sensor JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1658 of 2490

Exha

ust System - Cataly

tic Converter Gasket LH 4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Re

move the centre trim panel

from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

3. Repo

sition the expansion tank from the mounting.

1. Disconnect the coolant level sensor connector.

2. Remove the nuts which secures the tank.

4. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

Di spl

ace the multiplugs from the engine mounting bracket.

Dis

connect the plug(s) from the oxygen sensor(s).

5.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

Page 1660 of 2490

In

stallation

1.

Fit a ne

w gasket to the mani

fold mating flange on the

downpipe.

2. Fit

the downpipe catalytic converter.

1. Fit the downpipe assembly to the manifold.

Fit,

but do not fully tighten, the mounting bracket securing

bolts. (Leave loose until the nu ts securing the downpipe to

the exhaust manifold are fitted.)

3. Lower the ramp.

4. Tigh te

n the nuts securing the downpipe flange to the manifold

flange.

5. Connec t

the oxygen sensor multiplugs.

Con

n

ect the plug(s) to the respective (previously noted)

sensor(s).

Cor r

ectly position the multiplu

gs on the mounting bracket.

6. Fi

t the coolant header tank.

1. Reposition the tank and fit the securing nuts.

2. Connect the harness connector

7. Refit the centre trim panel and th e left hand enclosure panel to

the engine compartment.

Page 1662 of 2490

Exha

ust System - Catalyti

c Converter Gasket RH4. 0L NA V8 - AJ27/3.2L

NA V8 - AJ26

Re mo

val and Installation

Remova

l

Installation

1. Op

en the engine compartment and fit paintwork protection

sheets.

2. Remove the front muffler; refer to Operation 30.10.18 in this

section.

3. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

Di spl

ace the multiplugs from the engine mounting bracket.

Dis

connect the plug(s) from the oxygen sensor(s).

4.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

5. Raise the vehicle on a ramp.

6. Re

move the downpipe catalytic converter.

R

e

move the bolts which se

cure the downpipe lower

mounting bracket.

Remove the down

pipe assembly.

7. Remove gasket from the manifold flange.

Clean and inspect th e manif

old joint faces.

Clean and inspect th

e threads on th

e downpipe studs.

1. Fit a new gasket to the mani fold mating flange on the

Page 1663 of 2490

do

wnpipe.

2. F

it the downpipe catalytic converter.

Fit the down

pipe assemb

ly to the manifold

Fi

t, but do not fully tighten, the mounting bracket securing

bolts. (Leave loose until the nu ts securing the downpipe to

the exhaust manifold are fitted.)

3. Lower the ramp.

4. Tigh

ten the nuts securing the downpipe flange to the manifold

flange..

5. Connec

t the oxygen sensor multiplugs.

Con

nect the plug(s) to the respective (previously noted)

sensor(s).

Cor

rectly position the multiplu

gs on the mounting bracket.

6. Raise the ramp.

7. Tigh

ten the mounting brac

ket securing bolts.

8. Fit the front muffler; refer to Operation 30.10.18.

9. Lower the ramp.

10

.

Remove the paintwork protection sheets and close the engine

cover.

Page 1664 of 2490

Exha

ust System - Cataly

tic Converter Gasket RH 4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

Di spl

ace the multiplugs from the engine mounting bracket.

Dis

connect the plug(s) from the oxygen sensor(s)

3.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

4. Raise the vehicle on a ramp.

5. Re

move the bolts which secure

the rear of the front muffler

assembly to the engine rear mounting.

6. Remove the nuts which secure the front flanges of the front

muffler to the downpipe flanges.

Page 1666 of 2490

3. Lower the ramp.

4. Tighte

n the nuts securing the downpipe flange to the manifold

flange.

5. Connec t

the oxygen sensor multiplugs.

Con

n

ect the plug(s) to the respective (previously noted)

sensor(s).

Cor r

ectly position the multiplu

gs on the mounting bracket.

6. Raise the vehicle on the ramp.

7. Tigh ten th

e mounting brac

ket securing bolts.

