chain JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 624 of 2490

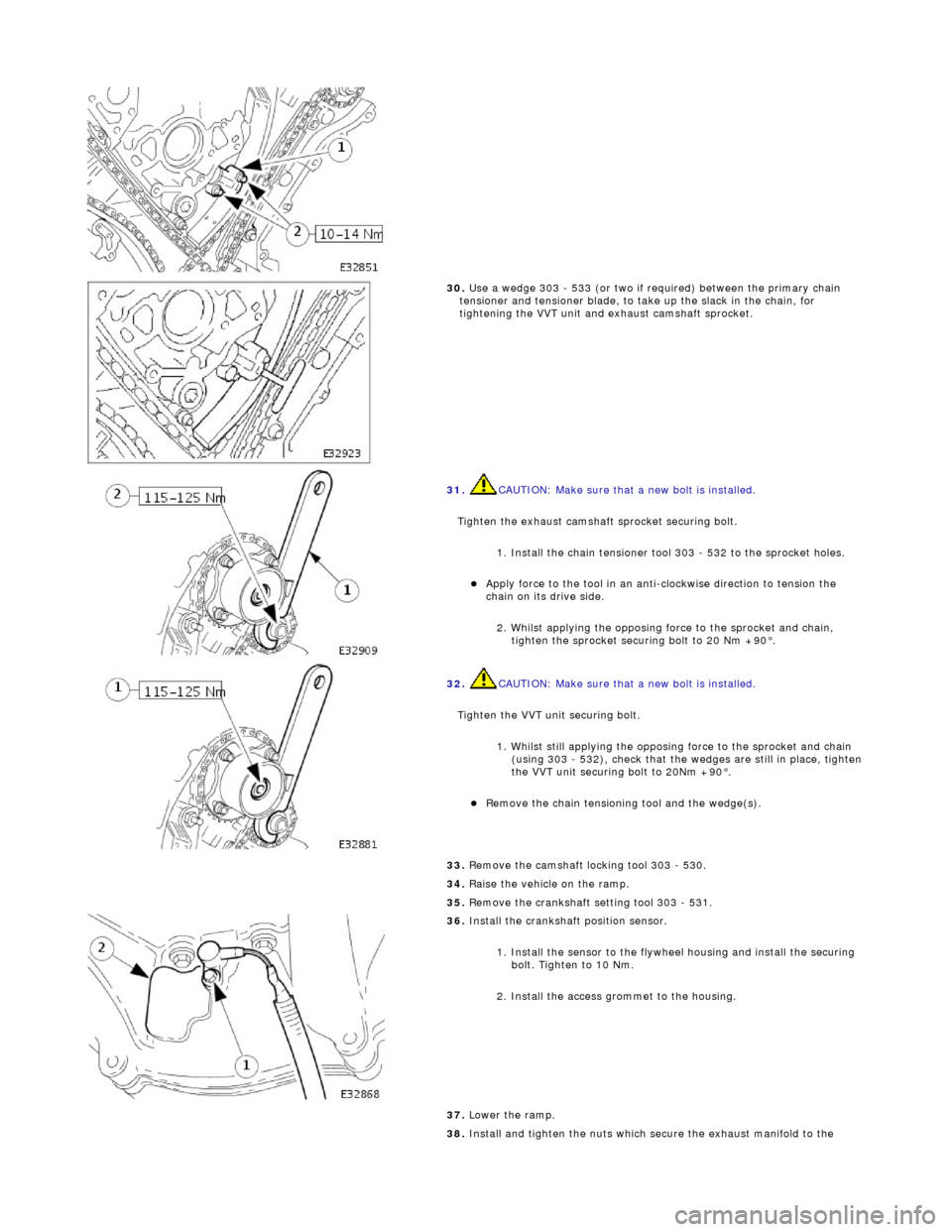

30. U

se a wedge 303 - 533 (or two if required) between the primary chain

tensioner and tensioner blade, to ta ke up the slack in the chain, for

tightening the VVT unit and exhaust camshaft sprocket.

31 . C

AUTION: Make sure that a new bolt is installed.

Tighten the exhaust camshaft sprocket securing bolt. 1. Install the chain tensioner tool 303 - 532 to the sprocket holes.

пЃ¬Apply

force to the tool in an anti

-clockwise direction to tension the

chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprocket securing bolt to 20 Nm +90В°.

32 . C

AUTION: Make sure that a new bolt is installed.

Tighten the VVT unit securing bolt. 1. Whilst still applying the opposing force to the sprocket and chain (using 303 - 532), check that the wedges are still in place, tighten

the VVT unit securing bolt to 20Nm +90В°.

пЃ¬Re

move the chain tensioning tool and the wedge(s).

33

. R

emove the camshaft locking tool 303 - 530.

