ECU JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2317 of 2490

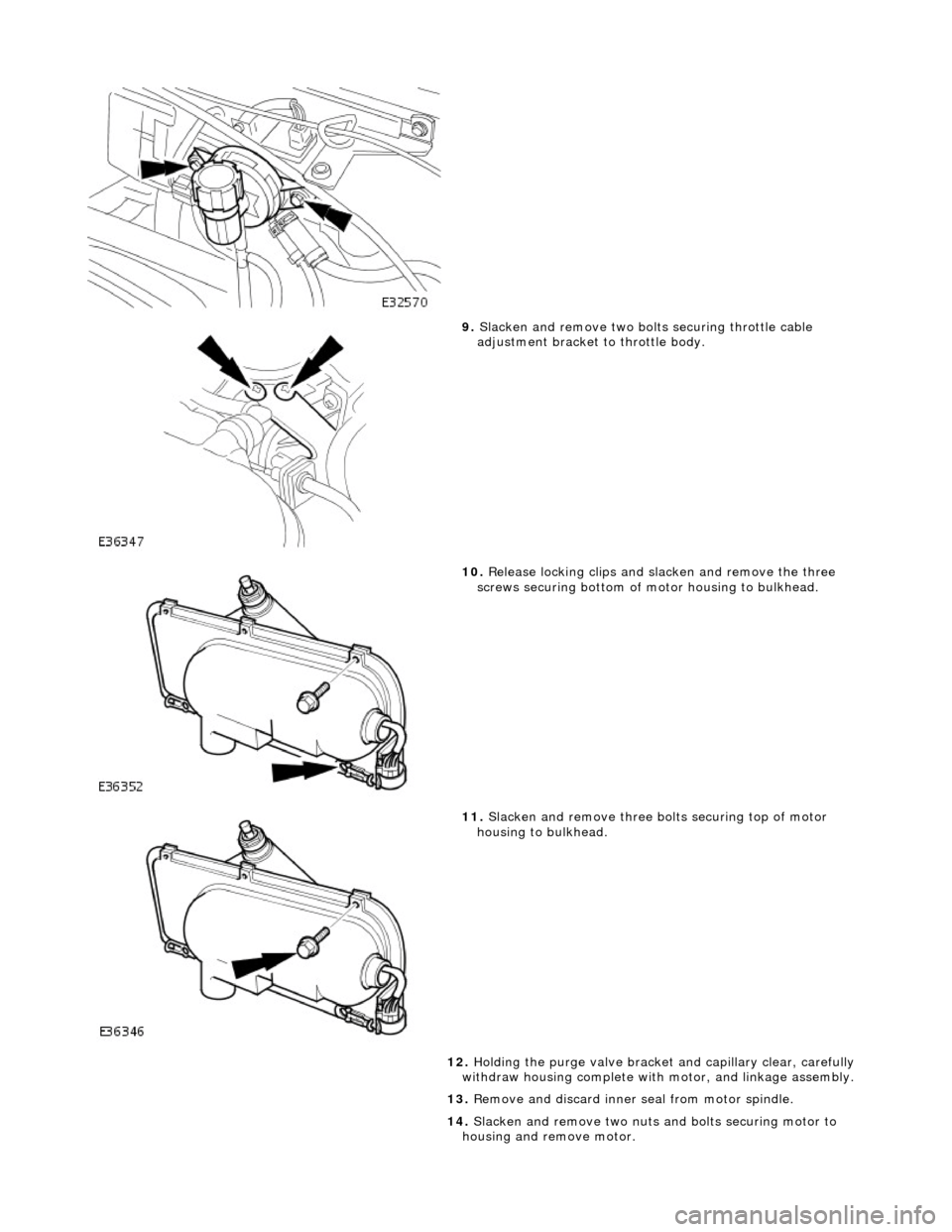

9. Slacken and remove two bolts securing throttle cable

adjustment bracket to throttle body.

10. Release locking clips and sl acken and remove the three

screws securing bottom of motor housing to bulkhead.

