heater JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2175 of 2490

Installation

12. Disconnect seat motor and squab heater harness multiplugs.

13. Slacken and remove four bolts securing seat frame to floor

and remove seat from vehicle.

1. Position seat in vehi cle and fit but do not tighten four bolts

securing frame to floor.

2. Fit and fully tighten the two bolt s securing squab frame to rear

panel.

3. Fully tighten bolts securing frame to floor.

4. Connect seat motor and squab heater harness multiplugs.

5. Position side trim panel and carefully pass seat belt lower

anchor through escutcheon and trim aperture.

6. Fit and tighten seat belt anchor securing bolt.

7. Position side trim and push do wnwards to engage keyhole on

squab outer fixing.

8. Position trim lower end over st ud and fit and fully seat new

scrivet.

9. Position seat cushion for access and connect cushion heater

harness multiplug.

10. Push seat cushion rearwards to engage it in rear securing

lugs.

Page 2191 of 2490

Glass, Frames and Mechanisms - Rear Door Window Glass

Removal and Installation

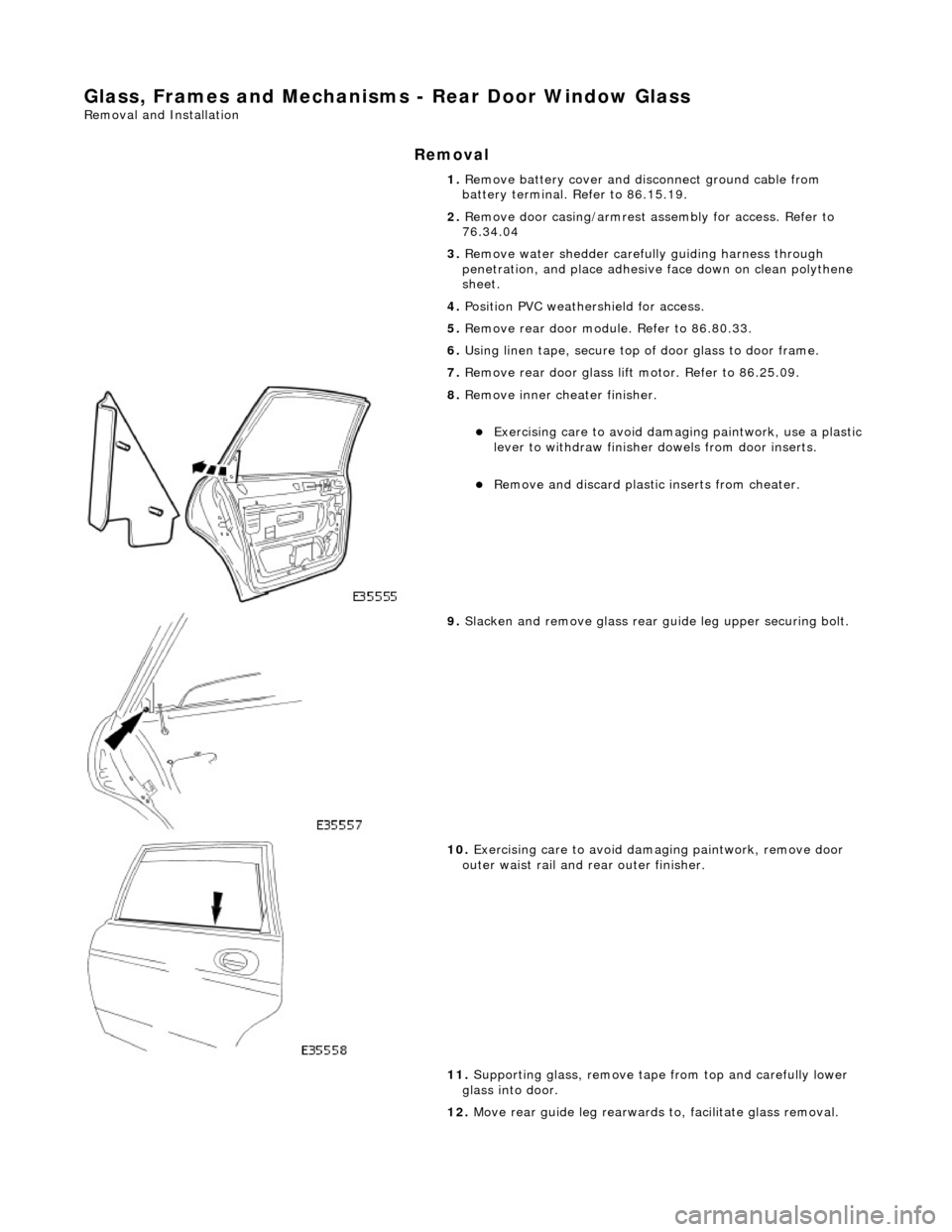

Removal

1. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Remove door casing/armrest as sembly for access. Refer to

76.34.04

3. Remove water shedder carefu lly guiding harness through

penetration, and place adhesive face down on clean polythene

sheet.

4. Position PVC weathe rshield for access.

5. Remove rear door module. Refer to 86.80.33.

6. Using linen tape, secure top of door glass to door frame.

7. Remove rear door glass lift motor. Refer to 86.25.09.

8. Remove inner cheater finisher.

пЃ¬Exercising care to avoid dama ging paintwork, use a plastic

lever to withdraw finisher dowels from door inserts.

пЃ¬Remove and discard plasti c inserts from cheater.

9. Slacken and remove glass rear guide leg upper securing bolt.

10. Exercising care to avoid damaging paintwork, remove door

outer waist rail and rear outer finisher.

11. Supporting glass, remove tape from top and carefully lower

glass into door.

