fuel sensor JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1205 of 2490

TP se

nsor to ECM sensing circuits

('1' or '2') short circuit to high

voltage

TP sensor

failure

Throttl

e motor disconnected

Th

rottle motor to ECM drive circuits

short circuit or open circuit

Throttl

e motor failure

Throttl

e assembly failure

Test

K. . F

or throttle motor circuit

tests,GO to Pinpoint Test T.

. For

throttle body i

nformation,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

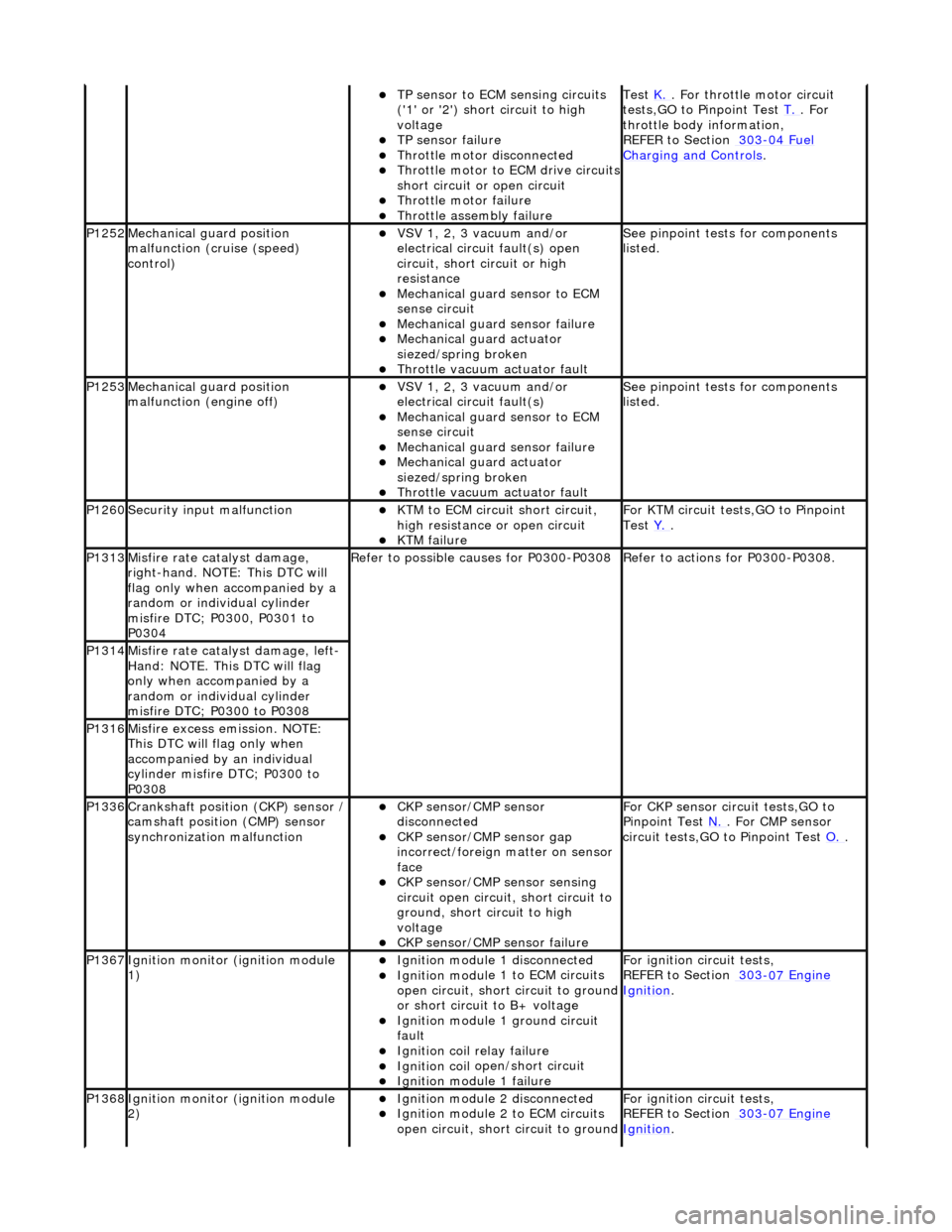

P1252Mec

hanical gu

ard position

malfunction (cruise (speed)

control)

VSV 1, 2, 3 v

acuum and/or

electrical circuit fault(s) open

circuit, short circuit or high

resistance

Mechanica

l guard sensor to ECM

sense circuit

Mechanica

l guard sensor failure

Mechanica

l guard actuator

siezed/spring broken

Throttl

e vacuum actuator fault

Se

e pinpoint tests for components

listed.

P1253Mec

hanical gu

ard position

malfunction (engine off)

VSV 1, 2, 3 v

acuum and/or

electrical circuit fault(s)

Mechanica

l guard sensor to ECM

sense circuit

Mechanica

l guard sensor failure

Mechanica

l guard actuator

siezed/spring broken

Throttl

e vacuum actuator fault

Se

e pinpoint tests for components

listed.

P1260Se

curity input malfunction

K

TM to ECM circuit short circuit,

high resistance or open circuit

KTM failu

re

F

or KTM circuit tests,GO to Pinpoint

Test Y.

.