11. Slacken and remove three bo lts securing top of motor

housing to bulkhead.

12. Holding the purge valve bracket and capillary clear, carefully

withdraw housing complete with motor, and linkage assembly.

13. Remove and discard inner seal from motor spindle.

14. Slacken and remove two nuts and bolts securing motor to

housing and remove motor.

Page 2318 of 2490

Installation

1.

Position motor in housing and fi t and tighten securing nuts and

bolts.

2. Apply suitable lubricant to bore of new spindle inner seal and

fit seal over motor spindle.

3. Holding the capillary and purge valve clear, position

motor/housing assembly on bulkhead.

4. Seat motor spindle seal correctly in upper plenum aperture and

ensure that housing lo cates on lower studs.

5. Fit and tighten the housin g upper securing bolts.

6. Fit and tighten the housing lower securing screws and slide

locking clips inwards.

7. Position throttle cable adjustment bracket on throttle body and

fit and tighten securing bolts.

8. Position purge valve bracket at bulkhead and fit and tighten

securing bolt and nuts.

9. Position engine harness multiplu g on mounting bracket and fit

and tighten securing nut.

10. Connect motor harness multiplug and locate in retaining clip.

11. Apply suitable lubricant to bore of new outer seal and fit with

washer to motor spindle.

12. Fit and fully tighten collar nut on motor spindle.

13. Fit plenum cover. Refer to 76.10.01.

14. Fit wiper arm and blade. Refer to 84.15.44.90.

15. Fit top covers to LH and RH bulkheads and rear of engine

compartment. refer to 76.11.33 and 76.11.35.

16. Fit ground cable to battery te rminal and cover to battery.

Refer to 86.15.15.

Page 2319 of 2490

Wipers and Washers - Windshield Wiper MotorVehicles Built From:

10/1997

Removal and Installation

Removal

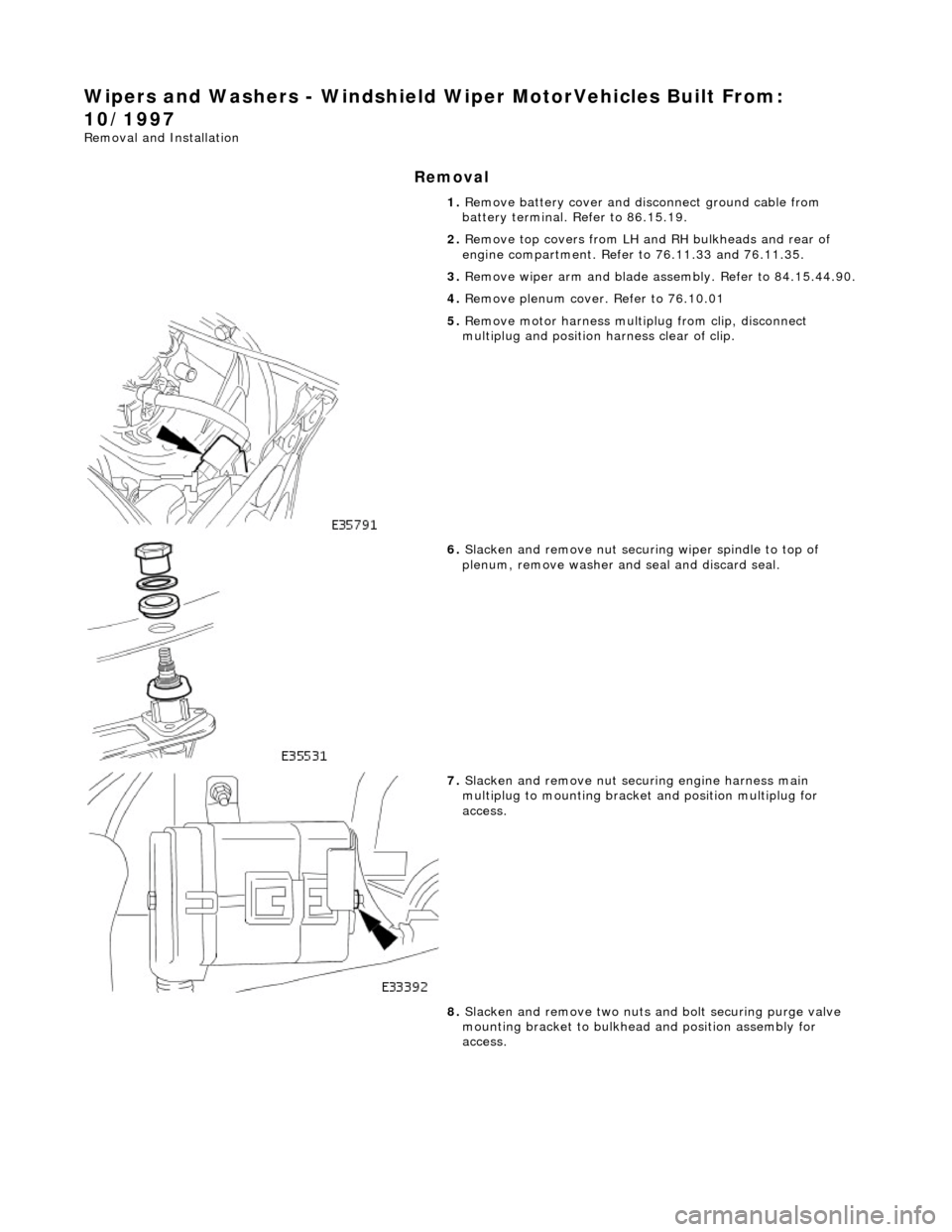

1. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Remove top covers from LH an d RH bulkheads and rear of

engine compartment. Refer to 76.11.33 and 76.11.35.

3. Remove wiper arm and blade as sembly. Refer to 84.15.44.90.

4. Remove plenum cover. Refer to 76.10.01

5. Remove motor harness multiplug from clip, disconnect

multiplug and position harness clear of clip.

6. Slacken and remove nut securi ng wiper spindle to top of

plenum, remove washer and seal and discard seal.

7. Slacken and remove nut securing engine harness main

multiplug to mounting bracke t and position multiplug for

access.

8. Slacken and remove two nuts an d bolt securing purge valve

mounting bracket to bulkhead and position assembly for

access.

