wheel alignment JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 290 of 2490

In

stallation

(and axle shaft if i

t

is to be re-used)

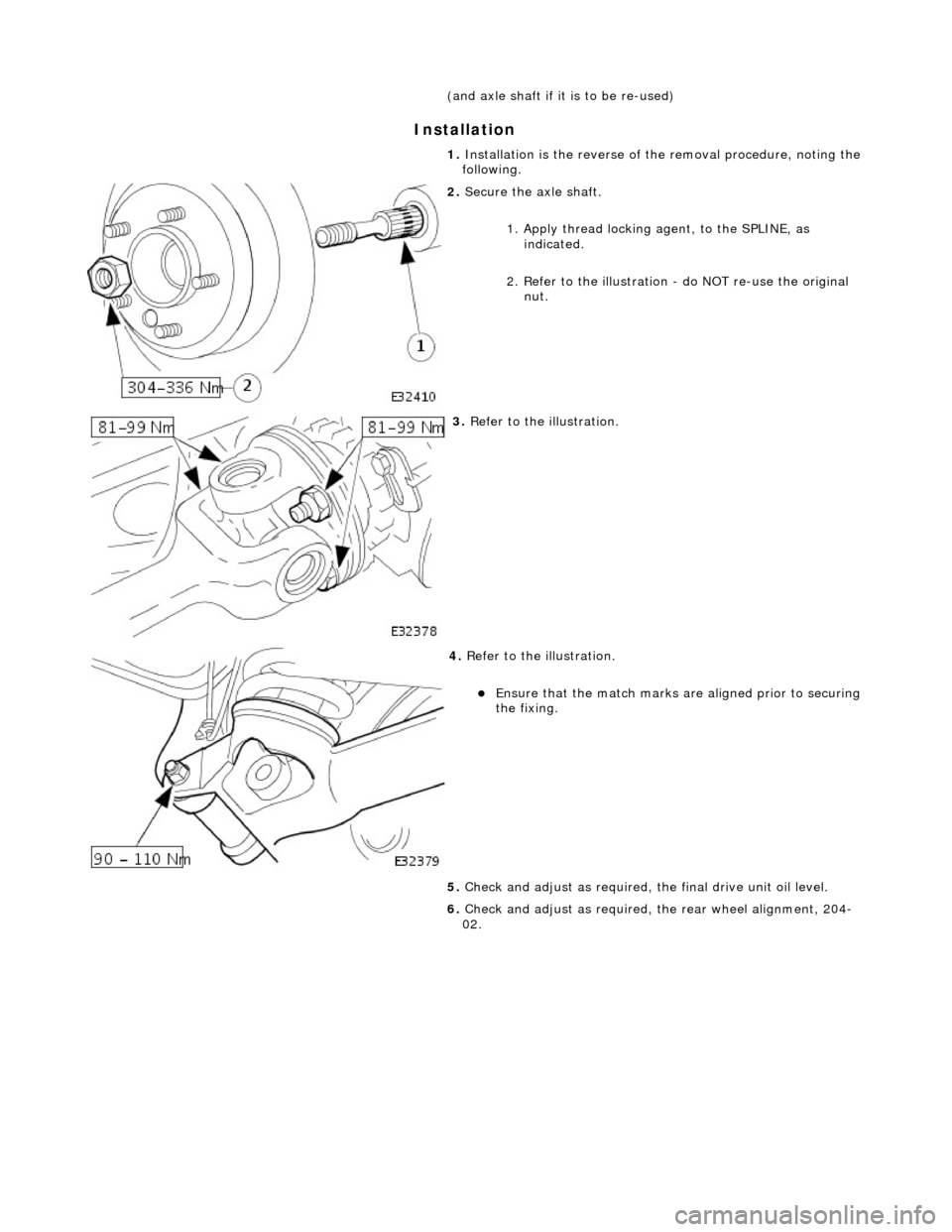

1. Installation is the re verse of the removal procedure, noting the

following.

2. Secure the axle shaft.

1.

Apply thread locking agent, to the SPLINE, as

indicated.

2. Refer to the illustration - do NOT re-use the original

nut.

3. Re

fer to the illustration.

4. Re

fer to the illustration.

E

n

sure that the match marks ar

e aligned prior to securing

the fixing.

5. Check and adjust as required, the final drive unit oil level.

6. Check and adjust as required, the rear wheel alignment, 204-

02.