34. Raise the vehicle on the ramp.

35. Remove the crankshaft setting tool 303 - 531.

36 . In

stall the crankshaft position sensor.

1. Install the sensor to the flywheel housing and install the securing bolt. Tighten to 10 Nm.

2. Install the access grommet to the housing.

37. Lower the ramp.

38. Install and tighten the nuts which secure the exhaust manifold to the

Page 627 of 2490

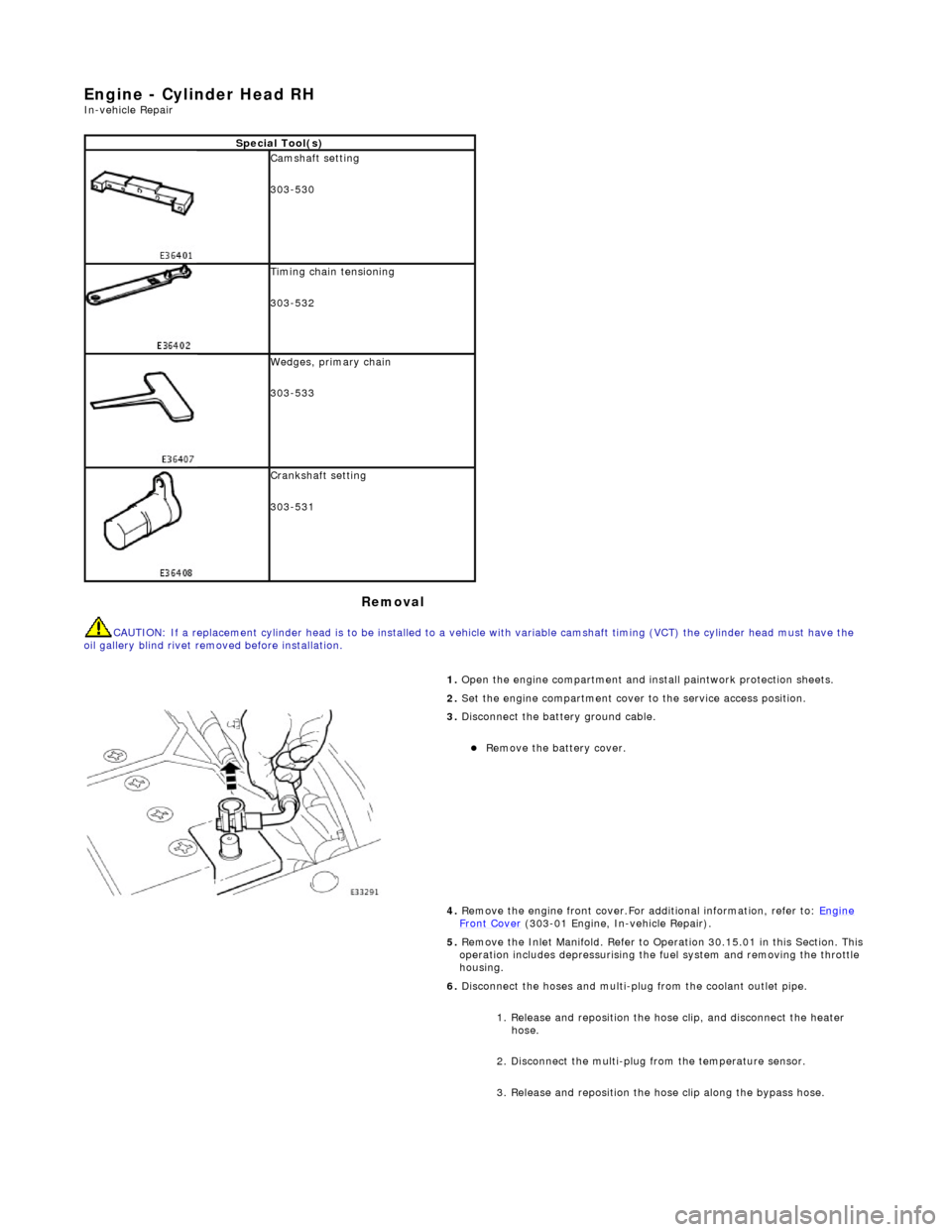

E

ngine - Cylinder Head RH

In-ve

hicle Repair

Remova

l

CAU

TION: If a replacement cylinder head is to be installed to a

vehicle with variable camshaft timing (VCT) the cylinder head m ust have the

oil gallery blind rivet removed before installation.

Spe

cial Tool(s)

Cams

haft setting

303-530

Ti

ming chain tensioning

303-532

Wedges, prim

ary chain

303-533

Cr

ankshaft setting

303-531

1.

Open the engine compartment and install paintwork protection sheets.

2. Set the engine compartment cover to the service access position.

3.