P1313M

isfire rate catalyst damage,

right-hand. NOTE: This DTC will

flag only when accompanied by a

random or individual cylinder

misfire DTC; P0300, P0301 to

P0304

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

P1314Mi

sfire rate catalyst damage, left-

Hand: NOTE. This DTC will flag

only when accompanied by a

random or individual cylinder

misfire DTC; P0300 to P0308

P1316M

isfire excess emission. NOTE:

This DTC will flag only when

accompanied by an individual

cylinder misfire DTC; P0300 to

P0308

P1336Cranksh

aft position

(CKP) sensor /

camshaft position (CMP) sensor

synchronization malfunction

CKP s

ensor/CMP sensor

disconnected

CKP sensor/CM

P sensor gap

incorrect/foreign matter on sensor

face

CKP s

ensor/CMP sensor sensing

circuit open circuit, short circuit to

ground, short circuit to high

voltage

CKP s

ensor/CMP sensor failure

F

or CKP sensor circ

uit tests,GO to

Pinpoint Test N.

. For CM

P sensor

circuit tests,GO to Pinpoint Test O.

.

P1367Ignit

ion monitor (ignition module

1)

Ignition modu

le

1 disconnected

Ignition modul

e 1 to ECM circuits

open circuit, short circuit to ground

or short circuit to B+ voltage

Ignition modul

e 1 ground circuit

fault

Ignition coil

relay failure

Ignition coil

open/short circuit

Ignition modul

e 1 failure

F

or ignition circuit tests,

REFER to Section 303

-07

Engine

Ignition.

P1368Ignit

ion monitor (ignition module

2)

Ignition modu

le

2 disconnected

Ignition modul

e 2 to ECM circuits

open circuit, short circuit to ground

F

or ignition circuit tests,

REFER to Section 303

-07

Engine

Ignition.

Page 1207 of 2490

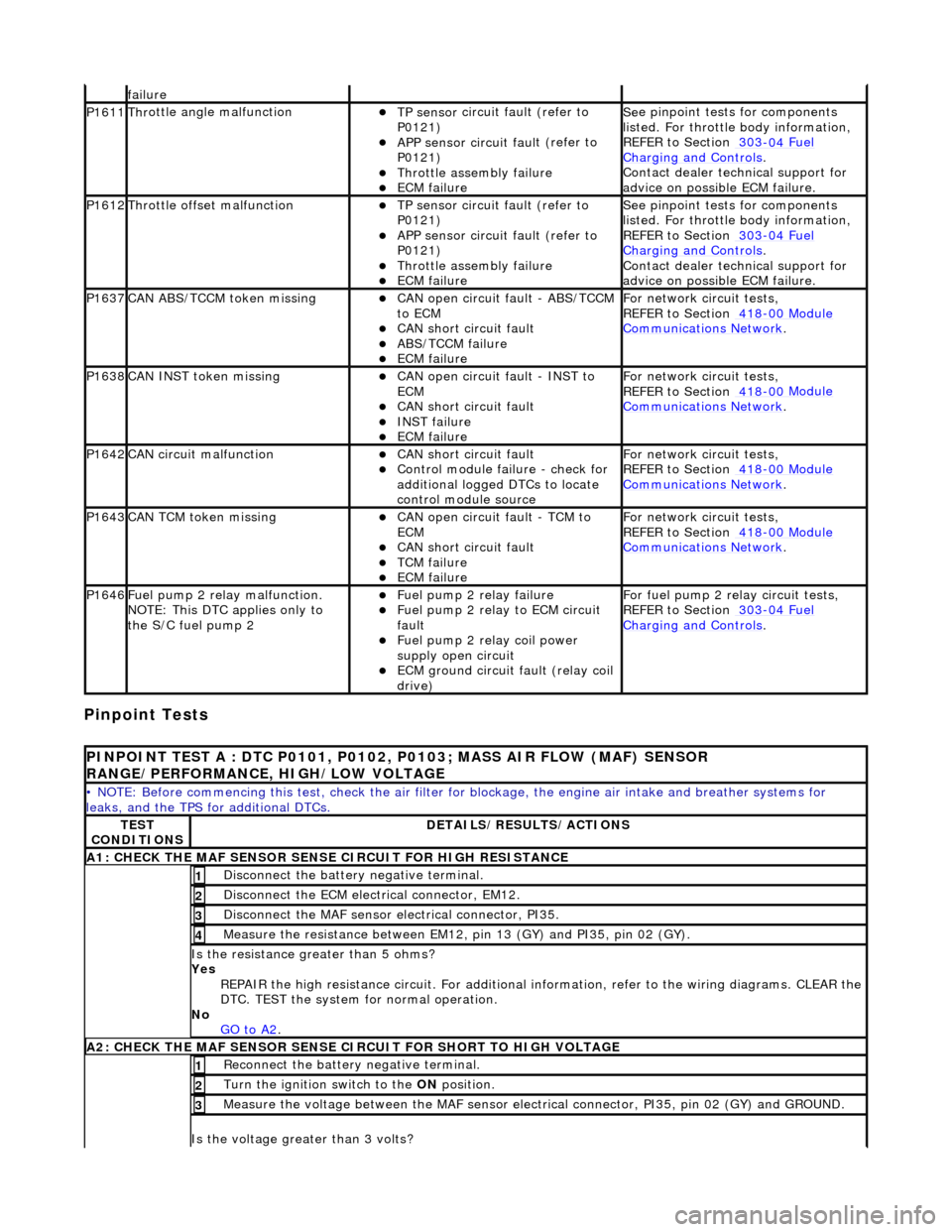

Pinpoint Tests

f

ailure

P1611Thr

ottle angle malfunction

TP sensor

circuit fault (refer to

P0121)

APP sensor circuit faul

t (refer to

P0121)

Throttl

e assembly failure

ECM failu

re

Se

e pinpoint tests for components

listed. For throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Contact deal

er technical support for

advice on possible ECM failure.

