ECU JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2273 of 2490

Handles, Locks, Latches and Entry Systems - Handles, Locks, Latches and

Entry Systems

Description and Operation

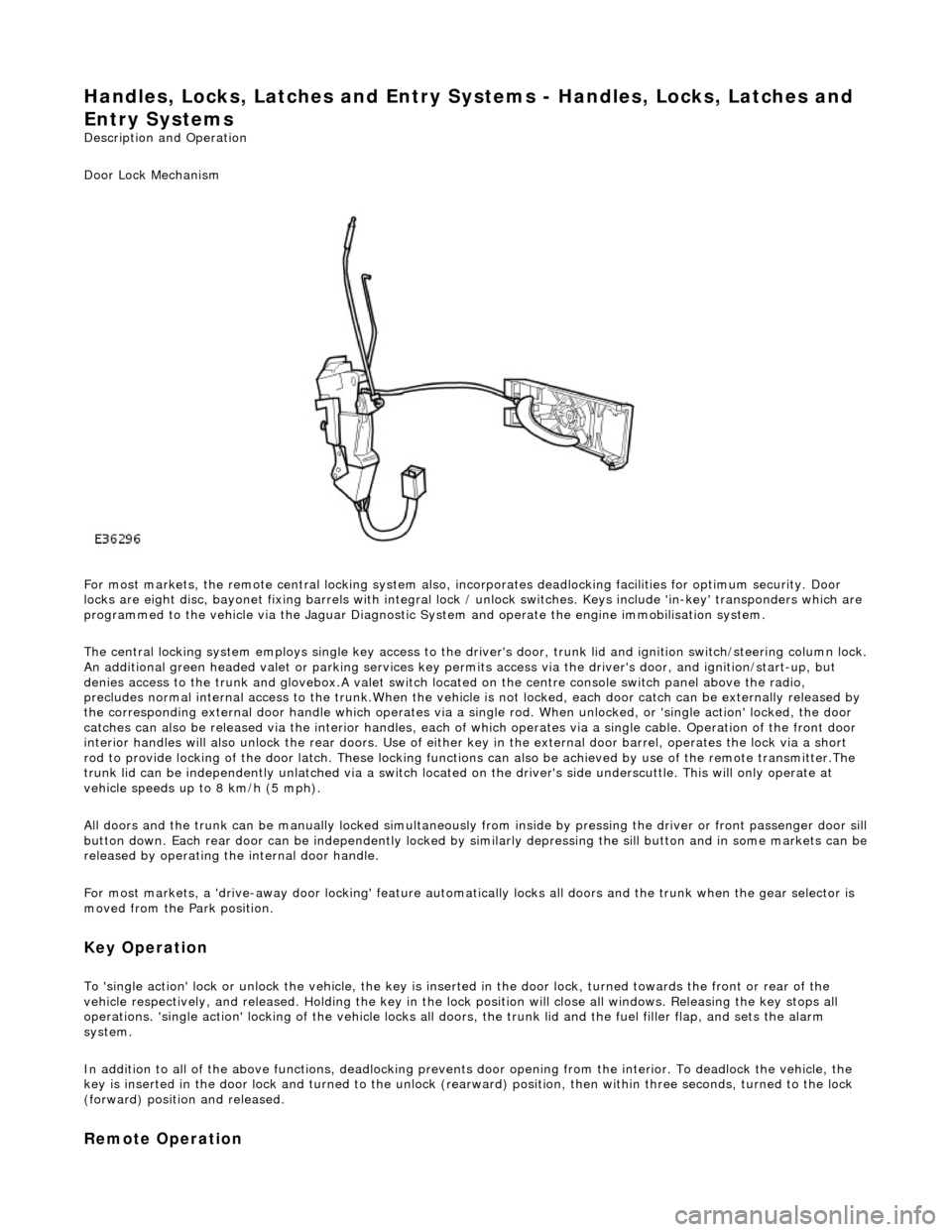

Door Lock Mechanism

For most markets, the remote central locking system also, in corporates deadlocking facilities for optimum security. Door

locks are eight disc, bayonet fixing barrels with integral lock / unlock switches. Keys include 'in-key' transponders which are

programmed to the vehicle via the Jaguar Diagnostic Sy stem and operate the engine immobilisation system.

