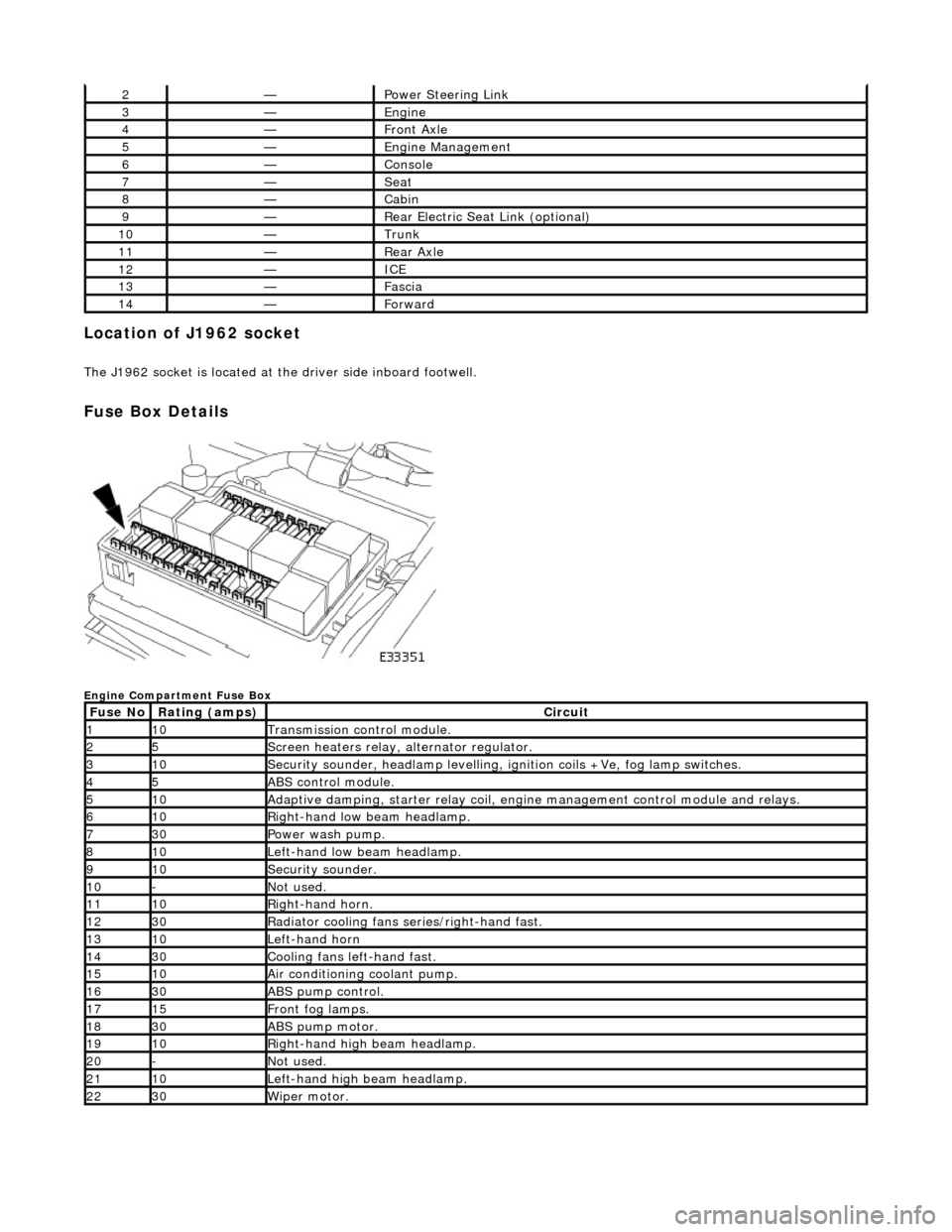

Page 1975 of 2490

Location of J1962 socket

The J1962 socket is located at the driver side inboard footwell.

Fuse Box Details

Engine Compartment Fuse Box

2—Power Steering Link

3—Engine

4—Front Axle

5—Engine Management

6—Console

7—Seat

8—Cabin

9—Rear Electric Seat Link (optional)

10—Trunk

11—Rear Axle

12—ICE

13—Fascia

14—Forward

Fuse NoRating (amps)Circuit

110Transmission control module.

25Screen heaters relay, alternator regulator.

310Security sounder, headlamp levelling, ignition coils +Ve, fog lamp switches.

45ABS control module.

510Adaptive damping, starter relay coil, engine management control module and relays.

610Right-hand low beam headlamp.

730Power wash pump.

810Left-hand low beam headlamp.

910Security sounder.

10-Not used.

1110Right-hand horn.

1230Radiator cooling fans series/right-hand fast.

1310Left-hand horn

1430Cooling fans left-hand fast.

1510Air conditioning coolant pump.

1630ABS pump control.

1715Front fog lamps.

1830ABS pump motor.

1910Right-hand high beam headlamp.

20-Not used.

2110Left-hand high beam headlamp.

2230Wiper motor.

