engine JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 8 of 2490

В В В В В В В В В В В В 211‐02: В Powe rВ Steering В

В В В В В В В В В В В В В В В В Specif

ication

В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В PowerВ SteeringВ

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В PowerВ SteeringВ

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В SteeringВ Gear В (57.10.01) В

В В В В В В В В В В В В В В В В В В В В SteeringВ Gear В Bushing В (57.10.30) В

В

В В В В В В В В В В В В 211‐03: В SteeringВ LinkageВ

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В SteeringВ Linkage В

В

В В В В В В В В В В В В 211‐04: В SteeringВ ColumnВ

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Description В and В Operati

onВ

В В В В В В В В В В В В В В В В В В В В SteeringВ Column В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В SteeringВ ColumnВ LowerВ Shaft В (57.40.05) В

В

В В В В В В В В В В В В 211‐05: В SteeringВ ColumnВ Switches В

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В SteeringВ ColumnВ Switches В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В SteeringВ ColumnВ Multifunction В Switch В (86.65.92) В

В

В В В В 3: В PowertrainВ

В

В В В В В В В В 303: В Engine В

В

В В В В В В В В В В В В 303‐00: В Engine В System  ‐ General В Information В

В В В В В В В В В В В В В В В В

В В В В В В В В В В В В В В В В В В В В В

Page 9 of 2490

В В В В В В В В В В В В 303‐01: В En gine В

В В В В В В В В В В В В В В В В Diagnos

is

В and В Testing В

В В В В В В В В В В В В В В В В В В В В EngineВ

В В В В В В В В В В В В В В В В В В В В DTCВ P1392 В VVT В solenoidВ AВ circuit В low В input В

В В В В В В В В В В В В В В В В В В В В DTCВ P1397 В VVT В solenoidВ BВ circuit В low В input В

В В В В В В В В В В В В В В В В В В В В DTCВ P1393 В VVT В solenoidВ AВ circuit В high В input В

В В В В В В В В В В В В В В В В В В В В DTCВ P1398 В VVT В solenoidВ BВ circuit В high В input В

В В В В В В В В В В В В В В В В В В В В DTCВ P1396 В VVT В solenoidВ BВ malfunction В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ A:В P13

92В (P1397) В VVT В solenoidВ circuitВ low В input В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ B:В P1393В (P1398) В VVT В solenoidВ circuitВ high В input В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ C:В P1396 В VVT В solenoid В malfunction В

В В В В В В В В В В В В В В В В In

‐Vehicle В Repair В

В В В В В В В В В В В В В В В В В В В В ConnectingВ

RodВ Bearings В (12.17.16) В

В В В В В В В В В В В В В В В В В В В В CrankshaftВ

FrontВ Seal В Vehicles В Without: В Supe

rcharger В (12.21.14) В

В В В В В В В В В В В В В В В В В В В В CrankshaftВ

FrontВ Seal В Vehicles В With:В Supercharger В (12.21.14) В

В В В В В В В В В В В В В В В В В В В В CrankshaftВ

InnerВ SprocketВ 4.0L,В VehiclesВ Without:В SuperchargerВ (12.65.76)В

В В В В В В В В В В В В В В В В В В В В CrankshaftВ

InnerВ SprocketВ 3.2LВ (12.65.76) В

В В В В В В В В В В В В В В В В В В В В CrankshaftВ

OuterВ Sprocket В (12.65.75) В

В В В В В В В В В В В В В В В В В В В В CrankshaftВ

PulleyВ Vehicles В Without: В Supercharger В (12.21.09) В

В В В В В В В В В В В В В В В В В В В В CrankshaftВ

PulleyВ Vehicles В With: В SuperchargerВ (12.21.09)В

В В В В В В В В В В В В В В В В В В В В CrankshaftВ

RearВ Seal В VehiclesВ Without:В SuperchargerВ (12.21.20)В

В В В В В В В В В В В В В В В В В В В В CrankshaftВ

RearВ Seal В Vehic

lesВ With:В Supercharger В (12.21.20) В

В В В В В В В В В В В В В В В В В В В В CylinderВ

HeadВ LHВ (12.29.02) В

В В В В В В В В В В В В В В В В В В В В CylinderВ

HeadВ RH В (12.29.03) В

В В В В В В В В В В В В В В В В В В В В Engine

В FrontВ CoverВ (12.65.01) В

В В В В В В В В В В В В В В В В В В В В Engine

В FrontВ CoverВ Gasket В (12.65.04) В

В В В В В В В В В В В В В В В В В В В В Exhaust

В Camshaft В LH В (12.13.17) В

В В В В В В В В В В В В В В В В В В В В Exhaust

В Camshaft В RH В (12.13.15) В

В В В В В В В В В В В В В В В В В В В В Exhaust

В Camshaft В Sprocket В LH В 4.0L, В VehiclesВ Without:В SuperchargerВ (12.65.74)В