The central locking system employs single key access to the driv er's door, trunk lid and ignition switch/steering column lock.

An additional green headed valet or park ing services key permits access via the driver's door, and ignition/start-up, but

denies access to the trunk and glovebox.A valet switch located on the centre console switch panel above the radio,

precludes normal internal access to the trunk.When the vehicle is not locked, each door catch can be externally released by

the corresponding external door handle which operates via a si ngle rod. When unlocked, or 'single action' locked, the door

catches can also be released via the interior handles, each of which operates via a single cable. Operation of the front door

interior handles will also unlock the rear doors. Use of either key in the external door barrel, operates the lock via a short

rod to provide locking of the door latch. These locking functions can also be achieved by use of the remote transmitter.The

trunk lid can be independently unlatched via a switch located on the driver's side underscuttle. This will only operate at

vehicle speeds up to 8 km/h (5 mph).

All doors and the trunk can be manually lock ed simultaneously from inside by pressing the driver or front passenger door sill

button down. Each rear door can be independently locked by si milarly depressing the sill button and in some markets can be released by operating the internal door handle.

For most markets, a 'drive-away door locking' feature automati cally locks all doors and the trunk when the gear selector is

moved from the Park position.

Key Operation

To 'single action' lock or unlock the vehicle, the key is inserted in the door lock , turned towards the front or rear of the

vehicle respectively, and released. Holding the key in the lock position will close all windows. Releasing the key stops all

operations. 'single action' locking of the vehicle locks all doors, the trunk lid and the fuel filler flap, and sets the alarm

system.

In addition to all of the above functions, deadlocking prevents door opening from th e interior. To deadlock the vehicle, the

key is inserted in the door lock and turned to the unlock (rearw ard) position, then within three seconds, turned to the lock

(forward) position and released.

Remote Operation

Page 2274 of 2490

Remote Central Locking Transmitter Unit

A four-button transmitter unit provides for remote controlled central locking of the vehicle.

The button bearing a red closed padlock sy mbol locks the vehicle and arms the security system. To remote 'single action'

lock, the transmitter is pointed towards the vehicle and this bu tton is pressed and released. To deadlock the vehicle, the

above operation is repeated with in three seconds. This function can also be used to remote close any windows. Completion

of deadlocking is indicated by an audible 'chirp' from the security system and a single flash from the direction indicators.

The vehicle is unlocked and the security system disarmed by pressing the button with the open padlock symbol.

The trunk lock can also be remotely released by op erating the button bearing the trunk lid open symbol.

The button with dipped headlamp symbol is for emergency us e. When depressed three times within three seconds, it

switches the headlamps on for 25 seconds and operates the vehicle alarm 5 times.