Disconnect the battery ground cable.

пЃ¬Re

move the battery cover.

4. Remove the engine front cover.For additional information, refer to: Engine

Front Cover (303-01 Engi

ne, In-vehicle Repair).

5. Remove the Inlet Manifold. Refer to Operation 30.15.01 in this Section. This operation includes depressurising the fuel system and removing the throttle

housing.

6. Disconnect the hoses and multi-plug from the coolant outlet pipe.

1. Release and reposition the hose clip, and disconnect the heater hose.

2. Disconnect the multi-plug from the temperature sensor.

3. Release and reposition the hose clip along the bypass hose.

Page 630 of 2490

21. L

oosen the bolt which secures the VVT unit to the camshaft.

22. Remove the camshaft locking tool 303 - 530 (installed for previous

operation).

23. R

emove the primary chain tensioner bolts.

24 . R

emove the tensioner assembly.

1. Remove the tensioner.

2. Remove the tens ioner back-plate.

25 . R

emove the primary chain tensioner blade.

1. Remove the pivot bolt which secures the tensioner blade.

2. Remove the tensioner blade.

26. Remove the primary chain from the VVT unit and from the crankshaft

pulley.

27 . R

emove the VVT unit and exhaust camshaft sprocket.

1. Remove the securing bolt from both the VVT unit and the exhaust cam sprocket.

2. Remove the VVT unit, exhaust sprocket and secondary chain as an assembly (release the chain from the tensioner which is still

secured to the cylinder head).

пЃ¬Re

move the secondary chain from

the VVT unit and the sprocket.

28. Remove the secondary chain tensioner.

Page 631 of 2490

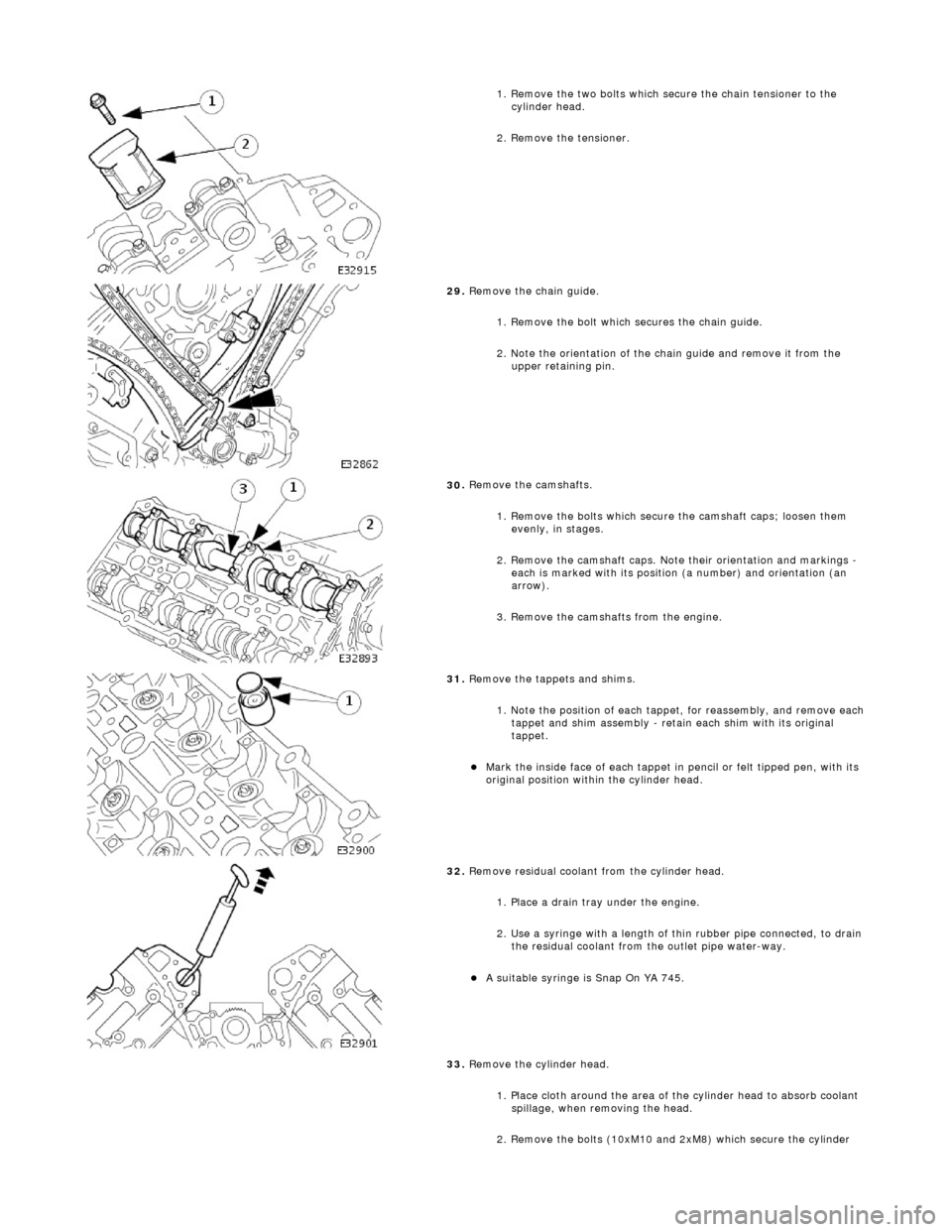

1.

