Powerwash JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2099 of 2490

Exterior Trim and Ornamentation - Exterior Trim

Description and Operation

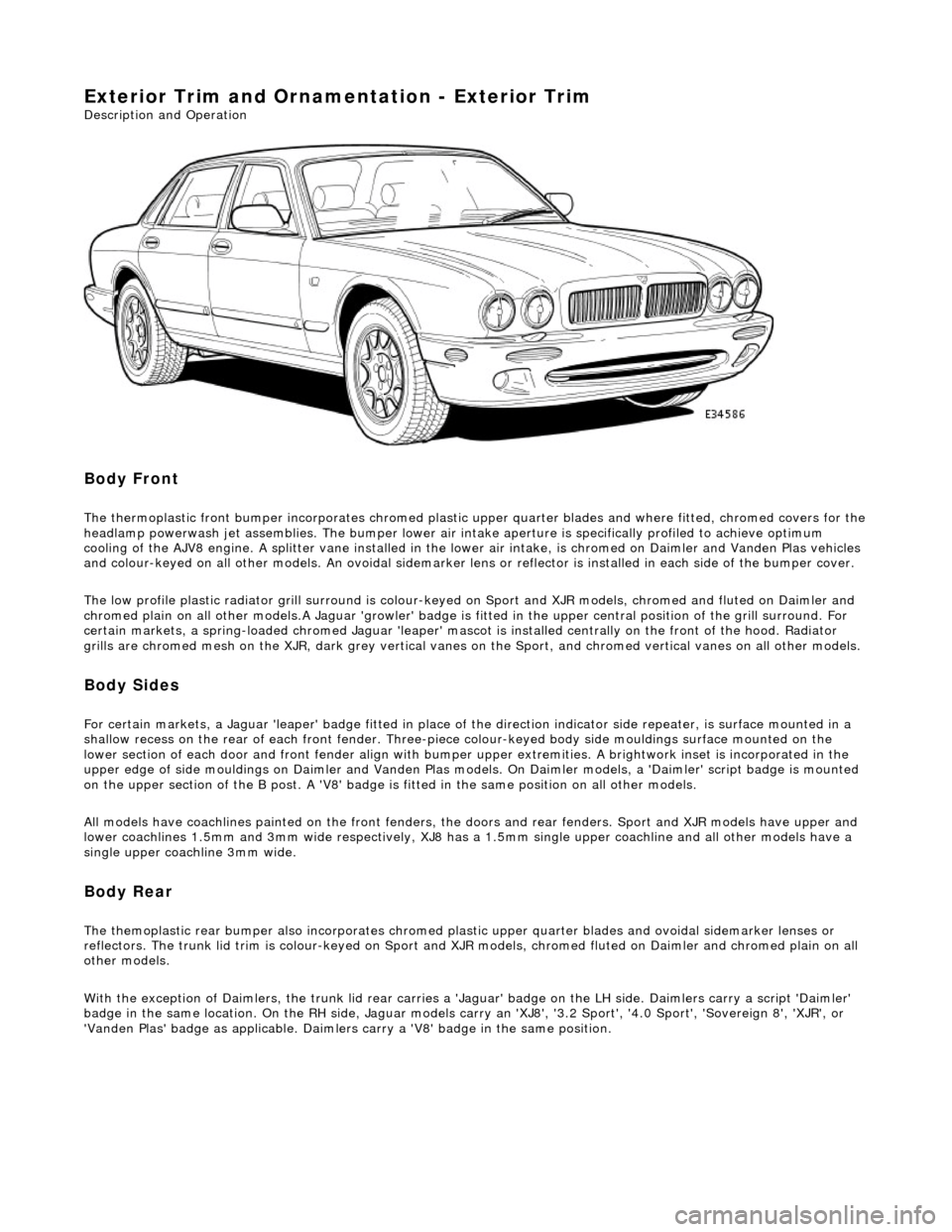

Body Front

The thermoplastic front bumper incorporates chromed plastic upper quarter blades and where fitted, chromed covers for the headlamp powerwash jet assemblie s. The bumper lower air intake aperture is specifically profiled to achieve optimum

cooling of the AJV8 engine. A splitter vane installed in the lowe r air intake, is chromed on Daimler and Vanden Plas vehicles

and colour-keyed on all other models. An ov oidal sidemarker lens or reflector is installed in each side of the bumper cover.