Page 1978 of 2490

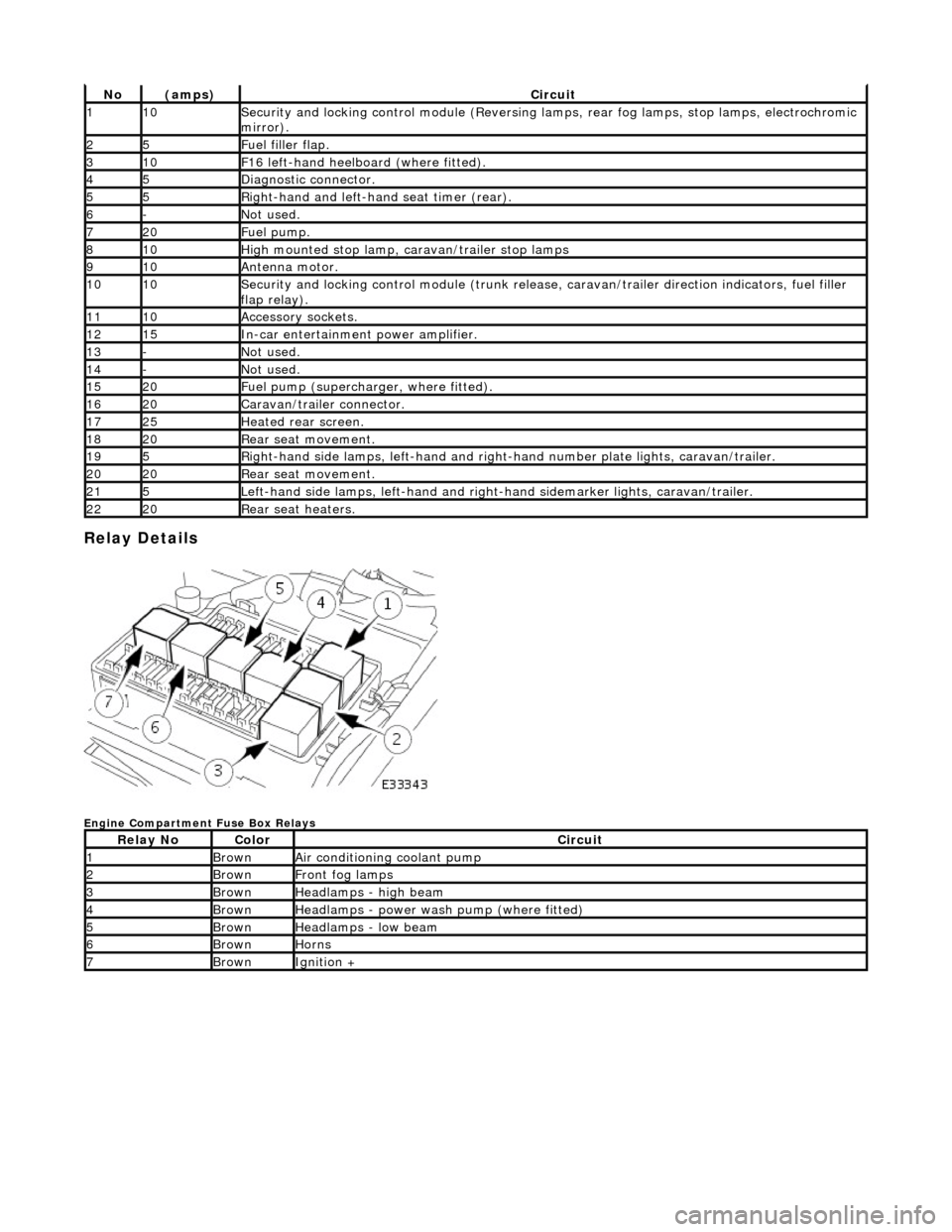

Relay Details

Engine Compartment Fuse Box Relays

No(amps)Circuit

110Security and locking control module (Reversing lamps, rear fog lamps, stop lamps, electrochromic

mirror).

25Fuel filler flap.

310F16 left-hand heelboard (where fitted).

45Diagnostic connector.

55Right-hand and left-han d seat timer (rear).

6-Not used.

720Fuel pump.

810High mounted stop lamp, caravan/trailer stop lamps

910Antenna motor.

1010Security and locking control module (trunk release, caravan/trailer direction indicators, fuel filler

flap relay).

1110Accessory sockets.

1215In-car entertainment power amplifier.

13-Not used.

14-Not used.

1520Fuel pump (supercharger, where fitted).

1620Caravan/trailer connector.

1725Heated rear screen.

1820Rear seat movement.

195Right-hand side lamps, left-h and and right-hand number pl ate lights, caravan/trailer.

2020Rear seat movement.

215Left-hand side lamps, left-hand and right-hand sidemarker lights, caravan/trailer.

2220Rear seat heaters.