Remove the two bolts which secure the chain tensioner to the

cylinder head.

2. Remove the tensioner.

29

.

Remove the chain guide.

1. Remove the bolt which secures the chain guide.

2. Note the orientation of the chain guide and remove it from the upper retaining pin.

30

.

Remove the camshafts.

1. Remove the bolts which secure the camshaft caps; loosen them evenly, in stages.

2. Remove the camshaft caps. Note their orientation and markings -

each is marked with its position (a number) and orientation (an

arrow).

3. Remove the camshafts from the engine.

31

.

Remove the tappets and shims.

1. Note the position of each tappet, for reassembly, and remove each

tappet and shim assembly - retain each shim with its original

tappet.

пЃ¬Mark

the inside face of each tappet in pencil or felt tipped pen, with its

original position within the cylinder head.

32

.

Remove residual coolant from the cylinder head.

1. Place a drain tray under the engine.

2. Use a syringe with a length of thin rubber pipe connected, to drain the residual coolant from the outlet pipe water-way.

пЃ¬A s

uitable syringe is Snap On YA 745.

33. Remove the cylinder head.

1. Place cloth around the area of th e cylinder head to absorb coolant

spillage, when removing the head.

2. Remove the bolts (10xM10 and 2xM8) which secure the cylinder

Page 637 of 2490

пЃ¬To th

e upper face of each bearing surface (two places) in the cylinder

head.

пЃ¬To th

e upper face of each bearing surface (two places) in each bearing

cap.

пЃ¬On

the cam lobes ONLY, not on the base circle area.

17

.

Install the camshafts.

1. Install the camshafts to position in the cylinder head, with the timing flats uppermost.

2. Install the camshaft caps to their respective locations (inlet 0 to 4 and exhaust 5 to 9 from the front) and in the correct orientation

(arrow to front of engine).

3. Install and tighten the cap securing bolts. Tighten evenly, in stages, to 10 Nm.

18. Install the camshaft locking tool 303 - 530, align the camshafts as

necessary.

19

.

Install the chain guide.

• NOTE: The chain guide must be installed so that the slotted hole is

towards the top, and the raised shoulder to the cylinder block. 1. Install the chain guide to the block and locate it onto the upper retaining pin.

2. Install the retaining bolt and tighten it to 12 Nm.

20

.

Push the secondary chain tensioner piston into the body to provide

clearance for installing the chain.

1. Insert a thin rigid wire through the hole in the end of the tensioner

piston to displace the ball from the non-return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

пЃ¬Re

move the wire.

21

.

Install the secondary chain tensioner to the engine.