The low profile plastic radiator grill surround is colour-keyed on Sport and XJR mo dels, chromed and fluted on Daimler and

chromed plain on all other models .A Jaguar 'growler' badge is fitted in the upper central positi on of the grill surround. For

certain markets, a spring-loaded chromed Ja guar 'leaper' mascot is installed centrally on the front of the hood. Radiator

grills are chromed mesh on the XJR, dark grey vertical vanes on the Sport, and chromed ve rtical vanes on all other models.

Body Sides

For certain markets, a Jaguar 'l eaper' badge fitted in place of the direction indicator side re peater, is surface mounted in a

shallow recess on the rear of each fro nt fender. Three-piece colour-keyed body side mouldings surface mounted on the

lower section of each door and front fender align with bumper upper extremities. A brightwork inset is incorporated in the

upper edge of side mouldings on Daimler and Vanden Plas models. On Daimler models, a 'Daimler' script badge is mounted

on the upper section of the B post. A 'V8' badge is fitted in the same position on all other models.

All models have coachlines painted on th e front fenders, the doors and rear fender s. Sport and XJR models have upper and

lower coachlines 1.5mm an d 3mm wide respectively, XJ8 has a 1.5mm single upper coachline and all other models have a

single upper coachline 3mm wide.

Body Rear

The themoplastic rear bumper also inco rporates chromed plastic upper quarter blades and ovoi dal sidemarker lenses or

reflectors. The trunk lid trim is colour-keyed on Sport and XJ R models, chromed fluted on Daimler and chromed plain on all

other models.

With the exception of Daimlers, the trunk lid rear carries a 'Jaguar' badge on the LH side. Daimlers carry a script 'Daimler'

badge in the same location. On th e RH side, Jaguar models carry an 'XJ8', '3.2 Sport', '4.0 Sport', 'Sovereign 8', 'XJR', or

'Vanden Plas' badge as applic able. Daimlers carry a 'V8' badge in the same position.

Page 2307 of 2490

cooling duct.

The windshield washer is operated by pressing the button at the end of the wiper control stalk switch. Pressing and

releasing the button operates the washer for 1 to 1.4 seconds and the wiper completes three sweeps. An optional drip wipe

function adds a further sweep of the wiper after a 4 second delay, to clear residual fluid from the windshield. If the button is

held depressed, the washer and wiper will operate continuous ly for up to 20 seconds. When the button is released, the

wiper will again complete three further sweeps.

Headlamp Powerwash

The headlamp powerwash system incorporates a chromed twin nozzle assembly mounted on the chromed bumper blade

immediately in front of each pair of he adlamps. Each nozzle assembly is connected via snap fittings to a powerwash pump

mounted adjacent to the windshield wash pump on the rear face of the washer fluid reservoir.The powerwash system

operates in conjunction with the windshield washers when the ignition switch is in position II and the headlamp switch is in

the dip or main beam position. When powerwash is initially activated, a wash cycle commences, consisting of two 400 ms

pulses separated by a three second delay. If powerwash is still selected on completion of this cycle, it will continue to

operate at the same frequency for a maximum period of 20 se conds. To conserve washer fluid, headlamp powerwash will

only function on every sixth operation of the windshie ld wash switch.When the 'WASHER FLUID LOW' message is

illuminated, the windshield washer will continue to operat e for a limited period but the headlamp powerwash will not

function until the fluid level is restored.

Rain Sensing System

The rain sensing system installed form so me markets, provides automatic wiper operation when rain is detected on the

windshield. The system detects differing le vels of rainfall and varies wiper operation ranging from intermittent to maximum

continuous, to suit prevailing requirements.

The system which is brought into operation by selecting AUTO on the wiper control switch bezel, does not preclude normal

manual control of wiper operation.

The system consists of a rain sensor, an electronic control module and a dedicated wiper control switch.

