Piston JAGUAR XF 2009 1.G AJ133 5.0L Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 36, PDF Size: 0.38 MB

Page 17 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-15

Engine Management System

Knock Sensors

KNOCK SENSORS

The ECM uses active knock control, which serves to

prevent engine damaging pre-ignition or detonation

under all operating conditions, enabling the engine to

operate without additional safety margins.

The ECM uses 4 piezo-ceramic knock sensors to determine

the point at which a cylinder is pre-detonating. Two sensors

are mounted on the intake side of each cylinder head.

Each sensor monitors engine knock by converting the

engine block noise into a suitable electrical signal, which

is then transmitted back to the ECM via a twisted-pair

cable. The signal is processed within the ECM to iden-

tify the data that characterizes knocking.

This information is compared to known signal profiles to

determine whether pre-ignition is present. If so, the

closed loop control system retards the ignition on that

cylinder for a number of cycles, after which it gradually

moves back towards its original setting.

Safety Precautions CAUTION: Terminals in sensor and connec-

tor are gold plated for corrosion/temperature

resistance. Do not probe connections.

NOTE:

Accurate orientation of the knock sensors on the

cylinder block is required to ensure correct connection to

the vehicle wiring harness.

Failure Modes

• Sensor open circuit

• Short circuit to vehicle ground or battery voltage

• Faulty component or incorrectly torqued / coming loose

• Noise on vehicle 12V supply could look like knock signal causing knock fault

• Min fault usually due to open circuit

• Max fault short circuit to battery voltage or extreme mechanical engine noise/piston slap

• ECM calculates the default value if one sensor fails on each bank of cylinders

Failure Symptoms

• Knock control is disabled and a default ‘safe ignition map’ is used

• Possible rough running and reduced engine perfor- mance

Failure Mode Behaviors

• The vehicle control system constantly checks open circuit of knock sensor. Therefore, the knock sensor

is connected to the power source via pull-up line of

the ECM.

• When short/open circuit occurs to the knock sensor signal circuit, the system detects it, sets failure flag,

and commences maximum retard control on spark

advance.

• As far as the behavior of knock sensor is concerned, however, the above-mentioned failure modes cannot

cause serious outcomes such as heat generation,

smoke emission and/or fire hazard.

NP10V8100

Specification

Function

Power Source N/A

Wiring Type Twisted Pair

Shunt Resistance 4.8M Ohms

Operating Range 3kHz – 22kHz

Mounting Torque 20Nm +/- 3.8Nm

Page 34 of 36

3-3204/14/2009NP10-V8JLR: AJ133 5.0-Liter DFI V8 EngineTechnical Training

Crankcase Ventilation System Engine Management System

CRANKCASE VENTILATION SYSTEM

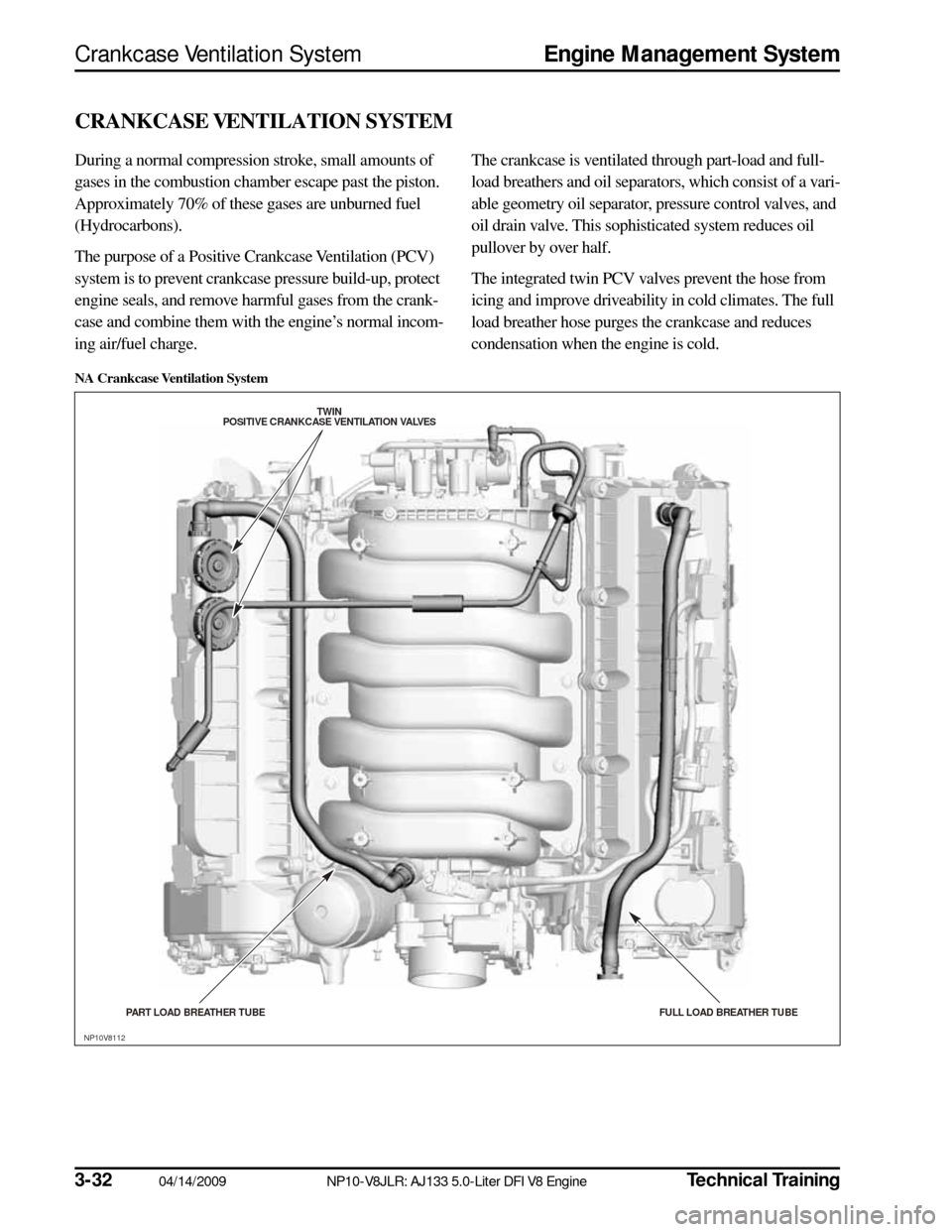

During a normal compression stroke, small amounts of

gases in the combustion chamber escape past the piston.

Approximately 70% of these gases are unburned fuel

(Hydrocarbons).

The purpose of a Positive Crankcase Ventilation (PCV)

system is to prevent crankcase pressure build-up, protect

engine seals, and remove harmful gases from the crank-

case and combine them with the engine’s normal incom-

ing air/fuel charge. The crankcase is ventilated through part-load and full-

load breathers and oil separators, which consist of a vari-

able geometry oil separator, pressure control valves, and

oil drain valve. This sophisticated system reduces oil

pullover by over half.

The integrated twin PCV valves prevent the hose from

icing and improve driveability in cold climates. The full

load breather hose purges the crankcase and reduces

condensation when the engine is cold.

NA Crankcase Ventilation System

TWIN

POS ITIVE CRANKCAS E VENTILATION VALVES

PART LOAD BREATHER TUBE FULL LOAD BREATHER TUBE

NP10V8112