В В В В В В В В В В В В В В В В В В В В Exhaust

В Camshaft В Sprocket В LH В 3.2L/4.0L, В VehiclesВ With:В Supercharger В (12.65.74) В

В В В В В В В В В В В В В В В В В В В В Exhaust

В Camshaft В Sprocket В RH В 4.0L, В Ve

hicles В Without: В Supercharger В (12.65.73) В

В В В В В В В В В В В В В В В В В В В В Exhaust

В Camshaft В Sprocket В RH В 3.2L/4.0L,В VehiclesВ With:В Supercharger В (12.65.73) В

В В В В В В В В В В В В В В В В В В В В Exhaust

В Manifold В LH В (30.15.55) В

ExhaustВ Manifold В RH В (30.15.56) В

Exhaust В Manifold В LH В and В RH В (30.15.57) В

Exhaust В Manifold В Gasket В LHВ (30.15.58) В

Exhaust В Manifold В Gasket В RH В (30.15.59) В

Exhaust В Manifold В Gasket В LHВ and В RH В (30.15.60) В

Page 11 of 2490

В В В В В В В В В В В В В В В В В В В В В В В В В В В В В

В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В Valve

В Co

verВ

LHВ (12.29.43) В

В В В В В В В В В В В В В В В В В В В В Valve

В CoverВ RHВ (12.29.44) В

В В В В В В В В В В В В В В В В В В В В Valve

В CoverВ Gasket В LHВ (12.29.40) В

В В В В В В В В В В В В В В В В В В В В Valve

В CoverВ Gasket В RH В (12.29.41) В

В В В В В В В В В В В В В В В В В В В В Valve

В SpringsВ LHВ

В В В В В В В В В В В В В В В В В В В В Valve

В SpringsВ RHВ

В В В В В В В В В В В В В В В В В В В В Variable

В Camshaft В Timing В Oil В Con

trolВ Unit В LHВ (12.65.71) В

В В В В В В В В В В В В В В В В В В В В Variable

В Camshaft В Timing В Oil В Control В Unit В RH В (12.65.70) В

В В В В В В В В В В В В В В В В В В В В Variable

В Camshaft В Timing В Oil В Control В Unit В Housing В LHВ (12.65.52) В

В В В В В В В В В В В В В В В В В В В В Variable

В Camshaft В Timing В Oil В Control В Unit В Housing В RH В (12.65.51) В

В

В В В В В В В В В В В В 303‐03A :В Engine В Cooling В

В В В В В В В В В В В В В В В В Descriptio

nВ and В Operation В

В В В В В В В В В В В В В В В В В В В В EngineВ Cooling В

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В EngineВ Cooling В

В В В В В В В В В В В В В В В В В В В В RelatedВ Faults В /В Codes В

В В В В В В В В В В В В В В В В В В В В DTCВ P0116 В ECT В circuit В rangeВ /В performanceВ problemВ

В В В В В В В В В В В В В В В В В В В В DTCВ P0125 В Insufficient В coolantВ temperature В for В closed В loopВ fuelВ control В

В В В В В В В В В В В В В В В В В В В В DTCВ P0117 В ECT В circuit В low В input В

В В В В В В В В В В В В В В В В В В В В DTCВ P0118 В ECT В circuit В high В input В

В В В В В В В В В В В В В В В В В В В В DTCВ P1474 В Intercooler В coolant В pum

pВ relay В malfunction В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ A:В P0116, В P0125 В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ B:В P0117 В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ C:В P0118 В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ D:В P1474 В

В В В В В В В В В В В В В В В В GeneralВ Procedures В

В В В В В В В В В В В В В В В В В В В В CoolingВ System В Draining,В FillingВ and В Bleeding  ‐ 3.2L В NA В V8  ‐ AJ26/4.0L В NA В V8  – В

В В В В В В В В В В AJ27В

В В В В В В В В В В В В В В В В В В В В CoolingВ System В Draining,В FillingВ and В Bleeding  ‐ 4.0L В SC В V8  ‐ AJ26 В