Page 2320 of 2490

Installation

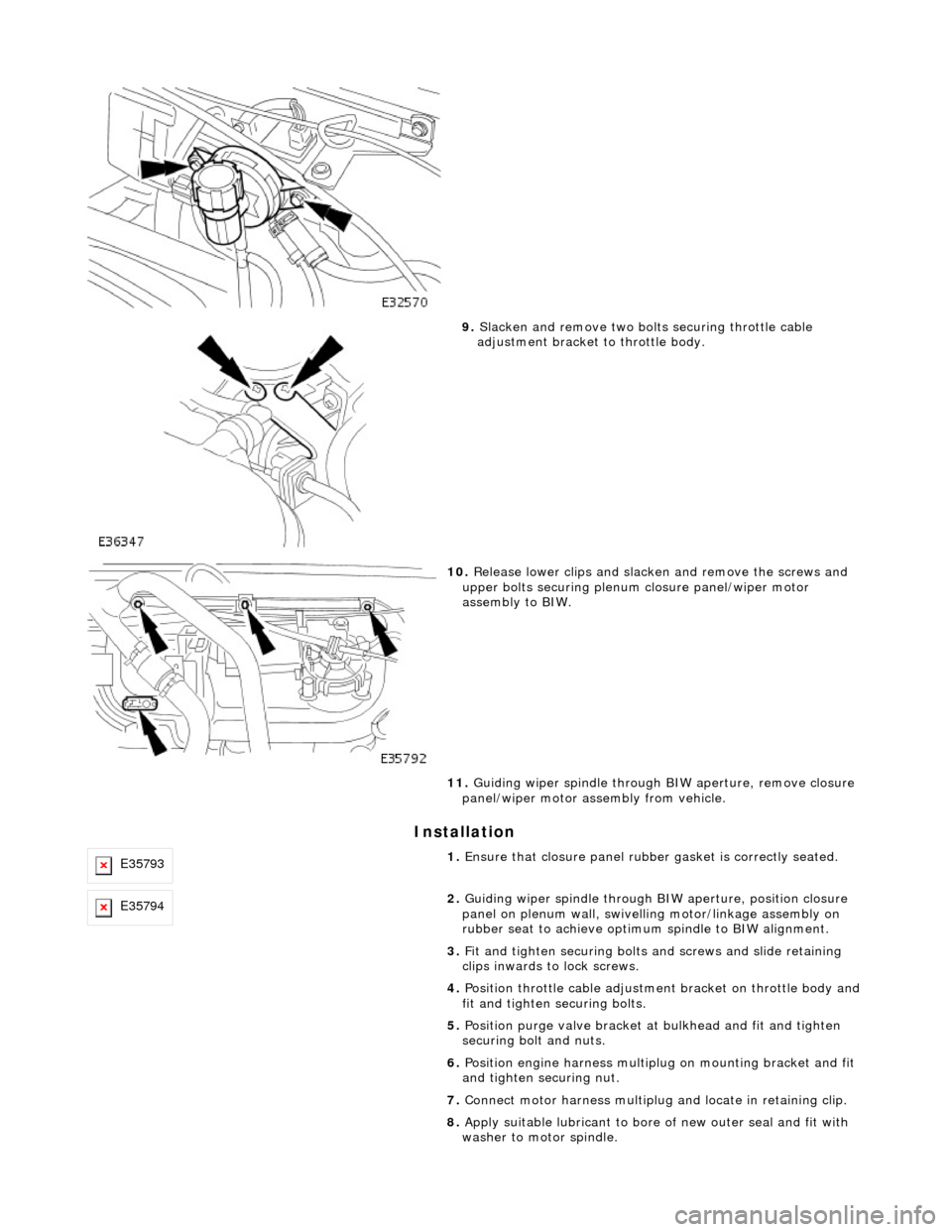

9. Slacken and remove two bolts securing throttle cable

adjustment bracket to throttle body.

10. Release lower clips and slacken and remove the screws and

upper bolts securing plenum closure panel/wiper motor

assembly to BIW.

11. Guiding wiper spindle through BIW aperture, remove closure

panel/wiper motor assembly from vehicle.

E357931. Ensure that closure panel rubbe r gasket is correctly seated.

E357942. Guiding wiper spindle through BI W aperture, position closure

panel on plenum wall, swivelling motor/linkage assembly on

rubber seat to achieve optimu m spindle to BIW alignment.

3. Fit and tighten securing bolts and screws and slide retaining

clips inwards to lock screws.

4. Position throttle cable adjustment bracket on throttle body and

fit and tighten securing bolts.

5. Position purge valve bracket at bulkhead and fit and tighten

securing bolt and nuts.

6. Position engine harness multiplu g on mounting bracket and fit

and tighten securing nut.

7. Connect motor harness multiplug and locate in retaining clip.

8. Apply suitable lubricant to bore of new outer seal and fit with

washer to motor spindle.

Page 2323 of 2490

10. Disconnect key interlock solenoid harness multiplug.

11. Release flasher/lamp/trip swit ch harness multiplugs from

retaining bracket and di sconnect multiplugs.

12. Disconnect cancellation module harness multiplugs.

13. Slacken and remove bolts securing switch

assemblies/cancellation module to column.

Page 2325 of 2490

Installation

18. Remove windshield wiper/ washer switch/mounting

bracket/audible warning speaker assembly from vehicle.

1. Position windshield wipe r/washer switch/mounting

bracket/audible warning speaker assembly for access in

vehicle.