Page 306 of 2490

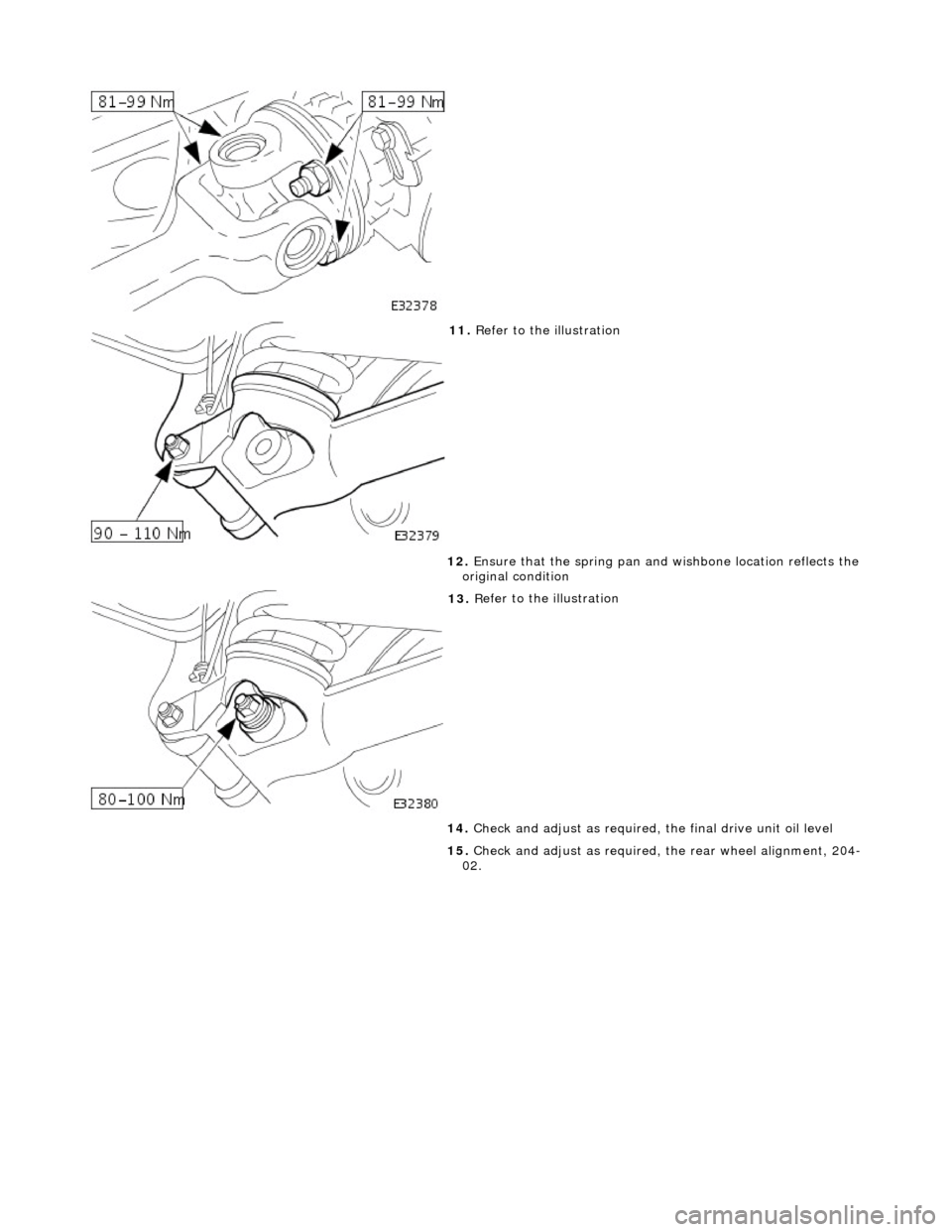

11

. R

efer to the illustration

12. Ensure that the spring pan and wishbone location reflects the

original condition

13 . R

efer to the illustration

14. Check and adjust as required, the final drive unit oil level

15. Check and adjust as required, the rear wheel alignment, 204-

02.

Page 309 of 2490

Brake System - General Inform

ation - Brake System

D

iagnosis and Testing

Principles of Operations

The brake system operates by transferring effort applied to th e brake pedal, by the driver to the brakes at each wheel.

The braking effort is distributed to each wheel, using a hydraulic system. The system is assisted using a vacuum brake

booster that reduces pedal effort for a given hydraulic pressure. The parking brake operates on the rear wheels and is

applied using a hand operated control.

I

nspection and Verification

•

NOTE: Prior to carrying out any diagno

sis, make sure that the brake system warning indicator is functional.

