Light JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 781 of 2490

1. Fit the crankshaft setting peg 303 - 531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Fit and tighten the bolt to secure the setting peg.

12. Remove the damper securing bolt from the crankshaft.

13. Lower the vehicle on the ramp.

14. Fit the camshaft locking tool 303 - 530 to the A-Bank

camshafts, aligning the shafts slightly as necessary.

15. Loosen the bolt which secures the sprocket to the camshaft.

16. Loosen the bolt which secure s VVT unit to the camshaft.

17. Remove the primary ch ain tensioner bolts.

Page 787 of 2490

Installation

2. Remove the tensioner blade.

10. Clean and inspect all relevant components.

1. Fit the chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

2. Fit the retaining / pivot bolt and tighten it to 12-16 Nm.

2. Remove the Tie-Stra p from the chain.

3. Refit the Timing Chain Tensioner - Primary. The camshafts may

need to be turned slightly to pr ovide slack in the chain, on the

tensioner side. Refer to Operation 12.65.55 in this Section.

4. Refit the VVT Bush Carrier As sembly. Refer to Operation

12.65.52 in this Section.

5. Refit the Timing Cover. Refer to Operation 12.65.01 in this

Section.

6. Move the engine compartment co ver from the service position

and connect the gas struts.

7. Remove the paint protection sheets and close the cover.

8. Connect the battery and fit the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 789 of 2490

Installation

from the upper retaining pin.

10. Clean and inspect all relevant components.

1. Fit the chain guide.

The chain guide must be fitted so that the slotted hole is

towards the top, and the raised shoulder to the cylinder

block.

1. Fit the chain guide to the block and locate it onto the upper retaining pin.

2. Fit the retaining bolt an d tighten it to 10-14 Nm.

2. Remove the Tie-Stra p from the chain.

3. Refit the Timing Chain Tensioner - Primary. The camshafts may

need to be turned slightly to pr ovide slack in the chain, on the

tensioner side. Refer to Operation 12.65.54 in this Section.

4. Refit the VVT Bush Carrier As sembly. Refer to Operation

12.65.51 in this Section.

5. Refit the Timing Cover. Refer to Operation 12.65.01 in this

Section.

6. Move the engine compartment co ver from the service position

and connect the gas struts.

7. Remove the paint protection sheets and close the cover.

8. Connect the battery and fit the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 791 of 2490

Installation

from the upper retaining pin.

10. Clean and inspect all relevant components.

1. Fit the chain guide.

The chain guide must be fitted so that the slotted hole is

towards the top, and the raised shoulder to the cylinder

block.

1. Fit the chain guide to the block and locate it onto the upper retaining pin.

2. Fit the retaining bolt an d tighten it to 10-14 Nm.

2. Remove the Tie-Stra p from the chain.

3. Refit the Timing Chain Tensioner - Primary. The camshafts may

need to be turned slightly to pr ovide slack in the chain, on the

tensioner side. Refer to Operation 12.65.55 in this Section.

4. Refit the VVT Bush Carrier As sembly. Refer to Operation

12.65.52 in this Section.

5. Refit the Timing Cover. Refer to Operation 12.65.01 in this

Section.

6. Move the engine compartment co ver from the service position

and connect the gas struts.

7. Remove the paint protection sheets and close the cover.

8. Connect the battery and fit the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 793 of 2490

Installation

2. Remove the tensioner blade.

10. Clean and inspect all relevant components.

1. Fit the chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

2. Fit the retaining / pivot bolt and tighten it to 12-16 Nm.

2. Remove the Tie-Stra p from the chain.

3. Refit the Timing Chain Tensioner - Primary. The camshafts may

need to be turned slightly to pr ovide slack in the chain, on the

tensioner side. Refer to Operation 12.65.54 in this Section.

4. Refit the VVT Bush Carrier As sembly. Refer to Operation

12.65.51 in this Section.

5. Refit the Timing Cover. Refer to Operation 12.65.01 in this

Section.

6. Move the engine compartment co ver from the service position

and connect the gas struts.