8. Connect the downpipe catalytic converter to the front muffler.

1. Position a new gasket to the flange studs at each side.

Page 1692 of 2490

Fuel Tank and Lines - Fuel Tank and Li

nes

Description an

d Operation

Fuel Tank

Parts List

The steel fuel tank is located inside the trunk and mounted across the vehicle behind the passenger compartment bulkhead.

The fuel tank is held in posi tion by two retaining straps fi tted to body-mounted brackets.

The fuel tank has an integral non-adjustable fill er pipe and integral breather and vapor pipework.

A single fuel pump is mounted inside the tank on vehicles with normally aspirated engines. For vehicles with supercharged

engines, two pumps are fitted in the tank. Fuel is drawn by the pump(s) from the fuel tank and supplied via the fuel lines

and 70 micron filter to the fuel rails.

The fuel lines run from front-to-rear down the vehicle's left-hand-side.

Ite

m

Part

Number

Descr

iption

1—Fu

el filler latch box

2—Pressure reli

ef pipe, ORVR

(shown) / tank breather pipe on non-ORVR systems

3—Tank grounding

cable

4—Evaporative flan

ge assembly

(ORVR type shown)

5—Trunk elec

trical harne

ss (part of)

6—Fue

l

level sensor

flange/connector

7—Fu

el tank retaining straps

8—F

u

el tank retaining stra

ps adjustable clamps

9—Fu

el tank retaining straps lower brackets

10—Tank vapor outlet pipe to un

derflo

or pipe quick-fit connector

11—F

u

el filler latch bo

x water drain pipe

Page 1693 of 2490

Filler Cap and P

ipe

The fuel

filler cap with bayonet-type fixi

ng is located beneath a remote-release sp ring-latched lid on the rear saddle panel

on the left-hand-side of the vehicle.

Fuel Pum

p

The fu

el pump(s) is energized by an ECM co

ntrolled relay. Fuel is drawn by this pu mp and supplied to the fuel injectors via

the fuel line, filter and fuel rails.

Servicing of the fuel pump re quires fuel tank removal.

Ev

aporative Loss Flange Assembly

The evaporative-loss flan

ge asse

mbly is mounted centrally on top of the tank. The flange assembly consists of a removeable

steel cap which mounts the evaporative emissions system vapor outlet valves and, if applicable, a pressure sensor. The

external electrical supply to th e fuel pump(s) is also made via a connector on the flange.

The flange assembly is fixed to the tank by a locking ring which is turned usin g special tool JD-174. A seal is fitted between

the flange assembly and the tank. Three di fferent flange assemblies are applicable according to the evaporative emission

system fitted to the vehicle. The fl ange size and fixing are identical fo r the three systems, as described.

Removal of the evaporative flange assembly is necessary to gain access to th e fuel pump(s) and other internal components.

To remove the evaporative fl ange assembly the fuel tank must first be removed.

The evaporative flange variant assemblies are described, together with service information, in Section 303-13.

Fuel R

eturn

Excess fuel

is directed back to

the fuel tank via a return line.

Fuel Pum

p Relay

The

fuel pump relay,

under control of the ECM, switches power to the fuel pump motor.

I

nertia Fuel Shutoff (IFS) Switch

The IF

S switch is located in the right-hand

side footwell behind the footboard carpet . When activated the switch isolates the

ignition system and fuel pump, releases any locked doors and disables unnecessary electrical systems. The system can be

reset by pressing down the flexible cover on the top of the switch.

• NOTE: The doors will not unlock if the IFS switch is tripped when the ignition switch is in position '0'.

Page 1694 of 2490

P a

rts List

The fuel level sensor is mounte d on the fuel tank vertical face and reacts to level changes via a float and pivot which is

connected to a potentiometer. As the fuel level drops the resistance increases.

The fuel level sensor can be serviced without removing the tank.

