heater JAGUAR X308 1998 2.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1834 of 2490

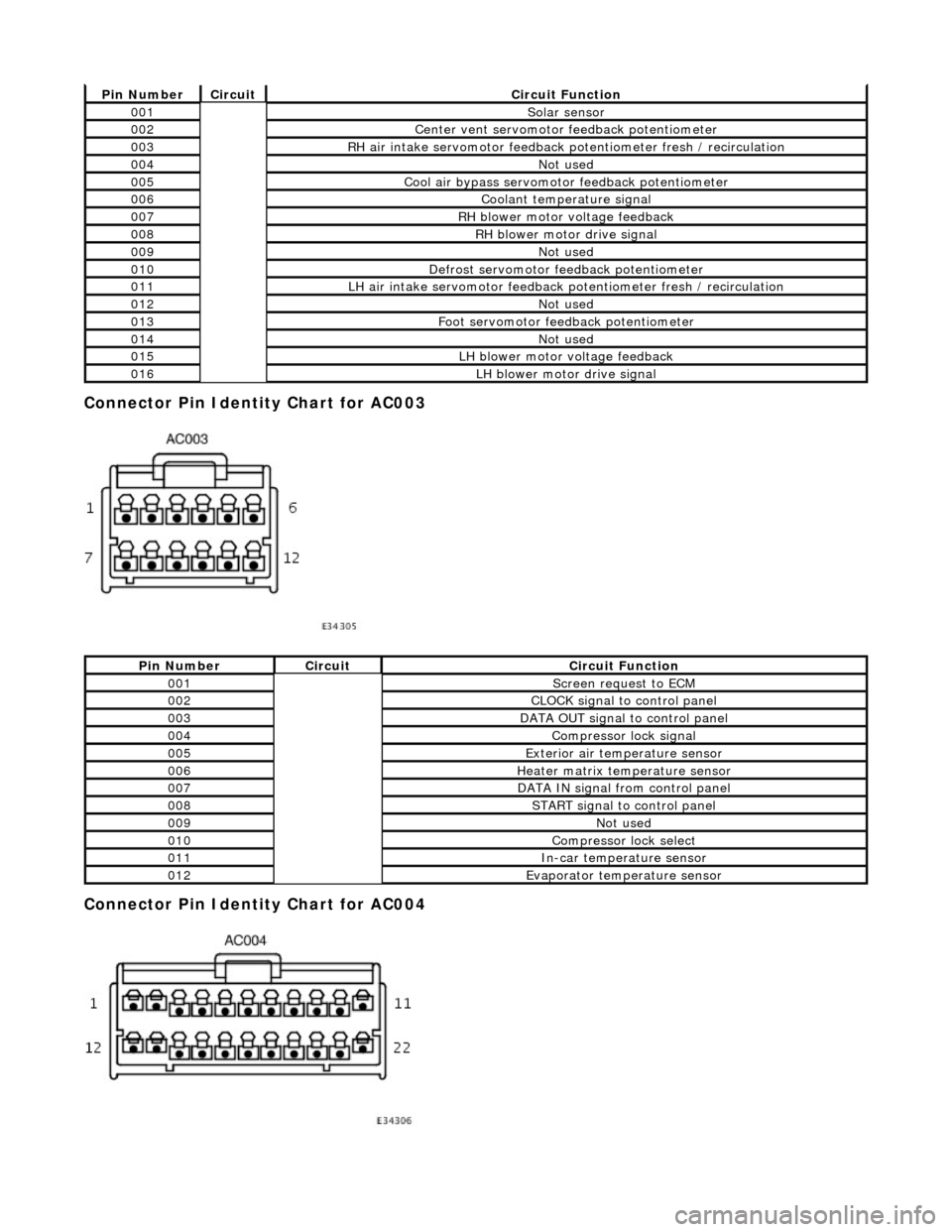

Connector Pin Identity Chart for AC003

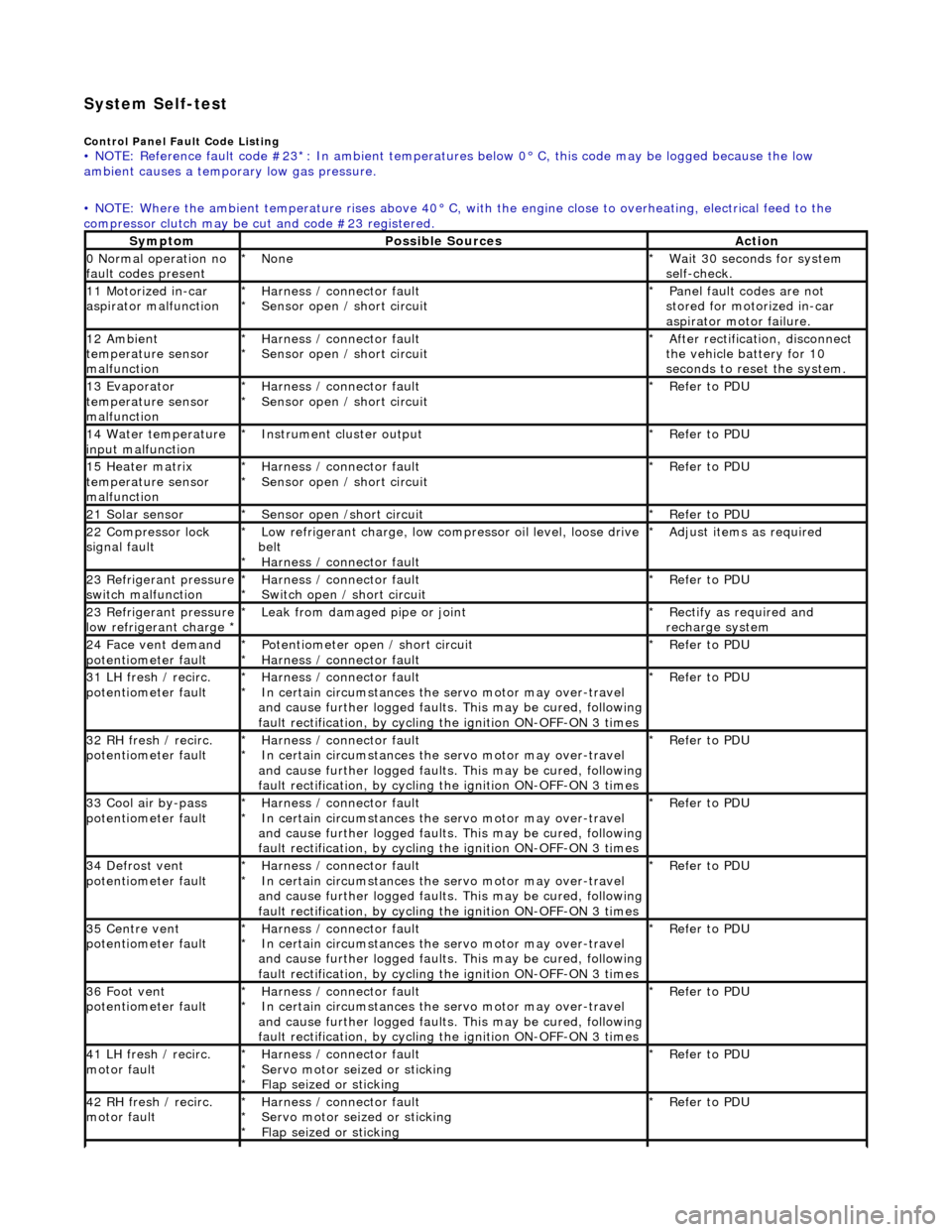

Connector Pin Identity Chart for AC004

Pin NumberCircuitCircuit Function

001Solar sensor

002Center vent servomotor feedback potentiometer

003RH air intake servomotor feedback potentiometer fresh / recirculation

004Not used

005Cool air bypass servomotor feedback potentiometer

006Coolant temperature signal

007RH blower motor voltage feedback

008RH blower motor drive signal

009Not used

010Defrost servomotor feedback potentiometer

011LH air intake servomotor feedback potentiometer fresh / recirculation

012Not used

013Foot servomotor feedback potentiometer

014Not used

015LH blower motor voltage feedback

016LH blower motor drive signal

Pin NumberCircuitCircuit Function

001Screen request to ECM

002CLOCK signal to control panel

003DATA OUT signal to control panel

004Compressor lock signal

005Exterior air temperature sensor

006Heater matrix temperature sensor

007DATA IN signal from control panel

008START signal to control panel

009Not used

010Compressor lock select

011In-car temperature sensor

012Evaporator temperature sensor

Page 1837 of 2490

System Self-test

Control Panel Fault Code Listing • NOTE: Reference fault code #23*: In ambient temperatures below 0° C, this code may be logged because the low

ambient causes a tempor ary low gas pressure.

• NOTE: Where the ambient temperature rises above 40° C, with the engine close to overheating, electrical feed to the

compressor clutch may be cut and code #23 registered.

SymptomPossible SourcesAction

0 Normal operation no

fault codes presentNone

*Wait 30 seconds for system

self-check.

*

11 Motorized in-car

aspirator malfunctionHarness / connector fault

Sensor open / short circuit

*

*Panel fault codes are not

stored for motorized in-car

aspirator motor failure.

*

12 Ambient

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*After rectification, disconnect

the vehicle battery for 10

seconds to reset the system.