Visually examine the front and rear tire and wheel assemblies for damage such as un even wear patterns, tread worn out or

sidewall damage. Verify the tires are th e same size, type and, where possible, same manufacture. Replace the damaged

wheel or excessively worn tire. For a dditional information, refer toSection 204

-0

4 Wheels and Tires

.

W

heels and tires must be cleared of an

y foreign matter and tire pressures ad justed to the correct specification.

If the tires exhibit uneven wear or feathering, the cause must be corrected. Check the steering and suspension components

for damage or wear and, if ne cessary, check and adjust front wheel alignment. For additional information, refer toSection

204

-00 Suspen

sion System

- General Informati

on

.

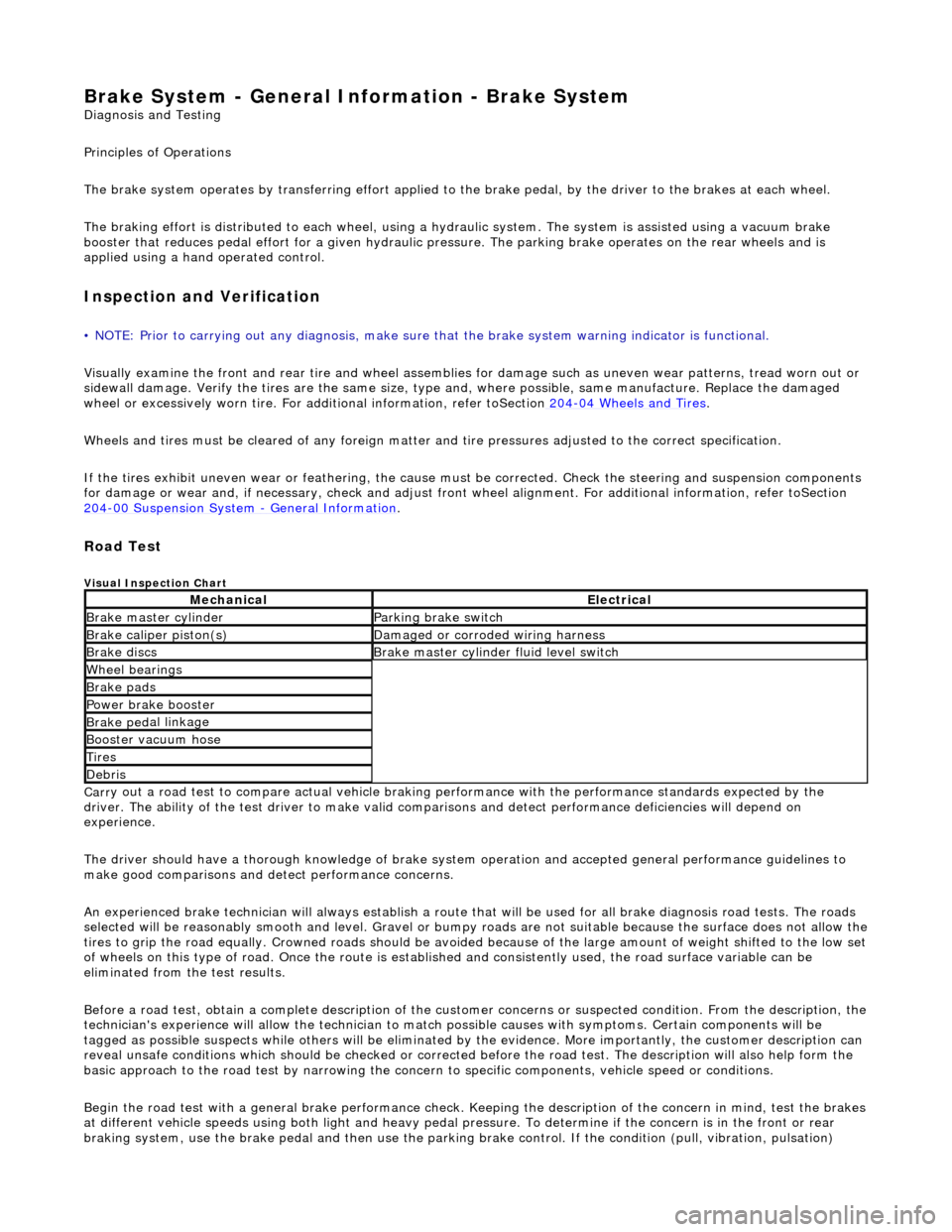

Road Test

V

isual Inspection Chart

Carr

y out a road test to compare actual vehicle braking performance with the

performance standards expected by the

driver. The ability of the test driver to make valid compar isons and detect performance deficiencies will depend on

experience.

