low beam JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2446 of 2490

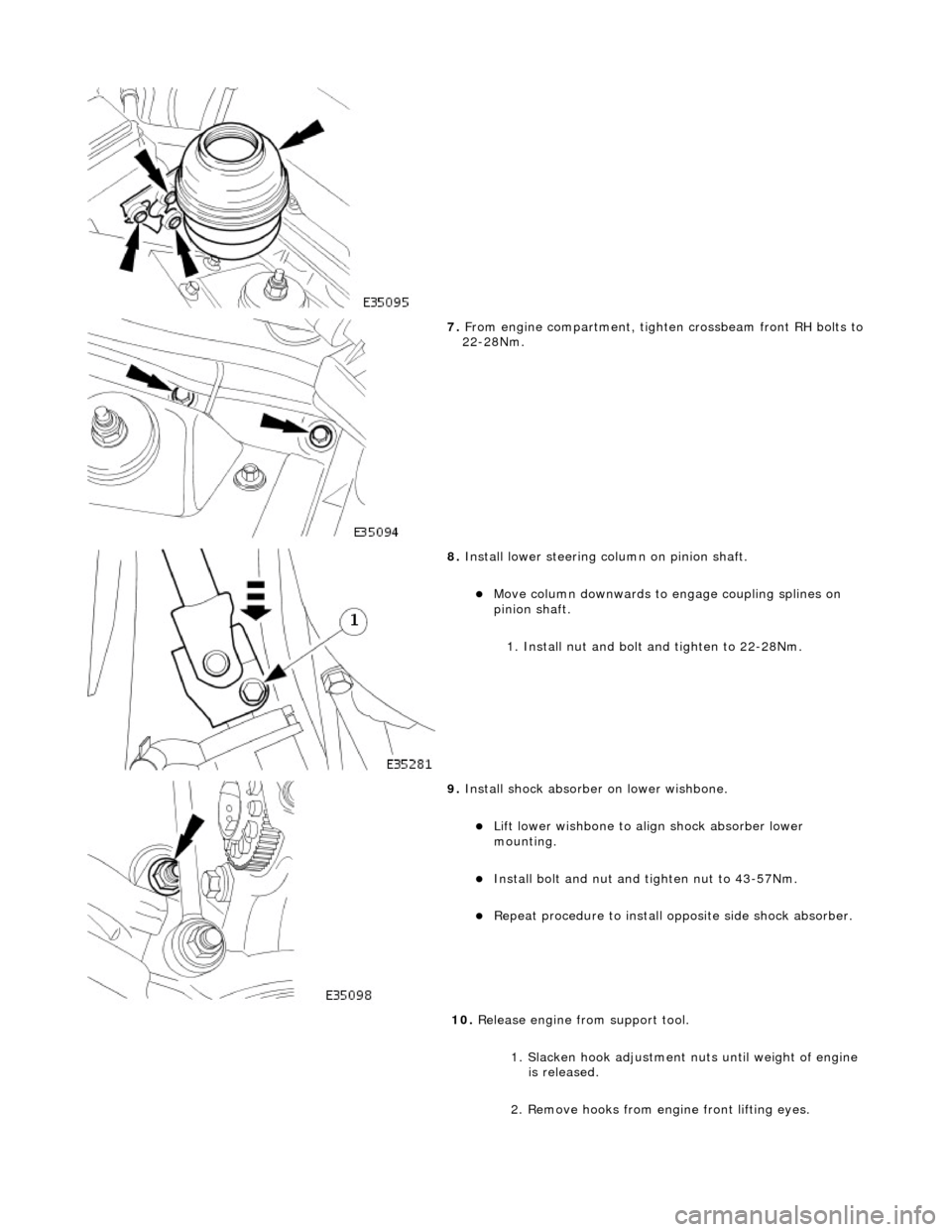

7. From engine compartment, tighten crossbeam front RH bolts to 22-28Nm.

8. Install lower steering column on pinion shaft.

Move column downwards to engage coupling splines on

pinion shaft.

1. Install nut and bolt and tighten to 22-28Nm.

9. Install shock absorber on lower wishbone.

Lift lower wishbone to align shock absorber lower

mounting.

Install bolt and nut and ti ghten nut to 43-57Nm.

Repeat procedure to install opposite side shock absorber.