1. Fully seat the tensioner to the cylinder head.

2. Install the two bolts which secure the tensioner and tighten to 12 Nm.

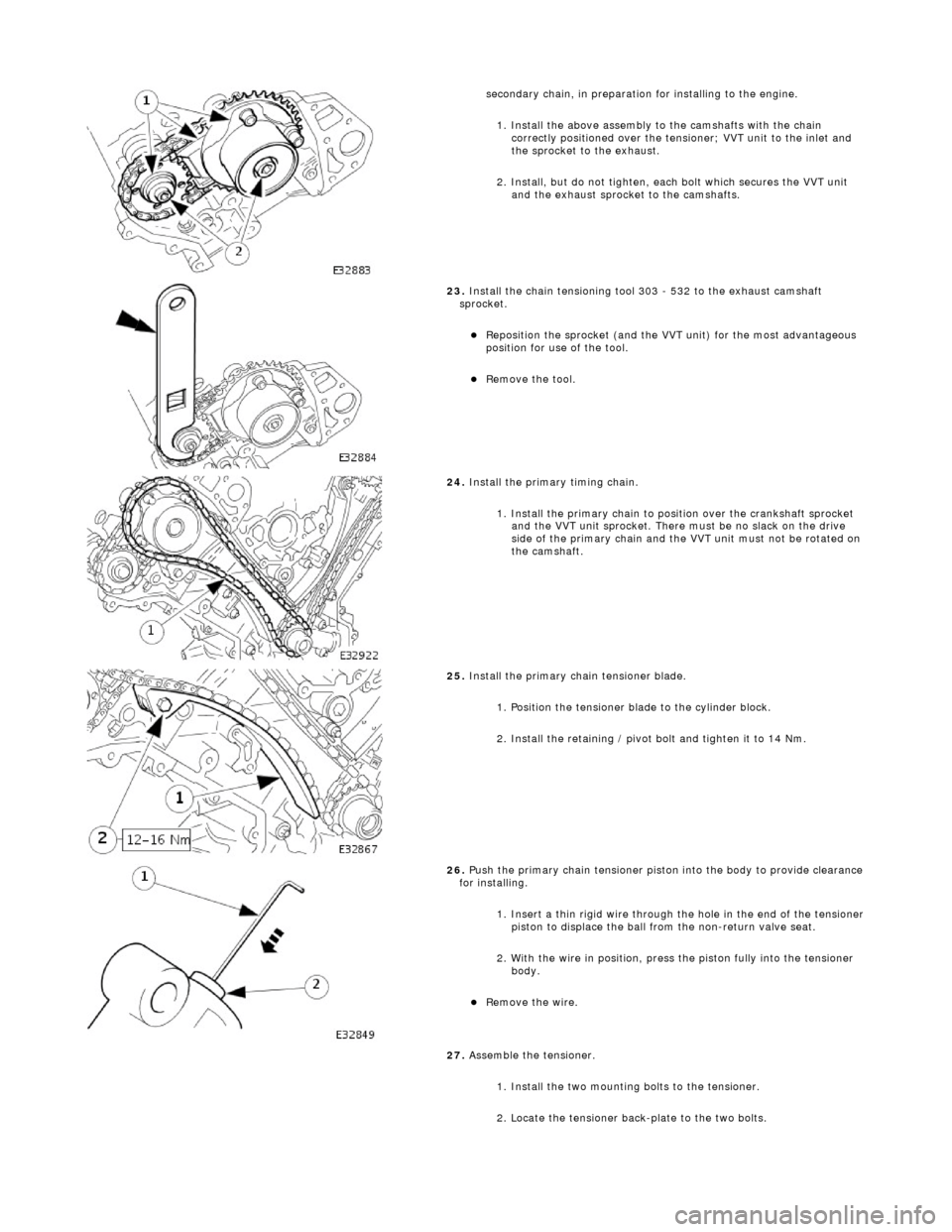

22. Install the VVT unit to the engine.

пЃ¬A

ssemble the VVT unit, the exhaust camshaft sprocket and the

Page 638 of 2490

se

condary chain, in preparation for installing to the engine.

1. Install the above assembly to the camshafts with the chain correctly positioned over the tensioner; VVT unit to the inlet and

the sprocket to the exhaust.

2. Install, but do not tighten, each bolt which secures the VVT unit and the exhaust sprocket to the camshafts.

23 .

Install the chain t

ensioning tool 303 - 532 to the exhaust camshaft

sprocket.

пЃ¬Re p

osition the sprocket (and the VVT unit) for the most advantageous

position for use of the tool.

пЃ¬Re

move the tool.

24 . Install the

primary timing chain.

1. Install the primary chain to position over the crankshaft sprocket and the VVT unit sprocket. There mu st be no slack on the drive

side of the primary chain and the VVT unit must not be rotated on

the camshaft.

25 . Install the pri

mary chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

2. Install the retaining / pivot bolt and tighten it to 14 Nm.

26 . P

ush the primary chain tensioner piston into the body to provide clearance

for installing.

1. Insert a thin rigid wire through the hole in the end of the tensioner

piston to displace the ball from the non-return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

пЃ¬Rem

ove the wire.

