ignition JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 14 of 2490

303‐07: En gine Ignition

Specification

Diagnosis and Testing

Engine Ignition

Diagnosis and Testing

Engine Ignition

Inspection and Verification

Driver Information Chart

Default mode Definitions

Diagnostic Trouble Code (DTC) index

Pinpoint Tests

Removal and Installation

Ignition Coil ‐On ‐Plug LH (18.20.44)

Ignition Coil ‐On ‐Plug RH (18.20.43)

Ignition Module (18.20.30)

Spark Plugs (18.20.02)

303‐08: En

gine Emission Control

Specification

Diagnosis and Testing

Engine Emission Control

Inspection and Verification

Diagnostic Trouble Code (DTC) Index

Pinpoint Tests

Removal and Installation

Exhaust Gas Recirculation (EGR) Valve (17.45.01)

Exhaust Manifold to Exhaust Gas Recirculation (E

GR) Valve Tube (17.45.11)

303‐12: Intake Air Distribution and Filtering

Removal and Installation

Air Cleaner (19.10.05)

Air Cleaner Element (19.10.08)

Charge Air Cooler LH (18.50.19)

Charge Air Cooler RH (18.50.18)

Charge Air Cooler Gasket LH (18.50.22)

Charge Air Cooler Gasket RH (18.50.21)

Supercharger (18.50.

15)

Page 39 of 2490

Before inspecting a component for wear or per

forming a dimensional check,

ensure that it is absolutely clean; a slight smear

of grease can conceal an incipient failure. When a component is to be checked dimensionally against figures quoted for it,

use the correct equipment (surface plates, micrometers, dial gauges etc.) in serviceable condition. The use of makeshift

equipment can be dangerous. Reject a component if its dimensio ns are outside the limits quoted, or if damage is apparent.

A part may be refitted if its critical di mension is exactly to the limit size and it is otherwise satisfactory. Use Plastigauge 12

Type PG-1 for checking bearing surface clearance, e.g. big end bearing shell to crank jour nal. Instructions for the use of

Plastigauge and a scale giving bearing clearances in steps of 0.0025 mm (0.0001 in) are supplied with the package.

Safety

Precautions

• WAR

NINGS:

WORKING ON THE FUEL SYSTEM RESULTS IN FUEL AND FUEL VAPOUR BEING PRESENT IN THE ATMOSPHERE. FUEL

VAPOUR IS EXTREMELY FLAMMABLE, HENCE GREAT CARE MUST BE TAKEN WHILST WORKING ON THE FUEL SYSTEM.

ADHERE STRICTLY TO THE FOLLOWING PRECAUTIONS:

DO

NOT SMOKE IN THE WORK AREA.

DISP

LAY 'NO SMOKING' SIGNS AROUND THE AREA.

DISCONNECT TH

E BATTERY BEFORE WORKING ON THE FUEL SYSTEM.

DO NOT CONNEC

T/DISCONNECT ELECTRICAL CIRCUITS

, USE ELECTRICAL EQUIPMENT OR OTHER TOOLS OR

ENGAGE IN WORKING PRACTICES WHICH IN ANY WAY MAY RESULT IN THE PRODUCTION OF SPARKS.

ENS

URE THAT A CO2 FIRE EXTINGUISHER IS CLOSE AT HAND.

ENS

URE THAT DRY SAND IS AVAILABLE TO SOAK UP ANY FUEL SPILLAGE.

EMP

TY FUEL USING SUITABLE FIRE PROOF EQUIPMENT IN

TO AN AUTHORIZED EXPLOSION PROOF CONTAINER.

DO NOT EMP

TY FUEL WHILE WORKING IN A WORKSHOP OR A PIT.

ENS

URE THAT WORKING AREA IS WELL VENTILATED.

ENS

URE THAT ANY WORK ON THE FUEL SYSTEM IS ON

LY CARRIED OUT BY EXPERIENCED AND WELL QUALIFIED

MAINTENANCE PERSONNEL.

ENS

URE THAT FUME EXTRACTION EQUIPMENT IS USED WHERE APPROPRIATE.

FUME EXTRACTION EQUIPMENT MUST BE IN OPERATION WHEN SOLVENTS ARE USED E.G. TRICHLOROETHANE,

WHITE SPIRIT, SBP3, METHYLENE CHLORIDE, PERCHLORETHY LENE. DO NOT SMOKE IN THE VICINITY OF VOLATILE

DEGREASING AGENTS.

General workshop practices:

Disc

onnect the grounded termin

al of the vehicle battery.

D

o not apply heat in an attempt to free seized nuts or fitt

ings; as well as causing damage to protective coatings,

there is a risk of damage from stray heat to electronic equipment and brake lines.

Keep oils and solven

ts away from naked flames and other sour

ces of ignition.

Adhere str

ictly to handling and safety inst

ructions given on containers and labels.

E

nsure that a suitab

le form of fire extinguisher is conveniently located.

Wh

en using electrical tools and equipment, inspect the power

lead for damage and check that it is properly earthed.

D

o not leave tools, equipment, spilt oil etc. around the work area.

Working beneath a vehicle:

Wh

enever possible, use a ramp or

pit in preference to jacking.

Posit

ion chocks at the wheels as we

ll as applying the parking brake.

N

ever rely on a jack alone to support a

vehicle; use axle stands, or blocks care fully placed at the jacking points, to

provide a rigid location.

