sensor JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1976 of 2490

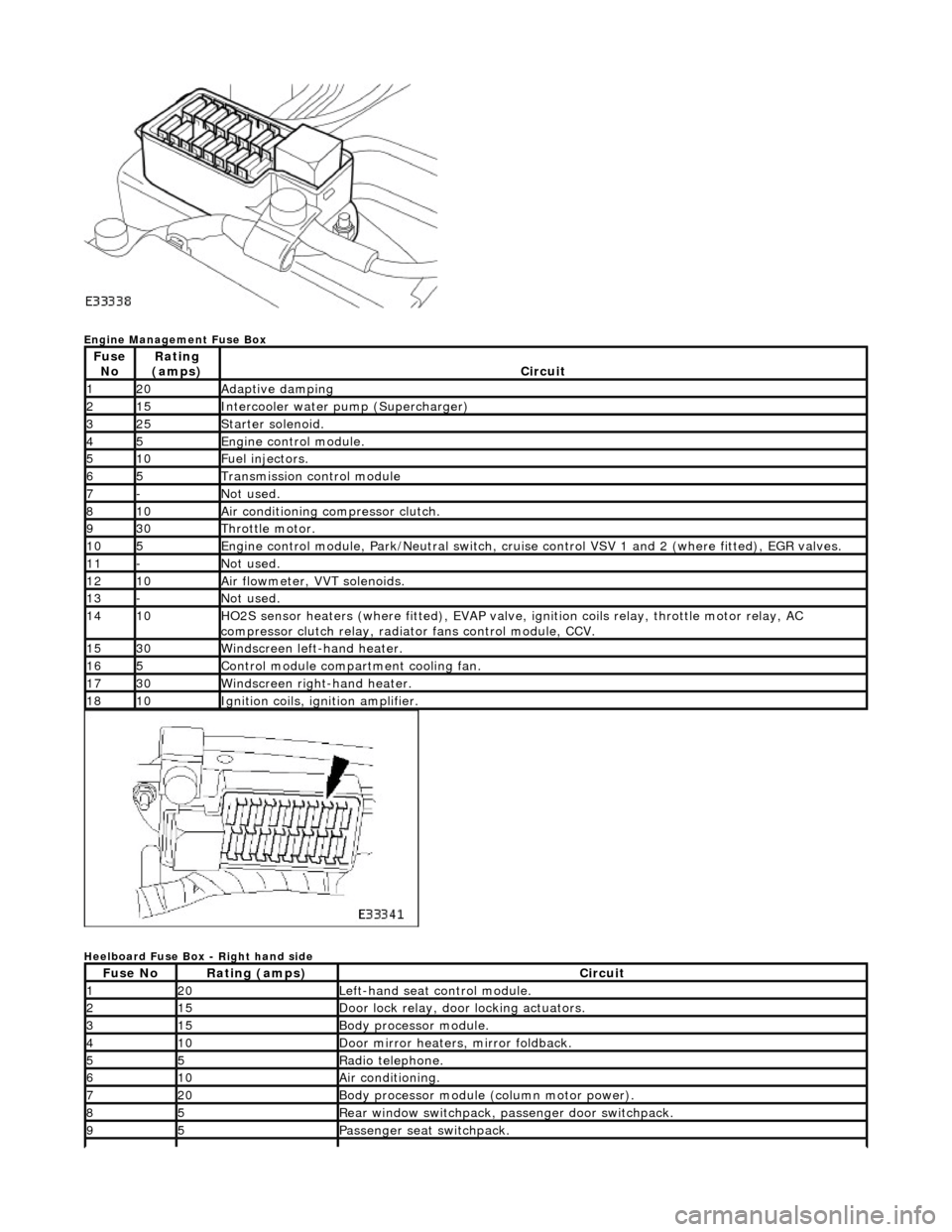

Engine Management Fuse Box

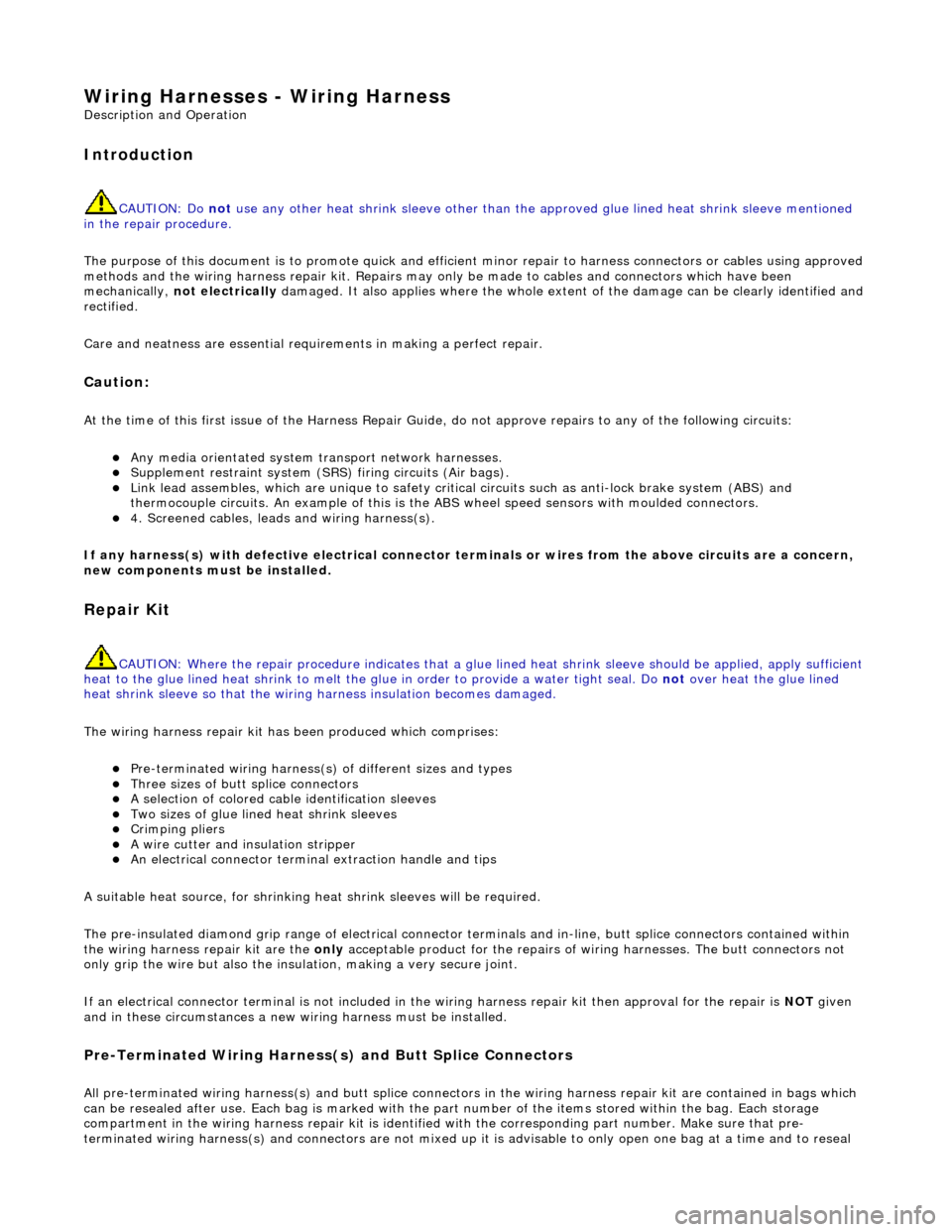

Heelboard Fuse Box - Right hand side

Fuse NoRating

(amps)Circuit

120Adaptive damping

215Intercooler water pump (Supercharger)

325Starter solenoid.

45Engine control module.

510Fuel injectors.

65Transmission control module

7-Not used.

810Air conditioning compressor clutch.

930Throttle motor.

105Engine control module, Park/Neutr al switch, cruise control VSV 1 and 2 (where fitted), EGR valves.

11-Not used.

1210Air flowmeter, VVT solenoids.

13-Not used.

1410HO2S sensor heaters (where fitted ), EVAP valve, ignition coils relay, throttle motor relay, AC

compressor clutch relay, radi ator fans control module, CCV.

1530Windscreen left-hand heater.

165Control module compartment cooling fan.

1730Windscreen right-hand heater.

1810Ignition coils, ignition amplifier.

Fuse NoRating (amps)Circuit

120Left-hand seat control module.