10. Release engine from support tool.

1. Slacken hook adjustment nuts until weight of engine is released.

2. Remove hooks from engine front lifting eyes.

Page 2453 of 2490

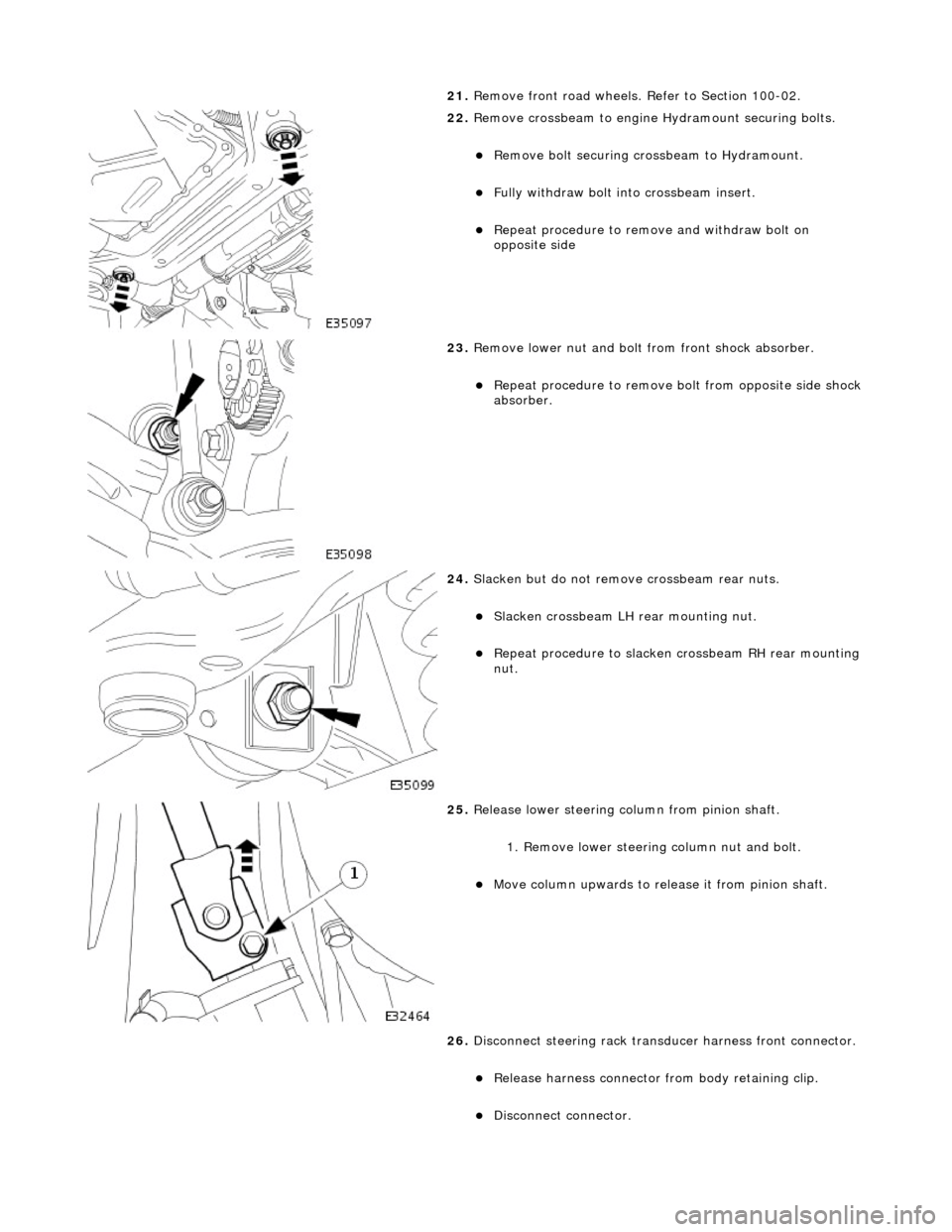

21. Remove front road wheels. Refer to Section 100-02.

22. Remove crossbeam to engine Hydramount securing bolts.

Remove bolt securing crossbeam to Hydramount.

Fully withdraw bolt into crossbeam insert.

Repeat procedure to remove and withdraw bolt on

opposite side

23. Remove lower nut and bolt from front shock absorber.

Repeat procedure to remove bo lt from opposite side shock

absorber.