The driver should have a thorough knowledge of brake system operation and accepted general performance guidelines to

make good comparisons and de tect performance concerns.

An experienced brake technician will always establish a route that will be used for all br ake diagnosis road tests. The roads

selected will be reasonably smooth and level. Gravel or bump y roads are not suitable because the surface does not allow the

tires to grip the road equally. Crowned roads should be avoide d because of the large amount of weight shifted to the low set

of wheels on this type of road. Once th e route is established and consistently used, the road surface variable can be

eliminated from the test results.

Before a road test, obtain a complete description of the customer concerns or suspec ted condition. From the description, the

technician's experience will allow the te chnician to match possible causes with symptoms. Certain components will be

tagged as possible suspects while others wi ll be eliminated by the evidence. More importantly, the customer description can

reveal unsafe conditions which should be ch ecked or corrected before the road test. The description will also help form the

basic approach to the road test by narrowing the concern to specific components, vehicle speed or conditions.

Begin the road test with a general brake performance check. Keeping the description of the concern in mind, test the brakes

at different vehicle speeds using both ligh t and heavy pedal pressure. To determine if the concern is in the front or rear

braking system, use the brake pe dal and then use the parking brake control. If the condition (pull, vibration, pulsation)

MechanicalElectrical

Brake m

aster cylinder

Parkin

g brake switch

Brake ca

liper piston(s)