В В В В В В В В В В В В В В В В В В В В CoolingВ Sy

stem В Draining В and В Vacuum В Filling В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В

Removal

В

Engine  ‐ Re m

oval

В (12.41.01) В

Installation В

Engine  ‐ Installation В (12.41.01) В

Page 12 of 2490

В В В В В В В В В В В В В В В В В В В В CoolantВ E x

pansion

В Tank В (26.15.01) В

В В В В В В В В В В В В В В В В В В В В

CoolantВ Outlet В Pipe В (26.31.08) В

В В В В В В В В В В В В В В В В В В В В

В В В В В В В В В В В В В В В В В В В В CoolingВ Fan В Motor В (26.25.24) В

В В В В В В В В В В В В В В В В В В В В CoolingВ Fan В Motor В and В Shroud В (26.25.25) В

В В В В В В В В В В В В В В В В В В В В CoolingВ Fan В Motors В (26.25.25) В

В В В В В В В В В В В В В В В В В В В В CoolingВ Fan В Shroud В (26.25.30) В

В В В В В В В В В В В В В В В В В В В В EngineВ Coolant В Level В Switch В (26.40.11) В

В В В В В В В В В В В В В В В В В В В В RadiatorВ (26.40.01)  ‐ 3.2L В NA В V8  ‐ AJ26/4.0LВ NAВ V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В В В В В RadiatorВ (26.40.01)  ‐ 4.0L В SCВ V8 ‐ AJ26 В

В В В В В В В В В В В В В В В В В В В В RadiatorВ LowerВ Hose В (26.30.07)  ‐ 3.2L В NA В V8  ‐ AJ26/4.0L В NA В V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В В В В В RadiatorВ LowerВ Hose В (26.30.07)  ‐ 4.0L В SCВ V8 ‐ AJ26 В

В В В В В В В В В В В В В В В В В В В В RadiatorВ UpperВ Ho

seВ (26.30.01)  ‐ 3.2L В NA В V8  ‐ AJ26/4.0L В NA В V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В В В В В RadiatorВ UpperВ Hose В (26.30.01)  ‐ 4.0L В SCВ V8 ‐ AJ26 В

В В В В В В В В В В В В В В В В В В В В Thermostat В (26.45.07)  ‐ 3.2L В NA В V8  ‐ AJ26/4.0L В NA В V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В В В В В Thermostat В (26.45.07)  ‐ 4.0L В SCВ V8 ‐ AJ26 В

В В В В В В В В В В В В В В В В В В В В Thermostat В Housing В Cover В (26.

45.22)  ‐ 3.2L В NA В V8  ‐ AJ26/4.0L В NA В V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В В В В В Thermostat В Housing В Cover В (26.45.22)  ‐ 4.0L В SCВ V8 ‐ AJ26 В

В В В В В В В В В В В В В В В В В В В В Thermostat В Housing В Cover В Seal В (26.45.20)  ‐ 3.2L В NA В V8  ‐ AJ26/4.0LВ NAВ V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В В В В В Thermostat В Housing В Cover В Seal В (26.45.20)  ‐ 4.0L В SCВ V8 ‐ AJ26 В

В В В В В В В В В В В В В В В В В В В В WaterВ Pump В (26.50.

01) ‐ 3.2L В NA В V8  ‐ AJ26/4.0LВ NAВ V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В В В В В WaterВ Pump В (26.50.01)  ‐ 4.0L В SCВ V8 ‐ AJ26 В

В В В В В В В В В В В В В В В В В В В В WaterВ Pump В Pulley В (26.50.05)  ‐ 3.2L В NA В V8  ‐ AJ26/4.0L В NA В V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В В В В В WaterВ Pump В Pulley В (26.50.05)  ‐ 4.0L В SCВ V8 ‐ AJ26 В

В

В В В В В В В В В В В В 303‐03B :В SuperchargerВ CoolingВ

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В WaterВ Pump В

В

303‐04:  Fu

elВ ChargingВ andВ Controls В

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В FuelВ ChargingВ andВ Controls В

В В В В В В В В В В В В В В В В InspectionВ andВ Verification В

В В В В В В В В В В В В В В В В В В В В DriverВ Information В Chart В

В В В В В В В В В В В В В В В В В В В В DefaultВ modeВ Definitions В

В В В В В В В В В В В В В В В В В В В В DiagnosticВ Trouble В Code В (DTC) В index В