215Door lock relay, door locking actuators.

315Body processor module.

410Door mirror heaters, mirror foldback.

55Radio telephone.

610Air conditioning.

720Body processor module (column motor power).

85Rear window switchpack, passenger door switchpack.

95Passenger seat switchpack.

Page 1989 of 2490

Wiring Harnesses - Wiring Harness

Description and Operation

Introduction

CAUTION: Do not use any other heat shrink sleeve other than the approved glue lined heat shrink sleeve mentioned

in the repair procedure.

The purpose of this document is to promote quick and efficient minor repair to harness connectors or cables using approved

methods and the wiring harness repair kit. Repairs may only be made to cables and connectors which have been

mechanically, not electrically damaged. It also applies wher e the whole extent of the damage can be clearly identified and

rectified.

Care and neatness are essential requir ements in making a perfect repair.

Caution:

At the time of this first issue of the Harness Repair Guide, do not approve re pairs to any of the following circuits:

Any media orientated system transport network harnesses. Supplement restraint system (SRS) firing circuits (Air bags). Link lead assembles, which are unique to safety critical circuits such as anti-lock brake system (ABS) and

thermocouple circuits. An example of this is the ABS wheel speed sensors with moulded connectors.

4. Screened cables, leads and wiring harness(s).

If any harness(s) with defective electrical connector te rminals or wires from the above circuits are a concern,

new components must be installed.

Repair Kit

CAUTION: Where the repair procedure indica tes that a glue lined heat shrink sleeve should be applied, apply sufficient

heat to the glue lined heat shrink to melt the glue in order to provide a water tight seal. Do not over heat the glue lined

heat shrink sleeve so that the wiring harness insulation becomes damaged.

The wiring harness repair kit has been produced which comprises:

Pre-terminated wiring harness(s) of different sizes and types Three sizes of butt splice connectors A selection of colored cable identification sleeves Two sizes of glue lined heat shrink sleeves Crimping pliers A wire cutter and insulation stripper An electrical connector terminal extraction handle and tips

A suitable heat source, fo r shrinking heat shrink sleeves will be required.

The pre-insulated diamond grip range of el ectrical connector terminals and in-line, butt splice connectors contained within

the wiring harness repair kit are the only acceptable product for the repairs of wi ring harnesses. The butt connectors not

only grip the wire but also the insu lation, making a very secure joint.

If an electrical connector terminal is not included in the wiring harness repair kit then approval for the repair is NOT given

and in these circumstances a new wi ring harness must be installed.

Pre-Terminated Wiring Harness( s) and Butt Splice Connectors

All pre-terminated wiring harness(s) and butt splice connectors in the wiring harness repair kit are contained in bags which

can be resealed after use. Each bag is marked with the part number of the items stored within the bag. Each storage

compartment in the wiring harness repair kit is identified with the corresponding part number. Make sure that pre-

terminated wiring harness(s) and connectors are not mixed up it is advisable to only open one bag at a time and to reseal

Page 2077 of 2490

Installation

All vehicles

Remove the retaining screw.

10. With the aid of another tech nician, lower the headliner.

11. With the aid of another techni cian, remove the headliner.

12. NOTE: Left-hand shown, right-hand similar.

Detach the anti-theft sensors.

13. NOTE: Left-hand shown, right-hand similar.

Remove the anti-t heft sensors.

1. Disconnect the electrical connector.

1. NOTE: Left-hand shown, right-hand similar.

Page 2078 of 2490

Install the anti-theft sensors. 1. Connect the electrical connector.

2. NOTE: Left-hand shown, right-hand similar.

Attach the anti-theft sensors.

3. CAUTION: With the aid of an other technician, support the

headliner.

Install the headliner.

4. With the aid of another tech nician, raise the headliner.

5. CAUTION: Support the headliner to ensure it is not folded or creased during installation.

• NOTE: Left-hand shown, right-hand similar.

Install the headliner retaining trims.

Install the retaining screw.

6. NOTE: Left-hand shown, right-hand similar.

Attach the screw cover.

Page 2113 of 2490

Rear View Mirrors - Auto-Dimming Interior Mirror

Removal and Installation

Removal

Installation

1.

Remove roof console for access and disconnect interior mirror

harness multiplugs. Refer to 76.13.69.90.