Ch

eck that any lifting equipment used has adeq

uate capacity and is fully serviceable.

Working on air conditioning systems:

D

o not disconnect any pipes of the refrigeration system

unless you are trained and instructed to do so; a refrigerant

is used which can cause blindness if allowed to come into contact with the eyes.

Health Protection

P

rolonged and repeated contact with mineral oil will result in the removal of natural oils from the skin, leading to dryness,

In

spection

Page 42 of 2490

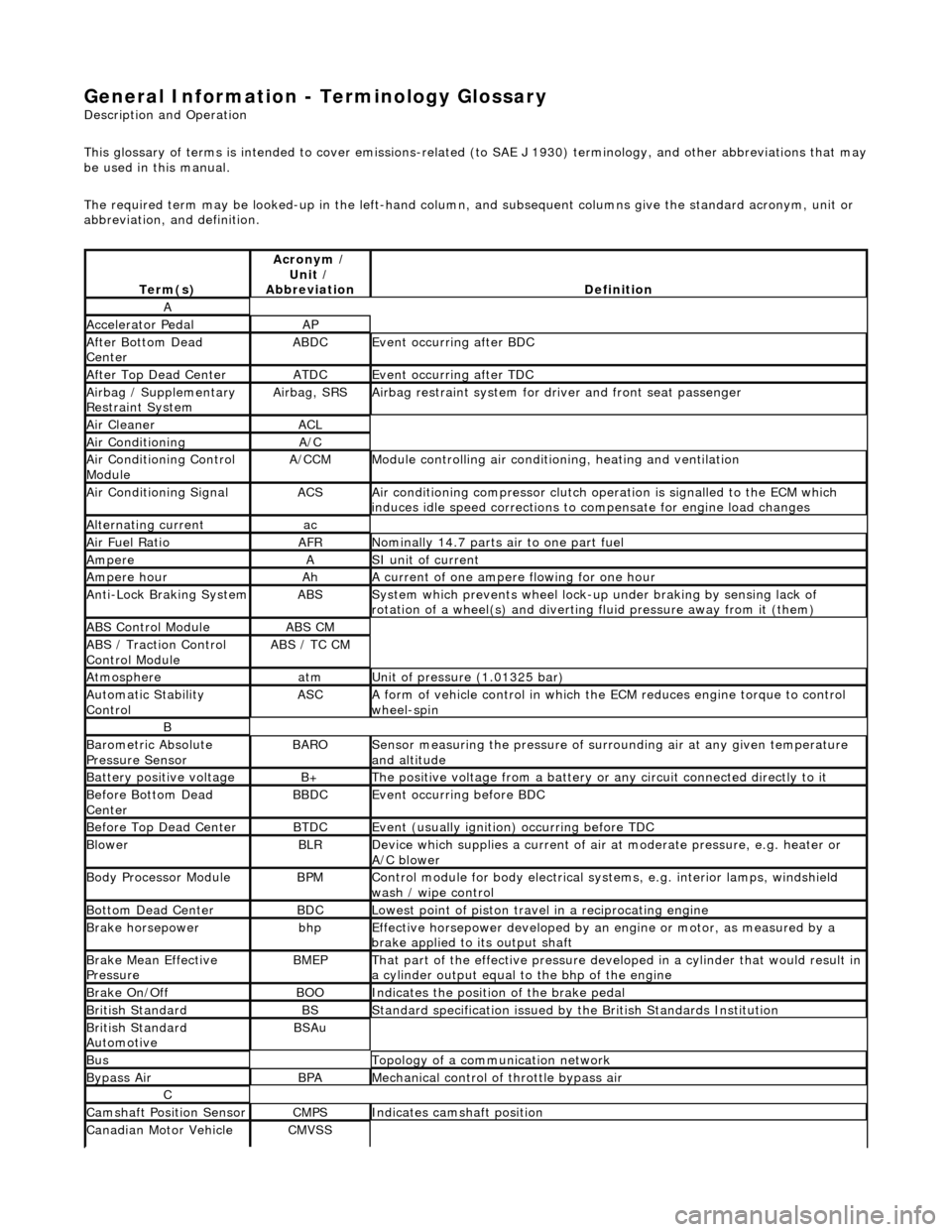

General Information - Terminology Glossary

Description an

d Operation

This glossary of terms is intended to cover emissions-related (to SAE J 1930) term inology, and other abbreviations that may

be used in this manual.

The required term may be looked-up in th e left-hand column, and subsequent columns give the standard acronym, unit or

abbreviation, and definition.

Te rm

(s)

Acr

ony

m /

Unit /

Abbreviation

De fi

nition

A

Accel

e

rator Pedal

AP

Af

ter Botto

m Dead

Center

ABDCEvent occurri ng after

BDC

Af

ter Top Dead CenterATDCEvent occurri ng after

TDC

Ai

rbag /

Supplementary

Restraint System

Airbag, SRSAi rbag restraint system for

dr

iver and front seat passenger

Air Cleane rACL

Air ConditioningA/C

Air Conditioning Con t

rol

Module

A/CCMModule c

ontrolling air conditioning, heating and ventilation

Air Conditioning SignalACSA

i

r conditioning compressor clutch operation is signalled to the ECM which

induces idle speed corrections to co mpensate for engine load changes

Alternating cu

rrent

ac

Ai

r Fuel R

atio

AFRN

omi

nally 14.7 parts air to one part fuel

Ampe

reASI unit of current

Ampere hourAhA current of one ampere

fl

owing for one hour

Anti-Lock Braking SystemABSS

y

stem which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and divertin g fluid pressure away from it (them)