Page 2277 of 2490

Handles, Locks, Latches and Entry Systems - Exterior Driver Door Handle

Removal and Installation

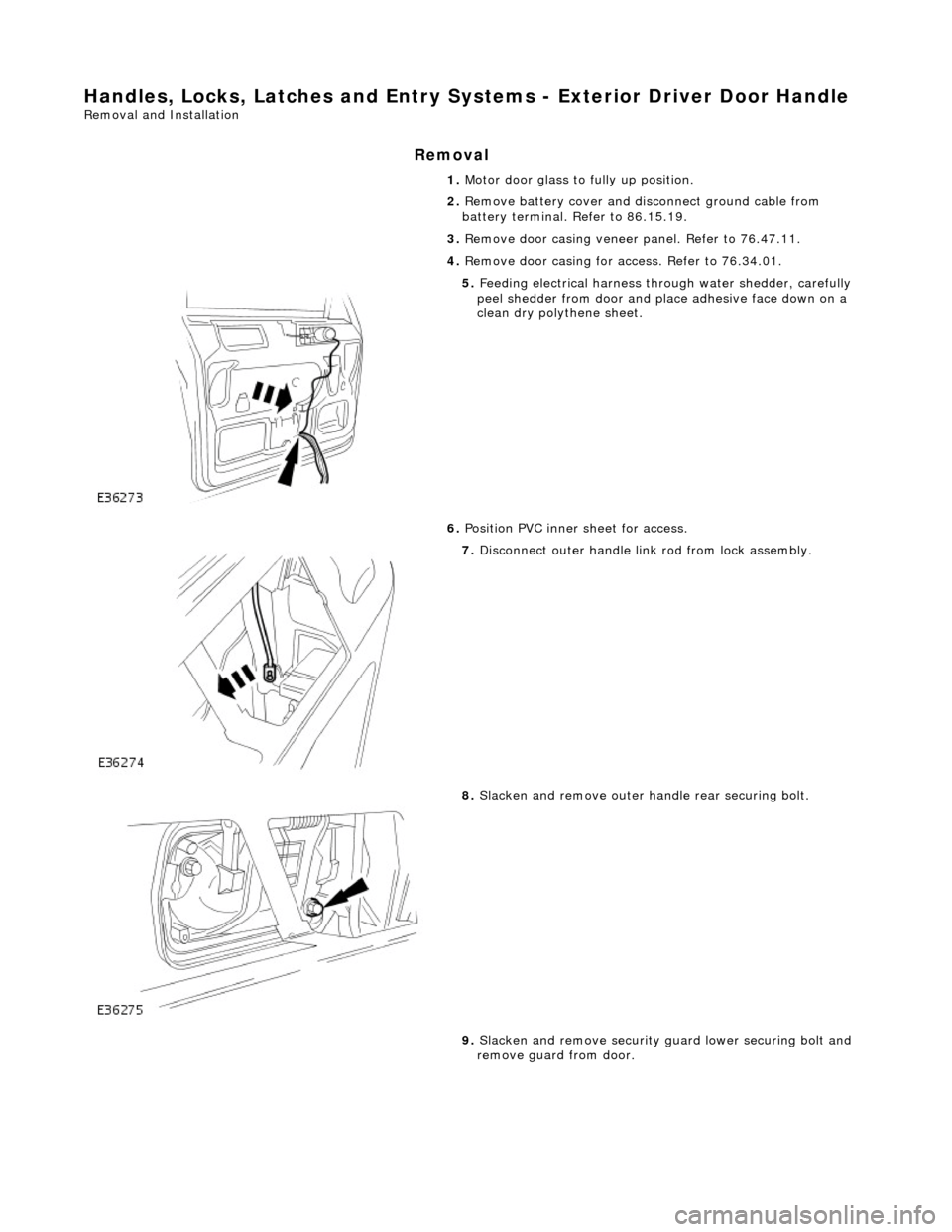

Removal

1. Motor door glass to fully up position.

2. Remove battery cover and disconnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove door casing veneer panel. Refer to 76.47.11.

4. Remove door casing for access. Refer to 76.34.01.

5. Feeding electrical harness thro ugh water shedder, carefully

peel shedder from door and pl ace adhesive face down on a

clean dry polythene sheet.

6. Position PVC inner sheet for access.

7. Disconnect outer handle link rod from lock assembly.

8. Slacken and remove outer handle rear securing bolt.

9. Slacken and remove security gu ard lower securing bolt and

remove guard from door.