*

13 Evaporator

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*Refer to PDU

*

14 Water temperature

input malfunctionInstrument cl uster output

*Refer to PDU

*

15 Heater matrix

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*Refer to PDU

*

21 Solar sensorSensor open /short circuit

*Refer to PDU

*

22 Compressor lock

signal faultLow refrigerant charge, low compressor oil level, loose drive

belt Harness / connector fault

*

*Adjust items as required

*

23 Refrigerant pressure

switch malfunctionHarness / connector fault

Switch open / short circuit

*

*Refer to PDU

*

23 Refrigerant pressure

low refrigerant charge * Leak from damaged pipe or joint

*Rectify as required and

recharge system

*

24 Face vent demand

potentiometer faultPotentiometer open / short circuit

Harness / connector fault

*

*Refer to PDU

*

31 LH fresh / recirc.

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

32 RH fresh / recirc.

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

33 Cool air by-pass

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

34 Defrost vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

35 Centre vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

36 Foot vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

41 LH fresh / recirc.

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

42 RH fresh / recirc.

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

Page 1838 of 2490

System Self-test

Other conditions which may exist but will NOT log fault codes:

Associated Faults

System Self-test

Panel Communication Check

The panel communication check veri fies the inputs and outputs from the control panel to the A/CCM.

Actuator Check Procedure

The system self test procedure drives all the actuator moto rs, to check their operation. If an actuator is operating

incorrectly or operating outside of its limi ts then a fault code will be present.

Before commencing with the actuator check procedure, ensure the ca r is operating under normal conditions.

1. 1. Switch ignition OFF.

2. 2. Press and hold the RECIRC and AUTO buttons simult aneously, switch ignition ON and run the engine.

3. 3. All the control panel LEDs and all LCD segments will flas h on and off. Any function LED indicator which does not

flash on / off suggests a fault condition within that area of the panel or, with the LED.

пЃ¬Any LCD element which fails to flash on / off indicates a fault within the display element or panel.

4. 4. Press AUTO

43 Cool air by-pass

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

43 Cool Air by-pass

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

44 Defrost vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

45 Centre vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

46 Foot vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

SymptomPossible SourcesAction

No heatAirlock in system.

*Refer section 303-03 for fill / bleed procedure

*

Heater water pump inoperative

Coolant flow valve stuck closed

*

*Check operation and circuit

*

Faulty engine coolant thermostat

*Renew as required

*

One vent failing to open / closeBroken linkage.

*Renew as required

*

Poor airflowBlower motors - incorrect operation

*Check operation and circuit

*

ItemCheck LEDCondition

IgnitionDefrostIGN input at 12V, check LED is illuminated

AuxiliaryFaceAUX input at 12V, check LED is illuminated

ClockFeet / faceClock input normal, check LED is illuminated

Start inputFootStart input normal, check LED is illuminated

Data outScreen / footData out input normal, check LED is illuminated

Dimmer overrideRecirc.Dimmer override input ON, check LED is illuminated

Page 1840 of 2490

Control Components - Air Discharge Temperature Sensor

Removal and Installation

Removal

Installation

1.

Remove heater matrix for access; refer to 82.25.10.

2. Detach sensor connector from heater / cooler assembly.

пЃ¬Disconnect connector.

3. Detach clip and sensor from evaporator.

пЃ¬Remove clip.

4. Remove sensor from heat er / cooler assembly.

пЃ¬Remove clip.

пЃ¬Lever case apart sufficient enough to withdraw sensor

through aperture.