ABS Control Mo

dule

ABS CM

ABS /

T

raction Control

Control Module

ABS / T

C CM

Atmosph

e

re

atmU

n

it of pressure (1.01325 bar)

Au

to

matic Stability

Control

ASCA form of vehicle

control

in which the ECM reduces en gine torque to control

wheel-spin

B

Baro me

tric Absolute

Pressure Sensor

BAR OSensor measuring the pressure of surr ou

nding air at any given temperature

and altitude

Bat t

ery positive voltage

B+The posi

ti

ve voltage from a battery or

any circuit connected directly to it

Before Bottom Dead

CenterBBDCEvent occurri ng before BD

C

Before Top Dead

Center

BTD

CEvent (usual ly

ignition) occurring before TDC

Blowe

rBLRDe

vice which supplies a current of air at

moderate pressure, e.g. heater or

A/C blower

Body Processor M

odule

BPMControl modu

le

for body electrical systems, e.g. interior lamps, windshield

wash / wipe control

Bott om D

ead Center

BD

CLowest poin t of piston

travel in a reciprocating engine

Brake hors

epowe

r

bhpEffecti

ve horsepower devel

oped by an

engine or motor, as measured by a

brake applied to its output shaft

Brake Mean Effective

Pres sureBME PThat p

art of the effective

pressure developed in a cyli nder that would result in

a cylinder output equal to the bhp of the engine

Brake On/ O

ff

BOOIn

dic

ates the position of the brake pedal

Br

it

ish Standard

BSStan

dar

d specification issued by the British Standards Institution

Br

it

ish Standard

Automotive

BSAu

BusTopology of a commu n

ication network

Bypass

AirBPAMechanica l

control of throttle bypass air

C

Camshaft Posit

i

on Sensor

CMPSIndi

cat

es camshaft position

Canadian Motor

V

ehicle

CMVSS

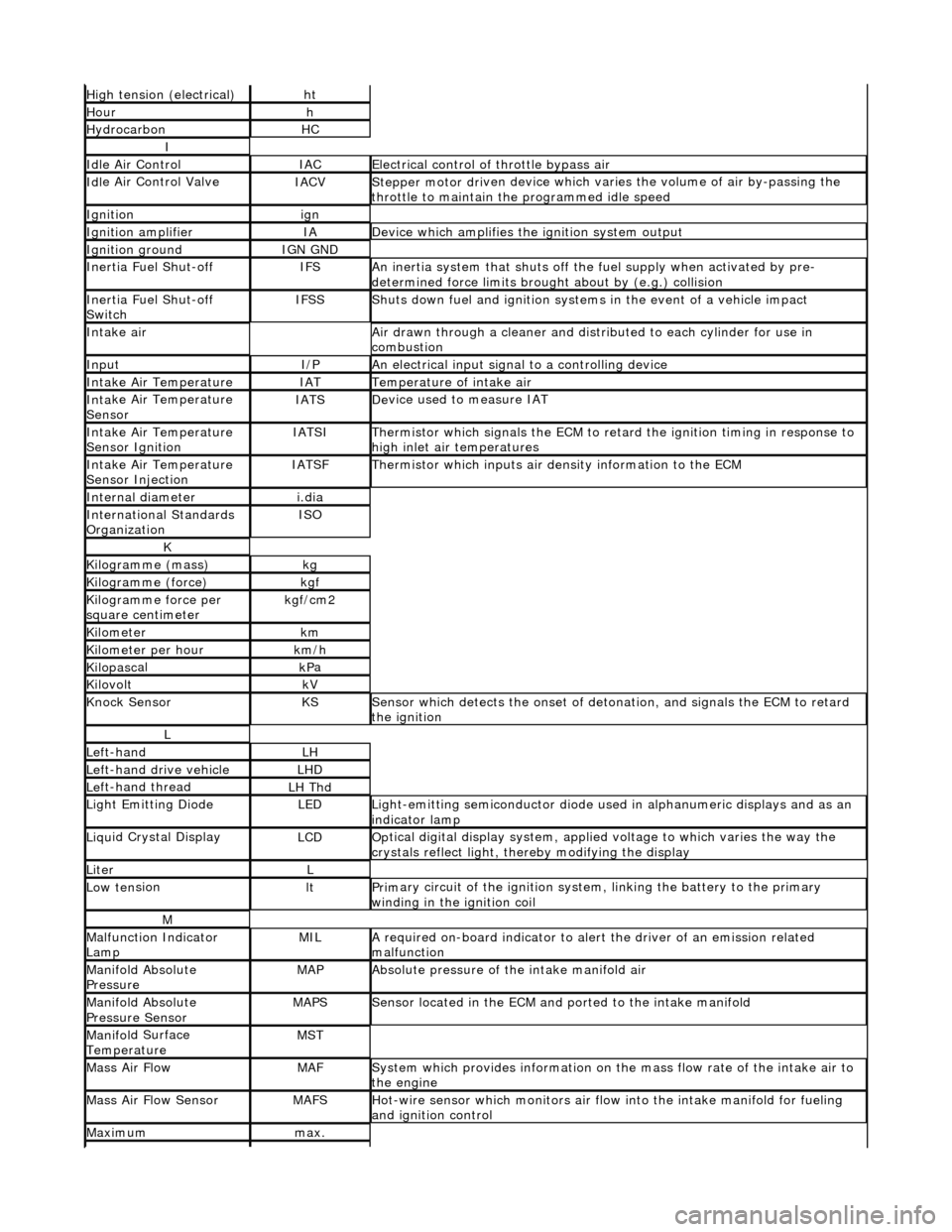

Page 45 of 2490

High

tension (electrical)

