tires JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 363 of 2490

Install brake pads

i

nto caliper.

Slo

wly retract caliper pi

stons into caliper.

1. Install pads.

2. Position anti-rattle spring.

3. Install pins.

4. Install 'R' clips.

4. Repeat above procedure to install opposite side brake pads.

5. Fit wheels.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

6. Remove stands and lower vehicle.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

7. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Check brake fluid level.

Check brak

e fluid level is

at the maximum mark.

Re

move cloth.

Fi

t cap.

8.

R

emove paint work protection

covers, and close engine

compartment.

9. Start the engine and repeatedly press the brake pedal until

brake pressure is evident.

Page 387 of 2490

Rear Dis

c Brake - Brake PadsVehicl

es With: High Performance Brakes

Re

moval and Installation

Remov

al

1.

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Brake pads must always be replaced in axle sets.

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

For additional information, refer to: General Service Information

(10

0-00 General Information,

Description and Operation).

The High performance brake caliper is aligned to the brake

disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the

caliper; remove the bolts that se cure the anchor bracket to the

vertical link only. DO NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise rear of vehicle an

d support on stands.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

3. Remove rear wheels.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

Position a cloth around the

reservoir to collect any fluid

spillage.

5. Remove brake

pads from caliper.

1. Withdraw pins from caliper.

2. Remove anti-rattle spring.

3. Discard brake pads.

Page 389 of 2490

Install brake pads.

1

. Install pads.

2. Position anti-rattle spring.

3. Install pins - make sure pin collets are fully engaged

into caliper.

4. Repeat above procedure to install opposite side brake pads.

5. Fit wheels.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

6. Remove stands an d lower vehicle.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

7. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Check brake fluid level.

Check brak

e fluid level is

at the maximum mark.

Re

move cloth.

Fi

t cap.

8.

R

emove paint work protection

covers, and close engine

compartment.

9. Start the engine and repeatedly press the brake pedal until

brake pressure is evident.