1. Installation is a reversal of the removal procedure.

Page 1842 of 2490

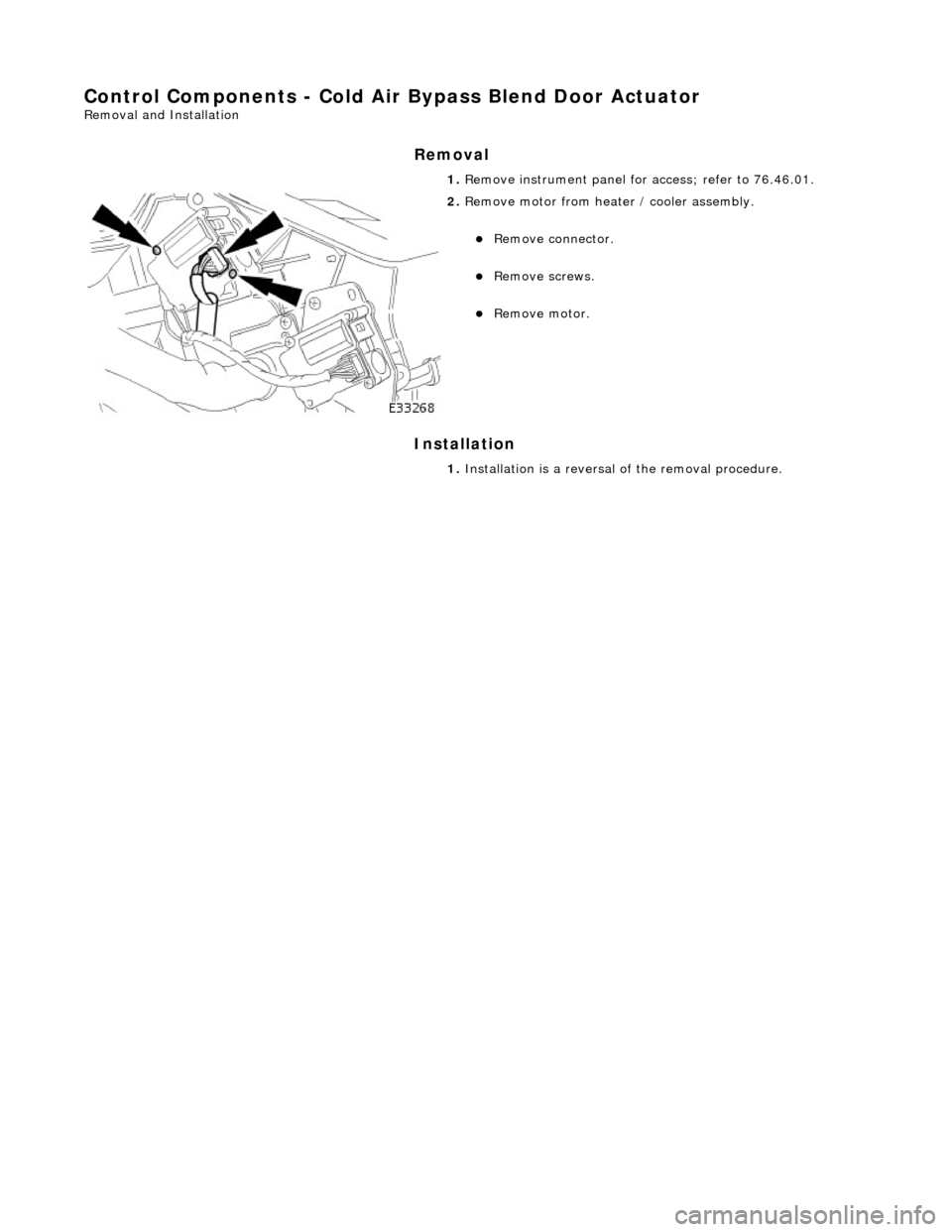

Control Components - Cold Air Bypass Blend Door Actuator

Removal and Installation

Removal

Installation

1.

Remove instrument panel for access; refer to 76.46.01.

2. Remove motor from heater / cooler assembly.

пЃ¬Remove connector.

пЃ¬Remove screws.

пЃ¬Remove motor.