P1612Throttl

e offset malfunction

TP sensor

circuit fault (refer to

P0121)

APP sensor circuit faul

t (refer to

P0121)

Throttl

e assembly failure

ECM failu

re

Se

e pinpoint tests for components

listed. For throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Contact deal

er technical support for

advice on possible ECM failure.

P1637CAN AB

S/TCCM token missing

CAN

open circuit fault - ABS/TCCM

to ECM

CAN s

hort circuit fault

ABS/TCCM failu

re

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1638CAN INST token missingCAN

open circuit fault - INST to

ECM

CAN s

hort circuit fault

INST

failure

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1642CAN c

ircuit malfunction

CAN s

hort circuit fault

Control modul

e failure - check for

additional logged DTCs to locate

control module source

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1643CAN TC

M token missing

CAN

open circuit fault - TCM to

ECM

CAN s

hort circuit fault

TCM failure

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1646F

uel pump 2 relay malfunction.

NOTE: This DTC applies only to

the S/C fuel pump 2

F

uel pump 2 relay failure

F

uel pump 2 relay to ECM circuit

fault

F

uel pump 2 relay coil power

supply open circuit

ECM ground circuit faul

t (relay coil

drive)

F

or fuel pump 2 relay circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P

INPOINT TEST A : DTC P0101, P0102, P0103; MASS AIR FLOW (MAF) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

•

NOTE: Before commencing this

test, check the air filter for blockage, the engine air inta ke and breather systems for

leaks, and the TPS for additional DTCs.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE MAF SENSOR SENS

E CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM12.

2

Di

sconnect the MAF sensor electrical connector, PI35.

3

Meas

ure the resistance between EM12, pin 13 (GY) and PI35, pin 02 (GY).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to A2

.

A2: CHECK

THE MAF SENSOR SENSE CI

RCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between the MAF sensor electrical connector, PI35, pin 02 (GY) and GROUND.

3

Is th

e voltage greater than 3 volts?

Page 1223 of 2490

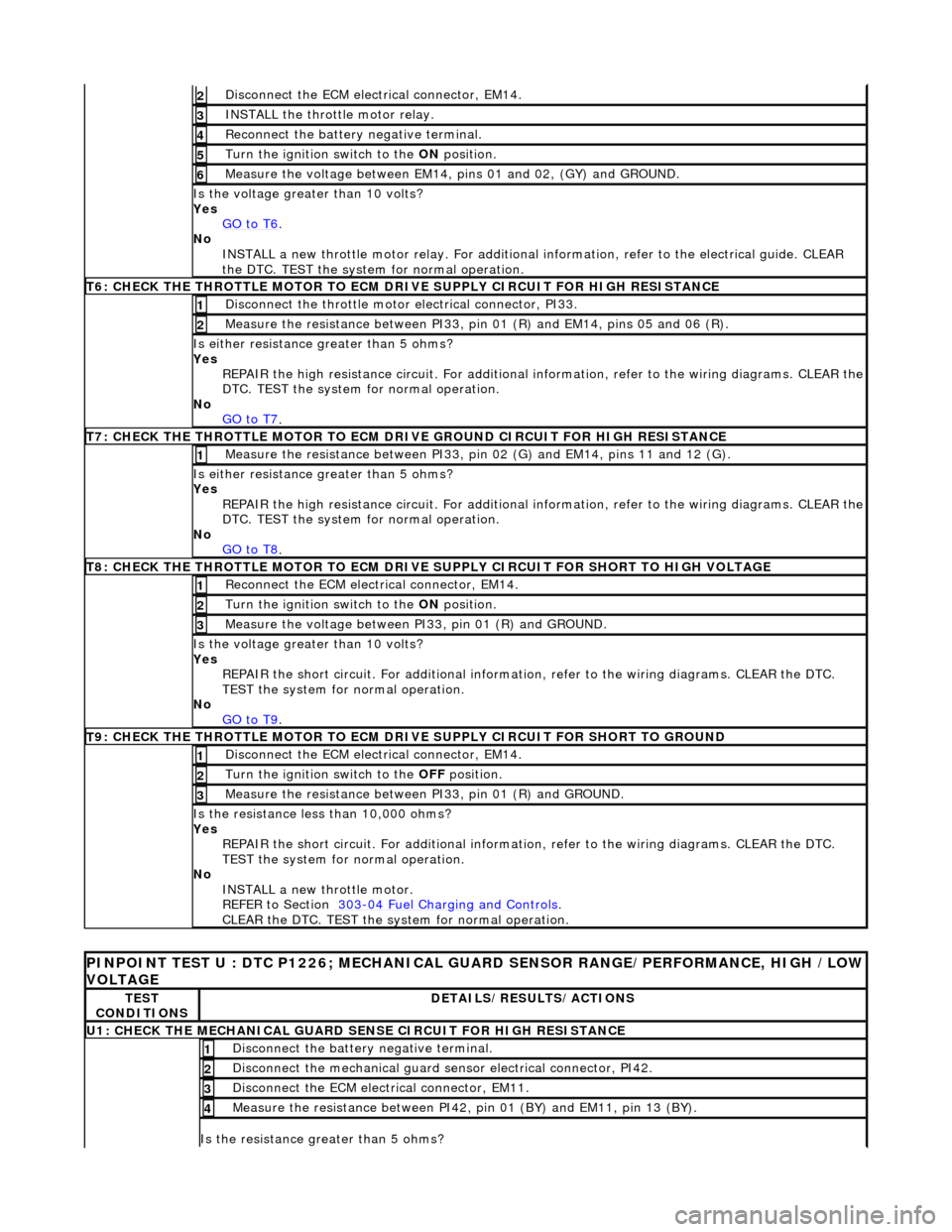

D

isconnect the ECM electrical connector, EM14.