12. Move rear guide leg rearwards to, facilitate glass removal.

Page 2193 of 2490

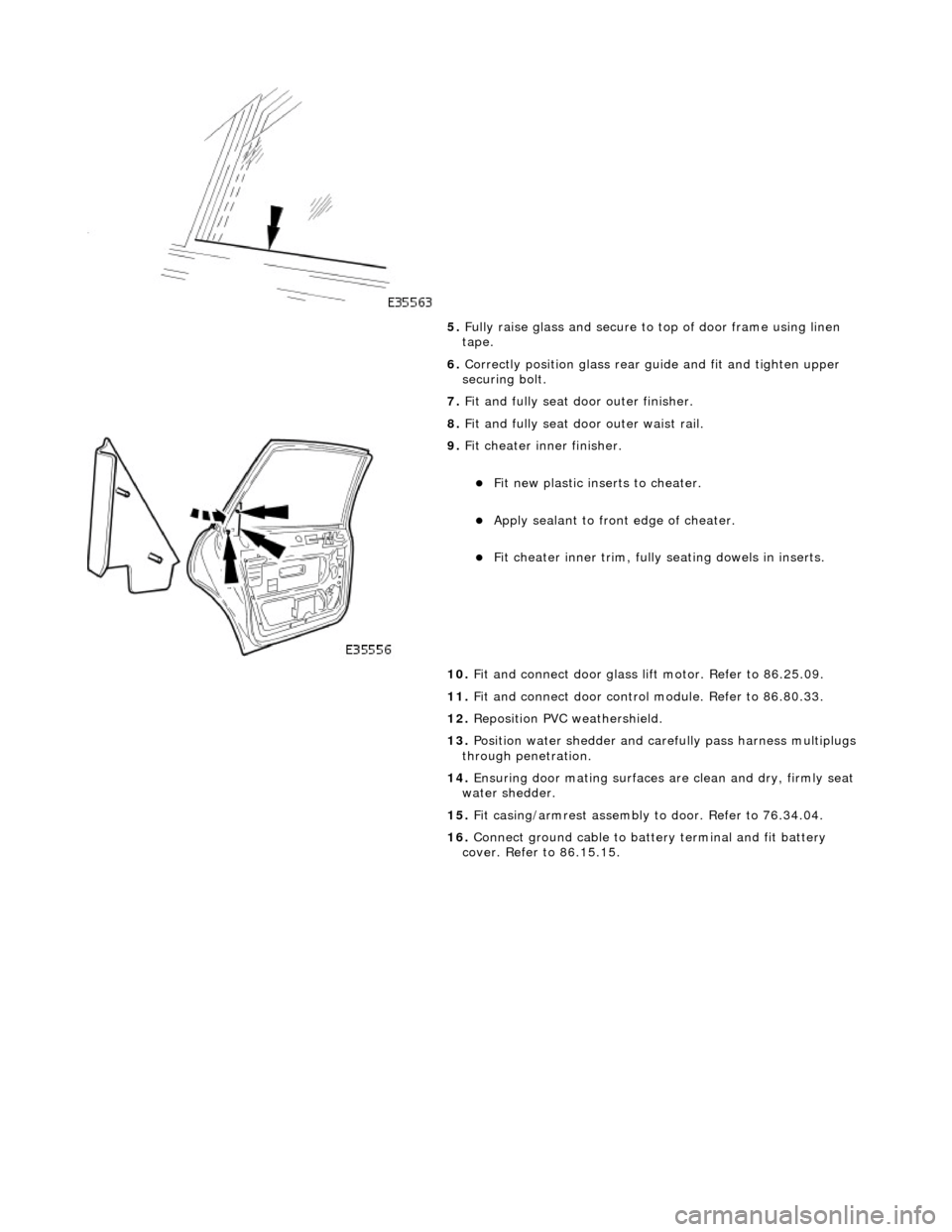

5. Fully raise glass and secure to top of door frame using linen

tape.

6. Correctly position glass rear guide and fit and tighten upper

securing bolt.

7. Fit and fully seat d oor outer finisher.

8. Fit and fully seat door outer waist rail.

9. Fit cheater i nner finisher.

пЃ¬Fit new plastic inserts to cheater.

пЃ¬Apply sealant to front edge of cheater.

пЃ¬Fit cheater inner trim, fully se ating dowels in inserts.

10. Fit and connect door glass lift motor. Refer to 86.25.09.

11. Fit and connect door control module. Refer to 86.80.33.

12. Reposition PVC weathershield.

13. Position water shedder and carefully pass harness multiplugs

through penetration.

14. Ensuring door mating surfaces ar e clean and dry, firmly seat

water shedder.

15. Fit casing/armrest assembly to door. Refer to 76.34.04.

16. Connect ground cable to batt ery terminal and fit battery

cover. Refer to 86.15.15.