1. Installation is a reversal of the removal procedure.

Page 1844 of 2490

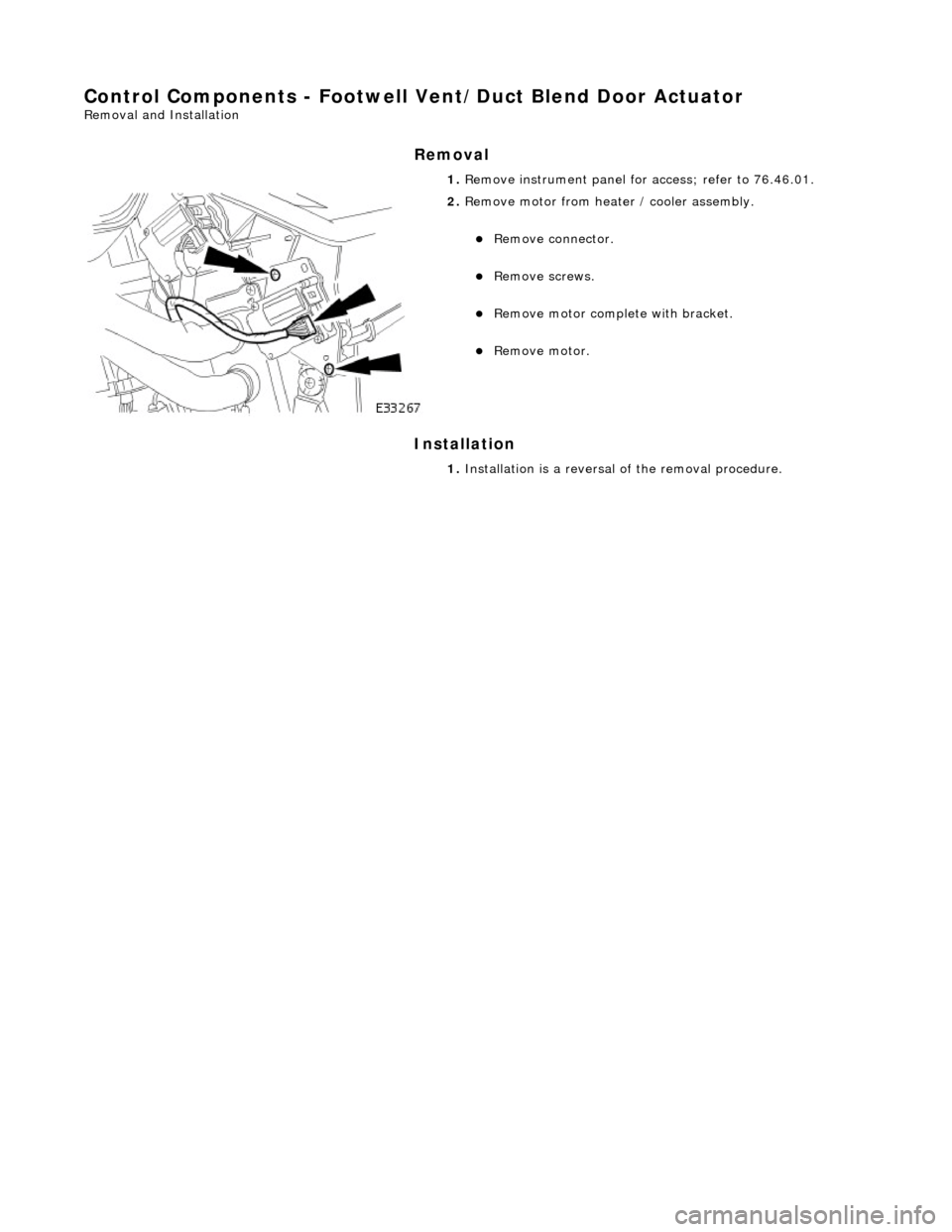

Control Components - Footwell Vent/Duct Blend Door Actuator

Removal and Installation

Removal

Installation

1.

Remove instrument panel for access; refer to 76.46.01.

2. Remove motor from heater / cooler assembly.

пЃ¬Remove connector.

пЃ¬Remove screws.

пЃ¬Remove motor complete with bracket.

пЃ¬Remove motor.