2. Fit cancellation module to mounting bracket.

3. Fit wiper/washer switch to cancellation module/mounting

bracket.

4. Fit flasher/lamp/trip switch to cancellation module/mounting

bracket.

5. Position switchgear assembly on steering column and fit and

tighten securing bolts.

6. Connect cancellation module harness multiplugs and fit

multiplugs to retaining bracket.

7. Connect flasher/lamp/trip switch harness multiplugs and fit

multiplugs to retaining bracket.

Page 2326 of 2490

8. Conne

ct key interlock solenoid harness multiplug.

9. Connect key t

ransponder exciter

coil multiplug and using new

tie straps, secure mu ltiplug to harness.

10 . Conne

ct wiper/washer switch mu

ltiplug, and fit multiplug onto

retaining bracket.

11. Fit driver side underscu ttle. Refer to 76.46.11.

12. Fit steering column uppe r cowl. Refer to 76.46.02.

13. Fit steering column lower cowl. Refer to 76.46.03

14. Fit steering wheel.

15. Fit driver airbag module. Refer to 76.73.39.

16. Fit groun

d cable to battery te

rminal and fit battery cover.

Refer to 86.15.15.

Page 2327 of 2490

Wipers and Washers - Wiper Pivot Arm

Removal and Installation

Removal

Installation

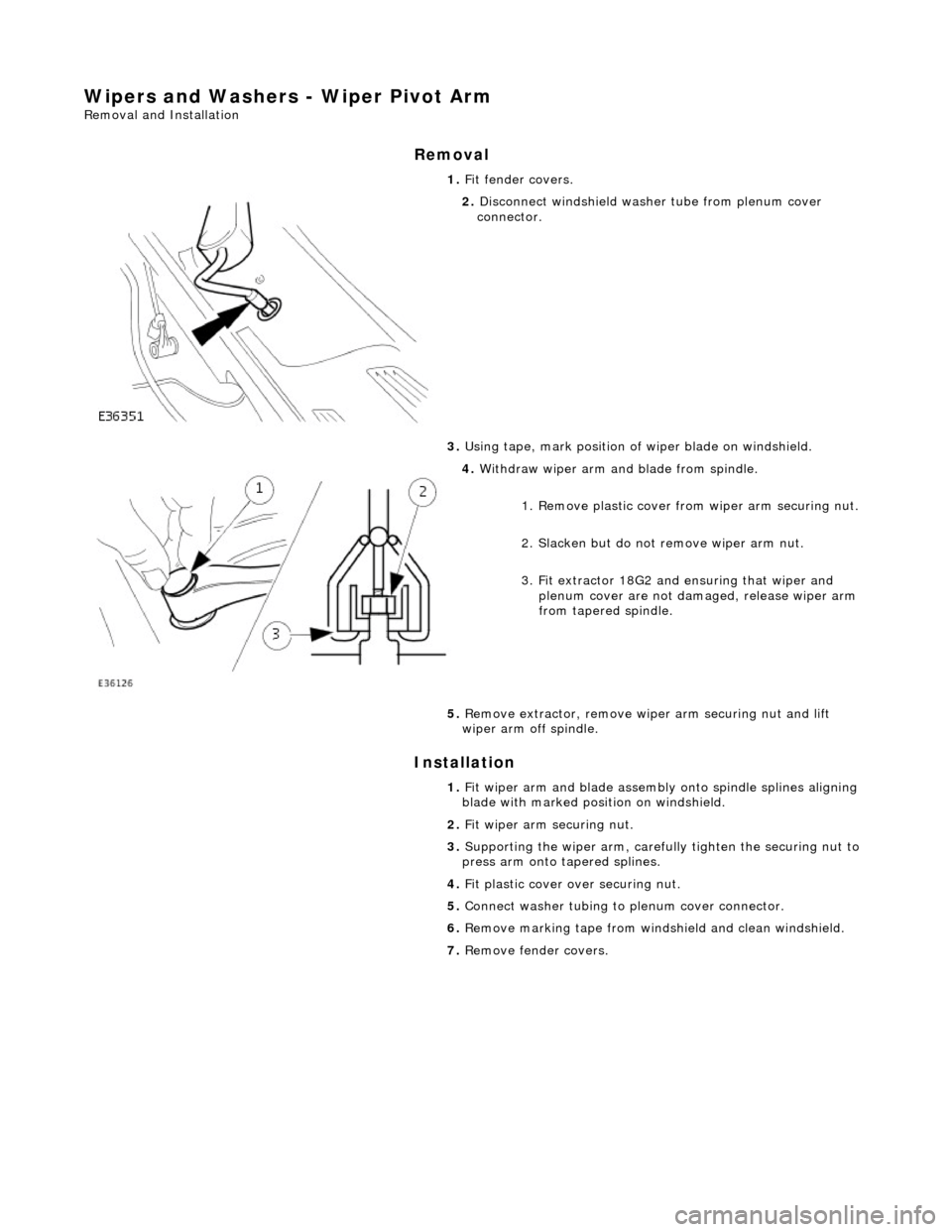

1.

Fit fender covers.

2. Disconnect windshield washer tube from plenum cover

connector.

3. Using tape, mark po sition of wiper blade on windshield.

4. Withdraw wiper arm and blade from spindle.

1. Remove plastic cover fro m wiper arm securing nut.

2. Slacken but do not remove wiper arm nut.

3. Fit extractor 18G2 and ensuring that wiper and

plenum cover are not dama ged, release wiper arm

from tapered spindle.

5. Remove extractor, remove wi per arm securing nut and lift

wiper arm off spindle.

1. Fit wiper arm and blade assembly onto spindle splines aligning

blade with marked position on windshield.

2. Fit wiper arm securing nut.

3. Supporting the wiper ar m, carefully tighten the securing nut to

press arm onto tapered splines.