ht

Hourh

Hydro

carbon

HC

I

Idl

e Air Control

IACEl

ectrical control of throttle bypass air

Idl

e Air Control Valve

IACVStepper motor dri

ven device which vari

es the volume of air by-passing the

throttle to maintain the programmed idle speed

Ignitionign

Ignition am

plifier

IAD

evice which amplifies the i

gniti

on system output

Ignition groundIGN GND

In

ertia Fuel Shut-off

IFSAn

inertia system that shuts off the fuel supply when activated by pre-

determined force limits brough t about by (e.g.) collision

In

ertia Fuel Shut-off

Switch

IFSSShut

s down fuel and ignition systems in the event of a vehicle impact

Inta

ke air

Air drawn t

hrough a cleaner and distri

buted to each cylinder for use in

combustion

InputI/PAn

electrical input signal to a controlling device

Inta

ke Air Temperature

IATTem

perature of intake air

Inta

ke Air Temperature

Sensor

IATSDe

vice used to measure IAT

Inta

ke Air Temperature

Sensor Ignition

IATSITherm

istor which signals the ECM to retard

the ignition timing in response to

high inlet air temperatures

Inta

ke Air Temperature

Sensor Injection

IATSFTher

mistor which inputs air density information to the ECM

Internal diameteri.

dia

Inte

rnational Standards

Organization

ISO

K

Kilogramme (mass)kg

Kilogram

me (force)

kg

f

Ki

logramme force per

square centimeter

kg

f/cm2

Kilom

eter

km

Ki

lometer per hour

km

/h

Kilopasc

al

kP

a

KilovoltkV

Knock

Sensor

KSSens

or which detects the onset of detonation, and signals the ECM to retard

the ignition

L

Le

ft-hand

LH

Left-hand drive veh

icle

LHD

Le

ft-hand thread

LH Thd

Ligh

t Emitting Diode

LEDLigh

t-emitting semiconductor diode used

in alphanumeric displays and as an

indicator lamp

Liqu

id Crystal Display

LCDOp

tical digital display system, applied voltage to which varies the way the

crystals reflect light, thereby modifying the display

LiterL

Low ten

sion

ltPrim

ary circuit of the ignition system, linking the battery to the primary

winding in the ignition coil

M

Malfu

nction Indicator

Lamp

MILA

required on-board indicator to aler

t the driver of an emission related

malfunction

Mani

fold Absolute

Pressure

MAPAbsolute pressure o

f the intake manifold air

Mani

fold Absolute

Pressure Sensor

MAPSSensor loca

ted in the ECM and

ported to the intake manifold

Manifol

d Surface

Temperature

MST

Mass Ai

r Flow

MAFSy

stem which provides inform

ation on the mass flow rate of the intake air to

the engine

Mass Ai

r Flow Sensor

MAFSHot-wi

re sensor which monitors air flow

into the intake manifold for fueling

and ignition control

Maxim

um

max.

Page 53 of 2490

Jacking and Lifting - Vehicle Recovery

Description an

d Operation

• NOTE: Prior to recovery, ensure that the vehicle keys are available and the security system disarmed.

Vehicle recovery methods are:

By fl

at-bed transporter.

By rear suspended tow.

By emergency to

wing for

very short distances.

Gears

hift Interlock

The

gear selector lever can only be moved

from the Park position by turning the igni tion key to position II and depressing

the brake pedal.

To remove the key from the ignition switch, the gear select or lever must be moved to the Park position. With the key

removed, the gear selector is locked in the Park position.

The selector lever can be manually unlocked from the Park position in the event of electrical failure or when moving the

vehicle without power. Refer to the general procedure in this section.

Transporter or Trailer Recovery

When the vehicle is being recove red by transporter or trailer:

The parking brake must be

be applied and the wheels chocked.

The

gear selector lever must be in Ne

utral. Do not select Park as the park ing lock mechanism may be damaged by

the forward and backward rocking motion of the vehicle.

The ve

hicle must be securely tied down to the transporter or

trailer. There are four tie-down brackets on the vehicle

underbody. Do not use the vehicle towing points or crossbeam tie bar.

Page 54 of 2490

Wh en t

he vehicle is being reco

vered by rear suspended tow:

The ignition key must be remo ved from the ig

nition switch to lock the stee

ring with the front wheels facing straight

ahead.

The re ar

wheels must be

correctly positioned in the lifting cradle and securely tied down.

Em

ergency Towing

WARNING: IF THE

ENGINE IS NOT

RUNNING, THE STEERING WILL BECOME HEAVY AND THE FORCE NECESSARY TO

EFFECTIVELY APPLY THE BRAKES WILL BE GREATLY INCREASED.

• CAUTIONS:

A vehicle with a defective transmission must be towed by rear suspended tow.

The vehicle towing point is not suit able for use with a solid tow-bar.

Do not use the crossbeam tie bar as a towing location.