24. Slacken but do not remove crossbeam rear nuts.

Slacken crossbeam LH rear mounting nut.

Repeat procedure to slacken crossbeam RH rear mounting

nut.

25. Release lower steering column from pinion shaft.

1. Remove lower steering column nut and bolt.

Move column upwards to release it from pinion shaft.

26. Disconnect steering rack transducer harness front connector.

Release harness connector from body retaining clip.

Disconnect connector.

Page 2455 of 2490

Installation

31. CAUTION: Slowly lower the crossbeam just sufficient to

provide the required clearance. Lowering the crossbeam

excessively can damage the suspension and steering pipes.

Carefully lower crossbeam to provide sufficient clearance

between front mounting and body.

32. Remove and discard heatshield from front mounting.

1. Install new heatshield over front mounting.

2. NOTE: It may be necessary to use a hammer and drift to

finally align new mounting with body location.

Carefully raise crossbeam assembly into position.

Ensure that dowels of both crossbeam mountings are

Page 2457 of 2490

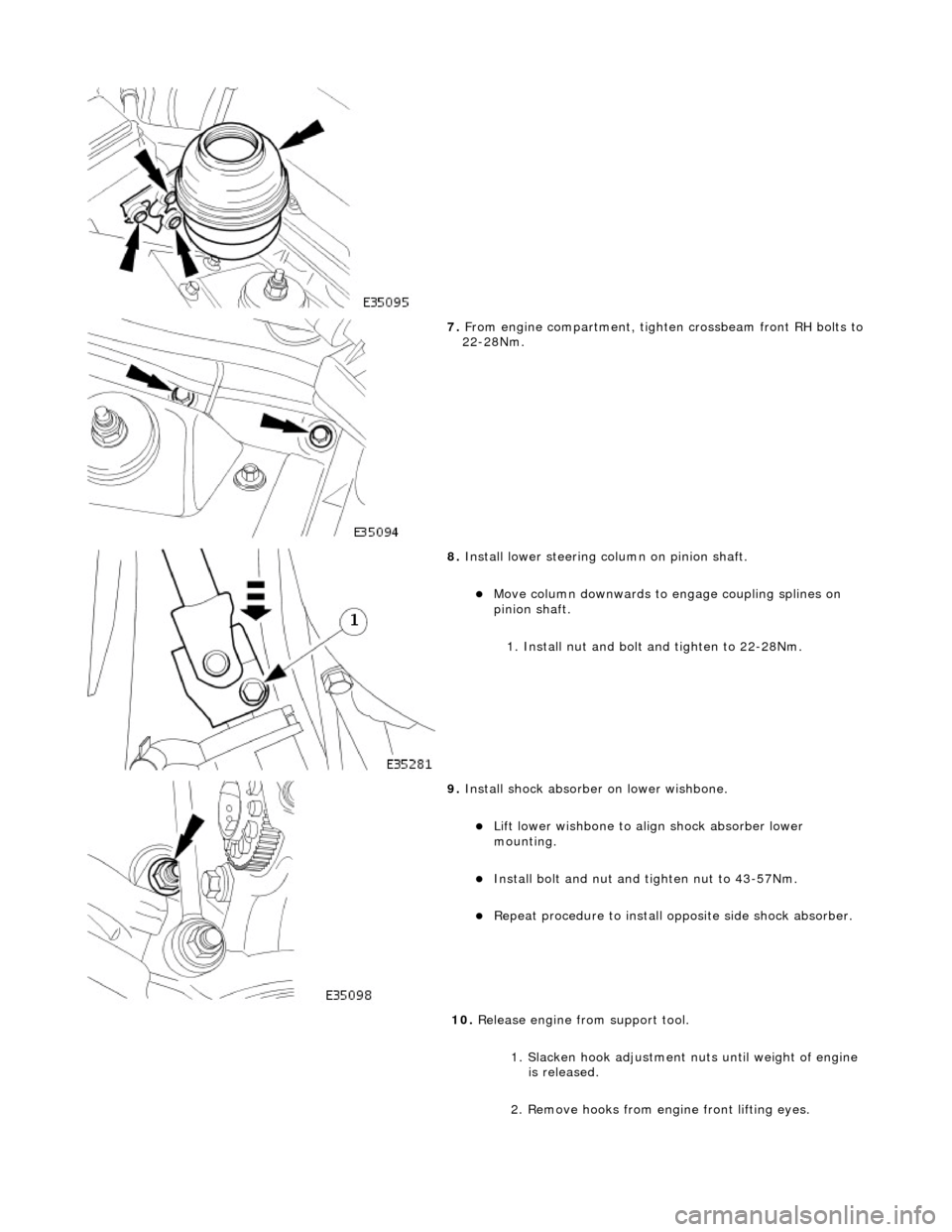

7. From engine compartment, tighten crossbeam front RH bolts to 22-28Nm.

8. Install lower steering column on pinion shaft.

Move column downwards to engage coupling splines on

pinion shaft.