Page 2278 of 2490

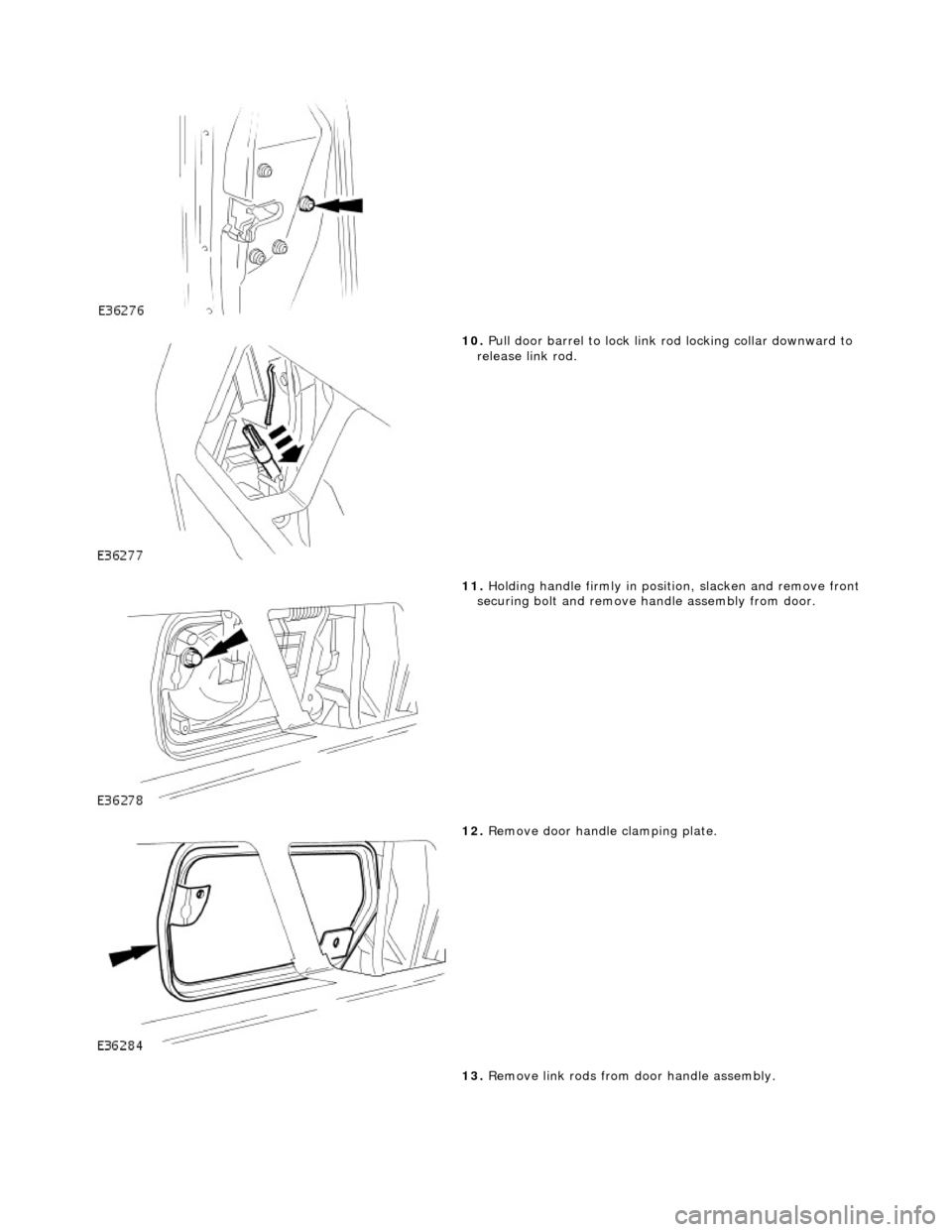

10. Pull door barrel to lock link rod locking collar downward to

release link rod.

11. Holding handle firmly in posi tion, slacken and remove front

securing bolt and remove ha ndle assembly from door.

12. Remove door handle clamping plate.

13. Remove link rods from door handle assembly.

Page 2279 of 2490

Installation

14. Slacken and remove lock barre l securing screw and remove

lock barrel from handle.

1. Align and fit lock barrel to door handle and fit and tighten

securing screw.

2. Fit link rods to door handle assembly.

3. Align and fit handle assembly to door

4. Position clamping plate inside door, and holding handle in

position, fit and tighten securing bolts.

5. Position barrel link rod on lock assembly and secure with

locking collar.

6. Check for satisfactory door handle operation.

7. Slacken and remove door handle rear securing bolt.

8. Position door lock security guard and fit and hand tighten lower

securing bolt.

9. Fit and tighten door handle rear /security guard upper securing

bolt.