The rain sensor is an optical transducer that is sensitive to changes in infra-red light penetration of the windshield created

by the refractive effects of water drople ts. The sensor elements consist of two groups of light emitting diodes which

alternately project infra-red light onto th e windshield and a photo-diode that receiv es resulting reflections from the glass. A ll

of the infra-red light is reflected back from a moisture-free windshield, resulting in a contact 5V output signal from the

sensor and no wiper activation. Rain falling on the light sensing area of the wi ndshield results in refraction and diffusion of a

proportion of the projected light with a corresponding imbalance of light received by the photodiode. This results in pulsed

outputs from the sensor, the frequency and duration of which are directly proportional to the number and size of water

droplets respectively. These pulses together with wiper switch position signals are received by the sensor control module

and processed to mimic column switch gear operation. In this recognisable form, signals are input to the body processor

module (BPM) where they are interprete d as normal wiper operation requests.

Page 2315 of 2490

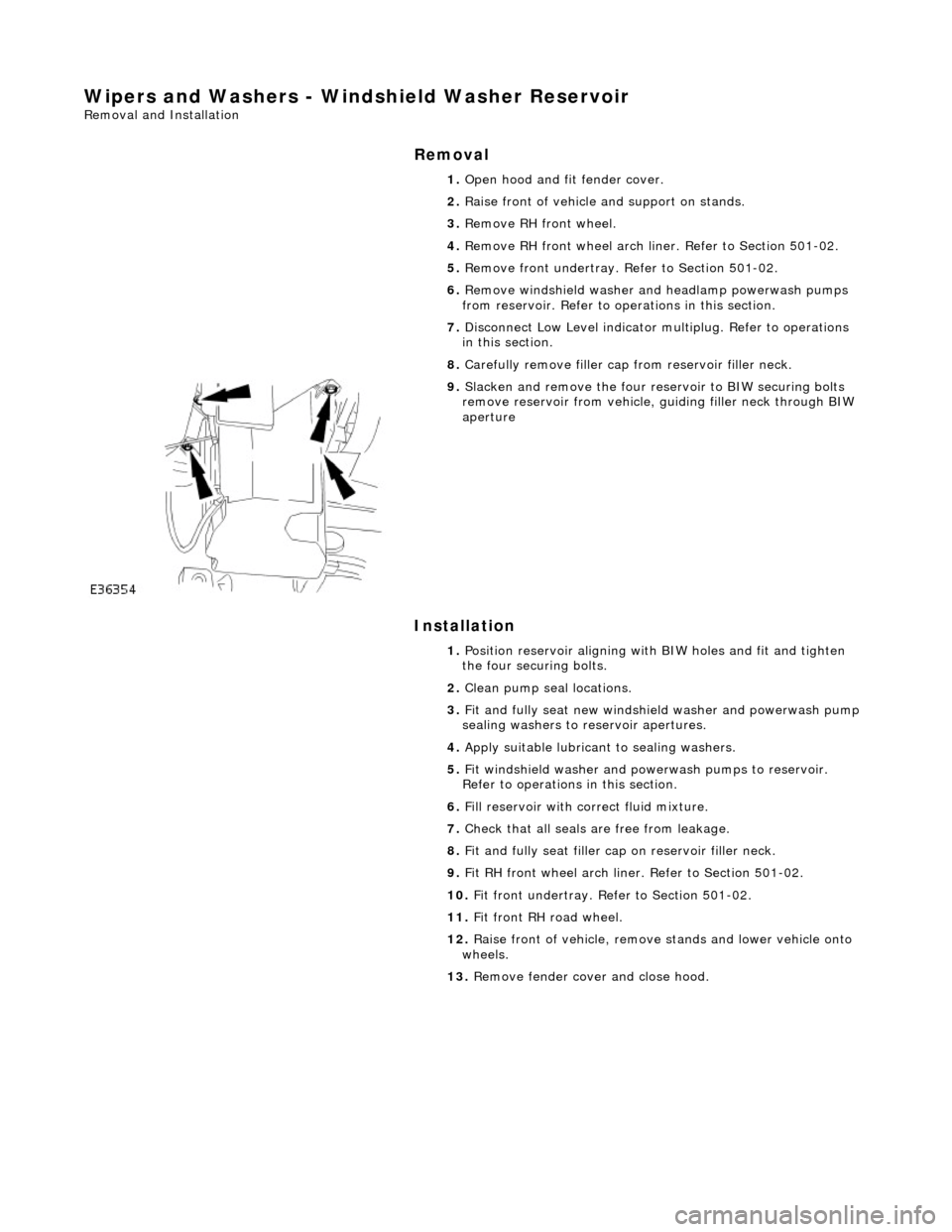

Wipers and Washers - Windshield Washer Reservoir

Removal and Installation

Removal

Installation

1.

