dead battery JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 42 of 2490

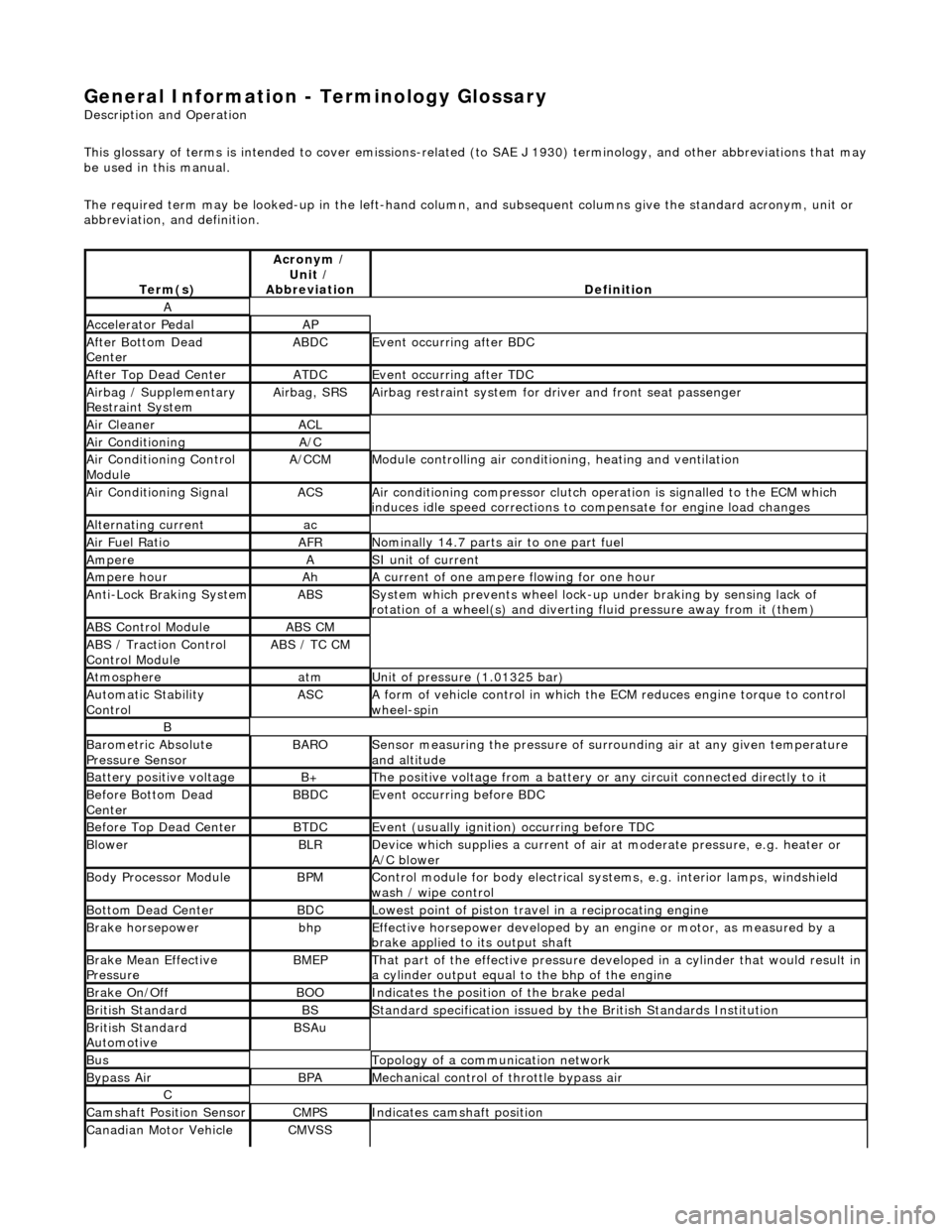

General Information - Terminology Glossary

Description an

d Operation

This glossary of terms is intended to cover emissions-related (to SAE J 1930) term inology, and other abbreviations that may

be used in this manual.