When the vehicle is being towed on its own wheels:

Loc a

l regulations for the towing of ve

hicles must be followed. In some co untries the registration number of the

towing vehicle and an 'On Tow' sign or warning triangle must be displayed at the rear of the towed vehicle.

The gear s

elector lever

must be in Neutral.

The

ignition switch must be in positi

on II to release the steering lock and make the direction indicators, horn and

stop lamps operate.

A di

stance of 0.8 km (0.5 mi

le) must not be exceeded.

A spe

ed of 48 km/h (30 mph) must not be exceeded.

The tow rope must be attached using th

e towi

ng location provided; refer to Front Towing Point in this section.

Rear Su

spended

Tow

Page 275 of 2490

R

equire no adjustment and are non-serviceable items.

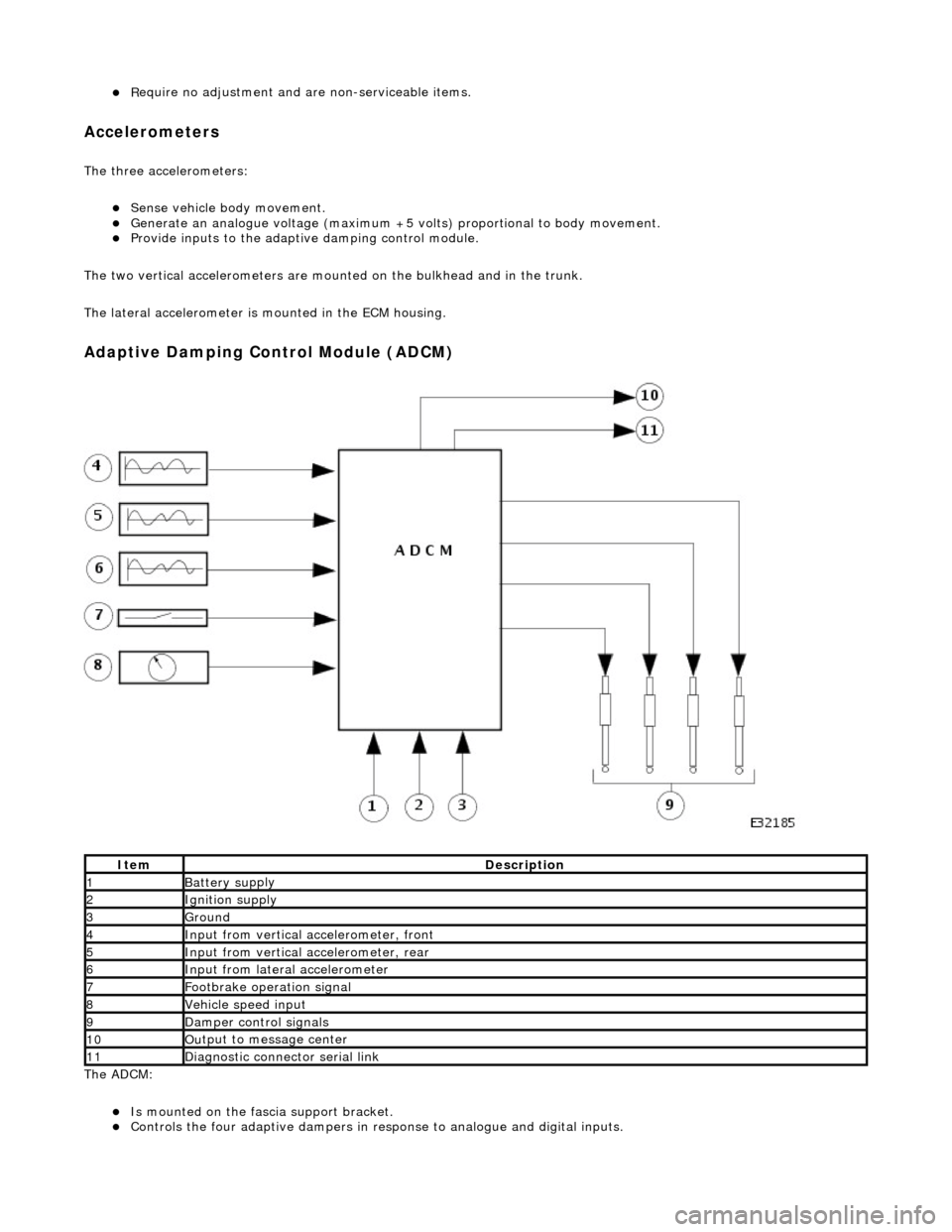

Accelerometers

The three accelerometers:

Sense veh

icle body movement.

Gen

erate an analogue voltag

e (maximum +5 volts) proportional to body movement.

Pr

ovide inputs to the adapti

ve damping control module.

The two vertical acce lerometers are mounted on the bulkhead and in the trunk.

The lateral accelerometer is mounted in the ECM housing.

Ada

ptive Damping Control Module (ADCM)

The ADCM

:

Is

mounted on the fascia support bracket.

Controls the four adaptiv

e dampers in re

sponse to analogue and digital inputs.