27. Assemble the tensioner.

1. Install the two mounting bolts to the tensioner.

2. Locate the tensioner back-plate to the two bolts.

Page 639 of 2490

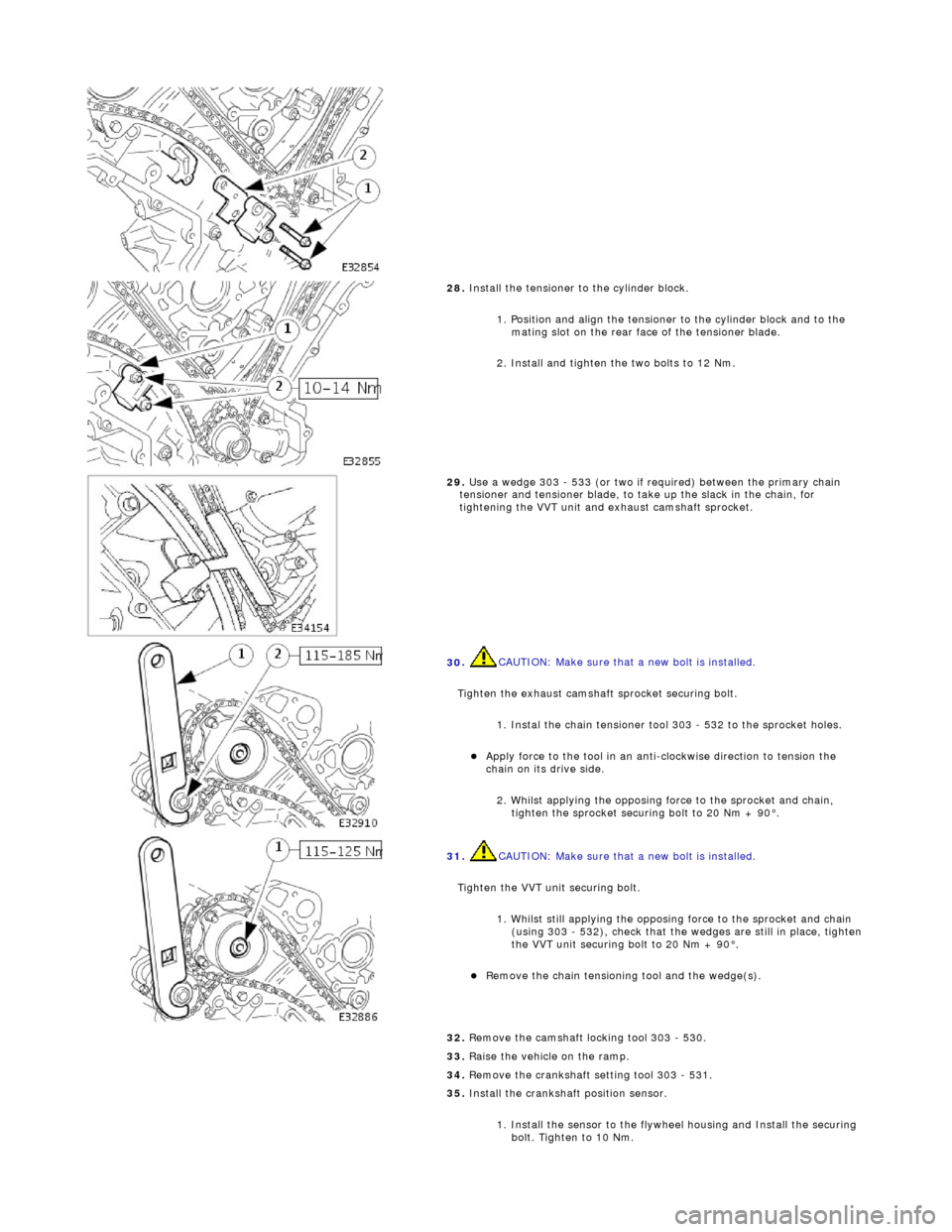

28

.

Install the tensioner to the cylinder block.

1. Position and align the tensioner to the cylinder block and to the mating slot on the rear face of the tensioner blade.

2. Install and tighten the two bolts to 12 Nm.

29

.

Use a wedge 303 - 533 (or two if required) between the primary chain

tensioner and tensioner blade, to ta ke up the slack in the chain, for

tightening the VVT unit and exhaust camshaft sprocket.

30

.

CAUTION: Make sure that a new bolt is installed.

Tighten the exhaust camshaft sprocket securing bolt. 1. Instal the chain tensioner t ool 303 - 532 to the sprocket holes.

пЃ¬Appl

y force to the tool in an anti

-clockwise direction to tension the

chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprocket securing bolt to 20 Nm + 90В°.

31

.

CAUTION: Make sure that a new bolt is installed.

Tighten the VVT unit securing bolt. 1. Whilst still applying the opposing force to the sprocket and chain (using 303 - 532), check that the wedges are still in place, tighten

the VVT unit securing bolt to 20 Nm + 90В°.

пЃ¬R

emove the chain tensioning tool and the wedge(s).

32

.

Remove the camshaft locking tool 303 - 530.