В В В В В В В В В В В В В В В В В В В В PinpointВ Tests В

Page 14 of 2490

303‐07:  En gine  Ignition

В

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В EngineВ Ignition В

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В EngineВ Ignition В

В В В В В В В В В В В В В В В В InspectionВ andВ Verification В

В В В В В В В В В В В В В В В В В В В В DriverВ Information В Chart В

В В В В В В В В В В В В В В В В В В В В DefaultВ modeВ Definitions В

В В В В В В В В В В В В В В В В В В В В DiagnosticВ Trouble В Code В (DTC) В index В

В В В В В В В В В В В В В В В В В В В В PinpointВ Tests В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В IgnitionВ Coil ‐On ‐Plug В LHВ (18.20.44) В

В В В В В В В В В В В В В В В В В В В В IgnitionВ Coil ‐On ‐Plug В RH В (18.20.43) В

В В В В В В В В В В В В В В В В В В В В IgnitionВ Module В (18.20.30) В

В В В В В В В В В В В В В В В В В В В В SparkВ PlugsВ (18.20.02) В

В

303‐08:  En

gine В Emission В Control В

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В EngineВ Emission В Control В

В В В В В В В В В В В В В В В В InspectionВ andВ Verification В

В В В В В В В В В В В В В В В В В В В В DiagnosticВ Trouble В Code В (DTC) В Index В

В В В В В В В В В В В В В В В В В В В В PinpointВ Tests В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В ExhaustВ Gas В RecirculationВ (EGR)В Valve В (17.45.01) В

В В В В В В В В В В В В В В В В В В В В ExhaustВ Manifold В to В Exhaust В Gas В RecirculationВ (E

GR)В Valve В Tube В (17.45.11) В

В

В В В В В В В В В В В В 303‐12: В Intake В AirВ Distribution В and В Filtering В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В AirВ Cleaner В (19.10.05) В

В В В В В В В В В В В В В В В В В В В В AirВ Cleaner В Element В (19.10.08) В

В В В В В В В В В В В В В В В В В В В В ChargeВ Air В Cooler В LHВ (18.50.19) В

В В В В В В В В В В В В В В В В В В В В ChargeВ Air В Cooler В RH В (18.50.18) В

В В В В В В В В В В В В В В В В В В В В ChargeВ Air В Cooler В Gasket В LHВ (18.50.22) В

В В В В В В В В В В В В В В В В В В В В ChargeВ Air В Cooler В Gasket В RH В (18.50.21) В

В В В В В В В В В В В В В В В В В В В В Supercharger В (18.50.

15)В

Page 15 of 2490

В В В В В В В В В В В В В В В В В В В В Superchar

ger

В OutletВ PipeВ (18.50.16) В

В В В В В В В В В В В В В В В В В В В В Supercharger В OutletВ PipeВ Gasket В (18.50.17) В

В В В В В В В В В В В В В В В В В В В В ThrottleВ Body В Elbow В (19.70.28) В

В В В В В В В В В В В В В В В В В В В В ThrottleВ Body В Elbow В Gasket В (19.70.29) В