D

amaged or corroded wiring harness

Brake di

scs

B

rake master cylinder fluid level switch

Wh

eel bearin

gs

Brake pads

Power brake booster

Brake ped

al linkage

Boost

er vacuum hose

Tire

s

De

bris

Page 310 of 2490

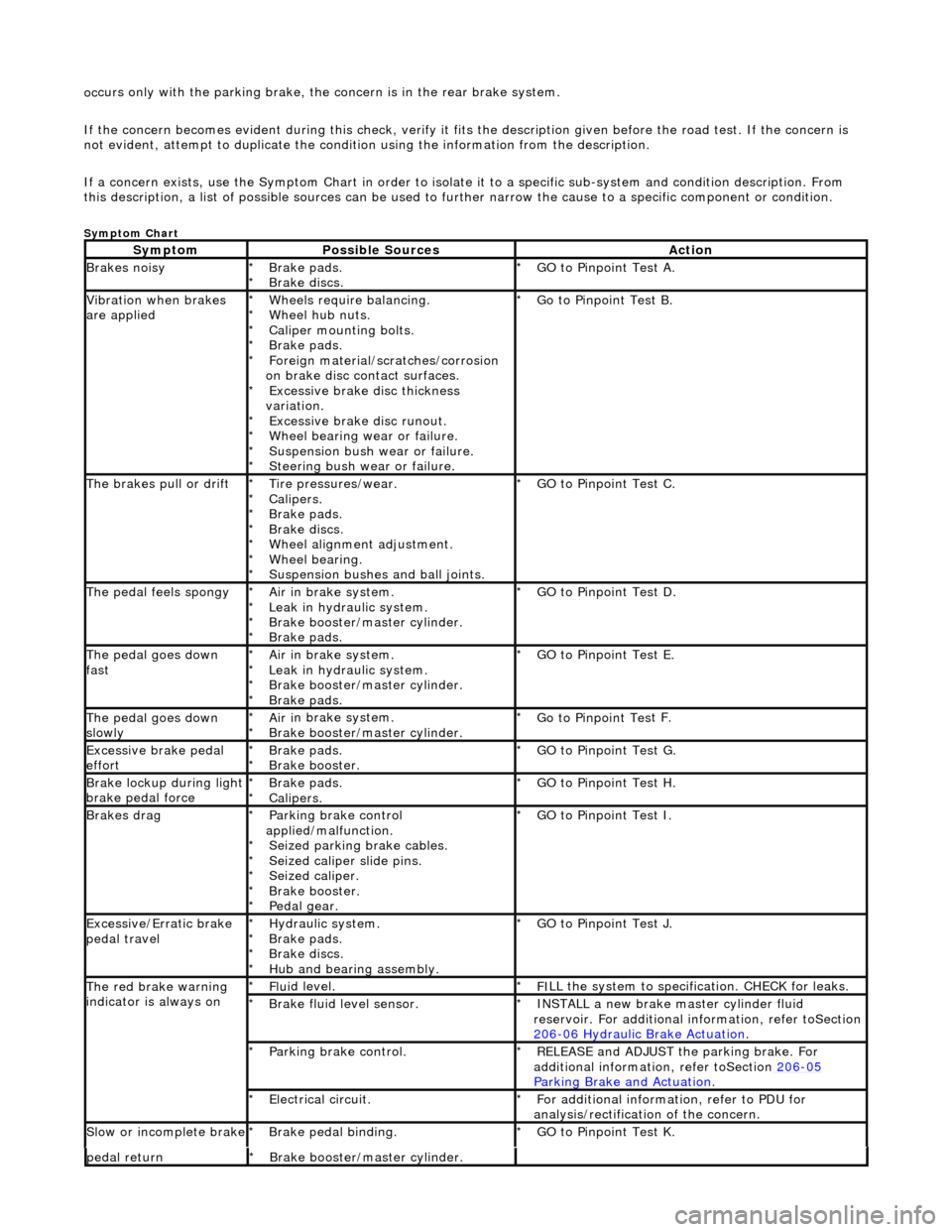

oc

curs only with the parking brake, th

e concern is in the rear brake system.

If the concern becomes evident during this check, verify it fits the description given before the road test. If the concern is

not evident, attempt to duplicate the condition using the information from the description.

If a concern exists, use the Symptom Chart in order to isolate it to a specific sub-system and condition description. From

this description, a list of possible sources can be used to further narrow the cause to a specific component or condition.

Sym

ptom Chart

Sy

m

ptom

Possib

l

e Sources

Acti

o

n

Brakes

n

oisy

Brake pads.

Brake di

scs

.

*

*

GO to Pinpoint

Tes

t A.

*

Vibration wh

en brakes

are applied

Wh eels require bala

ncing.

Wheel hub nuts.

Caliper mounting bolts.

Brake pads.

Foreign material/scr atches/corrosion

on brake disc contact surfaces. Excessive brake disc thickness

variation. Excessive brake disc runout.

Wheel bearing wear or failure.

Suspension bush wear or failure.

Steering bush wear or failure.

*

*

*

*

*

*

*

*

*

*

Go to Pinpoint

Tes

t B.

*

The brakes pull or drif tTire pressures/wear.

Calipers.

Brake pads.

Brake di

scs.

Wheel alignment adjustment.

Wheel bearing.

Suspension bushes and ball joints.

*

*

*

*

*

*

*

GO to Pinpoint

Tes

t C.

*

The pedal feels spongyAir i

n brake system.

Leak in hydraulic system.

Brake booster/master cylinder.

Brake pads.

*

*

*

*

GO to Pinpoint Tes

t D.

*

The pedal goes down

fa s

t

Ai

r i

n brake system.

Leak in hydraulic system.

Brake booster/master cylinder.

Brake pads.

*

*

*

*

GO to Pinpoint

Tes

t E.

*

The pedal goes down

slowl yAir i

n brake system.

Brake booster/master cylinder.

*

*

Go to Pinpoint

Tes

t F.

*

Excessive brake pedal

effor tBrake pads.

Brake booster.

*

*GO to Pinpoint

Tes

t G.

*

Brake lockup du ring ligh

t

brake pedal force

Brake pads.

Calipers.

*

*GO to Pinpoint

Tes

t H.

*

Brakes d r

ag

Parkin

g brake con

trol

applied/malfunction. Seized parking brake cables.

Seized caliper slide pins.

Seized caliper.

Brake booster.

Pedal gear.

*

*

*

*

*

*

GO to Pinpoint

Tes

t I.

*

Exce ssi

ve/Erratic brake

pedal travel

Hydrau li

c system.

Brake pads.

Brake discs.

Hub and bearing assembly.

*

*

*

*

GO to Pinpoint

Tes

t J.

*

The red brak e warning

indi

cator is always on

Fl

ui

d level.

*

F I

LL the system to specification. CHECK for leaks.

*

Brake flu i

d level sensor.

*

I N

STALL a new brake master cylinder fluid

reservoir. For additional in formation, refer toSection

206

-0 6

Hydraulic Brake Actuation

.

*

Parkin

g brake con

trol.

*

REL

E

ASE and ADJUST the parking brake. For

additional information, refer toSection 206

-05

Parkin g Brake an

d Actuation

.

*

E

l

ectrical circuit.

*

F or additional

information, refer to PDU for

analysis/rectification of the concern.

*

Sl

ow or i

ncomplete brake

Brake peda

l binding.