It

em

De

scription

1Battery su

pply

2Ignition su

pply

3Ground

4Input from verti

cal accelerometer, front

5Input from verti

cal accelerometer, rear

6Input from later

al accelerometer

7F

ootbrake operation signal

8Vehi

cle speed input

9D

amper control signals

10Ou

tput to message center

11D

iagnostic connector serial link

Page 276 of 2490

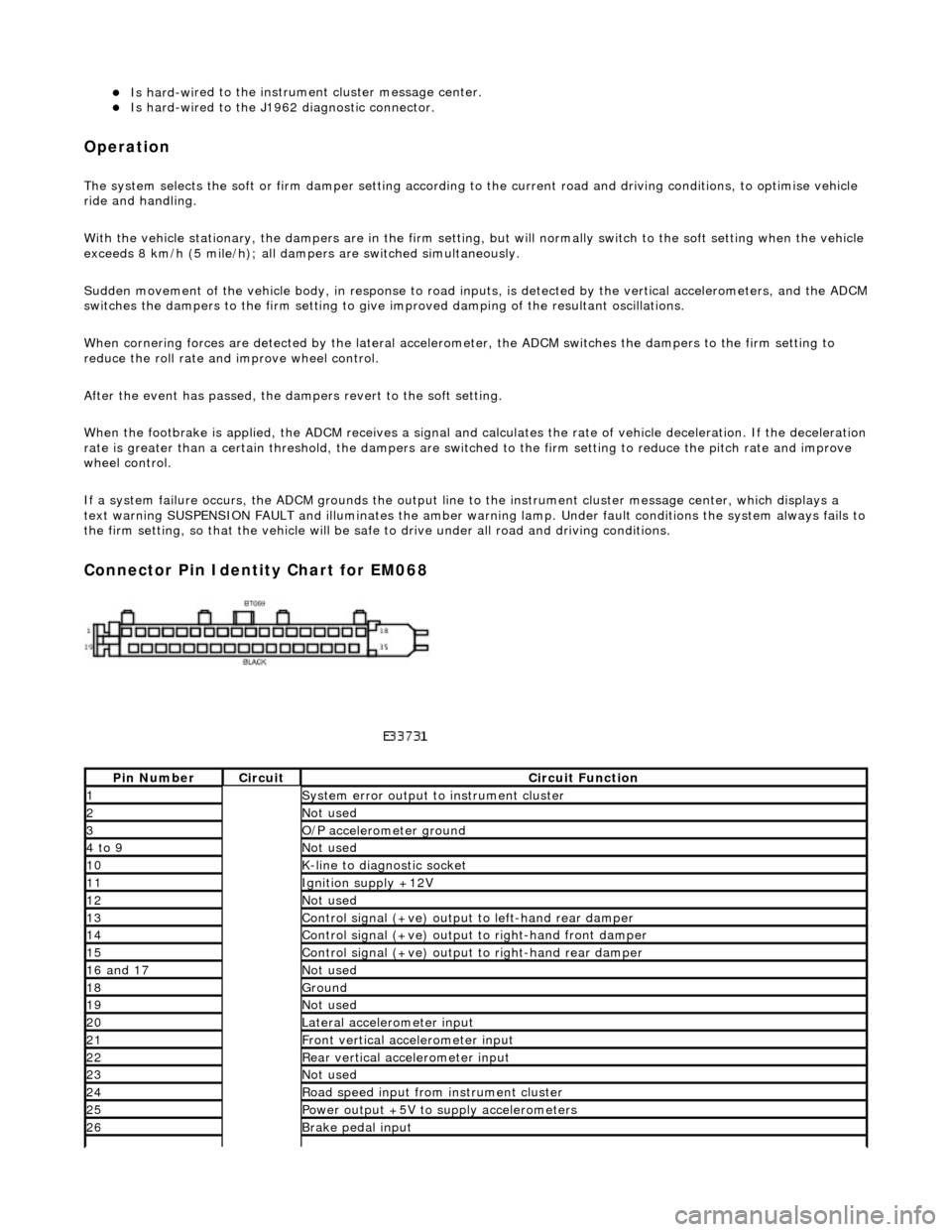

Is hard-wi

red to the instrume

nt cluster message center.

Is hard

-wired to the J1962 diagnostic connector.

Op

era

tion

Th

e

system selects the soft or

firm damper setting according to the current ro ad and driving conditions, to optimise vehicle

ride and handling.

With the vehicle stationary, the dampers are in the firm setting, but will normally switch to the soft setting when the vehicle

exceeds 8 km/h (5 mile/h); all dampers are switched simultaneously.

Sudden movement of the vehicle body, in response to road inputs, is detected by the vertical accelerometers, and the ADCM

switches the dampers to the firm setting to give improved damping of the resultant oscillations.

When cornering forces are detected by th e lateral accelerometer, the ADCM switches the dampers to the firm setting to

reduce the roll rate an d improve wheel control.

After the event has passed, the dampers revert to the soft setting.

When the footbrake is applied, the ADCM re ceives a signal and calculates the rate of vehicle deceleration. If the deceleration

rate is greater than a certain threshold, the dampers are switched to the firm setting to reduce the pitch rate and improve

wheel control.

If a system failure occurs, the ADCM grounds the output line to the instrument cluster message center, which displays a

text warning SUSPENSION FAULT and illuminates the amber warning lamp. Under fault conditions the system always fails to

the firm setting, so that the vehicle will be safe to drive un der all road and driving conditions.