Page 460 of 2490

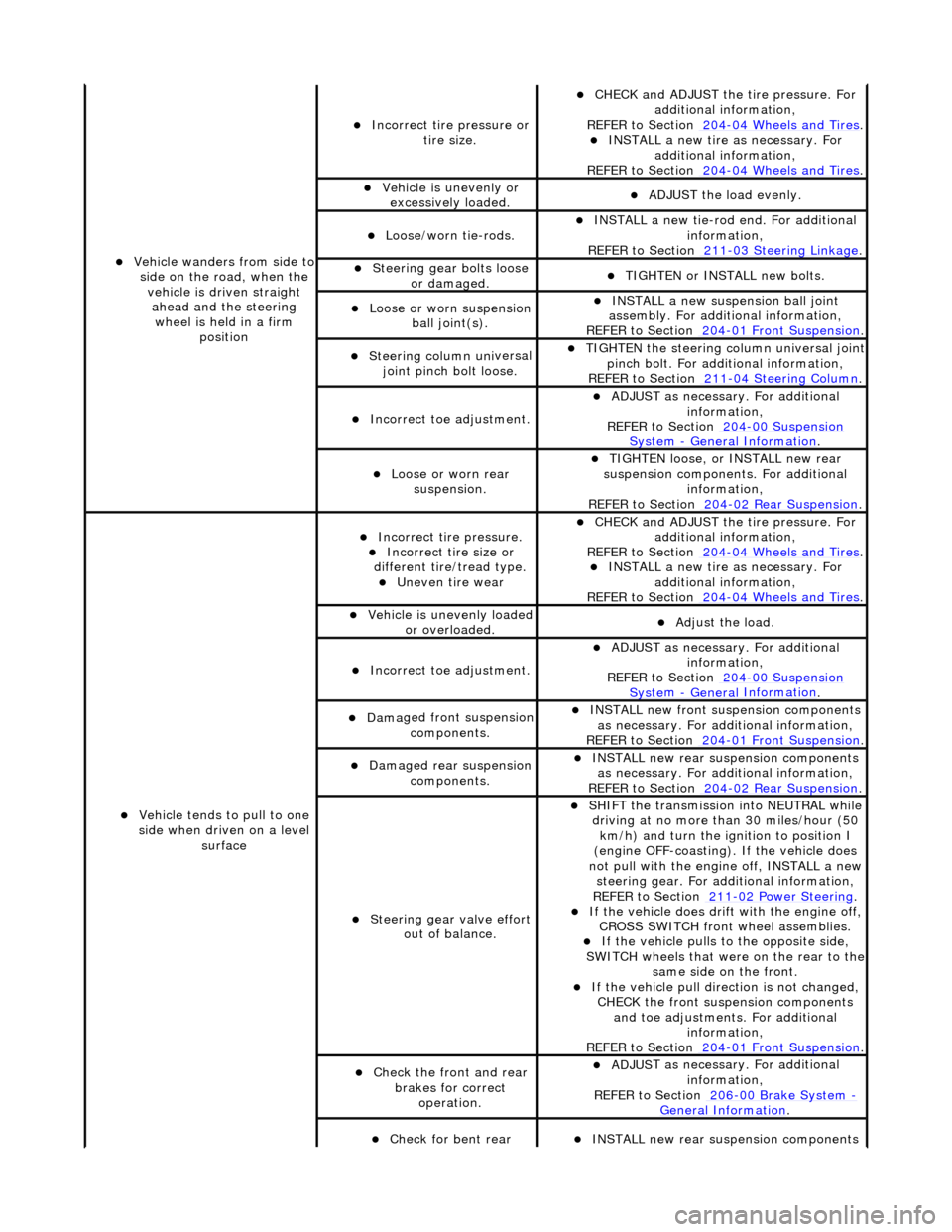

Vehicl

e wanders from side to

side on the road, when the vehicle is driven straight ahead and the steering wheel is held in a firm position

Incorrect ti re

pressure or

tire size.

CHECK and ADJ

UST the tire pressure. For

additional information,

REFER to Section 204

-0 4

Wheels and Tires

. IN

ST

ALL a new tire as necessary. For

additional information,

REFER to Section 204

-0 4

Wheels and Tires

.

Vehi

cl

e is unevenly or

excessively loaded.

A D

JUST the load evenly.

Loose/worn ti

e-

rods.

INST

ALL a ne

w tie-rod

end. For additional

information,

REFER to Section 211

-0 3

Steering Linkage

.

Steeri

ng gear bolts loose

o

r damaged.

TIGHTE

N or INSTALL

new bolts.

Loose or worn suspensi

on

ball jo

int(s).

INST

ALL a ne

w suspension ball joint

assembly. For additional information,

REFER to Section 204

-01 Fron

t Suspension

.

Steeri

ng column uni

versal

joint pinch bolt loose.

TI G

HTEN the steering column universal joint

pinch bolt. For additi onal information,

REFER to Section 211

-0 4

Steering Column

.

Incorre

ct

toe adjustment.

ADJUS

T as necessary. For additional

information,

REFER to Section 204

-00 Sus

pension

Sy

ste

m

- General

Information

.

Loose or worn rear

susp

ension.

TIGHTEN

loose, or IN

STALL new rear

suspension components. For additional information,

REFER to Section 204

-0 2

Rear Suspension

.

Vehicle t

e

nds to pull to one

side when driven on a level surface

Incorrect ti

re pressure.

Incorrect

ti

re size or

different tire/tread type.

Uneven tire wear

CHECK and ADJ

UST the tire pressure. For

additional information,

REFER to Section 204

-0 4

Wheels and Tires

. IN

ST

ALL a new tire as necessary. For

additional information,

REFER to Section 204

-04

Wheels and Tires

.

Vehicl

e is unevenly loaded

or overloaded.

Adjust the load

.

Incorre

ct

toe adjustment.

ADJUS

T as necessary. For additional

information,

REFER to Section 204

-00 Sus

pension

Sy

ste

m

- General

Information

.

Dam

a

ged front suspension

components.

I N

STALL new front suspension components

as necessary. For addi tional information,

REFER to Section 204

-01 Fron

t Suspension

.