*

GO to Pinpoint Tes

t K.

*

pedal retu rnBr

ake booster/master cylinder.

*

Page 326 of 2490

Fr

ont Brake Disc Runout Check Vehicles With: Brembo Brakes

Special Service tools

Di

al Test Indicator Gauge and Stand.

1.

WA

RNING:

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

CA

UTION:

Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts

throughout the vehicle. These devices restrict the number of times a nut or bolt can be used. See

section <<100-00>> for information.

CA

UTION:

The Brembo caliper is aligned to the brake disc when it is first installed to the vehicle, therefore,

care must be taken not to disturb this alignment. When removing the caliper; remove the bolts

that secure the anchor bracket to the vertical link only. DO NOT loosen any other caliper bolts.

Raise front of vehicle and support on stands. Refer to section <<100-02>>.

2. Remove wheel. Refer to section <<74.20.05>>.

Page 334 of 2490

Rear

Brake Disc Runout Check Vehicles With: Brembo Brakes

Special Service tools

Di

al Test Indicator Gauge and Stand.

1.

WA

RNING:

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

CA

UTION:

Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts

throughout the vehicle. These devices restrict the number of times a nut or bolt can be used. See

section <<100-00>> for information.

CA

UTION:

The Brembo caliper is aligned to the brake disc when it is first installed to the vehicle, therefore,

care must be taken not to disturb this alignment. When removing the caliper; remove the bolts

that secure the anchor bracket to the hub carrier only. DO NOT loosen any other caliper bolts.

Raise rear of vehicle and support on stands. Refer to section <<100-02>>.