2

IN

STALL the throttle motor relay.

3

R

econnect the battery negative terminal.

4

Turn the ignition swi

tch to the

ON position.

5

Measure the

voltage between EM14, pi

ns 01 and 02, (GY) and GROUND.

6

Is the vol

tage greater than 10 volts?

Yes GO to T6

.

No

INSTALL a new throttle motor relay. For additional information, refer to the electrical guide. CLEAR

the DTC. TEST the system for normal operation.

T

6: CHECK THE THROTTLE MOTOR TO ECM DRIVE SUPPLY CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the throttle motor electrical connector, PI33.

1

Meas

ure the resistance between PI33, pi

n 01 (R) and EM14, pins 05 and 06 (R).

2

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T7

.

T

7: CHECK THE THROTTLE MOTOR TO ECM DRIVE GROUND CIRCUIT FOR HIGH RESISTANCE

Meas

ure the resistance between PI33, pin

02 (G) and EM14, pins 11 and 12 (G).

1

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T8

.

T

8: CHECK THE THROTTLE MOTOR TO ECM DRIVE SU

PPLY CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the ECM electrical connector, EM14.

1

Turn the ignition swi

tch to the

ON position.

2

M

easure the voltage between PI33, pin 01 (R) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to T9

.

T

9: CHECK THE THROTTLE MOTOR TO ECM DRIVE SUPPLY CIRCUIT FOR SHORT TO GROUND

D

isconnect the ECM electrical connector, EM14.

1

Turn the ignition swi

tch to the

OFF position.

2

Meas

ure the resistance between PI33, pin 01 (R) and GROUND.

3

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new throttle motor.

REFER to Section 303

-0

4 Fuel Charging and Controls

.

CLEAR t

he DTC. TEST the system for normal operation.

P

INPOINT TEST U : DTC P1226; MECHANICAL

GUARD SENSOR RANGE/PERFORMANCE, HIGH /LOW

VOLTAGE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

U1: CHECK T

HE MECHANICAL GUARD SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the mechanical guard sensor electrical connector, PI42.

2

D

isconnect the ECM electrical connector, EM11.

3

Me

asure the resistance between PI42, pin 01 (BY) and EM11, pin 13 (BY).

4

Is th

e resistance greater than 5 ohms?