Open hood and fit fender cover.

2. Raise front of vehicle and support on stands.

3. Remove RH front wheel.

4. Remove RH front wheel arch li ner. Refer to Section 501-02.

5. Remove front undertray. Refer to Section 501-02.

6. Remove windshield washer and headlamp powerwash pumps

from reservoir. Refer to op erations in this section.

7. Disconnect Low Level indicator mu ltiplug. Refer to operations

in this section.

8. Carefully remove filler cap from reservoir filler neck.

9. Slacken and remove the four re servoir to BIW securing bolts

remove reservoir from vehicle, guiding filler neck through BIW

aperture

1. Position reservoir aligning with BIW holes and fit and tighten

the four securing bolts.

2. Clean pump seal locations.

3. Fit and fully seat new windshie ld washer and powerwash pump

sealing washers to reservoir apertures.

4. Apply suitable lubricant to sealing washers.

5. Fit windshield washer and powerwash pumps to reservoir.

Refer to operations in this section.

6. Fill reservoir with correct fluid mixture.

7. Check that all seals are free from leakage.

8. Fit and fully seat filler cap on reservoir filler neck.

9. Fit RH front wheel arch liner. Refer to Section 501-02.

10. Fit front undertray. Refer to Section 501-02.

11. Fit front RH road wheel.

12. Raise front of vehicle, remove stands and lower vehicle onto

wheels.