Damaged rear

suspen

sion

components.

INST ALL ne

w rear suspension components

as necessary. For addi tional information,

REFER to Section 204

-0 2

Rear Suspension

.

Steeri

ng gear val

ve effort

out of balance.

SHIF T the

transmission into NEUTRAL while

driving at no more than 30 miles/hour (50 km/h) and turn the ignition to position I

(engine OFF-coasting). If the vehicle does

not pull with the engine off, INSTALL a new steering gear. For additional information,

REF E

R to Section 211

-0

2

Power Steering

. If t

he

vehicle does drift with the engine off,

CROSS SWITCH front wheel assemblies.

If the

vehicle pulls to

the opposite side,

SWITCH wheels that were on the rear to the

same side on the front.

If the v

ehicle pull dire

ction is not changed,

CHECK the front susp ension components

and toe adjustments. For additional information,

REFER to Section 204

-01 Fron

t Suspension

.

Chec

k

the front and rear

brakes for correct operation.

ADJUS

T as necessary. For additional

information,

REFER to Section 206

-0 0

Brake System

-

General Informati on.

Check fo

r bent rear

INST

ALL ne

w rear suspension components

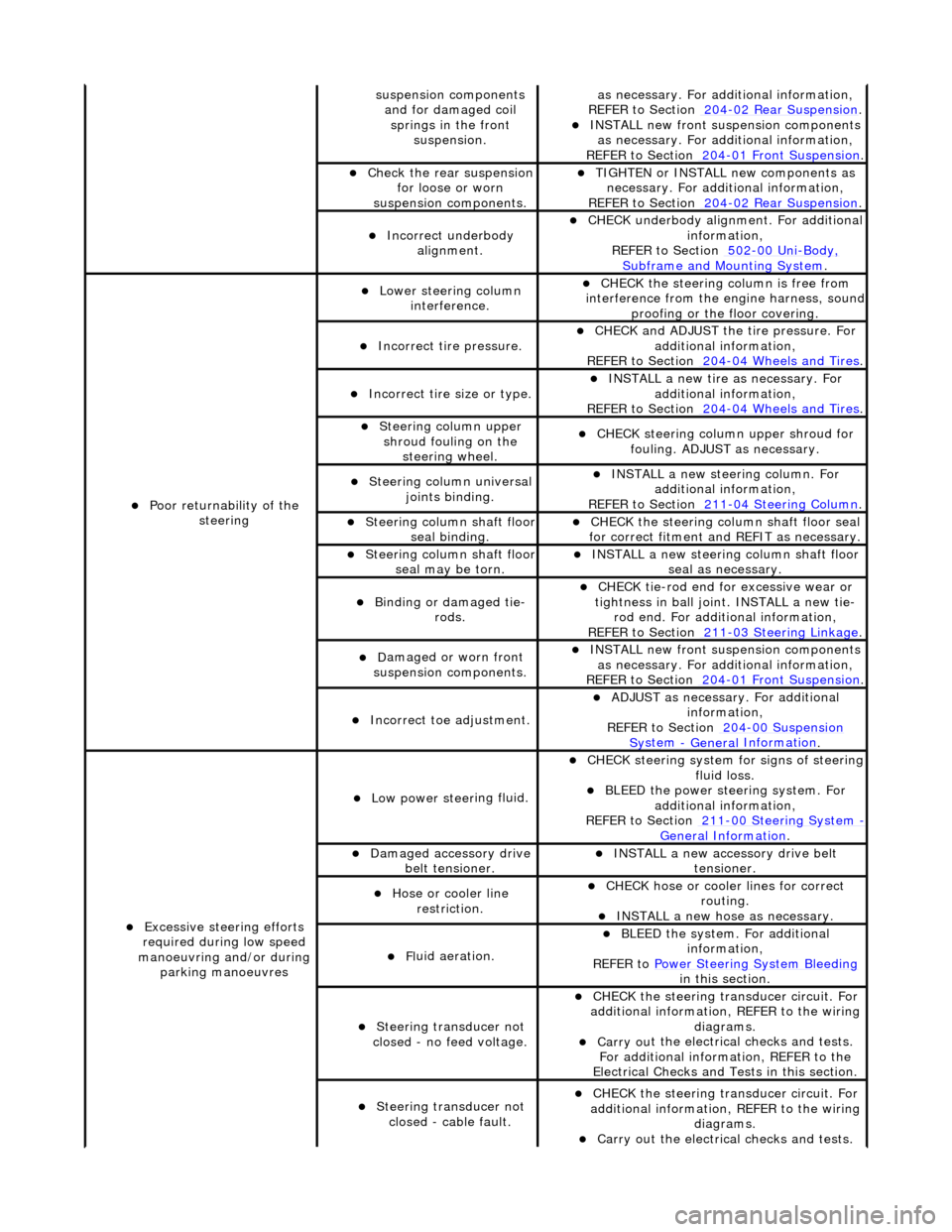

Page 461 of 2490

sus

pension components

and for damaged coil springs in the front suspension.

as necessary. For addi tional information,

REF

ER to Section 204

-0

2 Rear Suspension

. I

NSTALL new front suspension components

as necessary. For addi tional information,

REFER to Section 204

-01

Front Suspension

.

Chec

k the rear suspension

for loose or worn

suspension components.

TIGHTE

N or INSTALL new components as

necessary. For additi onal information,

REFER to Section 204

-0

2 Rear Suspension

.

Incorre

ct underbody

alignment.

CHECK

underbody alignment. For additional

information,

REFER to Section 502

-00

Uni

-Body, Subframe and M

ounting System

.

Poor r

eturnability of the

steering

Lower steeri

ng column

interference.

CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

Incorrect

tire pressure.

CHECK

and ADJUST the tire pressure. For

additional information,

REFER to Section 204

-0

4 Wheels and Tires

.

Incorrect

tire size or type.

IN