Page 1224 of 2490

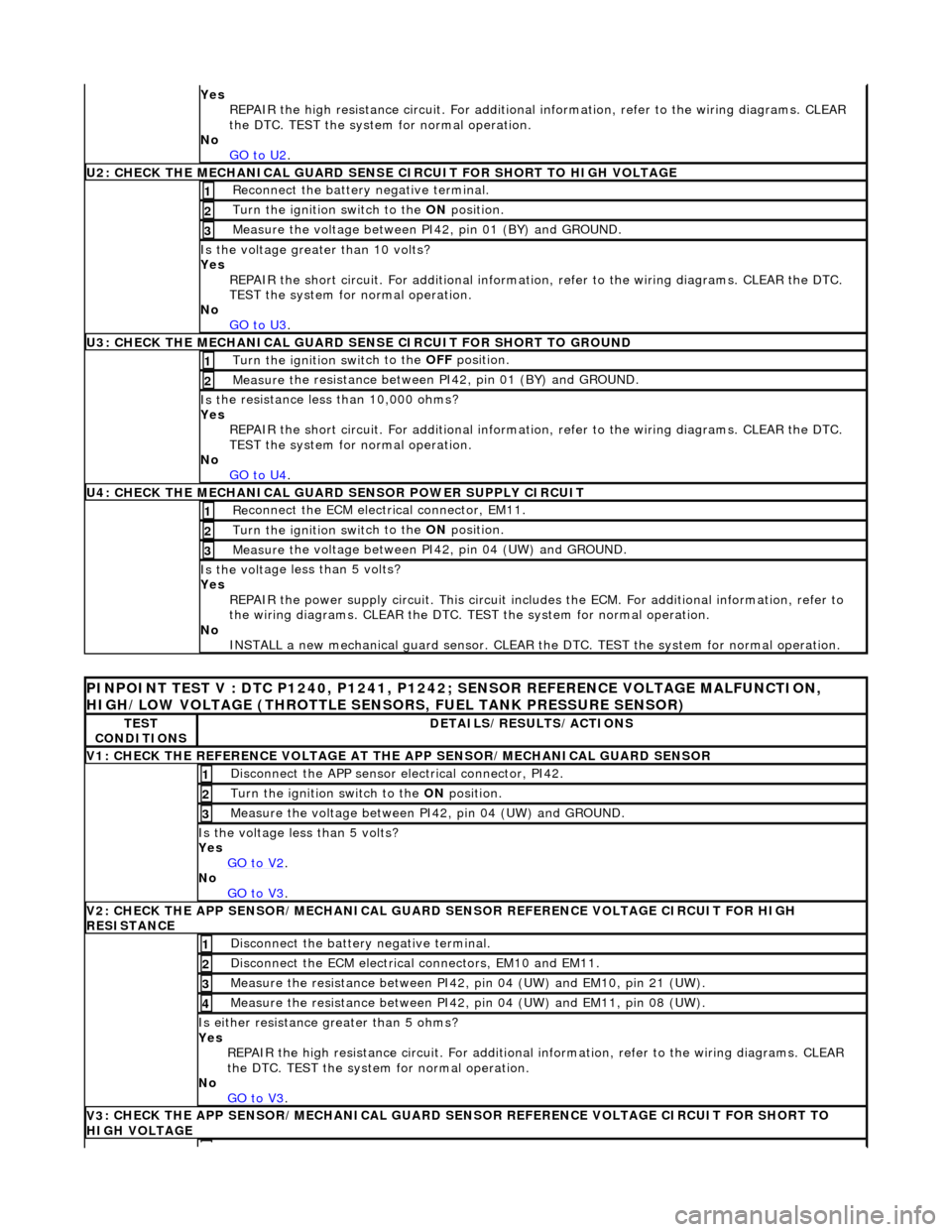

Yes

R

EPAIR the high resistance circui

t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to U2

.

U2: CHECK T H

E MECHANICAL GUARD SENSE

CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between PI42, pin 01 (BY) and GROUND.

3

Is the volt

age greater than 10 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to U3

.

U3: CHECK T H

E MECHANICAL GUARD SE

NSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between PI42, pin 01 (BY) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to U4

.

U4: CHECK THE MEC H

ANICAL GUARD SENSOR POWER SUPPLY CIRCUIT

Re

conn

ect the ECM electrical connector, EM11.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between PI42, pin 04 (UW) and GROUND.

3

Is th

e volt

age less than 5 volts?

Yes

REPAIR the power supply circuit. This circuit includ es the ECM. For additional information, refer to

the wiring diagrams. CLEAR the DTC. TE ST the system for normal operation.

No INSTALL a new mechanical guard sensor. CLEAR the DTC. TEST the system for normal operation.

PINPO

INT TEST V : DTC P1240, P1241, P1242

; SENSOR REFERENCE VOLTAGE MALFUNCTION,

HIGH/LOW VOLTAGE (THROTTLE SENSORS, FUEL TANK PRESSURE SENSOR)

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

V

1

: CHECK THE REFERENCE VOLTAGE AT TH

E APP SENSOR/MECHANICAL GUARD SENSOR

Disc

onnect the APP sensor electrical connector, PI42.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure the voltage between PI

42,

pin 04 (UW) and GROUND.

3

Is th

e volt

age less than 5 volts?

Yes GO to V2

.

No

GO to V3

.

V2

: CHECK THE APP SENSOR/MECHA

NICAL GUARD SENSOR REFERENCE VOLTAGE CIRCUIT FOR HIGH

RESISTANCE

Di sc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connectors, EM10 and EM11.

2

Me

asure

the resistance between PI42, pin 04 (UW) and EM10, pin 21 (UW).

3

Me

asure

the resistance between PI42, pin 04 (UW) and EM11, pin 08 (UW).

4

Is either resi

stance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to V3

.

V3

: CHECK THE APP SENSOR/MECHA

NICAL GUARD SENSOR REFERENCE VOLTAGE CIRCUIT FOR SHORT TO

HIGH VOLTAGE

Page 1225 of 2490

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

Measure the

voltage between PI

42, pin 04 (UW) and GROUND.

3

Is th

e voltage greater than 6 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to V4

.

V

4: CHECK THE APP SENSOR/MECHA

NICAL GUARD SENSOR REFERENCE VOLTAGE CIRCUIT FOR SHORT TO

GROUND

Turn the ignition swi

tch to the

OFF position.

1

Meas

ure the resistance between PI42, pin 04 (UW) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to V5

.

V

5: CHECK THE REFERENCE VOLTAGE AT THE THROTTLE POSITION SENSOR

Re

connect the ECM electrical connectors, EM10 and EM11.

1

Disc

onnect the TP sensor electrical connector, PI06.

2

Turn the ignition swi

tch to the ON

position.

3

Measure the

voltage between PI

06, pin 04 (UW) and GROUND.

4

Is th

e voltage less than 5 volts?

Yes GO to V6

.

No

GO to V7

.

V

6: CHECK THE THROTTLE POSITION SENSOR REFE

RENCE VOLTAGE CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

D

isconnect the ECM electrical connectors, EM10 and EM11.

2

Me

asure the resistance between PI06, pin 04 (UW) and EM10, pin 21 (UW).

3

Me

asure the resistance between PI06, pin 04 (UW) and EM11, pin 08 (UW).

4

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to V7

.

V

7: CHECK THE THROTTLE POSITION SENSOR REFERENCE VOLTAGE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Turn the ignition swi

tch to the ON

position.

1

Measure the

voltage between PI

06, pin 04 (UW) and GROUND.

2

Is th

e voltage greater than 6 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No

GO to V8

.

V

8: CHECK THE THROTTLE POSITION SENSOR REFE

RENCE VOLTAGE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between PI06, pin 04 (UW) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to V9

.

V

9: CHECK THE REFERENCE VOLTAGE AT THE FUEL TANK PRESSURE SENSOR

Di

sconnect the FTP sensor electrical connector, FP01.

1

Re

connect the ECM electrical connectors, EM10 and EM11.

2

Turn the ignition swi

tch to the ON

position.