Connector Pin Identity Chart for EM068

Pin

Number

Ci

rcui

t

Circuit Functi

on

1System erro

r output to instrument

cluster

2Not

used

3O/

P a

ccelerometer ground

4 to

9

Not

used

10K-

li

ne to diagnostic socket

11Ignition su

pply +12V

12Not

used

13Control signal (+ve) output

to l

eft-hand rear damper

14Control signal (+ve) output

to right-hand front damp

er

15Control signal (+ve) output

to right-hand rear

damper

16

a

nd 17

No

t

used

18Ground

19No

t

used

20Lateral

accelerometer i

nput

21Front vertical ac

celerometer in

put

22Rear vertical

acce

lerometer input

23No

t

used

24R

o

ad speed input from

instrument cluster

25Power output +5V to suppl y accelerometers

26Brake peda

l input

Page 432 of 2490

It is a reciprocating two

-circuit pu

mp in which one brake circuit is as signed to each pump circuit.

It supplies th

e fluid pressure and vo

lume to supply the brake circuits under ABS and Traction control.

The pump is driven by an electri

c motor, with the pump

housing incorporating two lo w pressure accumulators and

damping chambers for each brake circuit.

The ac cu

mulator stores the pressure and smooths out the output pu

lses from the pump.

ABS Warning Lamp

The sys

tem will be set in a fail-safe mode if a problem is de

tected; a warning lamp on the instrument panel will notify the

driver there is a problem.

Anti-Lock Braking Sy

stem (ABS)

The AB

S components are combined with

an hydraulic booster and a tandem master cylinder to provide a two circuit braking

system. The system comprises, four wheel speed sensor s, a brake control modulator and an ABS warning lamp.

Should a wheel start to lock-up during braking a signal tr ansmitted from the wheel speed sensor to the brake control

modulator will start the hydraulic pump. The brake control modula tor will close the input valve of the line connected to the

locked-wheel to stop any increase in fluid pressure to the br ake caliper. If this fails to prevent the wheel locking, the

pressure in the caliper will be decreased by opening the return valve until th e wheel starts accelerating again. The fluid

pressure from the return va lve is directed into the low pressure accumulator, housed in the pump.

From the low pressure accumulator, fl uid is pumped through the damping cham ber to the brake master cylinder. The

pressure to the brake caliper will then be increased in small steps to maintain maximum adhesion between the tire and road

surface. This is achieved by closing the return valve, and opening the input valve and using the hydraulic pump to increase

the pressure.

Although the system senses all four wheels independently, the rear wheels are regulated as a pair. If a sensor on a rear

wheel detects a wheel decelerating rapidly, then the fluid pressure to both wheels is reduced. The fluid pressure is then

dictated by the wheel having the lowe st adhesion with the road surface.

The ABS system will be set in a fail-safe mode if a problem is detected; a warn ing lamp on the instrument panel will notify

the driver there is a problem. The brake system will still operate conventionally and with the same standard of performance

as a vehicle not equipped with ABS.

Automa tic Stability Control (ASC)

Th

e ASC utilizes the ABS sensing arrangement to provide the maximum traction force to propel the vehicle.

The ASC is switched on when the engine is started. The system can be switched off by pressing the 'ASC OFF' (the switched

is marked 'TRAC OFF' on vehicles fitted with traction control). The switch, which is situated in the center console switchpack,

lights up to warn that the system is sw itched off. An 'ASC' amber warning light flashes on the instrument panel when the

system detects a spinning wheel.

The ASC system uses engine intervention to reduce the torque delivered to the drive wheels to prevent them spinning.

Engine torque is re duced in three ways:

The

throttle is moved towards the closed position.

The ignition is retarded. F

u

el is cut-off at the cylinder injectors.

Wheel spin is detected by the wheel sp eed sensors and communicated to the AB S/TCCM. The ABS/TCCM uses information

from the controller area network (CAN) to calculate the torque that the engine should produce to stop the wheel spinning.

Torque reductions are then requested from the engine control module (ECM ) through the CAN. The throttle is then

positioned to provide the target torque, which has been calculated to prevent wheel spin. During the transient phase of

torque reduction the fuel is cut-off and th e ignition retarded Both the fuel cut-off an d ignition retard will be restored to

normal when the throttle is set to its new position.

The ASC uses a brake control modulator with six solenoid va lves: three normally open inlet valves and three normally