It e

m

Par

t

Number

De

scr

iption

1—Lockin

g rin

g

2—Fue

l

level sensor

3—Seal

Fuel

Level Sensor

Page 1695 of 2490

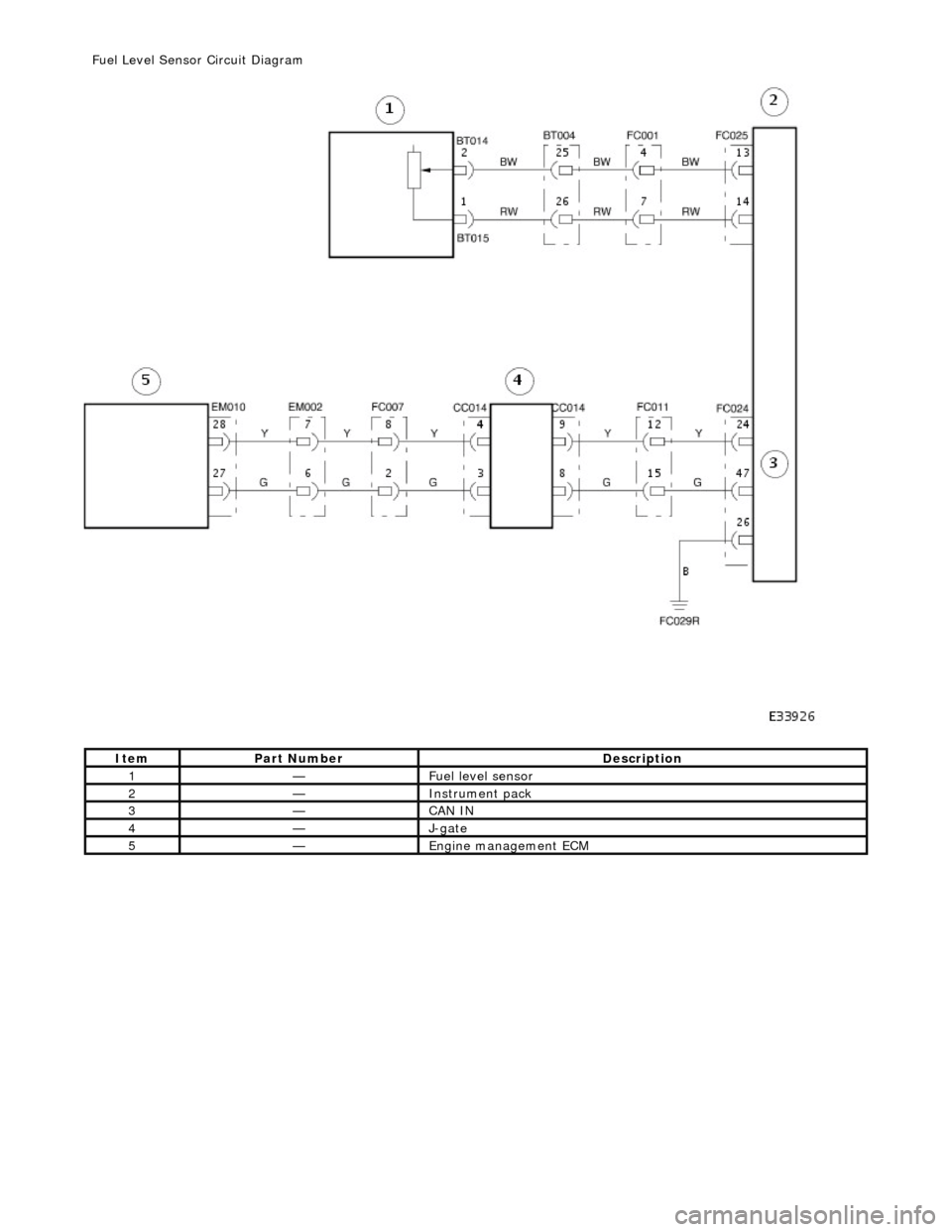

It

em

Par

t Number

De

scription

1—Fue

l level sensor

2—Instrument pack

3—CAN IN

4—J-

gate

5—Engine

management ECM

F

uel Level Sensor Circuit Diagram