Page 2228 of 2490

Instrument Panel and Console - Floor Console Extension

Removal and Installation

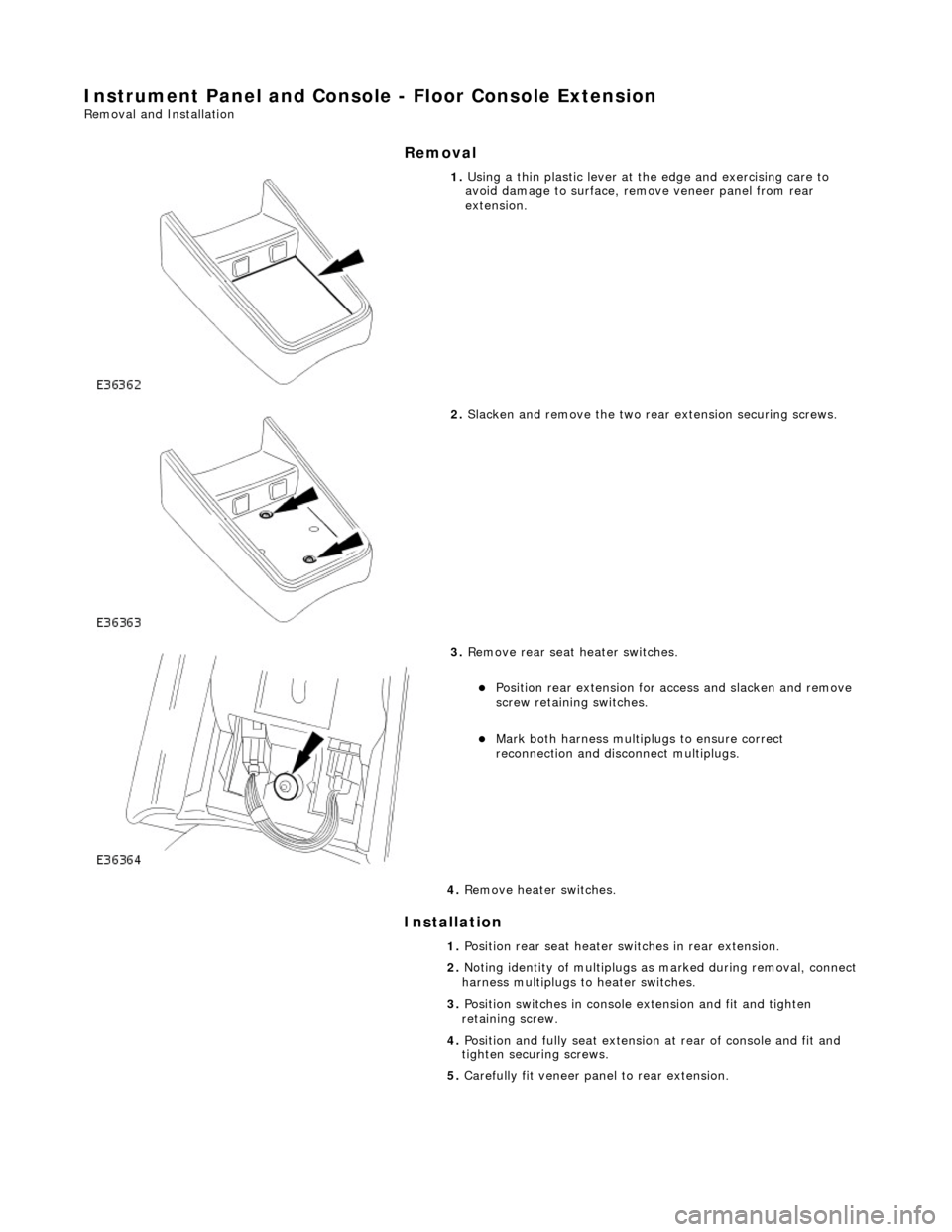

Removal

Installation

1. Using a thin plastic lever at th e edge and exercising care to

avoid damage to surface, remove veneer panel from rear

extension.

2. Slacken and remove the two rear extension securing screws.

3. Remove rear seat heater switches.

пЃ¬Position rear extension for access and slacken and remove

screw retaining switches.

пЃ¬Mark both harness multip lugs to ensure correct

reconnection and disconnect multiplugs.

4. Remove heater switches.

1. Position rear seat heater switches in rear extension.

2. Noting identity of multiplugs as marked during removal, connect

harness multiplugs to heater switches.

3. Position switches in console extension and fit and tighten

retaining screw.

4. Position and fully seat extension at rear of console and fit and

tighten securing screws.