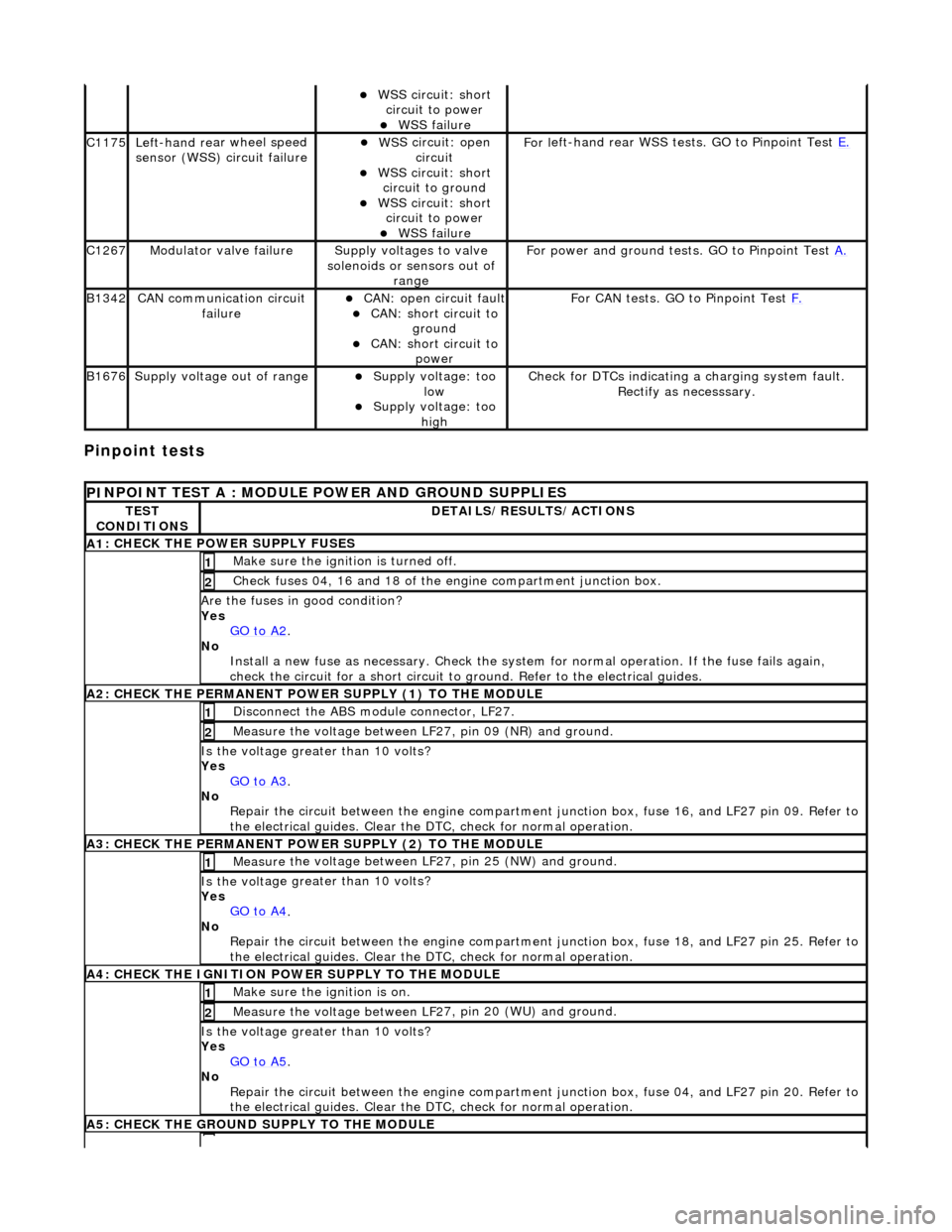

Page 436 of 2490

Pinpoint tests

W

S

S circuit: short

circuit to power

WSS f

ailure

C1

175Left -hand re

ar wheel speed

sensor (WSS) circuit failure

W S

S circuit: open

circuit

WS

S circuit: short

circuit to ground

W S

S circuit: short

circuit to power

WSS f

ailure

F

or l

eft-hand rear WSS test

s. GO to Pinpoint Test E.

C1267Modulat or valv

e failure

Supply volt

ages

to valve

solenoids or sensors out of range

Fo

r power and ground tests. GO to Pinpoint Test

A.

B1342CAN co

mmunication circuit

failure

CAN :

open circuit fault

CAN:

short circuit to

ground

CAN :

short circuit to

power

Fo

r CAN tests. GO to Pinpoint Test

F.

B1676Supply volt

age out of range

Supply voltage:

too

low

Supply volt age:

too

high

Check fo

r DTCs indicating a charging system fault.

Rectify as necesssary.

PI

NPOINT TEST A : MODULE

POWER AND GROUND SUPPLIES

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

A

1

: CHECK THE POWER SUPPLY FUSES

Make sure the igniti

on is turned off. 1

Chec

k fuses 04, 16 and 18 of the engine compartment junction box.

2

Are th

e fus

es in good condition?

Yes GO to A2

.

No

Install a new f

use as

necessary. Check the syst em for normal operation. If the fuse fails again,

check the circuit for a short circuit to ground. Refer to the electrical guides.

A2: CHECK THE PERMANENT

POWER SUPPLY (1) TO THE MODULE

Disc

onnect the ABS module connector, LF27.

1

Measure the voltage between LF

2

7, pin 09 (NR) and ground.

2

Is the vol

t

age greater than 10 volts?

Yes GO to A3

.

No Re

pair the circuit between the engine compartment

junction box, fuse 16, and LF27 pin 09. Refer to

the electrical guides. Clear the DTC, check for normal operation.

A3: CHECK THE PERMANENT

POWER SUPPLY (2) TO THE MODULE

Meas

ure t

he voltage between LF27, pin 25 (NW) and ground.

1

Is the vol

t

age greater than 10 volts?

Yes GO to A4

.

No

Re

pair the circuit between the engine compartment ju

nction box, fuse 18, and LF27 pin 25. Refer to

the electrical guides. Clear the DTC, check for normal operation.

A4: CHECK

THE IGNITION POWER SUPPLY TO THE MODULE

Make sure the ignition is on. 1

Measure the

voltage between LF 2

7, pin 20 (WU) and ground.

2

Is the vol

t

age greater than 10 volts?

Yes GO to A5

.

No Re

pair the circuit between the engine compartment ju

nction box, fuse 04, and LF27 pin 20. Refer to

the electrical guides. Clear the DTC, check for normal operation.

A5: CHECK

THE GROUND SUPPLY TO THE MODULE