The required term may be looked-up in th e left-hand column, and subsequent columns give the standard acronym, unit or

abbreviation, and definition.

Te rm

(s)

Acr

ony

m /

Unit /

Abbreviation

De fi

nition

A

Accel

e

rator Pedal

AP

Af

ter Botto

m Dead

Center

ABDCEvent occurri ng after

BDC

Af

ter Top Dead CenterATDCEvent occurri ng after

TDC

Ai

rbag /

Supplementary

Restraint System

Airbag, SRSAi rbag restraint system for

dr

iver and front seat passenger

Air Cleane rACL

Air ConditioningA/C

Air Conditioning Con t

rol

Module

A/CCMModule c

ontrolling air conditioning, heating and ventilation

Air Conditioning SignalACSA

i

r conditioning compressor clutch operation is signalled to the ECM which

induces idle speed corrections to co mpensate for engine load changes

Alternating cu

rrent

ac

Ai

r Fuel R

atio

AFRN

omi

nally 14.7 parts air to one part fuel

Ampe

reASI unit of current

Ampere hourAhA current of one ampere

fl

owing for one hour

Anti-Lock Braking SystemABSS

y

stem which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and divertin g fluid pressure away from it (them)

ABS Control Mo

dule

ABS CM

ABS /

T

raction Control

Control Module

ABS / T

C CM

Atmosph

e

re

atmU

n

it of pressure (1.01325 bar)