7. Remove the paint protection sheets and close the cover.

8. Connect the battery and fit the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 799 of 2490

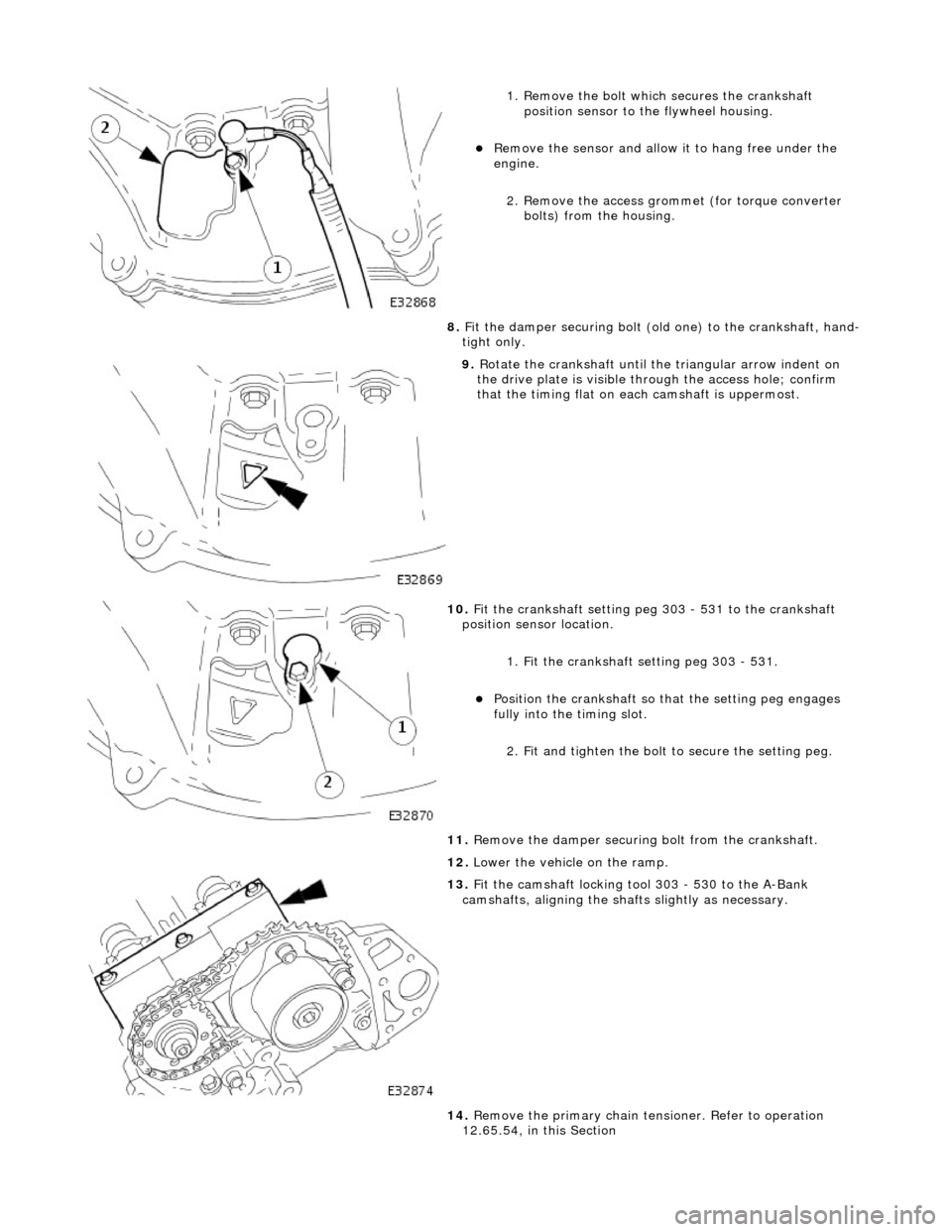

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

8. Fit the damper securing bolt (old one) to the crankshaft, hand-

tight only.

9. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

10. Fit the crankshaft setting peg 303 - 531 to the crankshaft

position sensor location.

1. Fit the crankshaft setting peg 303 - 531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Fit and tighten the bolt to secure the setting peg.

11. Remove the damper securing bolt from the crankshaft.

12. Lower the vehicle on the ramp.

13. Fit the camshaft locking tool 303 - 530 to the B-Bank

camshafts, aligning the shafts slightly as necessary.

14. Loosen the bolt which secures the sprocket to the exhaust

camshaft.

Page 805 of 2490

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

8. Fit the damper securing bolt (old one) to the crankshaft, hand-

tight only.

9. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

10. Fit the crankshaft setting peg 303 - 531 to the crankshaft

position sensor location.

1. Fit the crankshaft setting peg 303 - 531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Fit and tighten the bolt to secure the setting peg.

11. Remove the damper securing bolt from the crankshaft.

12. Lower the vehicle on the ramp.

13. Fit the camshaft locking tool 303 - 530 to the A-Bank

camshafts, aligning the shafts slightly as necessary.

14. Remove the primary chain tens ioner. Refer to operation

12.65.54, in this Section

Page 880 of 2490

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

8. Fit the damper securing bolt (old one) to the crankshaft, hand-

tight only.

9. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

10. Fit the crankshaft setting peg 303 - 531 to the crankshaft

position sensor location.

1. Fit the crankshaft setting peg 303 - 531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Fit and tighten the bolt to secure the setting peg.

11. Remove the damper securing bolt from the crankshaft.

12. Lower the vehicle on the ramp.

13. Fit the camshaft locking tool 303 - 530 to the B-Bank

camshafts, aligning the shafts slightly as necessary.

14. Loosen the bolt which secures the sprocket to the exhaust

camshaft.

Page 886 of 2490

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

8. Fit the damper securing bolt (old one) to the crankshaft, hand-

tight only.

9. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

10. Fit the crankshaft setting peg 303 - 531 to the crankshaft

position sensor location.

1. Fit the crankshaft setting peg 303 - 531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Fit and tighten the bolt to secure the setting peg.

11. Remove the damper securing bolt from the crankshaft.

12. Lower the vehicle on the ramp.

13. Fit the camshaft locking tool 303 - 530 to the A-Bank

camshafts, aligning the shafts slightly as necessary.

14. Remove the primary chain tens ioner. Refer to operation

12.65.54, in this Section

Page 909 of 2490

1. Remove the nut which secures the selector lever to

the transmission cross shaft.

2. Remove the selector cable abutment bolts.

3. Disconnect the selector arm from the cross shaft.

67. Loosen the bolt which secures the engine rear mounting

rubber to the transmission.

68. Position a transmission jack e.g. Epco V100 and raise the

support bed of the jack to take the weight of the transmission.

Fit and adjust the chains to secure the transmission to the jack.

69. Remove the engine rear mounting assembly.

Remove the mounting centre bolt.

Remove the four bolts which secure the crossmember to

the body.

Remove the crossmember and mounting assembly.

70. Release the engine and tran smission assembly from the

engine compartment.

Take the weight of the engine / transmission with the

hoist and move it towards th e front of the vehicle.

Lower the transmission jack slightly to release the

securing chains. Remove the ja ck from below the vehicle.