Relay NoColorCircuit

1BrownAir conditioning coolant pump

2BrownFront fog lamps

3BrownHeadlamps - high beam

4BrownHeadlamps - power wash pump (where fitted)

5BrownHeadlamps - low beam

6BrownHorns

7BrownIgnition +

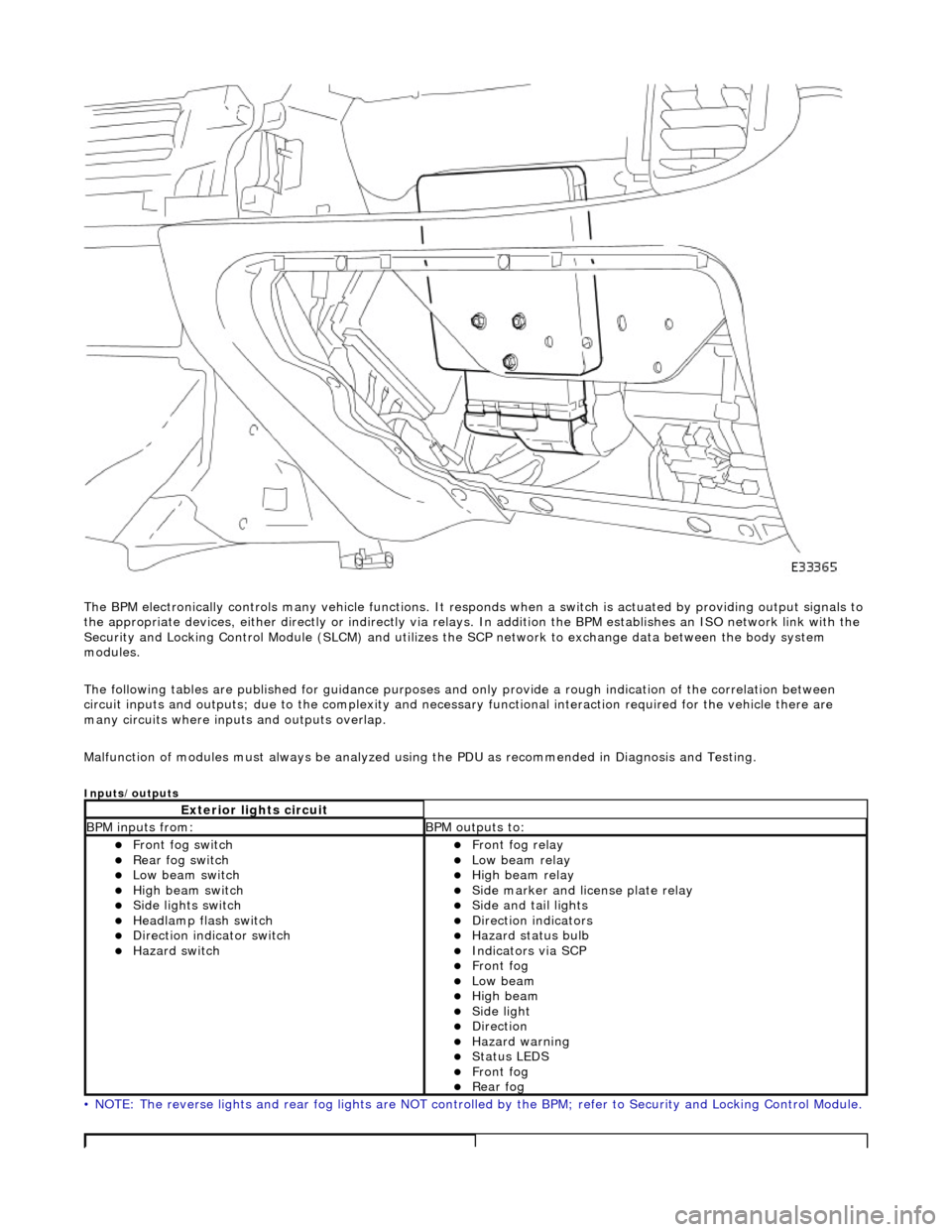

Page 2007 of 2490

The BPM electronically controls many vehicle functions. It responds when a switch is actuated by providing output signals to

the appropriate devices, either di rectly or indirectly via relays. In addition the BPM establishes an ISO network link with the

Security and Locking Control Module (SLC M) and utilizes the SCP network to exchange data between the body system

modules.

The following tables are publis hed for guidance purposes and only provide a rough indication of the correlation between

circuit inputs and outputs; due to the complexity and necess ary functional interaction required for the vehicle there are

many circuits where inpu ts and outputs overlap.

Malfunction of modules must always be analyzed using the PDU as recommended in Diagnosis and Testing.

Inputs/outputs

• NOTE: The reverse lights and rear fog lights are NOT controlled by the BPM; refer to Security and Locking Control Module.

Exterior lights circuit

BPM inputs from: BPM outputs to:

Front fog switch Rear fog switch Low beam switch High beam switch Side lights switch Headlamp flash switch Direction indicator switch Hazard switch

Front fog relay Low beam relay High beam relay Side marker and license plate relay Side and tail lights Direction indicators Hazard status bulb Indicators via SCP Front fog Low beam High beam Side light Direction Hazard warning Status LEDS Front fog Rear fog