Au

to

matic Stability

Control

ASCA form of vehicle

control

in which the ECM reduces en gine torque to control

wheel-spin

B

Baro me

tric Absolute

Pressure Sensor

BAR OSensor measuring the pressure of surr ou

nding air at any given temperature

and altitude

Bat t

ery positive voltage

B+The posi

ti

ve voltage from a battery or

any circuit connected directly to it

Before Bottom Dead

CenterBBDCEvent occurri ng before BD

C

Before Top Dead

Center

BTD

CEvent (usual ly

ignition) occurring before TDC

Blowe

rBLRDe

vice which supplies a current of air at

moderate pressure, e.g. heater or

A/C blower

Body Processor M

odule

BPMControl modu

le

for body electrical systems, e.g. interior lamps, windshield

wash / wipe control

Bott om D

ead Center

BD

CLowest poin t of piston

travel in a reciprocating engine

Brake hors

epowe

r

bhpEffecti

ve horsepower devel

oped by an

engine or motor, as measured by a

brake applied to its output shaft

Brake Mean Effective

Pres sureBME PThat p

art of the effective

pressure developed in a cyli nder that would result in

a cylinder output equal to the bhp of the engine

Brake On/ O

ff

BOOIn

dic

ates the position of the brake pedal

Br

it

ish Standard

BSStan

dar

d specification issued by the British Standards Institution

Br

it

ish Standard

Automotive

BSAu

BusTopology of a commu n

ication network

Bypass

AirBPAMechanica l

control of throttle bypass air

C

Camshaft Posit

i

on Sensor

CMPSIndi

cat

es camshaft position

Canadian Motor

V

ehicle

CMVSS

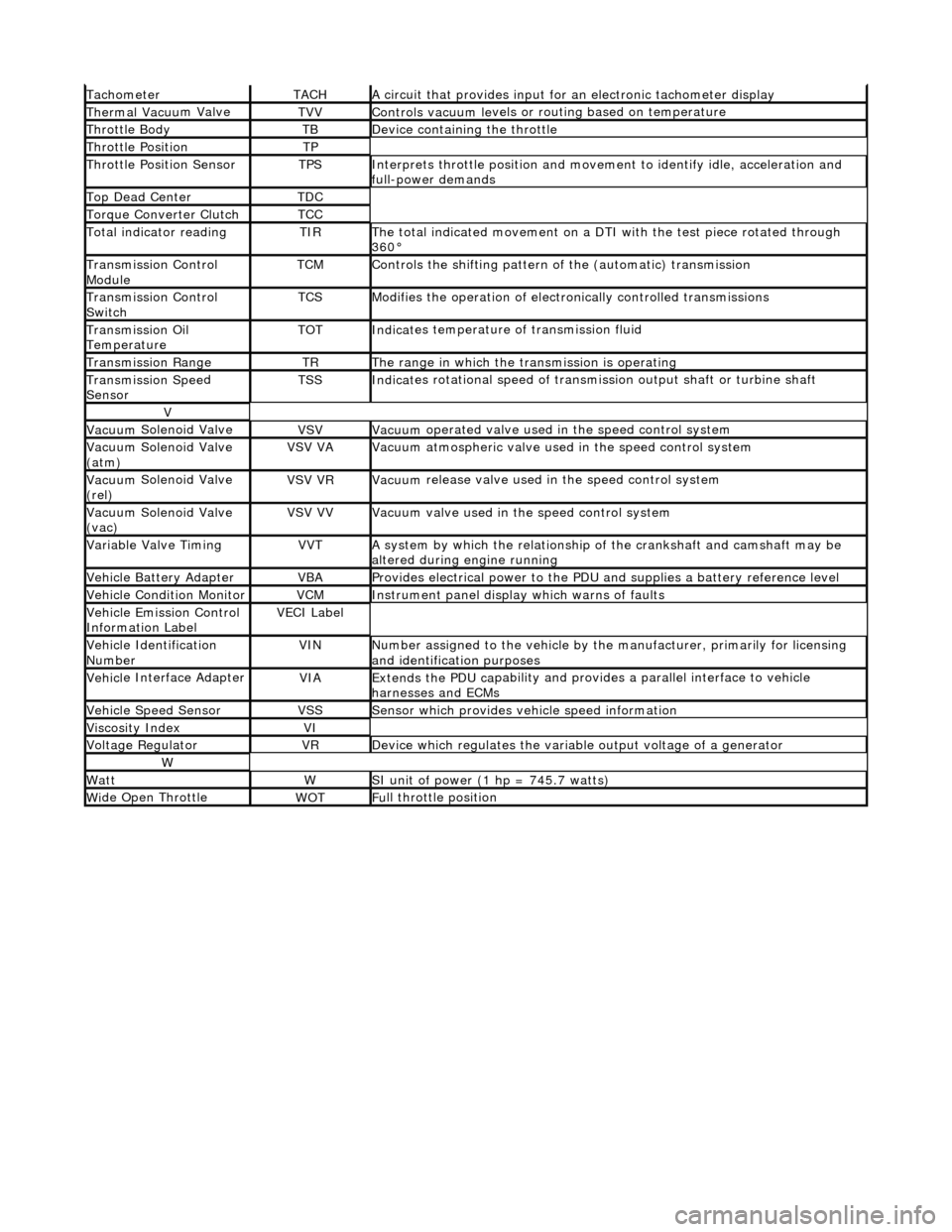

Page 48 of 2490

Tacho

meter

TACHA

ci

rcuit that provides input for

an electronic tachometer display

Thermal Vacuu

m Valve

TVVControls vacuum l

e

vels or

routing based on temperature

Throttle

Body

TBDe

vi

ce containing the throttle

Throttl

e

Position

TP

Throttl

e

Position Sensor

TPSInterprets throttl

e

position and movement to iden tify idle, acceleration and

full-power demands

Top Dead CenterTDC

Torque Converter C

lutch

TCC

To

tal

indicator reading

TIRThe t

o

tal indicated movement on a DTI with the test piece rotated through

360°

Transm

ission Control

Module

TCMControls

the shifting pattern

of the (automatic) transmission

Transm

ission Control

Switch

TCSModifi es

the operation of electronically controlled transmissions

Transmission Oil

TemperatureTOTIndi

cat

es temperature of transmission fluid

Transmission RangeTRThe ran

g

e in which the transmission is operating

Transmission Spe

e

d

Sensor

TSSIndi cat

es rotational speed of transmission output shaft or turbine shaft

V

Vacuu

m

Solenoid Valve

VSVVacuu

m

operated valve used in the speed control system

Vacuu

m

Solenoid Valve

(atm)