STALL a new tire as necessary. For

additional information,

REFER to Section 204

-0

4 Wheels and Tires

.

Steeri

ng column upper

shroud fouling on the steering wheel.

CHECK

steering column upper shroud for

fouling. ADJUST as necessary.

Steeri

ng column universal

joints binding.

IN

STALL a new steering column. For

additional information,

REFER to Section 211

-0

4 Steering Column

.

Steeri

ng column shaft floor

seal binding.

CHE

CK the steering column shaft floor seal

for correct fitm ent and REFIT as necessary.

Steeri

ng column shaft floor

seal may be torn.

IN

STALL a new steering column shaft floor

seal as necessary.

Bin

ding or damaged tie-

rods.

CHECK

tie-rod end for excessive wear or

tightness in ball joint. INSTALL a new tie- rod end. For additional information,

REFER to Section 211

-0

3 Steering Linkage

.

D

amaged or worn front

suspension components.

I

NSTALL new front suspension components

as necessary. For addi tional information,

REFER to Section 204

-01

Front Suspension

.

Incorre

ct toe adjustment.

AD

JUST as necessary. For additional

information,

REFER to Section 204

-00

Suspension

Sy

stem

- General

Information

.

Excessive steeri

ng efforts

required during low speed

manoeuvring and/or during parking manoeuvres

Low power steer

ing fluid.

CHE

CK steering system

for signs of steering

fluid loss.

BLEE

D the power steering system. For

additional information,

REFER to Section 211

-0

0 Steering System

- General Informati

on

.

Damaged accessory driv

e

belt tensioner.

INST

ALL a new accessory drive belt

tensioner.

Hose or cooler li

ne

restriction.

CHECK

hose or cooler lines for correct

routing.

INST

ALL a new hose as necessary.

Fl

uid aeration.

BLEE

D the system. For additional

information,

REFER to Power Steering System Bleeding

in t

his section.

Steeri

ng transducer not

closed - no feed voltage.

CHECK

the steering transducer circuit. For

additional information, REFER to the wiring diagrams.

Carry ou

t the electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

Steeri

ng transducer not

closed - cable fault.

CHECK

the steering transducer circuit. For

additional information, REFER to the wiring diagrams.