3

Page 1226 of 2490

Measure the voltage between FP 01

, pin 03 (UW) and GROUND.

4

Is th

e volt

age less than 5 volts?

Yes GO to V10

.

No

CHECK

for DTCs associated with

TP sensor, APP/mechanical guard sensor, or FTP sensor. INSTALL a

new sensor as indicated by the DTC. CLEAR the DTC. TEST the system for normal operation.

V

10: CHECK

THE FUEL TANK PRESSURE SENSOR

REFERENCE VOLTAGE CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connectors, EM10 and EM11.

2

Measure t

he resistance between FP01,

pin 03 (UW) and EM10, pin 21 (UW).

3

Measure t

he resistance between FP01,

pin 03 (UW) and EM11, pin 08 (UW).

4

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to V11

.

V11: CHECK

THE FUEL TANK PRESSURE SENSOR REFE

RENCE VOLTAGE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure the voltage between FP 01

, pin 03 (UW) and GROUND.

3

Is th

e volt

age greater than 6 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to V12

.

V12: CHECK

THE FUEL TANK PRESSURE SENSOR

REFERENCE VOLTAGE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between

FP01, pin 03 (UW) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No CHECK for DTCs associated with TP sensor, APP/mechanical guard sensor, or FTP sensor. INSTALL a

new sensor as indicated by the DTC. CLEAR the DTC. TEST the system for normal operation.

PI

NPOINT TEST W : DTC P1243; SENSOR RE

FERENCE GROUND MALFUNCTION (THROTTLE

SENSORS, FUEL TANK PRESSURE SENSOR, ECT, IAT, IAT 2 SENSORS)

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

W1: CHECK THE SENSO

R

REFERENCE

GROUND AT THE THROTTLE SENSORS

Disc

onne

ct the TP sensor electrical connector, PI06.

1

Meas

ure t

he resistance between PI06, pin 01 (BG) and GROUND.

2

Is th

e res

istance greater than 5 ohms?

Yes GO to W2

.

No

GO to W3

.

W2: CHECK TH

E THROTTLE SENSOR REFERENCE GROUND CIRCUIT FOR HIGH RESISTANCE

D

i

sconnect the ECM electrical connectors, EM10 and EM11.

1

Meas

ure t

he resistance between PI06,

pin 01 (BG) and EM10, pin 20 (BG).

2

Measure t

he resistance between PI06,

pin 01 (BG) and EM11, pin 12 (BG).

3

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to W3

.

W3: CHECK THE SENSO R

REFERENCE GROUND AT

THE APP SENSOR/MECHANICAL GUARD SENSOR

Page 1227 of 2490

Di

sconnect the APP sensor/mechanical guard sensor electrical connector, PI42.

1

Re

connect the ECM electrical connectors, EM10 and EM11.

2

Meas

ure the resistance between PI42, pin 02 (BG) and GROUND.

3

Is th

e resistance greater than 5 ohms?

Yes GO to W4

.

No

GO to W5

.

W4: CHECK THE APP

SENSOR/MECHANICAL GUARD SE

NSOR REFERENCE GROUND CIRCUIT FOR HIGH

RESISTANCE

D

isconnect the ECM electrical connectors, EM10 and EM11.

1

Meas

ure the resistance between PI42,

pin 02 (BG) and EM10, pin 20 (BG).

2

Meas

ure the resistance between PI42,

pin 02 (BG) and EM11, pin 12 (BG).

3

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to W5

.

W5: CHECK THE SENSO

R REFERENCE GROUND AT THE FUEL TANK PRESSURE SENSOR

Di

sconnect the FTP sensor electrical connector, FP01.

1

Re

connect the ECM electrical connectors, EM10 and EM11.

2

Meas

ure the resistance between

FP01, pin 01 (BG) and GROUND.

3

Is th

e resistance greater than 5 ohms?

Yes GO to W6

.

No

GO to W7

.

W6: CHECK THE FUEL

TANK PRESSURE SENSOR RE

FERENCE GROUND CIRCUIT FOR HIGH RESISTANCE

D

isconnect the ECM electrical connectors, EM10 and EM11.

1

Meas

ure the resistance between FP01,

pin 01 (BG) and EM10, pin 20 (BG).

2

Meas

ure the resistance between FP01,

pin 01 (BG) and EM11, pin 12 (BG).

3

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to W7

.

W7: CHECK THE SENSO

R REFERENCE GROUND AT THE ECT SENSOR

Re

connect the ECM electrical connectors, EM10 and EM11.

1

D

isconnect the ECT sensor electrical connector, PI04.

2

Meas

ure the resistance between PI04, pin 01 (BG) and GROUND.

3

Is th

e resistance greater than 5 ohms?

Yes GO to W8

.

No

GO to W9

.

W8: CHECK THE ECT SEN

SOR REFERENCE

GROUND CIRCUIT FOR HIGH RESISTANCE

D

isconnect the ECM electrical connectors, EM10 and EM11.

1

Meas

ure the resistance between PI04,

pin 01 (BG) and EM10, pin 20 (BG).

2

Meas

ure the resistance between PI04,

pin 01 (BG) and EM11, pin 12 (BG).

3

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to W9

.

W9: CHECK THE SENSO

R REFERENCE GR

OUND AT THE IAT SENSOR (MAF)

Re

connect the ECM electrical connectors, EM10 and EM11.

1

Di

sconnect the IAT sensor (MAF) electrical connector, PI35.

2

Meas

ure the resistance between PI35, pin 04 (BG) and GROUND.