13. Remove fender cover and close hood.

Page 2344 of 2490

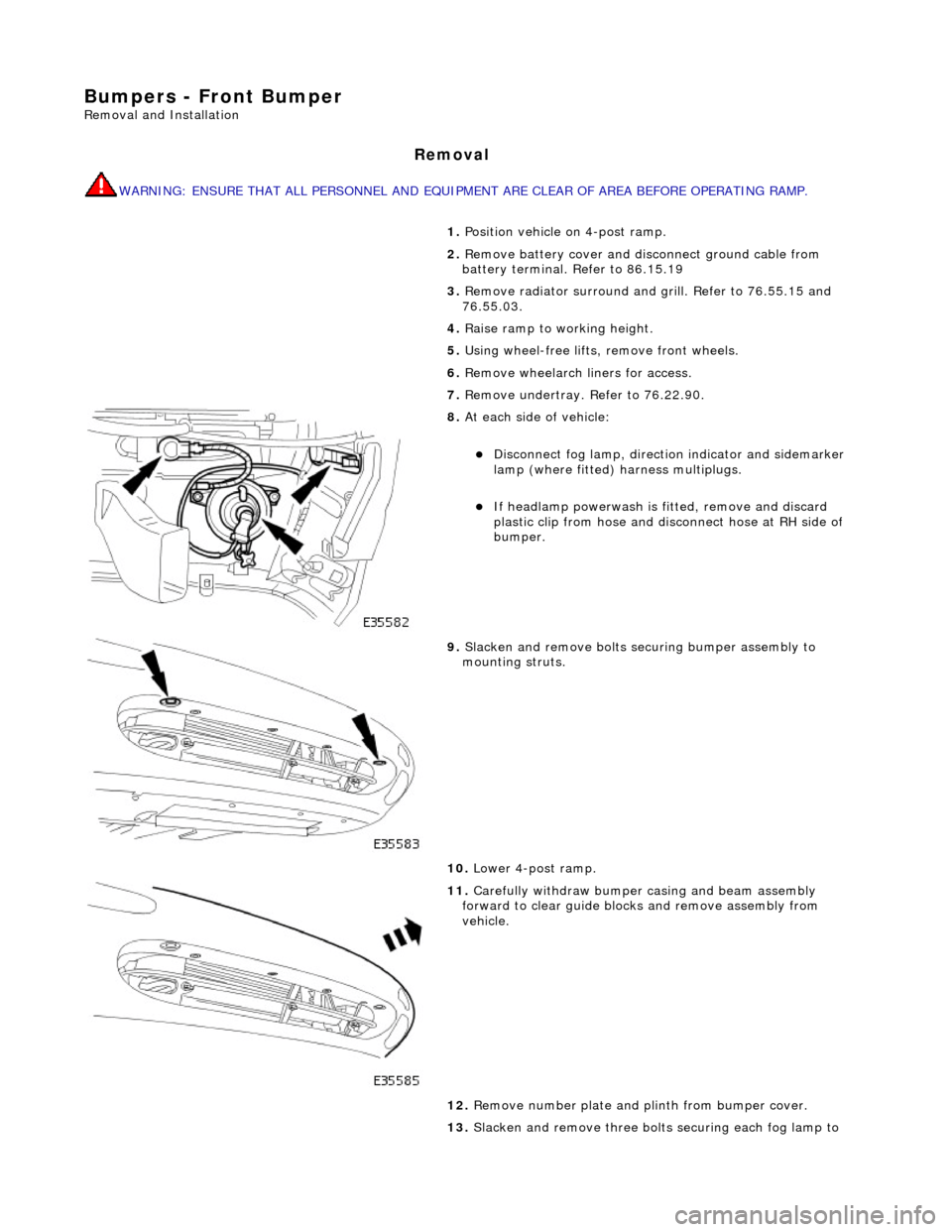

Bumpers - Front Bumper

Removal and Installation

Removal

WARNING: ENSURE THAT ALL PERSONNEL AND EQUIPMENT ARE CLEAR OF AREA BEFORE OPERATING RAMP.

1. Position vehicle on 4-post ramp.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19

3. Remove radiator surround and grill. Refer to 76.55.15 and

76.55.03.

4. Raise ramp to working height.

5. Using wheel-free lifts, remove front wheels.

6. Remove wheelarch liners for access.

7. Remove undertray. Refer to 76.22.90.

8. At each side of vehicle:

Disconnect fog lamp, directio n indicator and sidemarker

lamp (where fitted) harness multiplugs.

If headlamp powerwash is fitted, remove and discard

plastic clip from hose and disconnect hose at RH side of

bumper.

9. Slacken and remove bolts securing bumper assembly to

mounting struts.

10. Lower 4-post ramp.

11. Carefully withdraw bumper casing and beam assembly

forward to clear guide blocks and remove assembly from

vehicle.

12. Remove number plate and plinth from bumper cover.

13. Slacken and remove three bolts securing each fog lamp to

Page 2345 of 2490

bumper cover and remove both lamps from cover.

14. Release sidemarker lamp/refle ctor clips and remove both

lamps/reflectors from bumper cover.

15. Remove direction indicators fr om bumper assembly. Refer to

Section 417.01.

16. Remove powerwash jet assemb lies and hoses from top of

bumper assembly. Refer to Section 501-16.

17. Remove bumper blades.

1. Slacken and remove three screws securing each blade

to bumper cover.

2. Slide each blade forward to release two side tangs from cover and remove blade from bumper.

18. Rotate three splitter vane fasteners 1/4 turn counter-

clockwise and remove splitter vane from air intake.

19. Release tangs securing brake cooling ducts to cover and

remove ducts from bumper.

Page 2346 of 2490

In

stallation

20

. Remove an

d discard four scrive

ts securing upper section of

air intake to beam.

21 . D

rill out rivets securing uppe

r section of cover to bumper

beam.

22. Withdraw bumper beam from cover.

1. Position beam in cover, ensuring that tangs locate correctly in

beam slots.