1. Install nut and bolt and tighten to 22-28Nm.

9. Install shock absorber on lower wishbone.

Lift lower wishbone to align shock absorber lower

mounting.

Install bolt and nut and ti ghten nut to 43-57Nm.

Repeat procedure to install opposite side shock absorber.

10. Release engine from support tool.

1. Slacken hook adjustment nuts until weight of engine is released.

2. Remove hooks from engine front lifting eyes.

Page 2465 of 2490

24. Drain power steering fluid.

Disconnect pipes and al low fluid to drain.

Remove and discard 'O'-ring seals from pipe connectors.

Fit blanking plugs to pipe connectors and pinion housing

ports.

25. Remove drain receptacle.

26. Remove pipe support from steering rack.

Release return pipe from support.

Remove support from rack.

27. Ensure that steering is in central position.

28. Release lower steering column from pinion shaft.

1. Remove lower steering co lumn securing nut and bolt.

Move column upwards to release it from pinion shaft.

29. Support weight of crossbeam.

Position a jack under crossbeam.

Page 2467 of 2490

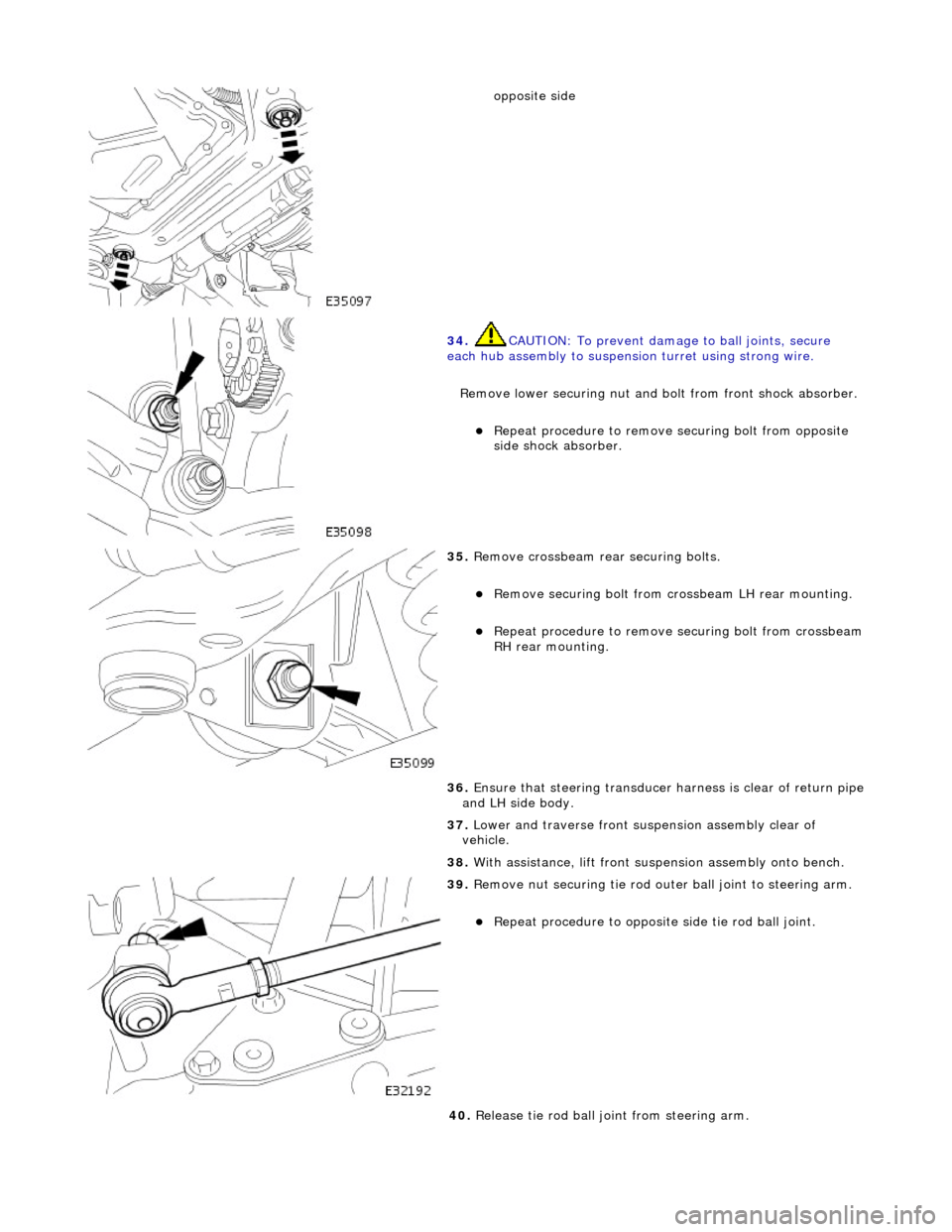

opposite side

34. CAUTION: To prevent damage to ball joints, secure

each hub assembly to suspensi on turret using strong wire.

Remove lower securing nut and bolt from front shock absorber.

Repeat procedure to remove securing bolt from opposite

side shock absorber.

35. Remove crossbeam rear securing bolts.

Remove securing bolt from crossbeam LH rear mounting.

Repeat procedure to remove securing bolt from crossbeam RH rear mounting.

36. Ensure that steering transducer harness is clear of return pipe

and LH side body.

37. Lower and traverse front suspension assembly clear of

vehicle.

38. With assistance, lift front suspension as sembly onto bench.

39. Remove nut securing tie rod oute r ball joint to steering arm.

Repeat procedure to opposite side tie rod ball joint.