В

В В В В В В В В В В В В 303‐13: В Evaporative В Emissions В

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В EvaporativeВ EmissionsВ

В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В

Preliminary

В Inspection

В

В В В В В В В В В В В В В В В В В В В В Diagnostic

В Drive В Cycles В

В В В В В В В В В В В В В В В В В В В В Diagnostic

В Trouble В Code В (DTC) В index/Symptom В Chart В

В В В В В В В В В В В В В В В В В В В В Pinpoint

В Tests В

В В В В В В В В В В В В В В В В Removal

В and В Installation В

В В В В В В В В В В В В В В В В В В В В EvaporativeВ

EmissionВ Canister В (17.15.13) В

В В В В В В В В В В В В В В В В В В В В EvaporativeВ

EmissionВ Canister В PurgeВ ValveВ (17.15.30) В

В В В В В В В В В В В В В В В В В В В В Fuel

В Tank В Press

ureВ Sensor В (19.55.31) В

В В В В В В В В В В В В В В В В В В В В Fuel

В Vapor В Vent В Valve В Housing В (19.55.24) В

В В В В В В В В В В В В В В В В В В В В Fuel

В Vapor В Vent В Valve В Housing В Seal В (19.55.25) В

В

В В В В В В В В В В В В 303

‐14: В Electronic В Engine В Controls В

В В В В В В В В В В В В В В В В Description

В and

В

В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В Diagnosis

В and В Testing В

В В В В В В В В В В В В В В В В В В В В Electronic

В Engine В Con

trols В

В В В В В В В В В В В В В В В В В В В В Inspection

В and В Verification В

В В В В В В В В В В В В В В В В В В В В Driver

В Information В Chart В

В В В В В В В В В В В В В В В В В В В В DefaultВ

modeВ Definitions В

В В В В В В В В В В В В В В В В В В В В Diagnostic

В Trouble В Code В (DTC) В Index В

В В В В В В В В В В В В В В В В В В В В Pinpoint

В Tests В

В В В В В В В В В В В В В В В В Removal

В and В Installation В

В В В В В В В В В В В В В В В В В В В В CatalystВ

MonitorВ SensorВ LH В (18.30.81) В

В В В В В В В В В В В В В В В В В В В В CatalystВ

MonitorВ SensorВ RH В (18.30.80) В

В В В В В В В В В В В В В В В В В В В В HeatedВ Oxygen В Sensor В (HO2S) В LHВ (18.30.79) В

В В В В В В В В В В В В В В В В В В В В

HeatedВ Oxygen В Sensor В (HO2S) В RH В (18.30.78) В

В В В В В В В В В В В В В В В В В В В В

В В В В В В В В В В В В В В В В В В В В

Camshaft В

Position В

Sen s

or

В

ECM В

Position В

Sensor В

Crankshaft

Removal

Engine В

Coolant Temperature

SensorВ

Operation

Intake В AirВ Temperature В (IAT)В Sensor В (18.

30.52) В

Page 28 of 2490

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В DoorВ (76. 28.04) В

В В В В В В В В В В В В В В В В В В В В FrontВ Doo

rВ

Opening В Weatherstrip В (76.40.01) В

В В В В В В В В В В В В В В В В В В В В FuelВ Filler В Door В (76.10.25) В

В В В В В В В В В В В В В В В В В В В В HoodВ (76.16.01) В

В В В В В В В В В В В В В В В В В В В В HoodВ Hinge В (76.16.12) В

В В В В В В В В В В В В В В В В В В В В HoodВ Striker В (76.16.24) В

В В В В В В В В В В В В В В В В В В В В HoodВ Strut В (76.16.15) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ LidВ Hinge В (76.19.28) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ LidВ Opening В Weatherstrip В (76.19.06) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ LidВ Striker В (76.19.12) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ LidВ Strut В (76.19.27) В

В В В В В В В В В В В В В В В В В В В В RearВ Door В Opening В Weathe

rstripВ (76.40.02) В

В

В В В В В В В В В В В В 501‐05: В Interior В Trim В and В Ornamentation В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В InteriorВ Trim В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В A‐PillarВ TrimВ PanelВ (76.13.31) В

В В В В В В В В В В В В В В В В В В В В B‐PillarВ TrimВ PanelВ (76.13.28) В

В В В В В В В В В В В В В В В В В В В В CowlВ Side В Trim В PanelВ (76.13.30) В

В В В В В В В В В В В В В В В В В В В В C‐Pillar В Trim В PanelВ (76.13.73) В

В В В В В В В В В В В В В В В В В В В В DoorВ WindowВ ControlВ Switch В FinishВ Pane

lВ (76.47.33) В

В В В В В В В В В В В В В В В В В В В В EngineВ Cover В (76.11.35) В

В В В В В В В В В В В В В В В В В В В В FloorВ Covering В (76.49.08) В

В В В В В В В В В В В В В В В В В В В В FoldingВ Tray В (76.47.31) В

В В В В В В В В В В В В В В В В В В В В FoldingВ Tray В Finish В Panel В (76.47.32) В

В В В В В В В В В В В В В В В В В В В В FrontВ DoorВ Armrest В (76.34.22) В

В В В В В В В В В В В В В В В В В В В В FrontВ DoorВ TrimВ PanelВ FinishВ Panel В (76.47.11) В

В В В В В В В В В В В В В В В В В В В В FrontВ DoorВ Stowage В CompartmentВ (76.34.27)В

В В В В В В В В В В В В В В В В В В В В FrontВ DoorВ TrimВ PanelВ (76.34.01) В

В В В В В В В В В В В В В В В В В В В В HeadlinerВ (76.64.01) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ FrontВ TrimВ PanelВ (76.19.31) В

В В В В В В В В В В В В В В В В В В В В LuggageВ Compart

mentВ LidВ Trim В Panel В (76.19.05) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ RearВ Trim В PanelВ (76.19.44) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ SideВ Trim В PanelВ (76.19.22) В

В В В В В В В В В В В В В В В В В В В В OverheadВ Console В Finish В PanelВ (76.47.41) В

Page 37 of 2490

patc

hed fastener of the same specification fitted. All mating th

reads must be thoroughly cleaned prior to fitting of the new

fastener.