4. Fit plastic cover over securing nut.

5. Connect washer tubing to plenum cover connector.

6. Remove marking tape from windshield and clean windshield.

7. Remove fender covers.

Page 2328 of 2490

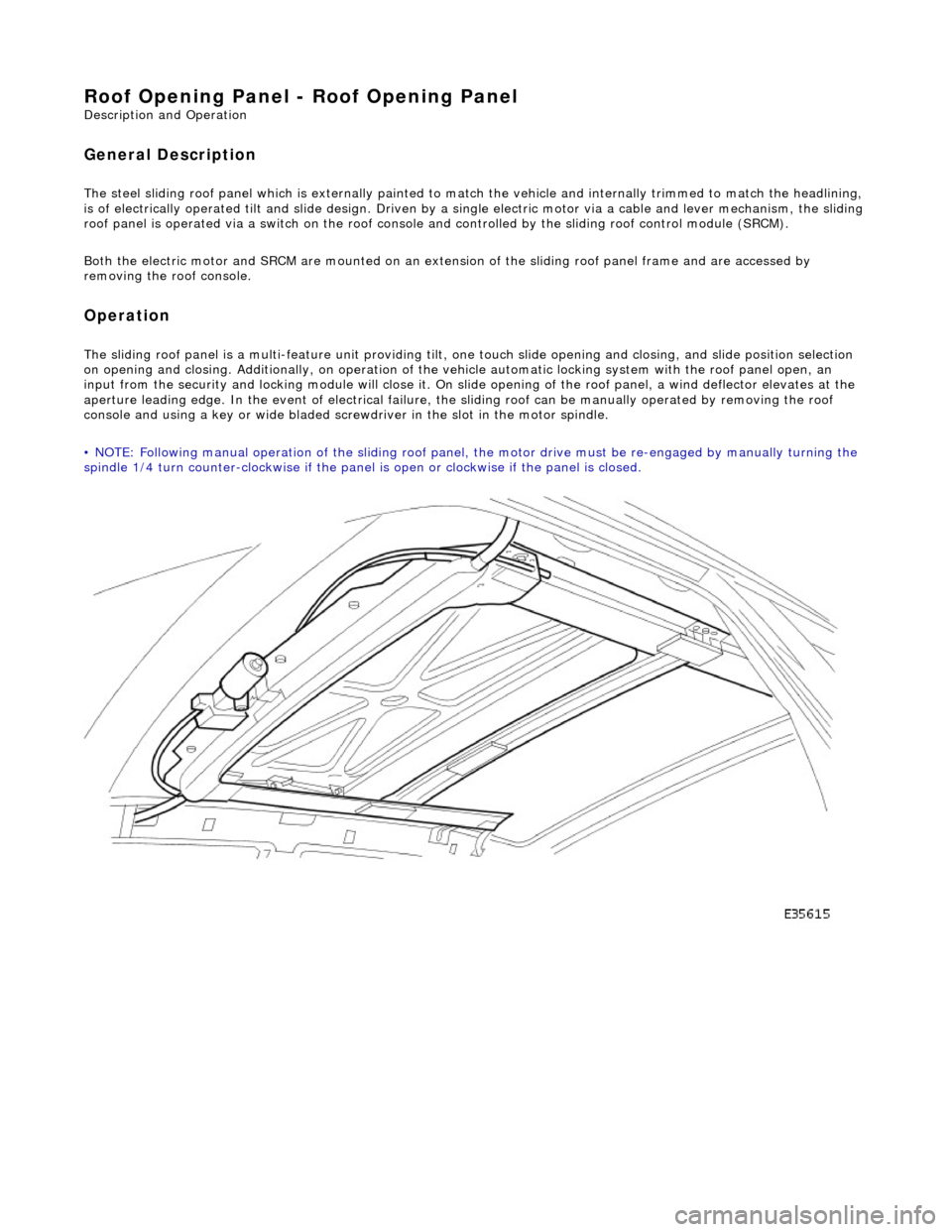

Roof Opening Panel - Roof Opening Panel

Description and Operation

General Description

The steel sliding roof panel which is externally painted to ma tch the vehicle and internally trimmed to match the headlining,

is of electrically operated tilt and slide design. Driven by a single electric motor via a cable and lever mechanism, the slidi ng

roof panel is operated via a switch on the roof console and controlled by the sliding roof control module (SRCM).

Both the electric motor and SRCM are mounted on an extens ion of the sliding roof panel frame and are accessed by

removing the roof console.

Operation

The sliding roof panel is a multi-feature unit providing tilt, one touch slide opening and closing, and slide position selectio n

on opening and closing. Additi onally, on operation of the vehicle automatic locking system with the roof panel open, an

input from the security and lockin g module will close it. On slide opening of the roof panel, a wind deflector elevates at the

aperture leading edge. In the event of electrical failure, the sliding roof can be manually operated by removing the roof

console and using a key or wide bladed scre wdriver in the slot in the motor spindle.

• NOTE: Following manual operation of the sliding roof panel, the motor drive must be re-engaged by manually turning the

spindle 1/4 turn counter-clockwise if the panel is open or clockwise if the panel is closed.