5. Carefully fit veneer panel to rear extension.

Page 2304 of 2490

Installation

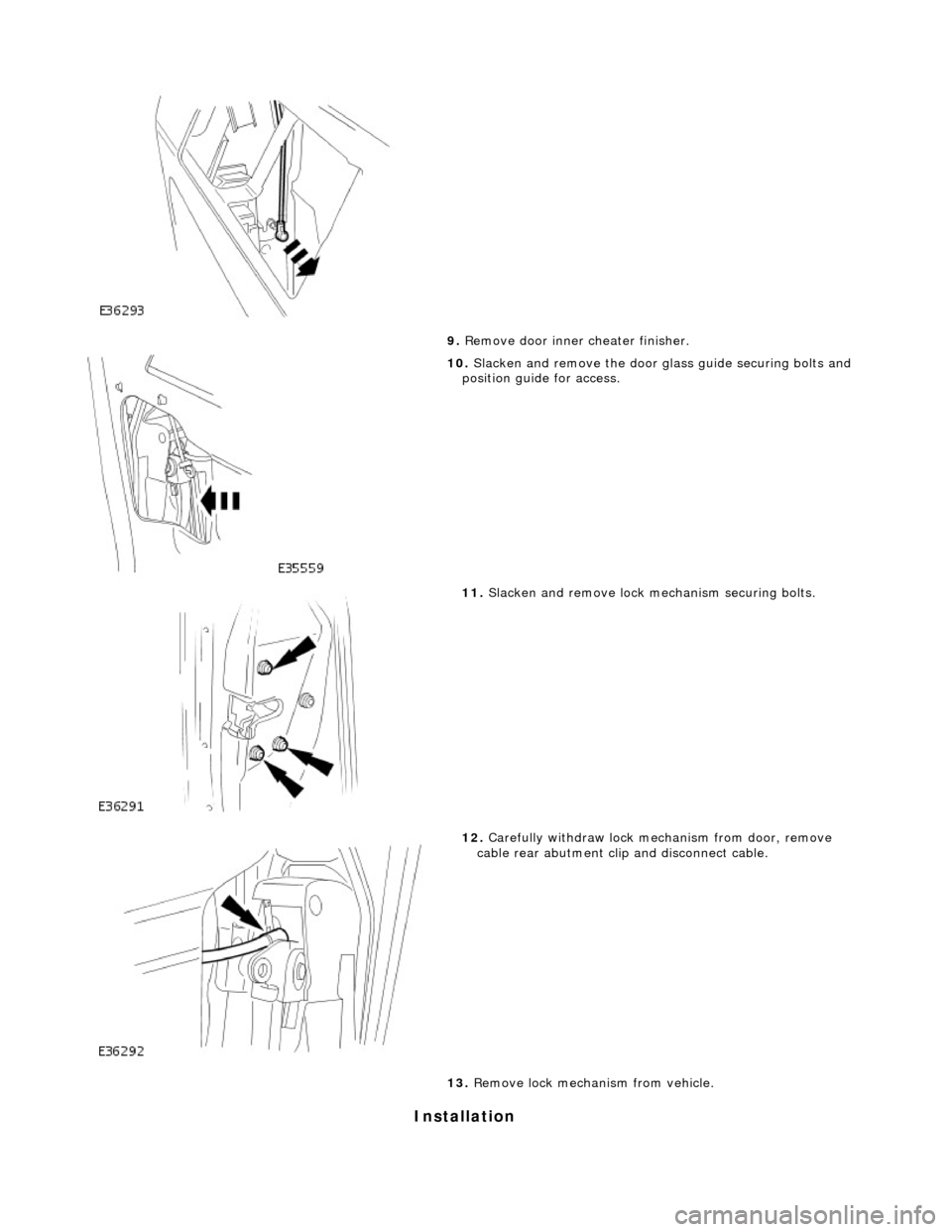

9. Remove door inner cheater finisher.

10. Slacken and remove the door glass guide securing bolts and

position guide for access.

11. Slacken and remove lock mechanism securing bolts.

12. Carefully withdraw lock me chanism from door, remove

cable rear abutment clip and disconnect cable.

13. Remove lock mechan ism from vehicle.

Page 2305 of 2490

1.

Position lock mechanism at door and connect operating cable.