Jaguar Specification JFS 02.01.04 patched fasteners incorporat e a plastic/polyester on the thread. Acting as a wedge

between the mating threads, this compound imposes a prevaili ng torque during tightening. Whilst this type of patched

fastener can be re-used, the imposed torq ue diminishes. It is therefore recommended that following third removal, this type

of patched fastener is discarded and a new fast ener of the same specification is fitted.

Special fasteners bearing the following pa rt numbers are of the micro-encapsulated adhesive type and following removal,

must be discarded and replaced by ne w items of the same specification:

CAC 8223

JZB 10060; JZB 10061; JZB 10078.

JZH 100027.

JZS 100082; JZS100087; JZS 100088; JZS 100089; JZS 100090; JZS 100118; JZS 100157; JZS 100164; JZS 100166.

NCA 1451 AA.

Vehicle Specifications

Purchasers are advised th

at th

e specification details set out in this manual apply to a range of vehicles and not to any

specific one. For the specificatio n of a particular vehicle, purchasers should consult their dealer.

The Manufacturer reserves the right to vary the specifications, with or without notice, and at such times and in such manner

as the Manufacturer thinks fit. Major as well as minor changes may be involved , in accordance with the Manufacturer's

policy of continuous improvement.

Whilst every effort is made to ensure the accuracy of the pa rticulars contained in this manual, neither the Manufacturer nor

the Dealer, by whom the manual is supplied, shall in any circumstances be held liable for any inaccuracy or the

consequences thereof.

Serv

ice Repair Operation Numbering

A

master index of numbered operations has been compiled for

universal application to all vehicles manufactured by Jaguar

Cars Ltd.

Each operation is allocated a number from the master index and cross-refers with an identical number in the Repair

Operation Times schedule. The number consists of six digits arranged in three pairs.

Each maintenance procedure in this manual is described in the sequence necessary to complete the operation in the

minimum time, as specified in the Repair Operation Times schedule for this range of vehicles.

Re

ferences to Left- and Right-Hand

R

eferences to the left- or

right-hand side of the vehicle are made as if viewing from the driver's seat.

Ref

erences to Engine Banks

Wi

th the engine installed in the vehicle, the right-hand cylinder

bank is designated Bank A, and the left-hand cylinder bank

is designated Bank B.

Specia

l Tools

Any special too

ls and equipment required

to perform a maintenance procedure, are shown at the beginning of each

maintenance procedure.

Page 40 of 2490

irri

tation and dermatitis. In addition, used engine oil contains potentially harmful contaminants which may cause skin

cancer. Washing facilities and adequate means of skin protection should be provided.

Observe these recommendations:

пЃ¬Wear pro t

ective clothing and impe

rvious gloves when necessary.

пЃ¬Do not put oily

rags in pockets. Avoid contaminat

ing clothes, particularly underwear, with oil.

пЃ¬Overal

ls must be cleaned re

gularly; discard oil impregna ted clothing and footwear wh ich cannot be washed or

cleaned.

пЃ¬Fi rst

Aid treatment should be obtained

immediately for open cuts or wounds.

пЃ¬Use barrier

creams, applying before each work period, to en

able easier removal of dirty oil and grease from the skin.

пЃ¬Wa

sh with soap and water to ensure th

at all oil is removed (skin cleaner and a nail brush will help). The use of

preparations containing lanolin will help to replace the natural skin oils which have been removed.

пЃ¬Do

not use petrol, kerosene, gas oil, th

inners or solvents for washing skin.

пЃ¬If

skin disorders develop, obtain medical advice immediately.

пЃ¬Wh

ere prac

ticable, degrease components prior to handling.

пЃ¬W

h

ere there is a risk of fluids coming into contact with th

e eyes, suitable eye protection should be worn - goggles or

face shield. An eye wash facility should be provided.

пЃ¬Ensure that a

dequate ventilation is provided when volatile degreasing agents are being used.

E

n

vironmental Protection

In so

m

e countries it is illegal to pour used oil onto the ground

, down sewers or drains, or into water courses. The burning of

used engine oil in small space heaters or boilers is not reco mmended unless emission control equipment is fitted. Dispose of

used oil through authorized waste disposal contractors, to licensed waste disposal sites or to the waste oil reclamation

trade. If in doubt, contact the Local Authority for advice on disposal facilities.