2. Remove wheel. Refer to operation <<74.20.05>>.

Page 341 of 2490

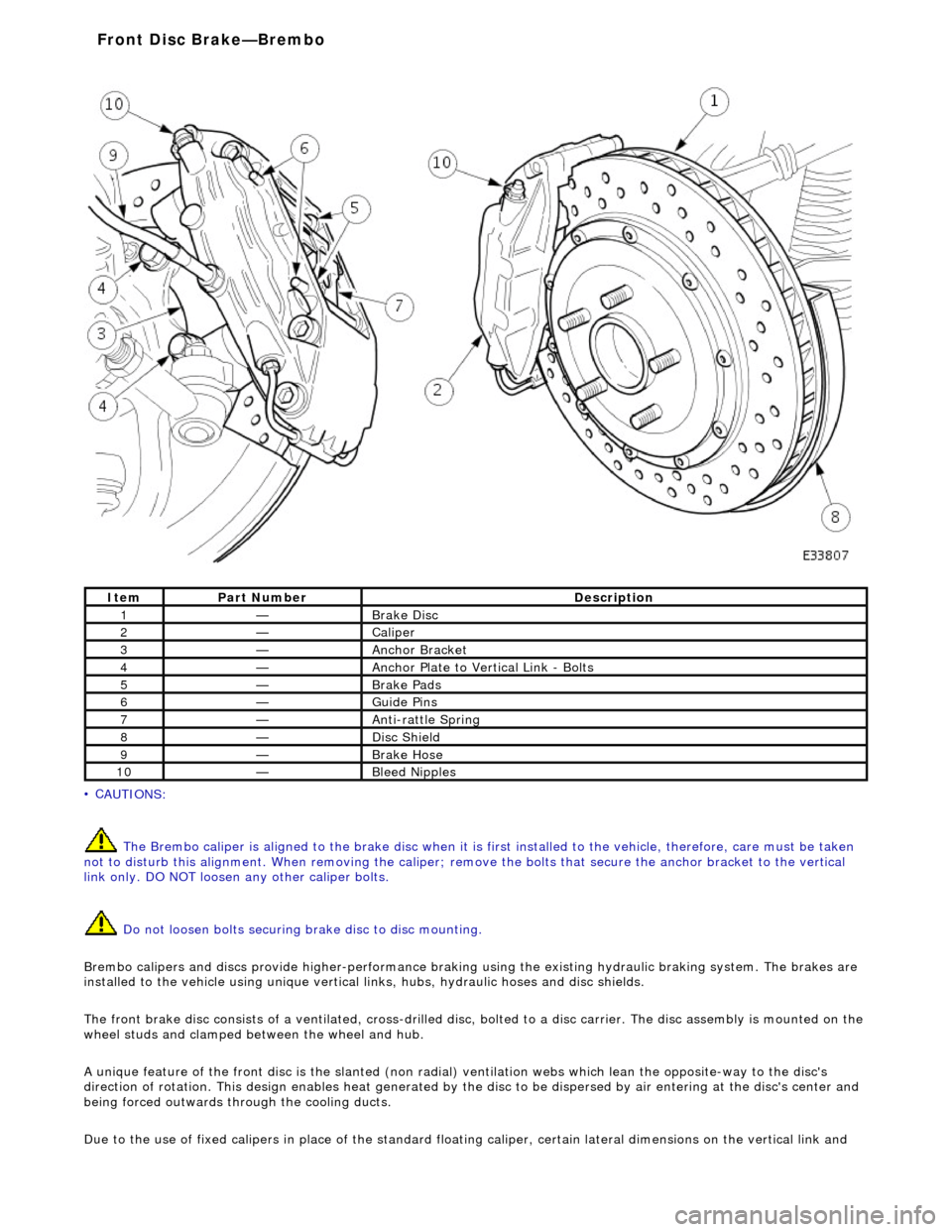

• C

AUTIONS:

The Brembo caliper is aligned to the brak e disc when it is first installed to the vehicle, therefore, care must be taken

not to disturb this alignment. When removi ng the caliper; remove the bolts that secure the anchor bracket to the vertical

link only. DO NOT loosen any other caliper bolts.

Do not loosen bolts securing brake disc to disc mounting.

Brembo calipers and discs provide higher -performance braking using the existing hydraulic braking system. The brakes are

installed to the vehicle using unique vertical links, hubs, hydraulic hoses and disc shields.

The front brake disc consists of a ventilated, cross-drilled disc, bolted to a disc carrier. The disc assemb ly is mounted on the

wheel studs and clamped be tween the wheel and hub.

A unique feature of the front disc is th e slanted (non radial) ventilation webs which lean the opposite-way to the disc's

direction of rotation. This design enables he at generated by the disc to be dispersed by air entering at the disc's center and

being forced outwards through the cooling ducts.

Due to the use of fixed calipers in place of the standard floating caliper, certain lateral dimensions on the vertical link and

It

em

Par

t Number

De

scription

1—B

rake Disc

2—Caliper

3—Anch

or Bracket

4—Anchor Pl

ate to Vertical Link - Bolts

5—Brake Pad

s

6—Guide P

ins

7—Anti-r

attle Spring

8—Di

sc Shield

9—Brake Hos

e

10—Bleed Nipp

les

Front Disc Brake—

Brembo

Page 347 of 2490

Front Disc Brake - Brake CaliperVehicles With: High Performance Brakes

Re

moval and Installation

Remov

al

S

pecial Tool(s)

Brake Pedal

Hold Tool

JDS 9013

1. WARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

See section 100-00 for information.

Remove brake fluid spillage immediately from paint work,

with clean water.

The Brembo caliper is aligned to the brake disc when it is

first installed to the vehicle, therefore, care must be taken not to

disturb this alignment. When removing the caliper; remove the

bolts that secure the anchor bracket to the vertical link only. DO

NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise vehicle on a four-post lift.

3. Raise front of vehicle and support on stands. Refer to Section

100-02.

4. Remove front wheels. Refe r to operation 74.20.05.

5. NOTE

: The following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect

a bleed tube and co

ntainer to the calipers.

O

pen bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using the special tool.