Page 2330 of 2490

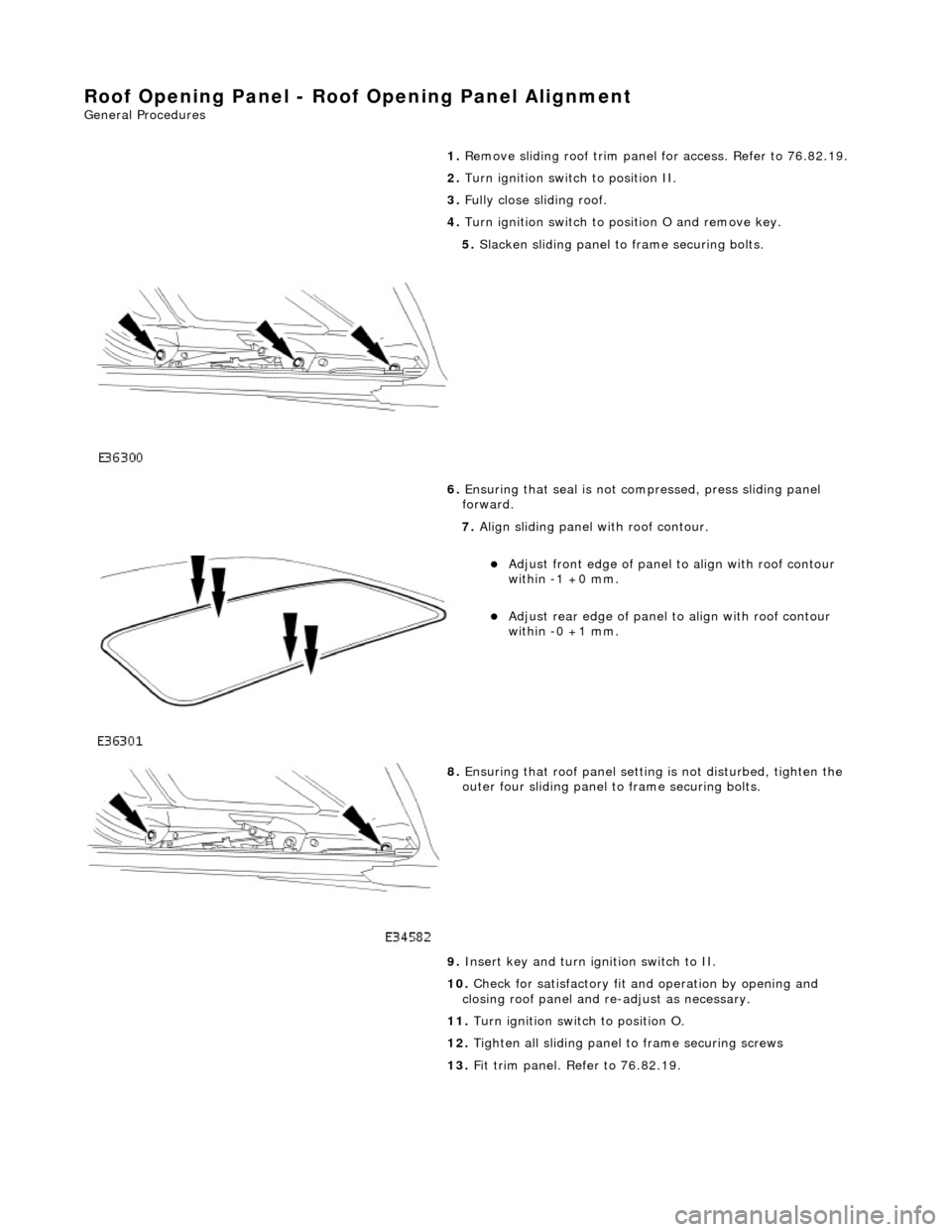

Roof Opening Panel - Roof Opening Panel Alignment

General Procedures

1.

Remove sliding roof trim panel for access. Refer to 76.82.19.

2. Turn ignition switch to position II.

3. Fully close sliding roof.

4. Turn ignition switch to po sition O and remove key.

5. Slacken sliding panel to frame securing bolts.

6. Ensuring that seal is not compressed, press sliding panel

forward.

7. Align sliding panel with roof contour.

Adjust front edge of panel to align with roof contour

within -1 +0 mm.

Adjust rear edge of panel to align with roof contour

within -0 +1 mm.

8. Ensuring that roof panel settin g is not disturbed, tighten the

outer four sliding panel to frame securing bolts.

9. Insert key and turn ig nition switch to II.

10. Check for satisfactory fit and operation by opening and

closing roof panel and re -adjust as necessary.

11. Turn ignition switch to position O.

12. Tighten all sliding panel to frame securing screws

13. Fit trim panel. Refer to 76.82.19.