On-Board Diagnostics (OBD)

Ve

hicles use programmed electronic control systems to prov

ide engine management and emission regulation, automatic

transmission operation and anti -lock braking control. These control systems ha ve an integral On-Board Diagnostics (OBD)

facility for use in conjunction with either Jaguar diagnostic equipment or a scan t ool which is capable of retrieving DTCs,

PIDs and performing active commands.

The OBD information in this manual provid es diagnostic and rectification procedures for emission related electrical and

mechanical systems. The informat ion is intended to facilitate fault diagnosis and the subsequent rectification of vehicles

without recourse to the portab le diagnostic unit (PDU).

OBD related information can be fo und in the following sections:

пЃ¬General Information

пЃ¬Engine M

anagement System

пЃ¬Auto

matic Transmission

пЃ¬Anti-lock Br

aking System

Where appropriate a section comprises the following sub-sections:

Description and Operation

пЃ¬A ge

neral illustration and parts list to help the identi

fication of the particular system or component.

пЃ¬A b

rief description of the system operating characteristics and monitoring procedure

accompanied by a component

illustration.

пЃ¬Addi ti

onal information, where appropriat

e, is provided in the form of component calibrations, characteristics and

cross sectional views.

пЃ¬A localized circui

t diagram is included to provide circuit iden

tification and details of connectors, splices, fuses, wire

gauge and colors. See Circuit Diagrams.

Diagnosis and Testing (dedicated to fault analysis and rectification)

пЃ¬Recommended special tools. пЃ¬Symptom chart; a ch

art contai

ning all relevant Diagnostic Trouble Code s (DTC), their possible causes and an

indication of the appropriate test.

пЃ¬Sp

ecific pinpoint test(s), de

signed so that fault diagnosis can be carr ied out in a logical and efficient manner.