40. Release tie rod ball joint from steering arm.

Page 2469 of 2490

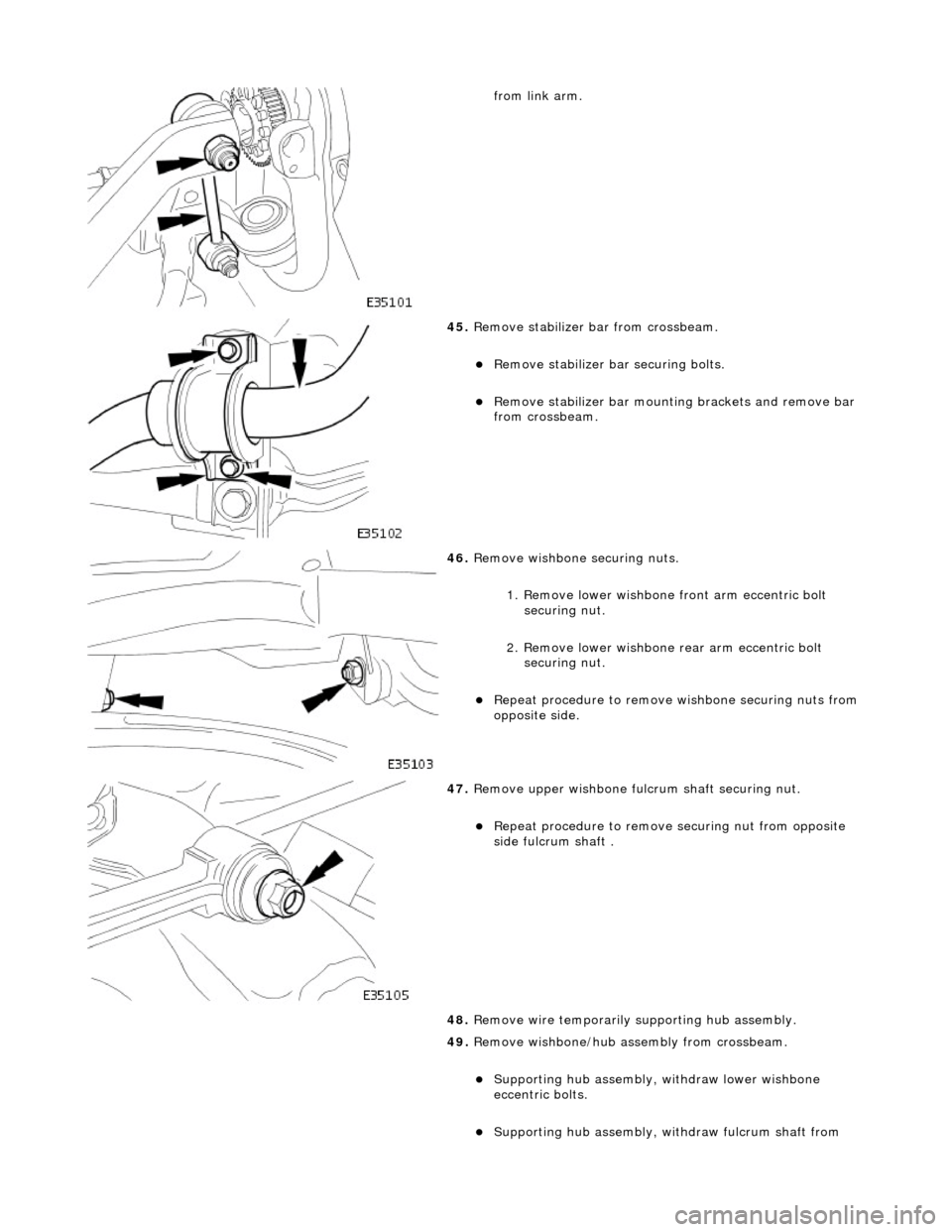

from link arm.

45. Remove stabilizer bar from crossbeam.

Remove stabilizer bar securing bolts.

Remove stabilizer bar mountin g brackets and remove bar

from crossbeam.

46. Remove wishbone securing nuts.

1. Remove lower wishbone front arm eccentric bolt

securing nut.

2. Remove lower wishbone rear arm eccentric bolt

securing nut.

Repeat procedure to remove wishbone securing nuts from

opposite side.

47. Remove upper wishbone fu lcrum shaft securing nut.

Repeat procedure to remove securing nut from opposite

side fulcrum shaft .

48. Remove wire temporarily supporting hub assembly.

49. Remove wishbone/hub assembly from crossbeam.

Supporting hub assembly, wi thdraw lower wishbone

eccentric bolts.