3

Page 1233 of 2490

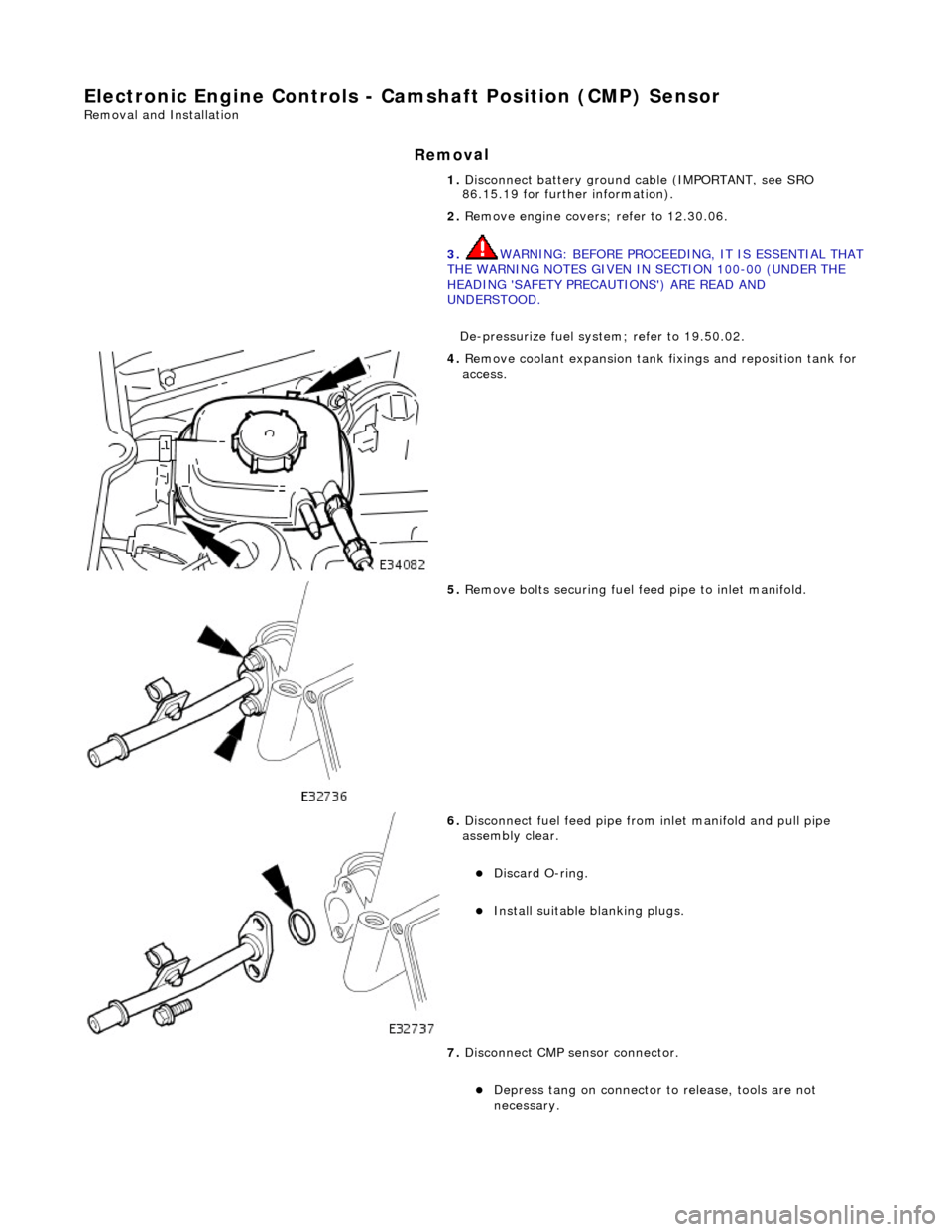

E

lectronic Engine Controls - Ca

mshaft Position (CMP) Sensor

Re

moval and Installation

Remov

al

1.

Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Remove engine covers ; refer to 12.30.06.

3. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

De-pressurize fuel system; refer to 19.50.02.

4. R

emove coolant expansion tank fixings and reposition tank for

access.

5. R

emove bolts securing fuel fe

ed pipe to inlet manifold.

6. Di

sconnect fuel feed pipe from inlet manifold and pull pipe

assembly clear.

Di

scard O-ring.

Inst

all suitable blanking plugs.

7. Disconnect CMP sensor connector.

De

press tang on connector to release, tools are not

necessary.

Page 1235 of 2490

3. Conne

ct CMP sensor connector.

4. Connect

fuel feed pipe to inlet manifold.

R

emove blanking plugs.

Install and lubricate new O-r

ing.

5. Install

bolts securing fuel feed

pipe to the inlet manifold.