Page 42 of 2490

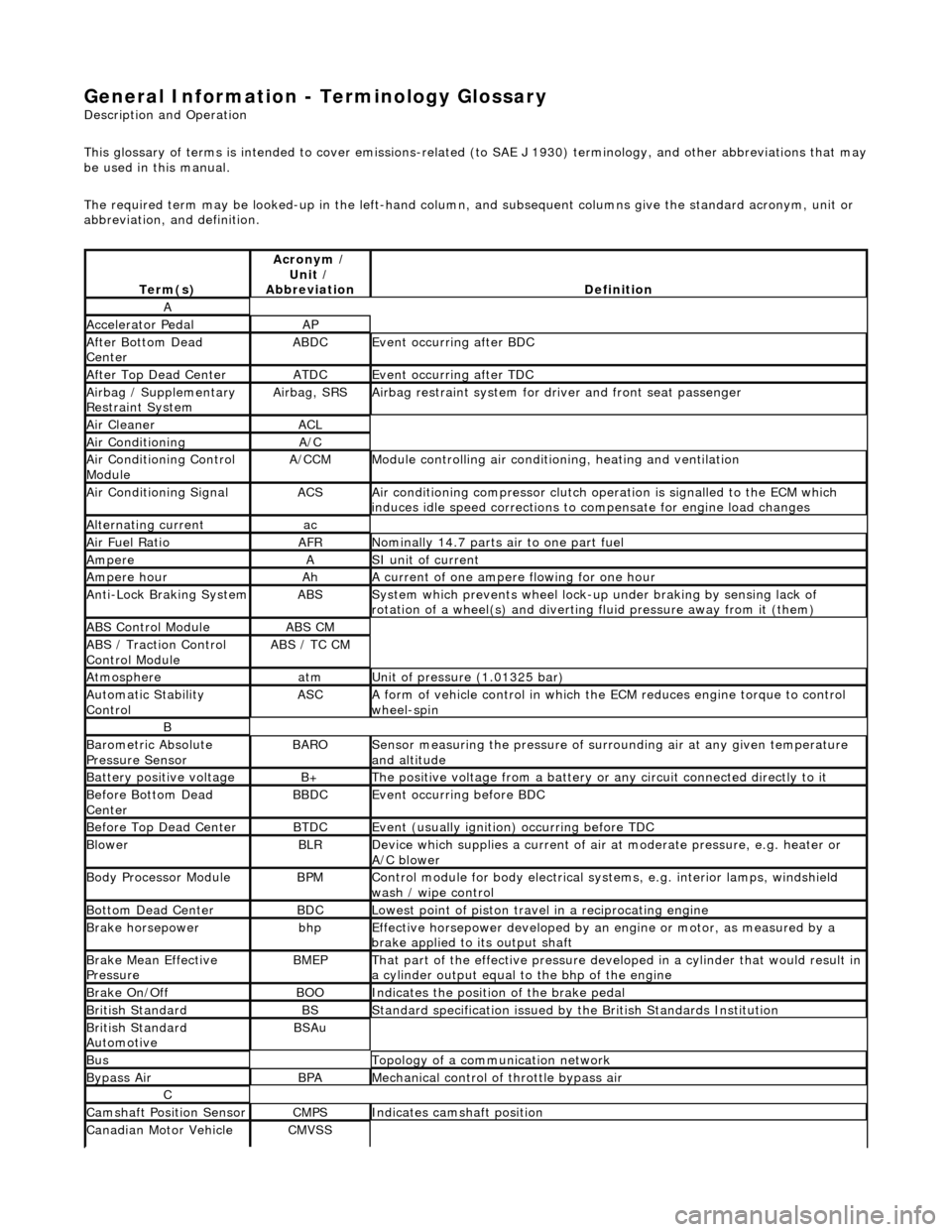

General Information - Terminology Glossary

Description an

d Operation

This glossary of terms is intended to cover emissions-related (to SAE J 1930) term inology, and other abbreviations that may

be used in this manual.

The required term may be looked-up in th e left-hand column, and subsequent columns give the standard acronym, unit or

abbreviation, and definition.

Te rm

(s)

Acr

ony

m /

Unit /

Abbreviation

De fi

nition

A

Accel

e

rator Pedal

AP

Af

ter Botto

m Dead

Center

ABDCEvent occurri ng after

BDC

Af

ter Top Dead CenterATDCEvent occurri ng after

TDC

Ai

rbag /

Supplementary

Restraint System

Airbag, SRSAi rbag restraint system for

dr

iver and front seat passenger

Air Cleane rACL

Air ConditioningA/C

Air Conditioning Con t

rol

Module

A/CCMModule c

ontrolling air conditioning, heating and ventilation

Air Conditioning SignalACSA

i

r conditioning compressor clutch operation is signalled to the ECM which

induces idle speed corrections to co mpensate for engine load changes

Alternating cu

rrent

ac

Ai

r Fuel R

atio

AFRN

omi

nally 14.7 parts air to one part fuel

Ampe

reASI unit of current

Ampere hourAhA current of one ampere

fl

owing for one hour

Anti-Lock Braking SystemABSS

y

stem which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and divertin g fluid pressure away from it (them)

ABS Control Mo

dule

ABS CM

ABS /

T

raction Control

Control Module

ABS / T

C CM

Atmosph

e

re

atmU

n

it of pressure (1.01325 bar)

Au

to

matic Stability

Control

ASCA form of vehicle

control

in which the ECM reduces en gine torque to control

wheel-spin

B

Baro me

tric Absolute

Pressure Sensor

BAR OSensor measuring the pressure of surr ou

nding air at any given temperature

and altitude

Bat t

ery positive voltage

B+The posi

ti

ve voltage from a battery or

any circuit connected directly to it

Before Bottom Dead

CenterBBDCEvent occurri ng before BD

C

Before Top Dead

Center

BTD

CEvent (usual ly

ignition) occurring before TDC

Blowe

rBLRDe

vice which supplies a current of air at

moderate pressure, e.g. heater or

A/C blower

Body Processor M

odule

BPMControl modu

le

for body electrical systems, e.g. interior lamps, windshield

wash / wipe control

Bott om D

ead Center

BD

CLowest poin t of piston

travel in a reciprocating engine

Brake hors

epowe

r

bhpEffecti

ve horsepower devel

oped by an

engine or motor, as measured by a

brake applied to its output shaft

Brake Mean Effective

Pres sureBME PThat p

art of the effective

pressure developed in a cyli nder that would result in

a cylinder output equal to the bhp of the engine

Brake On/ O

ff

BOOIn

dic

ates the position of the brake pedal

Br

it

ish Standard

BSStan

dar

d specification issued by the British Standards Institution

Br

it

ish Standard

Automotive

BSAu

BusTopology of a commu n

ication network

Bypass

AirBPAMechanica l

control of throttle bypass air

C

Camshaft Posit

i

on Sensor

CMPSIndi

cat

es camshaft position

Canadian Motor

V

ehicle

CMVSS