Supporting hub assembly, wi thdraw fulcrum shaft from

Page 2472 of 2490

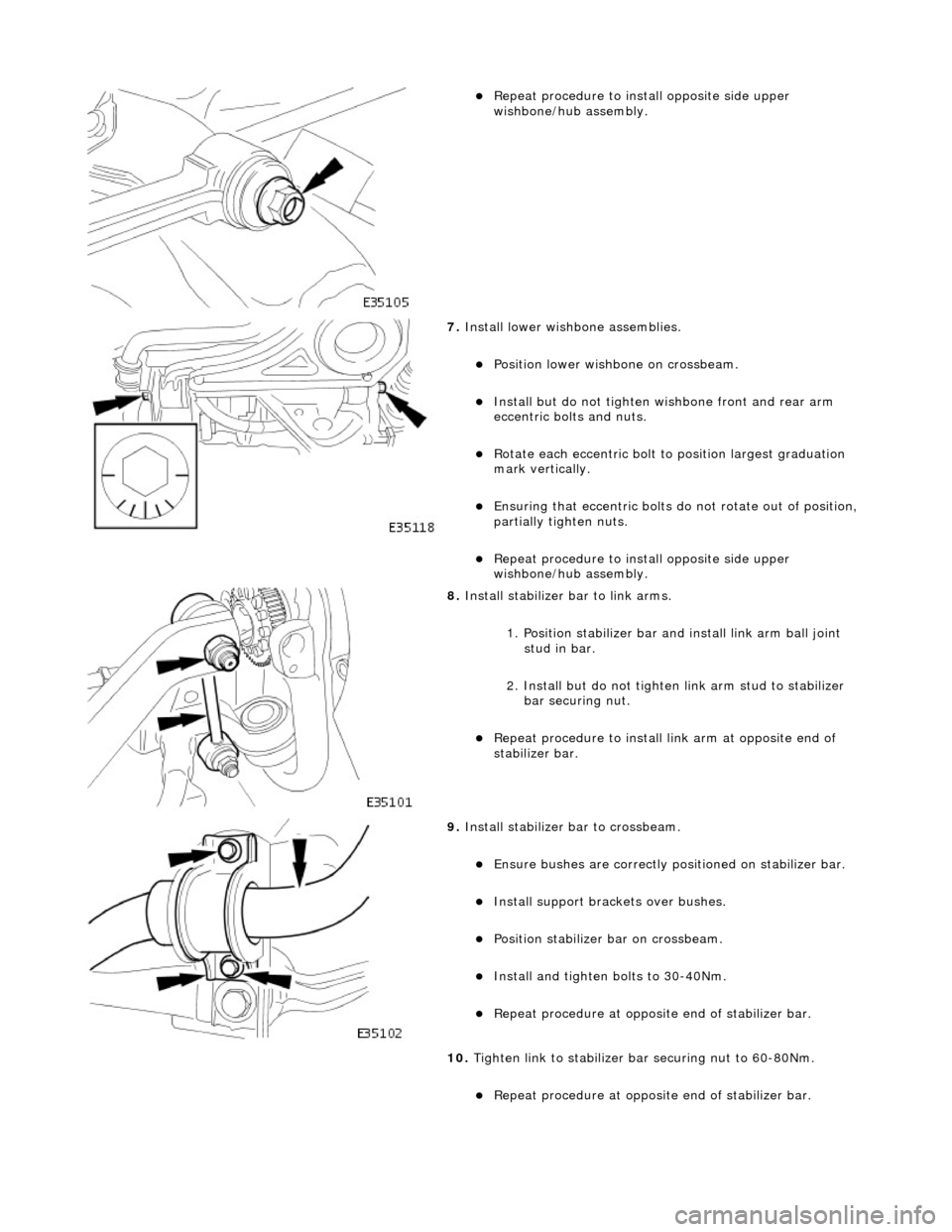

Repeat procedure to install opposite side upper

wishbone/hub assembly.

7. Install lower wishbone assemblies.

Position lower wishbone on crossbeam.

Install but do not tighten wi shbone front and rear arm

eccentric bolts and nuts.

Rotate each eccentric bolt to position largest graduation

mark vertically.

Ensuring that eccentric bolts do not rotate out of position,

partially tighten nuts.

Repeat procedure to inst all opposite side upper

wishbone/hub assembly.

8. Install stabilizer bar to link arms.

1. Position stabilizer bar and install link arm ball joint stud in bar.

2. Install but do not tighten link arm stud to stabilizer bar securing nut.

Repeat procedure to install link arm at opposite end of

stabilizer bar.

9. Install stabilizer bar to crossbeam.

Ensure bushes are correctly posi tioned on stabilizer bar.

Install support brackets over bushes.

Position stabilizer bar on crossbeam.

Install and tighten bolts to 30-40Nm.

Repeat procedure at opposite end of stabilizer bar.

10. Tighten link to stabilizer bar securing nut to 60-80Nm.

Repeat procedure at opposite end of stabilizer bar.

Page 2473 of 2490

11. Install steering rack on crossbeam.

Ensure that bushes are correct ly positioned on steering

rack.

Position steering rack on crossbeam.

Position support brac kets over bushes.