1. Installation is a reversal of the removal procedure.

Page 1847 of 2490

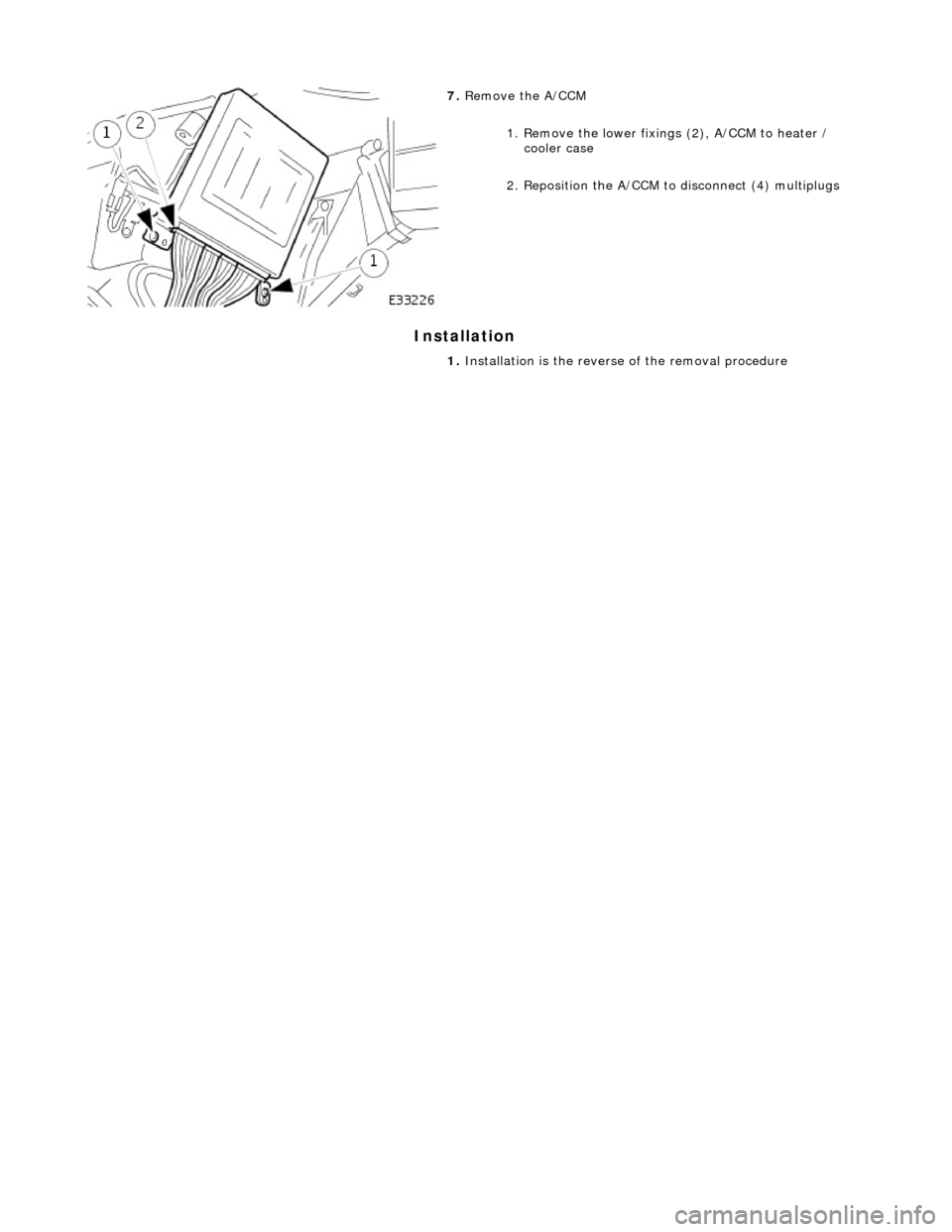

Installation

7. Remove the A/CCM

1. Remove the lower fixings (2), A/CCM to heater / cooler case

2. Reposition the A/CCM to disconnect (4) multiplugs

1. Installation is the revers e of the removal procedure

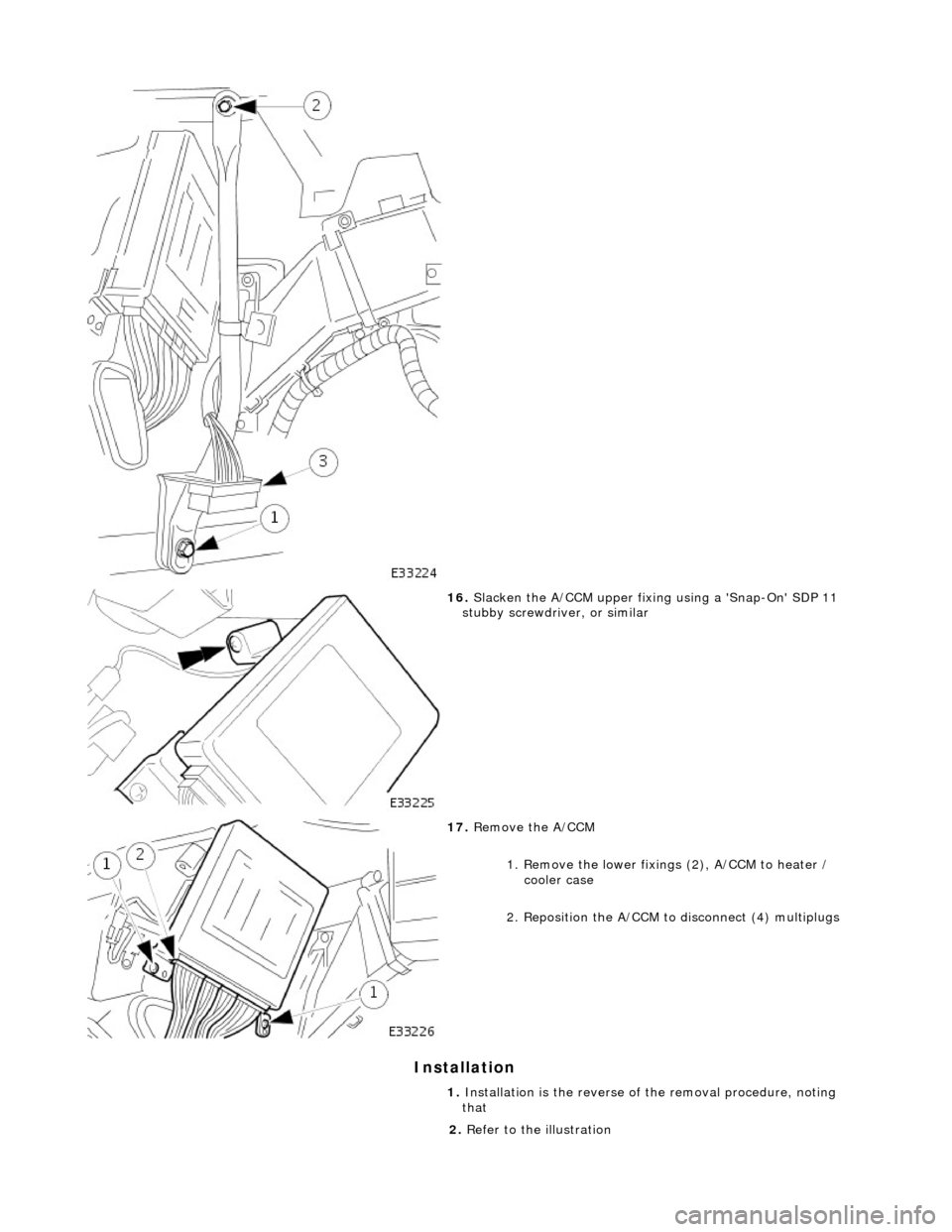

Page 1850 of 2490

Installation

16. Slacken the A/CCM upper fixing using a 'Snap-On' SDP 11

stubby screwdriver, or similar

17. Remove the A/CCM

1. Remove the lower fixings (2), A/CCM to heater / cooler case

2. Reposition the A/CCM to disconnect (4) multiplugs

1. Installation is the reverse of the removal procedure, noting

that

2. Refer to the illustration

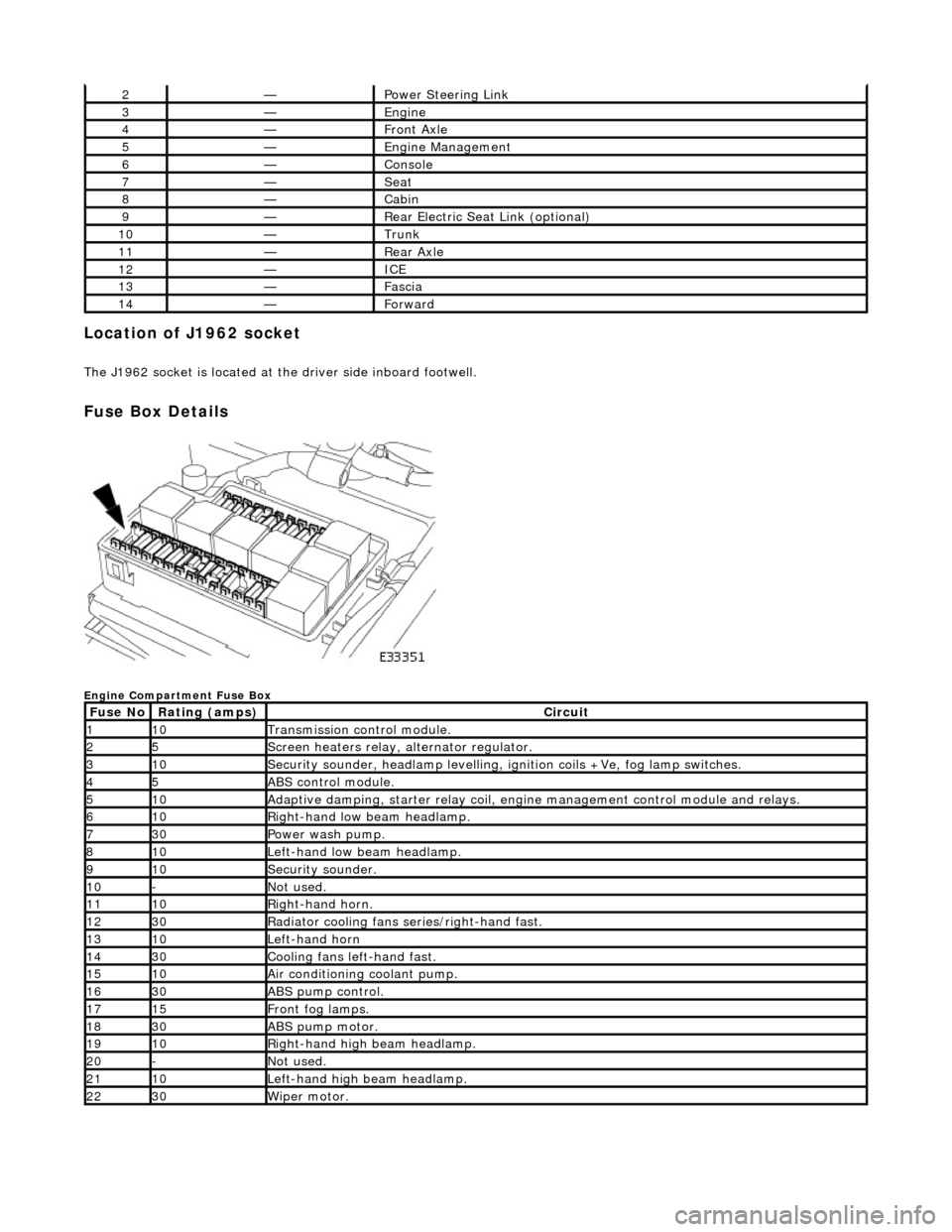

Page 1975 of 2490

Location of J1962 socket

The J1962 socket is located at the driver side inboard footwell.

Fuse Box Details

Engine Compartment Fuse Box

2—Power Steering Link

3—Engine

4—Front Axle

5—Engine Management

6—Console

7—Seat

8—Cabin

9—Rear Electric Seat Link (optional)

10—Trunk

11—Rear Axle

12—ICE

13—Fascia

14—Forward

Fuse NoRating (amps)Circuit

110Transmission control module.

25Screen heaters relay, alternator regulator.

310Security sounder, headlamp levelling, ignition coils +Ve, fog lamp switches.

45ABS control module.

510Adaptive damping, starter relay coil, engine management control module and relays.

610Right-hand low beam headlamp.

730Power wash pump.

810Left-hand low beam headlamp.

910Security sounder.

10-Not used.

1110Right-hand horn.

1230Radiator cooling fans series/right-hand fast.

1310Left-hand horn

1430Cooling fans left-hand fast.

1510Air conditioning coolant pump.

1630ABS pump control.

1715Front fog lamps.

1830ABS pump motor.

1910Right-hand high beam headlamp.

20-Not used.

2110Left-hand high beam headlamp.

2230Wiper motor.