2. Using new fir tree fast eners, scrivets and rivets, secure beam

to bumper cover.

3. Install fog lights, direction indicators, and side marker

lamps/reflectors in bumper cover.

4. Fit chrome blades to top of casing locating tangs in slots and fit

and tighten securing screws.

5. Fit powerwash jet assemblies to bumper cover. Refer to

Section 501.16.

6. Fit bumper assembly to vehicle. Refer to operations in this

section.

7. Position splitter vane in air intake and secure by rotating

fasteners 1/4 turn clockwise.

8. Fit number plate and plinth.

9. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 2347 of 2490

Bumpers - Front Bumper and Bumper Cover

Removal and Installation

Removal

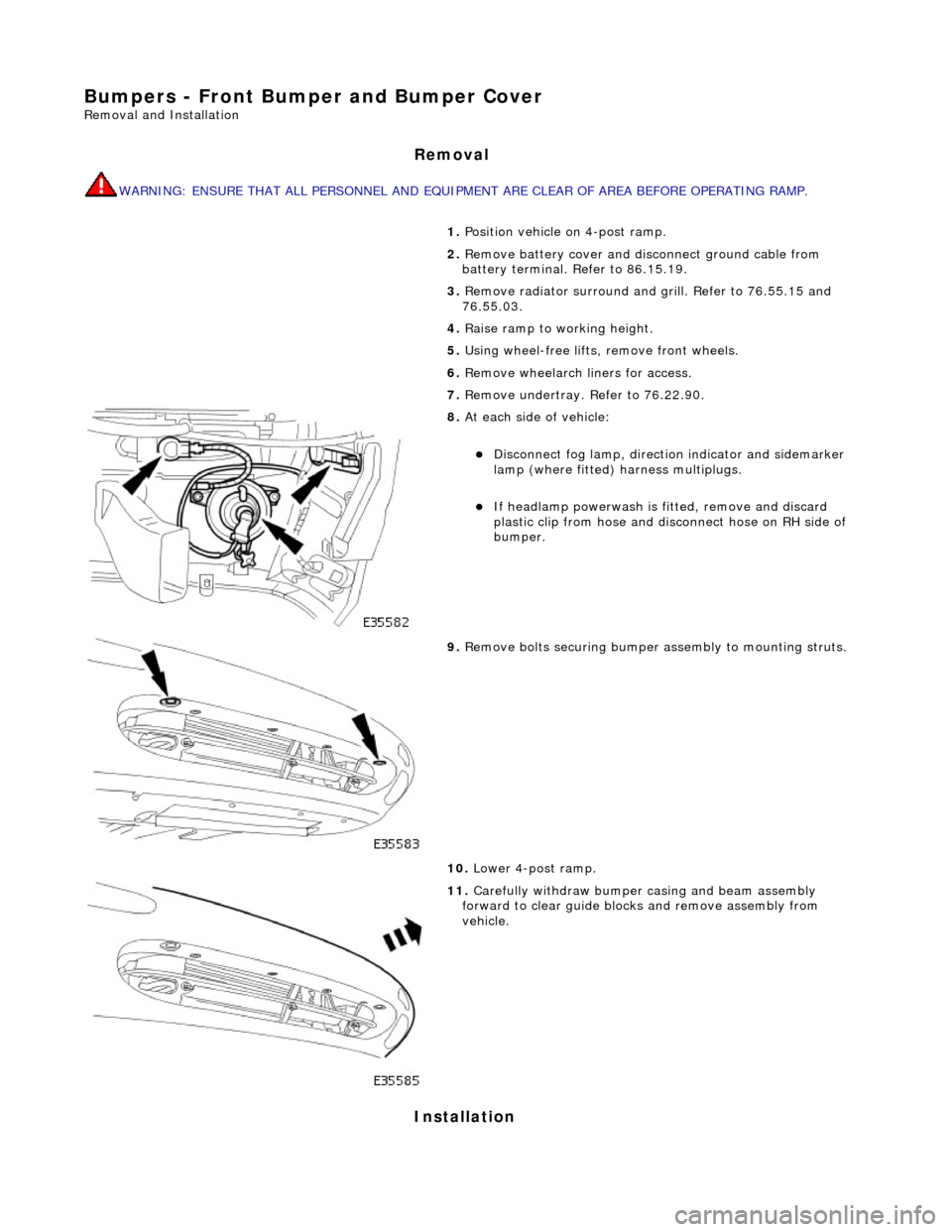

WARNING: ENSURE THAT ALL PERSONNEL AND EQUIPMENT ARE CLEAR OF AREA BEFORE OPERATING RAMP.