6. Install coolant expansion tank.

Page 1242 of 2490

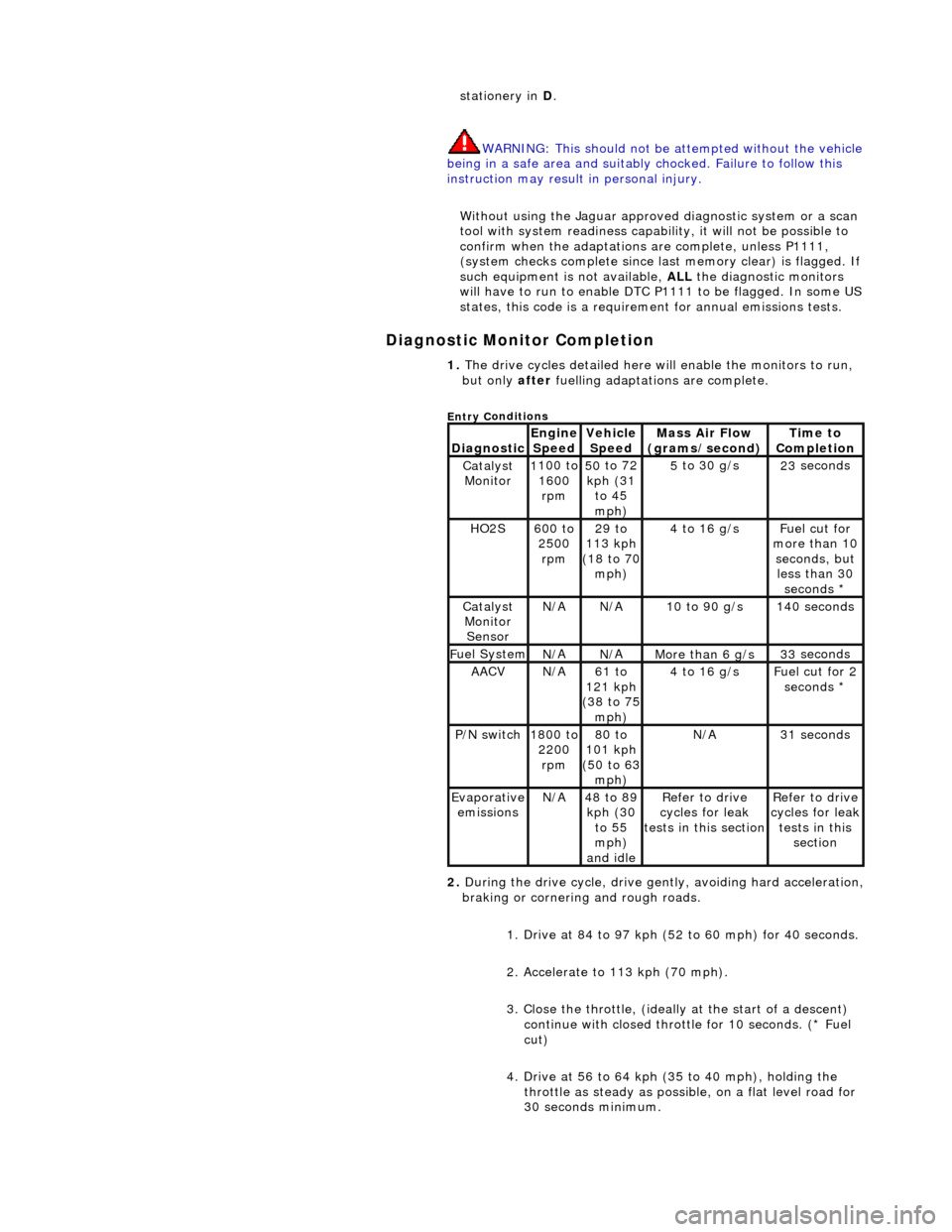

Diagnostic Monitor Comp

letion

stat

ionery in

D.

WARNING: This should not be attempted without the vehicle

being in a safe area and suitably chocked. Failure to follow this

instruction may result in personal injury.

Without using the Jaguar approved diagnostic system or a scan

tool with system readiness capability, it will not be possible to

confirm when the adaptations are complete, unless P1111,

(system checks complete since last memory clear) is flagged. If

such equipment is not available, ALL the diagnostic monitors

will have to run to enable DTC P1111 to be flagged. In some US

states, this code is a requirem ent for annual emissions tests.

1. The dri v

e cycles detailed here w

ill enable the monitors to run,

but only after fuelling adaptations are complete.

Entry C

onditions

Di

agno

stic

Engine

S p

eed

Ve

h

icle

Speed

Mass Air Flow

(gra ms/sec

ond)

Ti

m

e to

Completion

Catalyst Monitor1 100

to

1600 rpm

50 to

72

kph (31 to 45

mph)

5 to

30 g/s

23

se

conds

HO2S6

00 t

o

2500 rpm

29 to

113 kph

(18 to 70

mph)

4 to

16 g/s

F

u

el cut for

more than 10 seconds, but less than 30 seconds *

Catalyst Monitor SensorN/ AN/A10

to 90 g/s

14

0

seconds

F

u

el System

N/

AN/AMore than 6 g/s33 se

conds

AACVN/

A61 to

121 kph

(38 to 75

mph)

4 to

16 g/s

F

u

el cut for 2

seconds *

P /

N switch

1

800

to

2200 rpm

80 to

101 kph

(50 to 63

mph)

N/ A31 se

conds

Evaporative

em is

sions

N/

A48 to

89

kph (30 to 55

mph)

and idle

R e

fer to drive

cycles for leak

tests in this section

Re

fer to drive

cycles for leak

tests in this section

2. During the drive cycle, drive gent ly, avoiding hard acceleration,

braking or cornering and rough roads.

1. Drive at 84 to 97 kph (52 to 60 mph) for 40 seconds.

2. Accelerate to 113 kph (70 mph).

3. Close the throttle, (ideally at the start of a descent)

continue with closed throttle for 10 seconds. (* Fuel

cut)

4. Drive at 56 to 64 kph (35 to 40 mph), holding the throttle as steady as possib le, on a flat level road for

30 seconds minimum.