2. Remove upper cover from mirror stem.

3. Remove rain sensor unit. Refer to Section 501.16.

4. CAUTION: When removing mirror from base, care must

be exercised to ensure that base is not detached from windshield.

Applying firm downward pre ssure, remove mirror assembly

from base.

1. Position mirror at bottom of base and apply firm upward

pressure to fully seat and secure in position.

2. Install upper cover to mirror stem.

3. Position roof console at head er and connect mirror harness

multiplugs.

4. Install rain sensor unit. Refer to Section 501.16.

5. Install roof console. Refer to 76.13.69.

Page 2118 of 2490

Rear View Mirrors - Interior Mirror

Removal and Installation

Removal

CAUTION: When removing mirror from base, care must be exercised to ensure that base is not detached from

windshield.

Installation

1. Remove upper cover from mirror stem.

2. Remove rain sensor unit. Refer to Section 501.16.

3. Applying firm downward pre ssure, remove mirror assembly

from base.

1. Position mirror at bottom of base and apply firm upward

pressure to fully seat and secure in position.

2. Install rain sensor unit. Refer to Section 501.16.

3. Install upper cover to mirror stem.

Page 2119 of 2490

Rear View Mirrors - Interior Mirror Mounting Block

Removal and Installation

Removal

Installation

1. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Position a protective cover over top of facia.

3. Remove roof console for ac cess. Refer to 76.13.69.90.

4. Remove rain sensor unit. Refer to Section 501.16.

5. Remove mirror from mounting block. Refer to 76.10.51 or

76.10.56 (electrochromic).

6. Apply a suitable solvent around edge of mounting block.

7. Commencing at the top and exercising care to avoid windshield

damage, use a thin plastic knife to ease block free.

8. Using a suitable solvent, clean residual adhesive from block

mounting area.

1. Using masking tape, mark block mounting area on windshield.

2. Apply Permabond F Grade 5 Initiator to mounting area of

windshield.

3. Apply a bead of Permabond F246 to bottom and each vertical

side of block over 2/3 of block height.

Page 2120 of 2490

4. Press mounting block onto marked area and hold in position for one minute.

5. After a period of 15 minutes, remove and discard masking

tape.

6. Using a scraper, carefully re move any excess adhesive.

7. NOTE: The following time is the MINIMUM PERIOD required for

adhesive curing. Failure to allow th is period will result in bonding

failure, necessitating repeat of the complete procedure.

After a further period of at le ast 6 hours, install mirror on

mounting block. Refer to 76.10.51 or 76.10.56.

8. Install roof console. Refer to 76.13.69.90.

9. Install rain sensor unit. Refer to Section 501.16.

10. Remove protective cover from facia.

11. Connect ground cable to batter y terminal and install battery

cover. Refer to 86.15.15.

Page 2248 of 2490

reinforcement.

44. Remove illumination control module.

1. Disconnect illumination control module harness

multiplug.

2. Slide module upwards to release it from facia.

45. Remove captive bolt retaining body processor module harness multiplug and disconnect multiplug.

46. Remove three nuts securing body processor module to facia

and remove module.

47. Turn facia around to fa ce outwards on bench.

48. Remove instrument panel veneer. Refer to 76.47.24.

49. Remove major gauge module. Refer to 88.20.24.

50. Remove and discard instrument panel veneer retaining plastic

inserts from facia.

51. Release in-car sensor/trunk release switch assembly from

facia for access and disconnect trunk release switch harness

Page 2249 of 2490

multiplug.

52. Withdraw in-car sensor from housing and remove

housing/trunk release switch assembly.

53. Remove LH vent/duct assembly from facia.

Remove two screws securing vent/duct assembly to facia

and remove assembly. Remove and discard screw

retaining plastic inserts from facia.

54. WARNING: FOLLOWING DISCONNECTION OF THE

BATTERY, A PERIOD OF AT LEAST ONE MINUTE MUST BE

ALLOWED TO ELAPSE BEFORE ANY WORK IS CARRIED OUT ON

AN AIR BAG MODULE.

Remove passenger air bag depl oyment door for access, and

remove and discard deployment d oor retaining clips from facia.

55. Remove and discard four nuts securing passenger air bag

module to facia.