33. Raise the vehicle on the ramp.

34. Remove the crankshaft setting tool 303 - 531.

35. Install the crankshaft position sensor.

1. Install the sensor to the flywheel housing and Install the securing bolt. Tighten to 10 Nm.

Page 664 of 2490

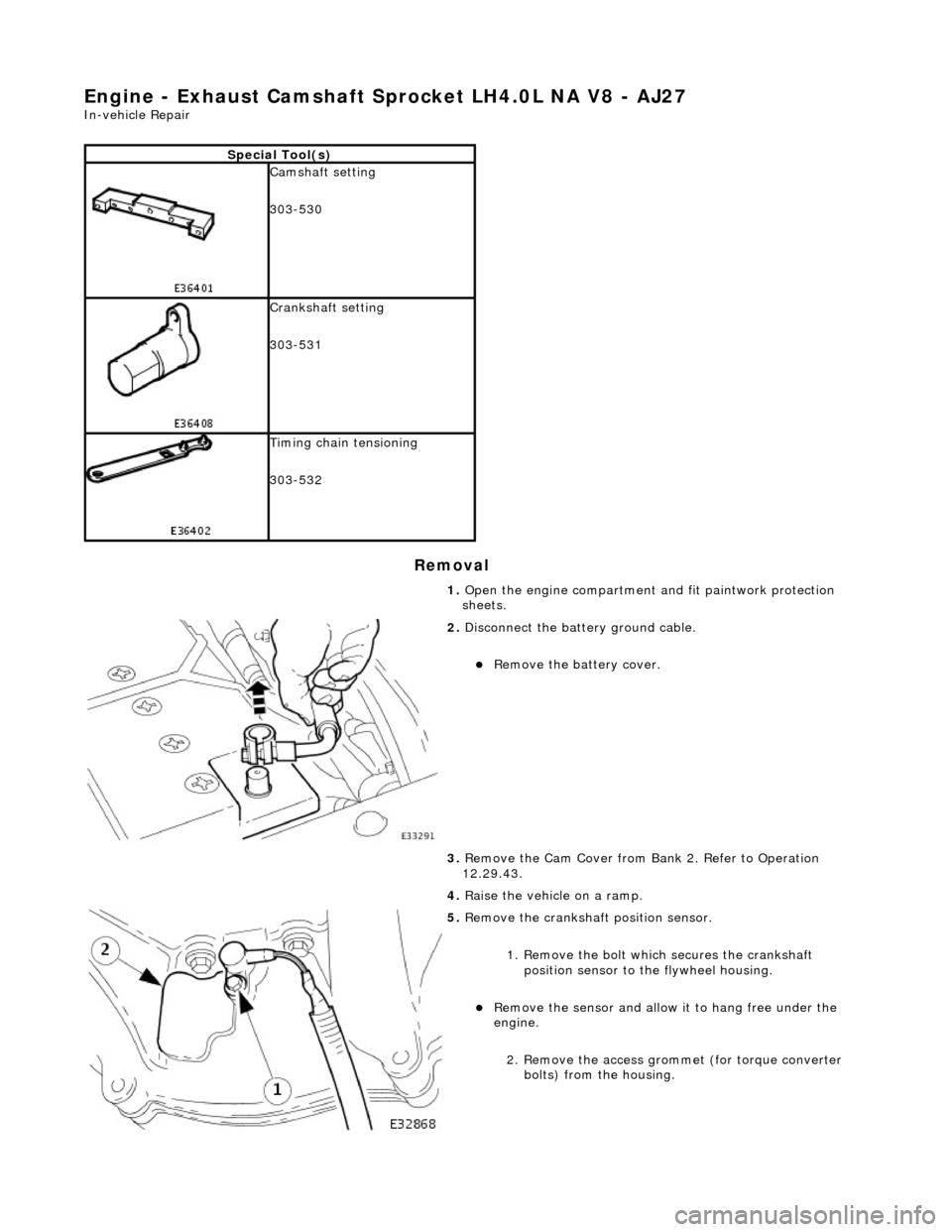

Engine - Exhaust Camshaft Sprocket LH4.0L NA V8 - AJ27

In-vehicle Repair

Removal

Special Tool(s)

Camshaft setting

303-530

Crankshaft setting

303-531

Timing chain tensioning

303-532

1. Open the engine compartment and fit paintwork protection

sheets.

2. Disconnect the batt ery ground cable.

пЃ¬Remove the battery cover.

3. Remove the Cam Cover from Ba nk 2. Refer to Operation

12.29.43.

4. Raise the vehicle on a ramp.

5. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

пЃ¬Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

Page 666 of 2490

Installation

12. Remove the bolt which secures the sprocket to the exhaust

camshaft.

пЃ¬Move the sprocket forward from the camshaft boss.

пЃ¬Remove the sprocket and leav e the chain resting on the

cylinder head.

13. Clean and inspect all relevant components.

1. Push the tensioner piston into the body to provide clearance

for installing. Tensioner fitted to cylinder head.

1. Insert a thin rigid wire th rough the hole in the end of

the tensioner piston to displace the ball from the non-

return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

пЃ¬Remove the wire.

2. Install the sprocket to the secondary chain.

1. With the sprocket installe d to the chain, temporarily

position (do not install the securing bolt) the sprocket

onto the camshaft.

2. Adjust the position of the sprocket within the chain to

allow the chain tensioning tool 303-532 to be

approximately vertical, as shown.