Installation

1. Position vehicle on 4-post ramp.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove radiator surround and grill. Refer to 76.55.15 and

76.55.03.

4. Raise ramp to working height.

5. Using wheel-free lifts, remove front wheels.

6. Remove wheelarch liners for access.

7. Remove undertray. Refer to 76.22.90.

8. At each side of vehicle:

Disconnect fog lamp, directio n indicator and sidemarker

lamp (where fitted) harness multiplugs.

If headlamp powerwash is fitted, remove and discard

plastic clip from hose and disconnect hose on RH side of

bumper.

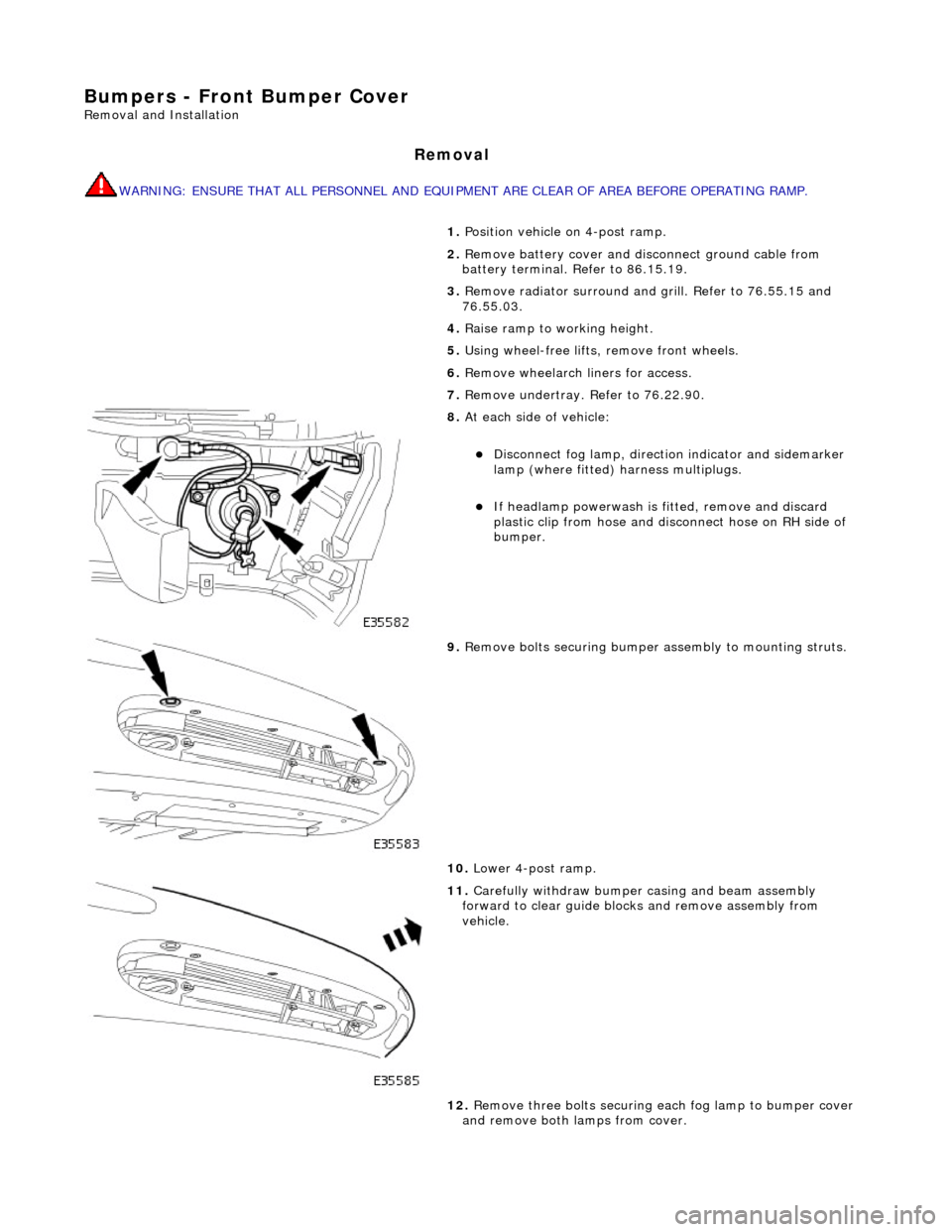

9. Remove bolts securing bumper assembly to mounting struts.

10. Lower 4-post ramp.

11. Carefully withdraw bumper casing and beam assembly

forward to clear guide blocks and remove assembly from

vehicle.

Page 2348 of 2490

1.

WARNING: ENSURE THAT ALL PERSONNEL AND

EQUIPMENT ARE CLEAR OF AREA BEFORE OPERATING RAMP.

Carefully slide bumper assembly onto fender guide blocks.

2. Raise ramp to working height.

3. Install but do not fully tighten bo lts securing bumper to struts.

4. Check clearance between top of bumper and bottom of fender.

If necessary, remove bumper, adjust guide blocks to achieve

correct clearance and refit bumper.

5. Connect harness multiplugs to foglamps, direction indicators

and where fitted side marker lamps.

6. Install harnesses in retaining clips at each side of cover.

7. Install powerwash hoses to jet assemblies and secure with new

plastic clips. Refer to Section 501.16.

8. Install radiator grill and su rround. refer to 76.55.03 and

76.55.15.

9. Check and as necessary adjust bumper cover to fender,

headlamps and radiator grill surround clearances. Refer to

Description and Operation in this section.

10. Fully tighten bumper assembly to strut securing bolts.

11. Install wheelarch liners.

12. Install undertray. Refer to 76.22.90.