10. Fully tighten security guard lower securing bolt.

11. Connect lock link rod to door handle.

12. Reposition PVC inner sheet.

13. Connect ground cable to battery terminal. Refer to 86.15.15.

14. Check for satisfactory operation of locking system

15. Disconnect ground cable from battery terminal. Refer to

86.15.15.

16. Ensure that shedder contact area of door is clean and dry.

17. Position water shedder at door and carefully pass harness

through.

18. Fit and firmly seat water shedder on door ensuring

satisfactory adhesion.

Page 2282 of 2490

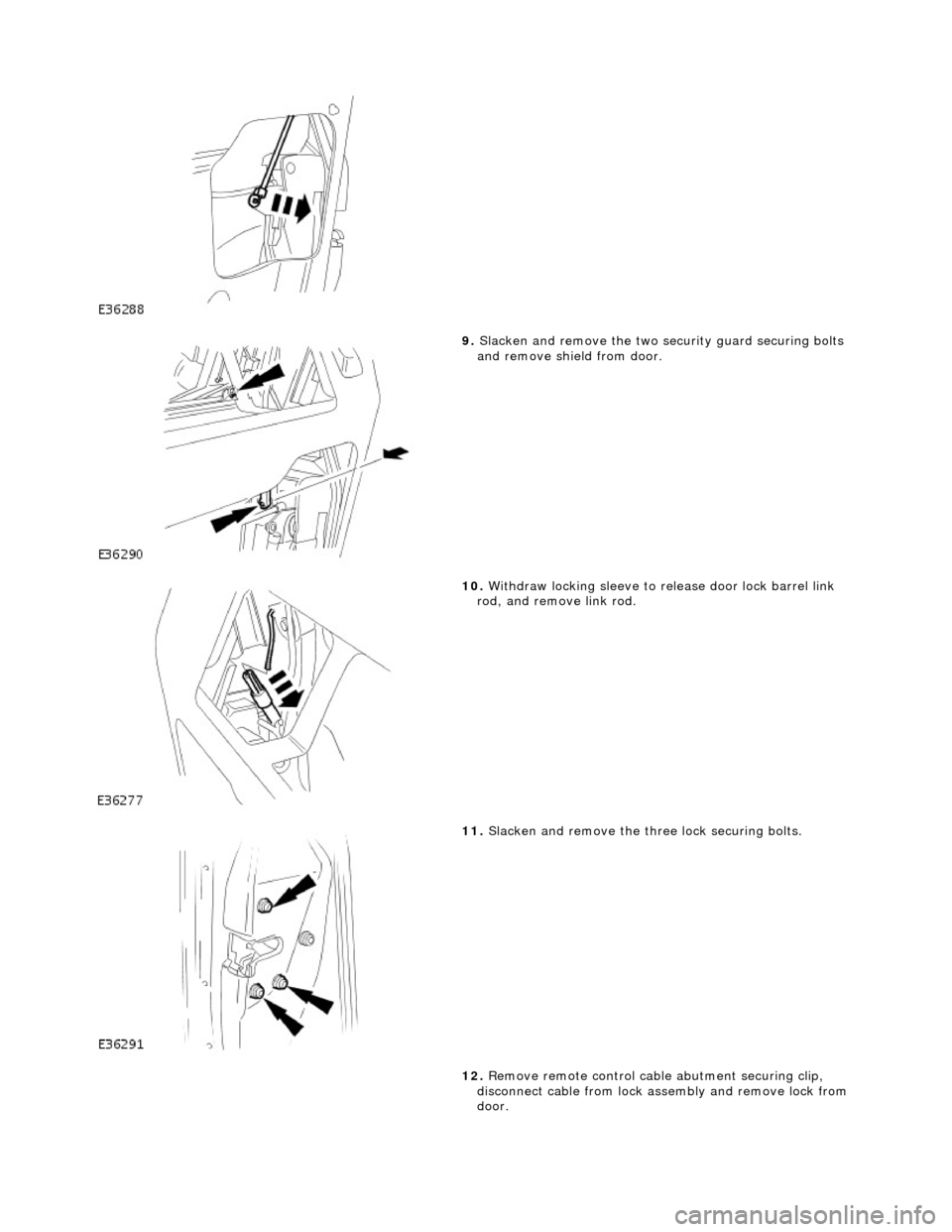

9. Slacken and remove the two se curity guard securing bolts

and remove shield from door.