2. Fit and fully seat cable rear abutment securing clip.

3. Fit and fully seat lock mechanism in door and fit and tighten

securing bolts.

4. Align glass guide and fit and tighten securing bolts.

5. Fit and fully seat inner cheater finisher.

6. Align and connect inner operating rod to lock mechanism.

7. Fit outer door handle operating rod to lock

8. Check for satisfactory door handle operation.

9. Reposition inner plastic sheet.

10. Connect lock actuator harness multiplug and fit to mounting

bracket.

11. Connect ground cable to battery terminal. Refer to 86.15.15.

12. From driver door, check for satisfactory operation of locking

system.

13. Disconnect ground cable from battery terminal. Refer to

86.15.19.

14. Ensure that water shedder contact area of door is clean and

dry.

15. Position water shedder at d oor and carefully pass door

harness through.

16. Fit and firmly seat water shedde r on door ensuring satifactory

adhesion.

17. Fit door casing. Refer to 76.34.04.

18. Fit door casing veneer panel. Refer to 76.47.12.

19. Connect ground cable to battery terminal and fit battery

cover. Refer to 86.15.15.

Page 2384 of 2490

Generally, resistance spot welding equipment used in the motor vehicle repair industry does not produce welds of equivalent strength to those achieved during manufactu re. The expression 'single row of resistance spot welds' indicates that the spots

should be spaced on a pitch of 19mm to 25mm, which normally results in mo re spot welds than those produced in the

original factory joint.

Resistance spot welds should be removed using a resistance spot weld cutter. If the new joint is to be MIG plug welded, old

resistance spot welds should be cut from the panel to be reta ined and the resulting holes used for plug welding. Suitable

holes may also be drilled or punched; 8,0 mm dia for sect ions up to 1,6 mm, and 10,0 mm dia for thicker sections.