Carry ou

t the electrical checks and tests.

Page 469 of 2490

Buzz (E

lectrical)

A

different steering buzz can be caused by

pulse width modulated (PWM) electric actuators used in variable assist steering

systems. This buzz is felt by turning the ignition key to run without starting the engine and holding onto the steering wheel.

In extreme cases, the buzz can be felt with the engine running also.

Column/Steering Wheel

Shake

Column shake is a low f

requenc

y vertical vibration excited by primary engine vibrations.

Nibble (Shimm

y)

Steeri

ng nibble is a rotary oscillation or

vibration of the steering wheel, which can be excited at a specific vehicle speed.

Nibble is driven by wheel and tire imbalance exciting a suspensi on recession mode, which then translates into steering gear

travel and finally steering wheel nibble.

Shudder (Judd

er)

Shudder i

s a low frequency oscillation of th

e entire steering system (tire, wheels, st eering gear and linkage, etc.) when the

vehicle is steered during static-park or at low sp eeds. Shudder is very dependent on road surface.

Torque Ri

pple

Torque rippl

e is a concern with Electric Power Steering (EPS) sy

stems. Torque ripple is most evident at static-park steering

the wheel very slowly from lock to lock. Torque ripple is primarily caused by motor commutation.

Torque/Veloc

ity Variation

(Phasing/Effort Cycling)

Steeri

ng wheel torque variation oc

curring twice in one revolution is normally as a result of problems with the lower steering

column (intermediate shaft), but foul cond itions generally result in either constant stiffnes s or single point stiffness.

Depending upon the orientation of the joints, the steering can fe el asymmetric (torque falling off in one direction and rising

in the other) or else it can simply have pronounced peaks and troughs as the steering moves from lock to lock.

Wheel Fight

(Kick Back)

W

heel fight is excess feedback of sudden road forces through th

e steering system and back to the driver. It is evaluated at

all vehicle speeds over cobblestones, rough roads, and potholes . The tires, wheels, and suspension generate forces into the

steering systems. Steering friction, hydraulic damping, hydr aulic compliance, mechanical compliance, steering ratio, and

assist gain all affect how much is transmitted to the driver.

Stee

ring Linkage

CAUTI

ON: Steering gear boots must be

handled carefully to avoid damage. Use new clamps when installing steering

gear boots.

Inspect the boots for cuts, deterioration, tw isting or distortion. Check the steering gear boots to make sure they are tight.

Install new boots or clamps as necessary.

• NOTE: The following steps must be carried out with assistance.

1. 1. With the wheels in the straight ahead po sition, gently turn the steering wheel to the left and the right to check for

free play.

2. 2. Free play should be between 0 and 6 mm (0 and 0.24 in) at the steering wheel rim. If the free play exceeds this

limit, either the ball joints are worn, the lower steering column joints are worn or the backlash of the steering gear

is excessive.