Page 355 of 2490

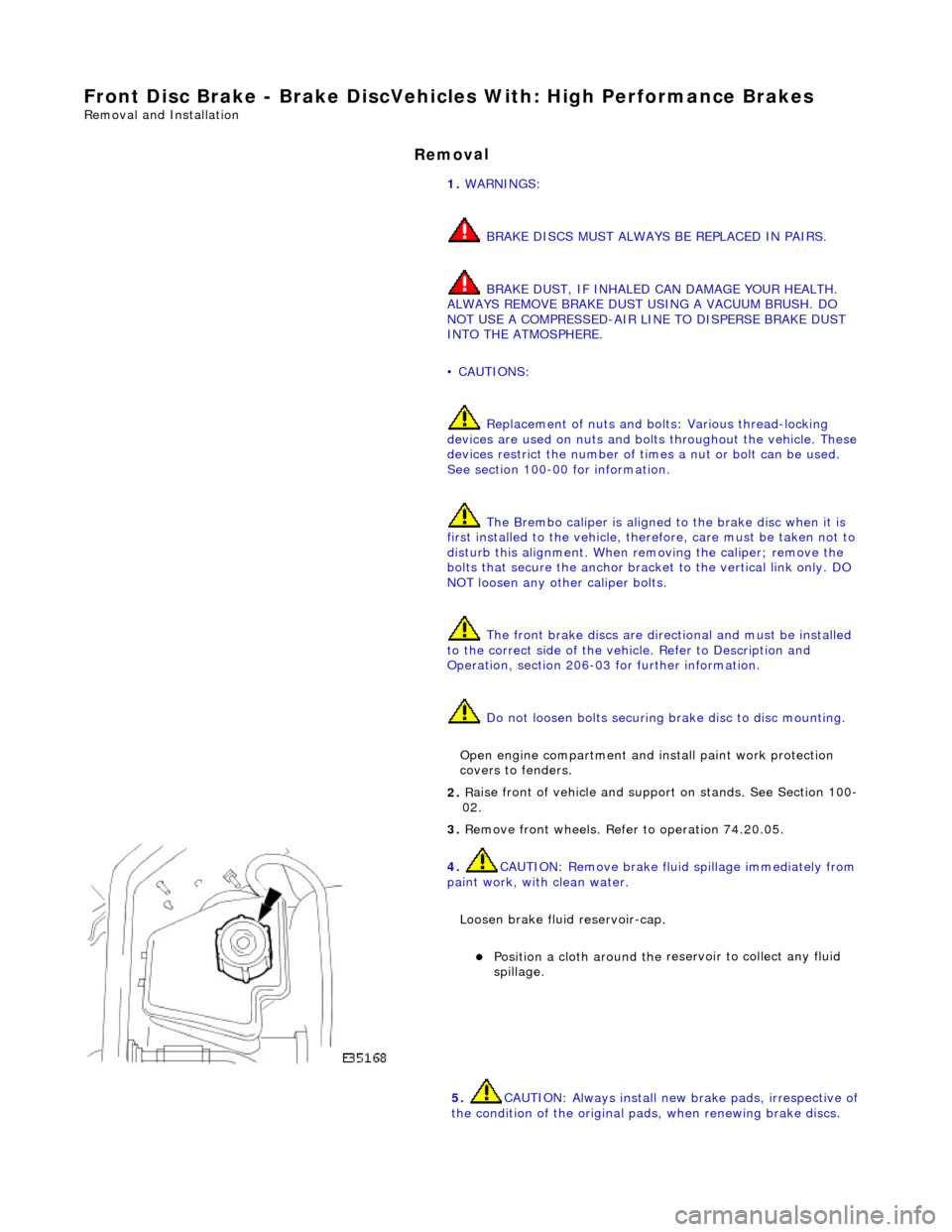

Front Dis

c Brake - Brake DiscVehicles With: High Performance Brakes

Re

moval and Installation

Remov

al

1.

WAR

NINGS:

BRAKE DISCS MUST ALWAYS BE REPLACED IN PAIRS.

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH.

ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO

NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

See section 100-00 for information.

The Brembo caliper is aligned to the brake disc when it is

first installed to the vehicle, therefore, care must be taken not to

disturb this alignment. When removing the caliper; remove the

bolts that secure the anchor bracket to the vertical link only. DO

NOT loosen any other caliper bolts.

The front brake discs are dire ctional and must be installed

to the correct side of the vehi cle. Refer to Description and

Operation, section 206-03 for further information.

Do not loosen bolts securing brake disc to disc mounting.

Open engine compartment and in stall paint work protection

covers to fenders.

2. R

aise front of vehicle and suppo

rt on stands. See Section 100-

02.

3. Remove front wheels. Refe r to operation 74.20.05.

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

Position a cloth around the

reservoir to collect any fluid

spillage.

5. CAUTI

ON: Always install new brake pads, irrespective of

the condition of the original pads, when renewing brake discs.

Page 361 of 2490

Front Dis

c Brake - Brake PadsVehicl

es With: High Performance Brakes

Re

moval and Installation

Remov

al

1.

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Brake pads must always be replaced in axle sets.

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

For additional information, refer to: General Service Information

(10

0-00 General Information,

Description and Operation).

The High Performance brake ca liper is aligned to the brake

disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the

caliper; remove the bolts that se cure the anchor bracket to the

vertical link only. DO NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise front of vehicle an

d support on stands.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

3. Remove front wheels. Refer to operation.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

Position a cloth around the

reservoir to collect any fluid

spillage.

5. Remove brake

pads from caliper.

1. Remove 'R' clips.

2. Withdraw pins from caliper.

3. Remove anti-rattle spring.

4. Discard brake pads.