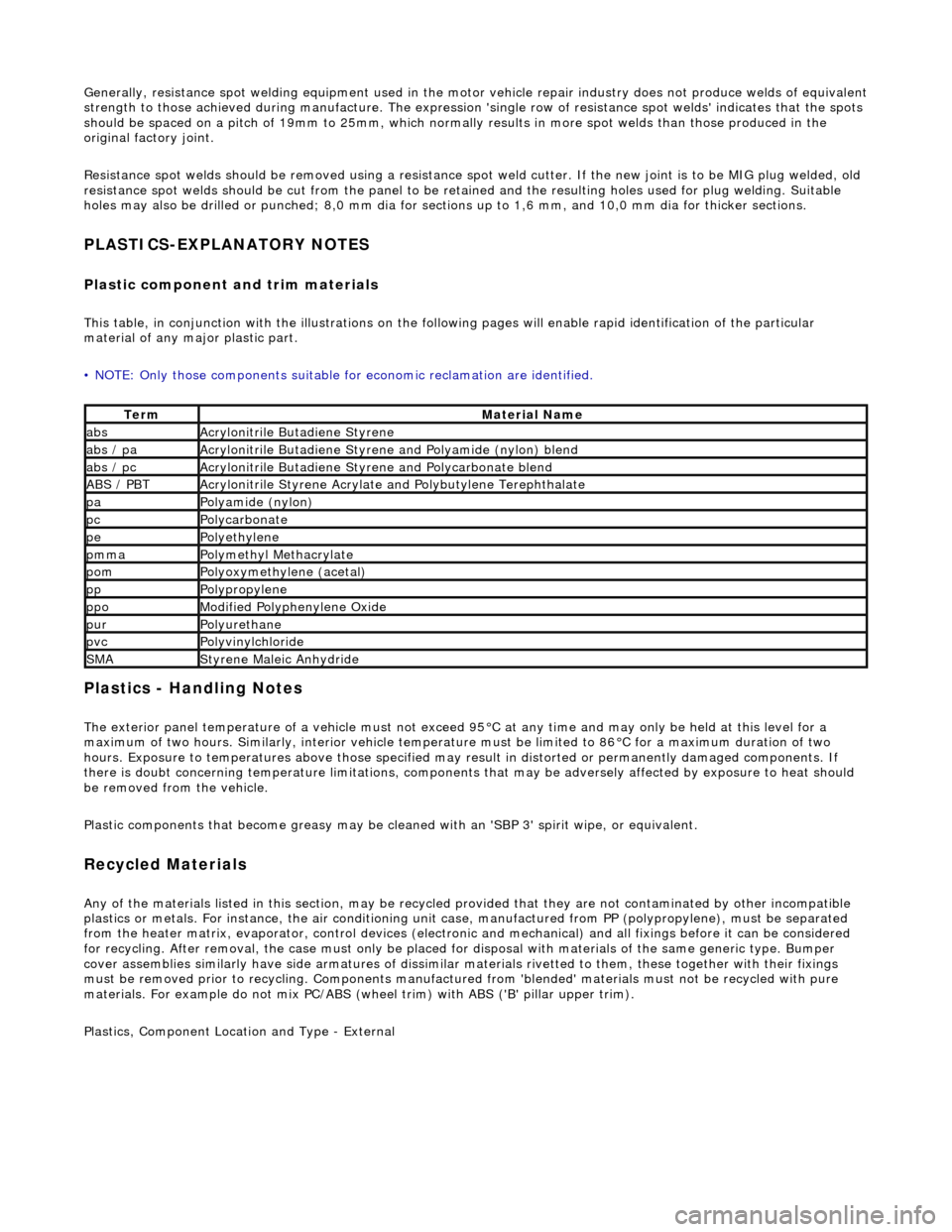

PLASTICS-EXPLANATORY NOTES

Plastic component and trim materials

This table, in conjunction with the illu strations on the following pages will enable rapid identification of the particular

material of any major plastic part.

• NOTE: Only those components suitable for economic reclamation are identified.

Plastics - Handling Notes

The exterior panel temperature of a vehicle must not exceed 95В°C at any time and may only be held at this level for a

maximum of two hours. Similarly, interior vehicle temperatur e must be limited to 86В°C for a maximum duration of two

hours. Exposure to temperatures above those specified may result in distorted or permanently damaged components. If

there is doubt concerning temperature limitations, components that may be adversel y affected by exposure to heat should

be removed from the vehicle.

Plastic components that become greasy may be clea ned with an 'SBP 3' spirit wipe, or equivalent.

Recycled Materials

Any of the materials listed in this section, may be recycled provided that they ar e not contaminated by other incompatible

plastics or metals. For instan ce, the air conditioning unit case, manufactur ed from PP (polypropylene), must be separated

from the heater matrix, evaporator, contro l devices (electronic and mechanical) and all fixings before it can be considered

for recycling. After removal, the case mu st only be placed for disposal with materials of the same generic type. Bumper

cover assemblies similarly have side arma tures of dissimilar materials rivetted to them, these together with their fixings

must be removed prior to recy cling. Components manufactured from 'blended' materials must not be recycled with pure

materials. For example do not mix PC/ABS (wheel trim) with ABS ('B' pillar upper trim).

Plastics, Component Location and Type - External

TermMaterial Name

absAcrylonitrile Butadiene Styrene

abs / paAcrylonitrile Butadiene Styrene and Polyamide (nylon) blend

abs / pcAcrylonitrile Butadiene Styrene and Polycarbonate blend

ABS / PBTAcrylonitrile Styrene Acrylate and Polybutylene Terephthalate

paPolyamide (nylon)

pcPolycarbonate

pePolyethylene

pmmaPolymethyl Methacrylate

pomPolyoxymethylene (acetal)

ppPolypropylene

ppoModified Polyphenylene Oxide

purPolyurethane

pvcPolyvinylchloride

SMAStyrene Maleic Anhydride