13. Lower 4-post ramp.

14. Install road wheels and lower wheel-free lifts.

Page 2349 of 2490

Bumpers - Front Bumper Cover

Removal and Installation

Removal

WARNING: ENSURE THAT ALL PERSONNEL AND EQUIPMENT ARE CLEAR OF AREA BEFORE OPERATING RAMP.

1. Position vehicle on 4-post ramp.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove radiator surround and grill. Refer to 76.55.15 and

76.55.03.

4. Raise ramp to working height.

5. Using wheel-free lifts, remove front wheels.

6. Remove wheelarch liners for access.

7. Remove undertray. Refer to 76.22.90.

8. At each side of vehicle:

Disconnect fog lamp, directio n indicator and sidemarker

lamp (where fitted) harness multiplugs.

If headlamp powerwash is fitted, remove and discard

plastic clip from hose and disconnect hose on RH side of

bumper.

9. Remove bolts securing bumper assembly to mounting struts.

10. Lower 4-post ramp.

11. Carefully withdraw bumper casing and beam assembly

forward to clear guide blocks and remove assembly from

vehicle.

12. Remove three bolts securing each fog lamp to bumper cover

and remove both lamps from cover.

Page 2350 of 2490

13. Release sidemarker lamp/refle ctor clips and remove both

lamps/reflectors from bumper cover.

14. Remove direction indicators fr om bumper assembly. Refer to

Section 417.

15. Release tangs securing brake cooling ducts to bumper cover

and remove ducts.

16. Remove powerwash jet assemb lies and hoses from top of

bumper assembly. Refer to 84.20.08.

17. Remove bumper blades.

1. Remove three screws secu ring each blade to bumper

cover.

2. Slide each blade forward to release two side tangs from cover and remove blades from bumper.

18. Rotate three splitter vane fasteners 1/4 turn counter-

clockwise and remove splitter vane from air intake.

19. Remove number plate and plinth.

20. Remove and discard four scrive ts securing upper section of