3. Install the cams haft sprocket.

пЃ¬Apply force to the tool (303-532) in an anti-clockwise

direction to tension the chain on its drive side.

пЃ¬Whilst applying the opposing force to the sprocket and

chain, tighten the sprocket securing bolt to 115-125 Nm.

пЃ¬Remove the chain tensioning tool.

Page 668 of 2490

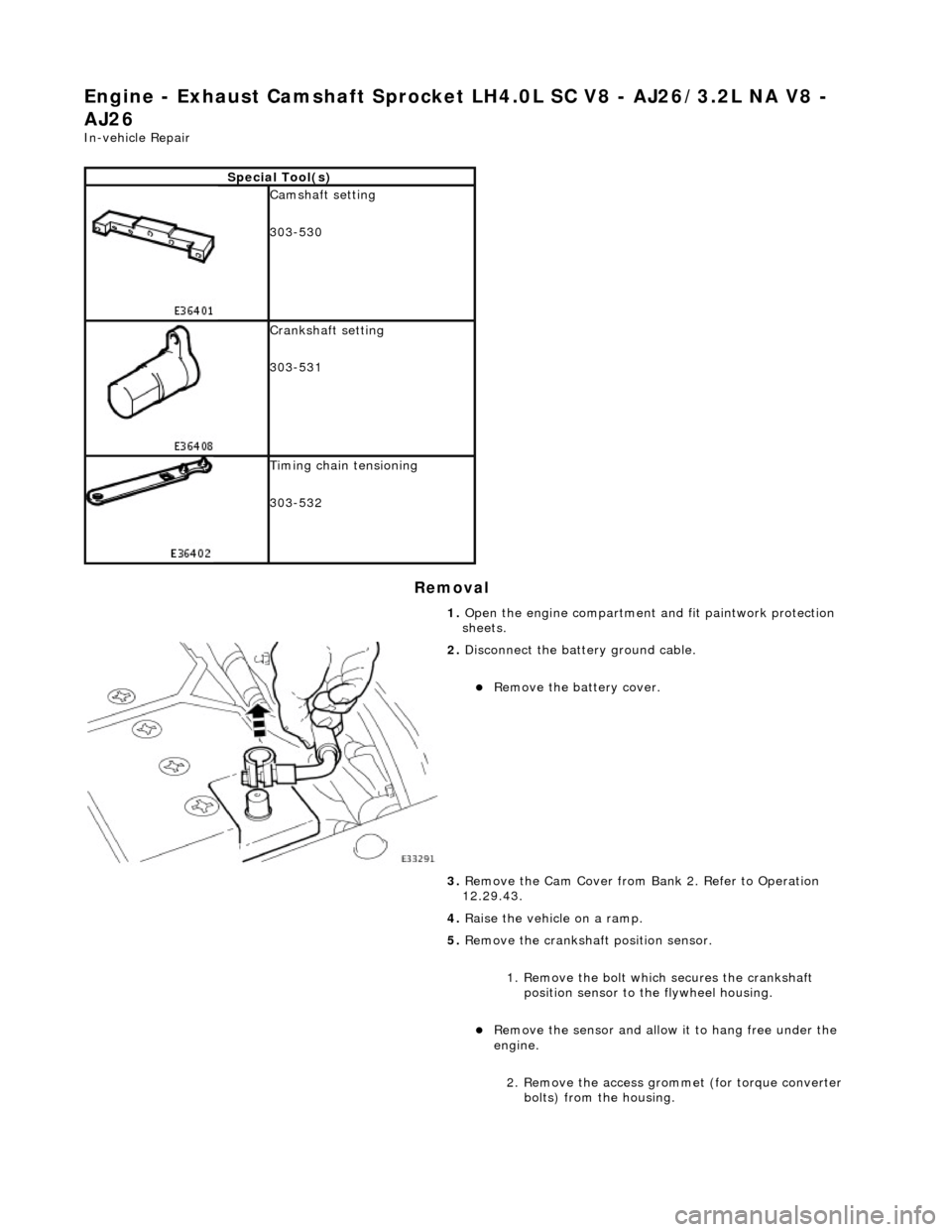

Engine - Exhaust Camshaft Sprocket LH4.0L SC V8 - AJ26/3.2L NA V8 -

AJ26

In-vehicle Repair

Removal

Special Tool(s)

Camshaft setting

303-530

Crankshaft setting

303-531

Timing chain tensioning

303-532

1. Open the engine compartment and fit paintwork protection

sheets.

2. Disconnect the batt ery ground cable.

пЃ¬Remove the battery cover.

3. Remove the Cam Cover from Ba nk 2. Refer to Operation

12.29.43.

4. Raise the vehicle on a ramp.

5. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

пЃ¬Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.