Page 1869 of 2490

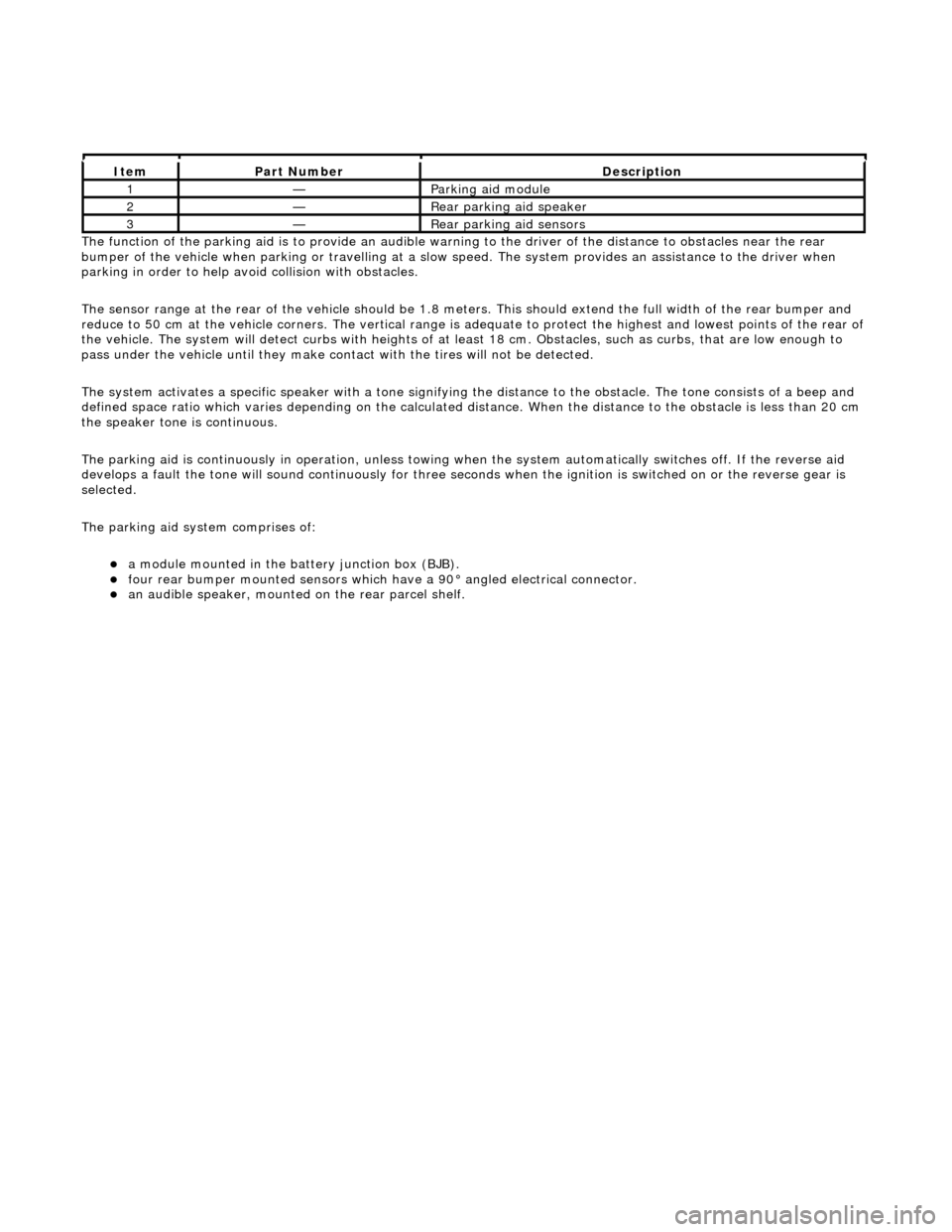

The functi

on of the parking aid is to prov

ide an audible warning to the driver of the distance to obstacles near the rear

bumper of the vehicle when parking or travelling at a slow sp eed. The system provides an assistance to the driver when

parking in order to help avoid collision with obstacles.

The sensor range at the rear of the vehicl e should be 1.8 meters. This should extend the full width of the rear bumper and

reduce to 50 cm at the vehicle co rners. The vertical range is adequate to protec t the highest and lowest points of the rear of

the vehicle. The system will detect curbs with heights of at least 18 cm. Obstacles, such as curbs, that are low enough to

pass under the vehicle until they make contact with the tires will not be detected.

The system activates a specific speaker with a tone signifying the distance to the obstacle. The tone consists of a beep and

defined space ratio which varies depending on the calculated distance. When the distance to the obstacle is less than 20 cm

the speaker tone is continuous.

The parking aid is continuously in operation, unless towing wh en the system automatically switches off. If the reverse aid

develops a fault the tone will sound continuously for three seconds when the igni tion is switched on or the reverse gear is

selected.

The parking aid system comprises of:

a

module mounted in the batte

ry junction box (BJB).

fou

r rear bumper mounted sensors which have a 90° angled electrical connector.

an audible speaker, moun

ted on

the rear parcel shelf.

It

em

Par

t Number

De

scription

1—Parkin

g aid module

2—Rear

parking aid speaker

3—Rear

parking aid sensors