10. Withdraw locking sleeve to release door lock barrel link

rod, and remove link rod.

11. Slacken and remove the three lock securing bolts.

12. Remove remote control cabl e abutment securing clip,

disconnect cable from lock as sembly and remove lock from

door.

Page 2283 of 2490

Installation

1. Position lock assembly in door, connect remote cable and fit

and fully seat securing clip.

2. Align lock assembly in door and fit and tighten the three

securing bolts.

3. Connect barrel to lock link rod and secure with locking sleeve.

4. Position security guard in door and fit but do not tighten lower

securing bolt.

5. Fit and tighten outer handle/security guard upper securing

bolt.

6. Finally tighten security guard lower securing bolt.

7. Position inner lock operating ro d in door and connect rod to

lock assembly.

8. Connect door outer handle operating rod to lock assembly.

9. Check for satisfactory door handle operation.

10. Reposition plastic inner sheet.

11. Connect lock actuator harness multiplug and fit multiplug to

mounting bracket.

12. Connect ground cable to battery terminal. Refer to 86.15.15.

13. Check for satisfactory door locking operation.

14. Disconnect ground cable from battery terminal. Refer to

86.15.15.

15. Ensure that water shedder contact area of door is clean and

dry.

16. Pass door harness through water shedder.

17. Fit and firmly seat water shedder on door ensuring

satisfactory adhesion.

18. Fit door casing. Refer to 76.34.01

19. Connect ground cable to battery terminal and fit cover to

batery. Refer to 86.15.15.

Page 2285 of 2490

Handles, Locks, Latches and Entry Systems - Glove Compartment Lid Lock

Cylinder

Removal and Installation

Removal

Installation

1. Remove glovebox handle and lock assembly. Refer to

76.52.08.

2. Remove plastic lock rod operat ing bush from lock barrel.

3. Remove operating bush bias spring from lock barrel.

4. Slacken and remove screw securing barrel to housing and

remove barrel from lock housing.