VSV VAVacuu m

atmospheric valve used in the speed control system

Vacuu

m

Solenoid Valve

(rel)

VSV VRVacuu m

release valve used in the speed control system

Vacuu

m

Solenoid Valve

(vac)

VSV VVVacuu m

valve used in the speed control system

Variable Valve TimingVVTA

s

ystem by which the relationship of the crankshaft and camshaft may be

altered during engine running

Vehi cl

e Battery Adapter

VBAProvide

s

electrical power to the PDU

and supplies a battery reference level

Vehicl

e Condition Monitor

VCMInst

rum

ent panel display which warns of faults

Ve

hic

le Emission Control

Information Label

VECI Label

Vehi cl

e Identification

Number

VINN u

mber assigned to the vehicle by the manufacturer, primarily for licensing

and identification purposes

Vehi cl

e Interface Adapter

VIAExtends the

PDU ca

pability and provid

es a parallel interface to vehicle

harnesses and ECMs

Vehicle Spe e

d Sensor

VSSSens

or which provides ve

hicle speed information

Viscosity In

dexVI

Voltage RegulatorVRDe

vice which regulates the variable output voltage of a generator

W

Wat

tWSI unit of power (1 hp = 7

45.7 watts)

W

i

de Open Throttle

WO

TFu

ll throttle position

Page 2054 of 2490

Interior Trim and Ornamentation - Interior Trim

Description and Operation

Carpets

The passenger compartment carpet is a one piece moulded constr uction with integral sound deadening material, heel mats

and driver's footrest. The carpet is attach ed to the vehicle floor by plastic clips fitted below the door treadplates. Removal of the carpet necessitates re moval of the front seats, lifting of the centre console rear extens ion and removal of the heelboard

carpet.

Fascia

The full width, slush moulded, soft feel PVC fascia is mounted on an injection moulded armature and is faced with wood

veneer. In addition to the air conditioning and central, outer and demisting vents, it accepts instrument packs dedicated to

market requirements and a centrally mounted analogue clock.

Doors

The one-piece door casings are trimmed in UEV to match the seating, with wood veneer at the waistline and a carpet insert

at the front lower corner. Each casing is secured to the door inner panel by fir tree press fast eners along the lower section,

two armrest fixings at the centre and vene er panel dowels and fixings at the top. The armrests which are common to front

and rear doors, are trimmed in matching leather or UEV according to specification. The door switchpacks, dedicated to

driver and front or rear passenger, are in corporated in the armrests. A speaker is in stalled in the lower section of each door

and a tweeter is incorporated behind each interior door handle escutcheon. Where premium ICE is fitted, the front tweeters

are installed in the upper A posts.

A, B, C and D Posts

On each side,a grained UEV finisher trimmed to match the headlining is secured to the 'A' post and cantrail by fir tree

fasteners locating in BIW apertures. The upper 'D' post finisher is trimmed and secured in the same manner. The single

piece'B/C' post finishers, also finished in grained matching UEV, each have a front se at belt exit aperture and are secured to

the BIW by four spring clips and two fir tree fasteners.

Headlining

The one-piece headlining consists of a 6mm thick polyurethane foam membrane covered with suede effect knitted polyester. The headlining is secured to the BIW roof by body tangs, the roof console, sun visors, combined grab handles and coat

hooks, the cantrail finishers and where fitt ed, the sliding roof finisher and clips.

Trunk

Carpet covered trims line the trunk and are secured by fir tr ee fasteners to the sides and front inner panel. The carpet

covered, two-section, removable trunk fl oor provides access to the spare wheel and wheel changing equipment, the battery

and electrical carrier. The floor board rests on the spare wheel, with the front and rear edges locating in blocks on the fuel

tank backboard and the rear of the body. The support blocks provide for two floor he ight settings to accommodate either a

space saver or full size spare wheel.A moulded finisher covering the rear of the trunk below the sill is secured to the rear

panel by tabs and fir tree fasteners. Finish er panels fitted to the rear lamp units provide trunk interior access to the lamps.

The trunk lid underside is fitted with a removabl e moulded liner and two trunk illumination lights.