Page 1976 of 2490

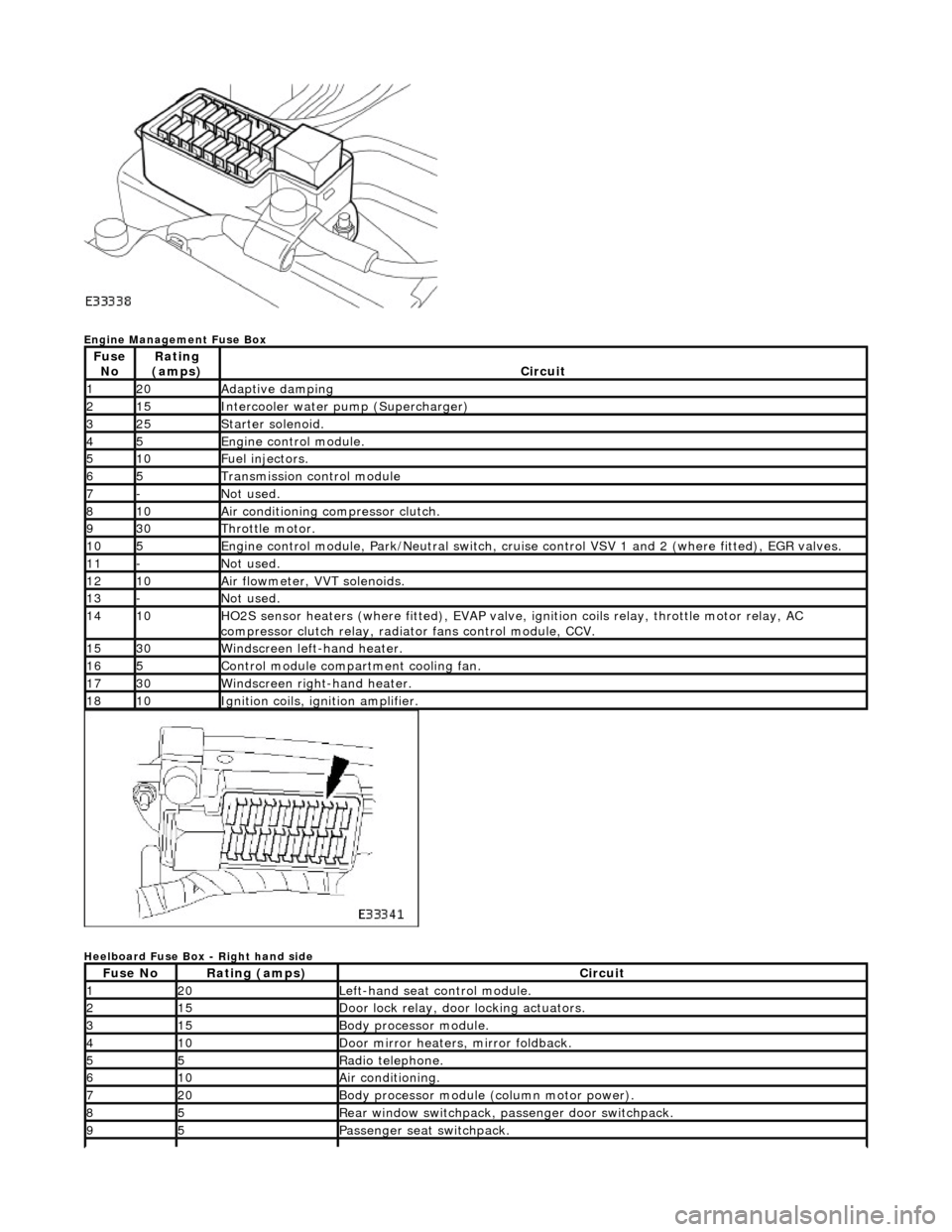

Engine Management Fuse Box

Heelboard Fuse Box - Right hand side

Fuse NoRating

(amps)Circuit

120Adaptive damping

215Intercooler water pump (Supercharger)

325Starter solenoid.

45Engine control module.

510Fuel injectors.

65Transmission control module

7-Not used.

810Air conditioning compressor clutch.

930Throttle motor.

105Engine control module, Park/Neutr al switch, cruise control VSV 1 and 2 (where fitted), EGR valves.

11-Not used.

1210Air flowmeter, VVT solenoids.

13-Not used.

1410HO2S sensor heaters (where fitted ), EVAP valve, ignition coils relay, throttle motor relay, AC

compressor clutch relay, radi ator fans control module, CCV.

1530Windscreen left-hand heater.

165Control module compartment cooling fan.

1730Windscreen right-hand heater.

1810Ignition coils, ignition amplifier.

Fuse NoRating (amps)Circuit

120Left-hand seat control module.

215Door lock relay, door locking actuators.

315Body processor module.

410Door mirror heaters, mirror foldback.

55Radio telephone.

610Air conditioning.

720Body processor module (column motor power).

85Rear window switchpack, passenger door switchpack.

95Passenger seat switchpack.