Install mounting bracket bolt s and tighten to 41-54Nm.

12. Install tie rods on steering arms.

Position and fully seat tie rod ball joint taper pin on

steering arm.

Install tie rod ball joint nu t and tighten to 71-85Nm.

Repeat procedure to install opposite side tie rod ball joint.

13. Install steering harness on suspension turret.

Noting positions marked during removal, tape new

securing clips to st eering harness.

Install securing clips/harness on LH turret.

14. With assistance position crossbeam/suspension assembly on

jack with protective wood under.

15. Traverse assembly into position below vehicle.

16. Ensure steering harn ess connector is positioned to avoid

damage during crossbeam lift .

17. NOTE: It may be necessary to use a hammer and drift to

finally align new mounting with body location.

Page 2475 of 2490

22. Install power steering fluid reservoir.

Position reservoir on mounting bracket.

Install reservoir securi ng nuts and bolts.

23. From engine compartment, tighten crossbeam front RH bolts

to 22-28Nm.

24. Install shock absorber on lower wishbone.

Lift lower wishbone to align shock absorber lower

mounting.

Install bolt and nut and ti ghten nut to 43-57Nm.

Repeat procedure to install opposite side shock absorber.

25. Install lower steering column on pinion shaft.

Move column downwards to engage coupling splines on

pinion shaft.

1. Install nut and bolt and tighten to 22-28Nm.