5. Thoroughly clean lock housing.

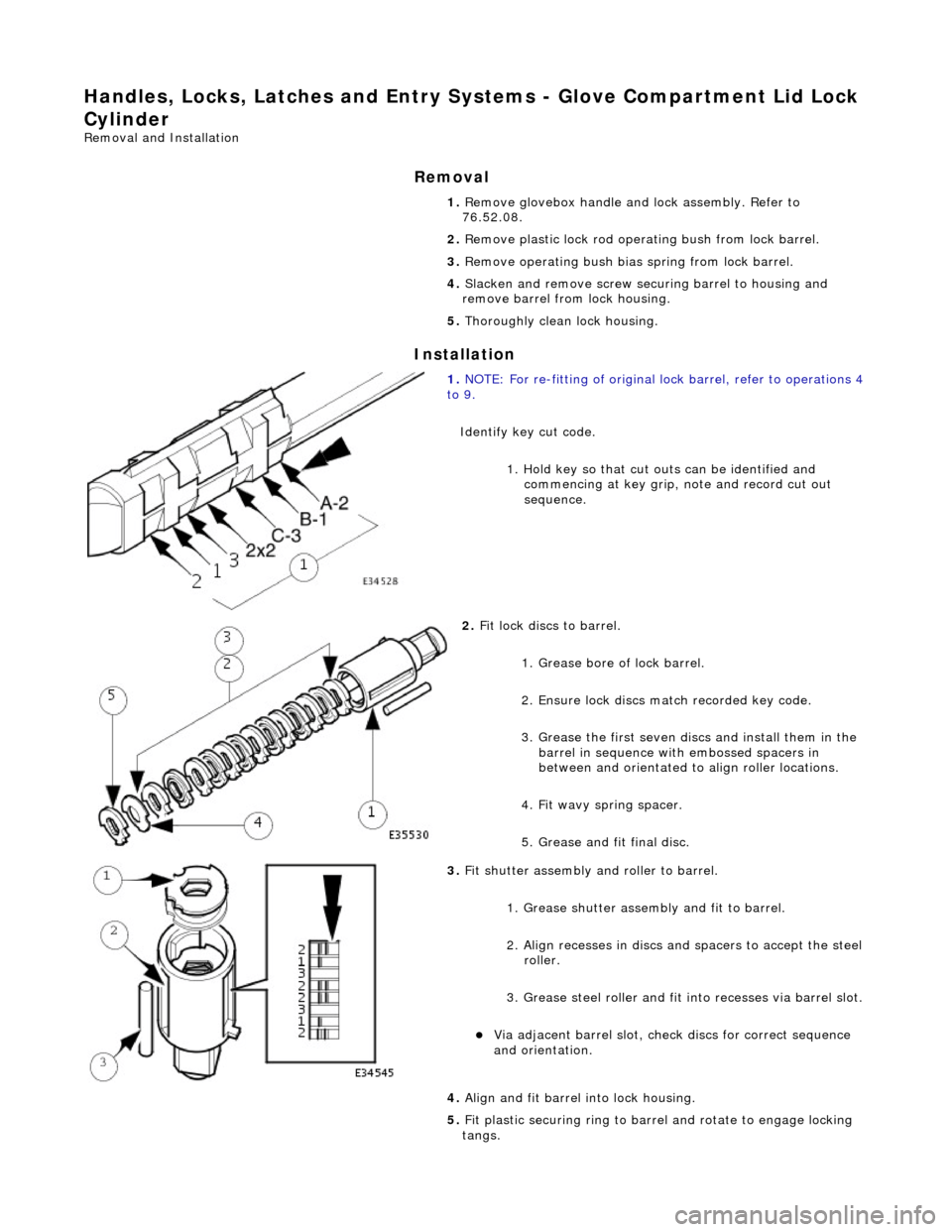

1. NOTE: For re-fitting of original lock barrel, refer to operations 4 to 9.

Identify key cut code. 1. Hold key so that cut ou ts can be identified and

commencing at key grip, note and record cut out

sequence.

2. Fit lock discs to barrel.

1. Grease bore of lock barrel.

2. Ensure lock discs match recorded key code.

3. Grease the first seven discs and install them in the barrel in sequence with embossed spacers in

between and orientated to align roller locations.

4. Fit wavy spring spacer.

5. Grease and fit final disc.

3. Fit shutter assembly an d roller to barrel.

1. Grease shutter assemb ly and fit to barrel.

2. Align recesses in discs and spacers to accept the steel roller.

3. Grease steel roller and fit into recesses via barrel slot.

Via adjacent barrel slot, check discs for correct sequence

and orientation.

4. Align and fit barrel into lock housing.

5. Fit plastic securing ring to barrel and rotate to engage locking

tangs.

Page 2286 of 2490

6.

Fit bias spring to operating arm ensuring it is fully seated and

tensioned, with ends positioned each side of pillar.

7. Fit operating arm and bias spring assembly to barrel and

secure with 'C' clip.

8. Fit lock barrel assembly to housing.

9. Position lock assembly in handle and fit and tighten securing

screw.

10. Fit key and check lock function.

11. Remove key from lock.

12. Fit handle and lock assembly to glovebox lid.. Refer to 76.52

08.

Page 2287 of 2490

Handles, Locks, Latches and Entry Systems - Luggage Compartment Lid

Latch

Removal and Installation

Removal

1. Remove trunk lamp assemblies. Refer to 86.45.16.

2. Remove covers from the two tr unk latch finisher securing

bolts and slacken and remove securing bolts.

3. Remove latch finisher from trunk.

4. Release and discard the four trunk lid liner rear fasteners

and position liner for access.

5. Release trunk open switch multiplug from retaining clip and

disconnect multiplug.

6. Slacken and remove the latch assembly securing bolt.