JAGUAR XF 2009 1.G AJ133 5.0L Engine Manual

Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 36, PDF Size: 0.38 MB

Page 1 of 36

Technical Training

Technical Introduction

NP10

-

V8JLR: AJ133 5.0

-

Liter DFI V8 Engine

Engine Management System

NP10-V8JLR 04/2009Printed in USA

NP10V8COV

Page 2 of 36

This publication is intended for instructional purposes only. Always refer to the appropriate service publication for

specific details and procedures.

All rights reserved. All material contained herein is based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

© 2009 Jaguar Land Rover North America LLC

Page 3 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-1

Engine Management System

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Engine Control Module . . . . . . . . . . . . . . . . . . . . . . 8

Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Crankshaft Position Sensor . . . . . . . . . . . . . . . . . . 11

Camshaft Position Sensor . . . . . . . . . . . . . . . . . . . 13

Engine Coolant Temperature Sensor . . . . . . . . . . 14

Knock Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Manifold Absolute Pressure Sensor . . . . . . . . . . . 16

Mass Air Flow Sensor . . . . . . . . . . . . . . . . . . . . . . 17

Temp. / Manifold Absolute Pressure Sensor . . . . 18

Throttle Position Sensor . . . . . . . . . . . . . . . . . . . . 19

Accelerator Pedal Position Sensor . . . . . . . . . . . . 21

Heated Oxygen Sensors . . . . . . . . . . . . . . . . . . . . 22

Ambient Air Temperature Sensor. . . . . . . . . . . . . 26

Ignition Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fuel Tank Canister Purge Valve . . . . . . . . . . . . . . 28

Viscous Fan Control (Land Rover only) . . . . . . . 29

Controller Area Network. . . . . . . . . . . . . . . . . . . . 30

On-Board Diagnostic Monitoring . . . . . . . . . . . . . 31

Crankcase Ventilation System . . . . . . . . . . . . . . . 32

Page 4 of 36

3-2

04/14/2009 NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine

Technical Training

Overview

Engine Management System

OVERVIEW

The 5.0-Liter V8 normally aspirated (NA) and super-

charged (SC) engines are managed by the engine control

module (ECM), which controls the following:

• Engine fuel metering

• Ignition timing

• Camshaft timing

• Camshaft Profile Switching (CPS)

• Closed loop fuel metering

• Knock control

• Idle speed control

• Emission control

• On-Board Diagnostics (OBD)

• Interface with the immobilization system

• Speed control

The ECM controls the engine fuel metering by provid-

ing sequential fuel injection to all cylinders. Ignition is

controlled by a direct ignition system, provided by eight

coil-on-plug (COP) units. The ECM is able to detect and

correct for ignition knock on each cylinder and adjust the

ignition timing for each cylinder to achieve optimum

performance.

The ECM uses a torque-based strategy to generate the

torque required by driver demand and the other vehicle

control modules, using input from various sensors to cal-

culate the required torque. The ECM also interfaces with

other vehicle electronic control modules to obtain addi-

tional information (road speed from the ABS control

module, for example). The ECM processes these signals

and determines how much torque to generate, using vari-

ous actuators to supply air, fuel, and spark to the engine

(electronic throttle, injectors, coils, etc.).

Page 5 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-3

Engine Management System

Overview

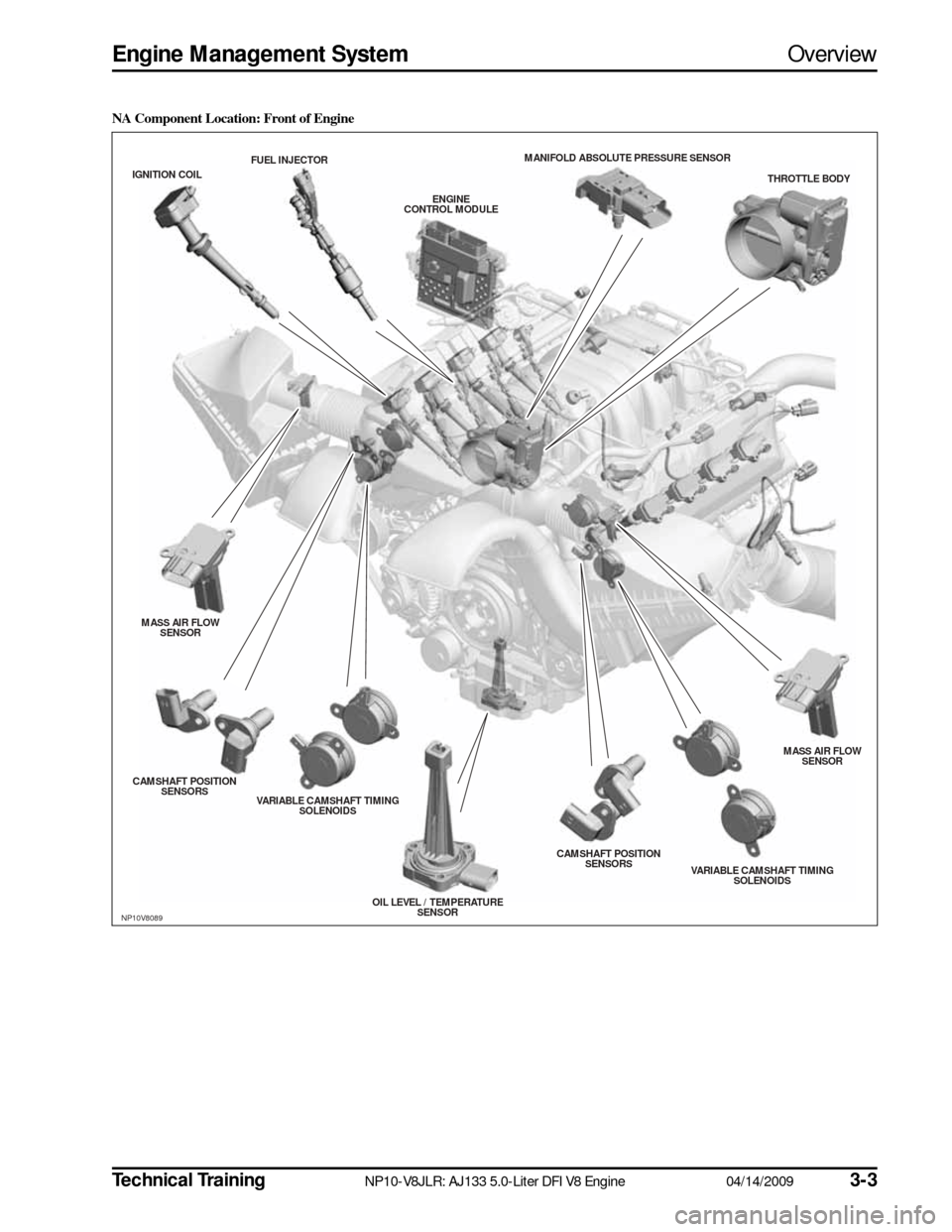

NA Component Location: Front of Engine

NP10V8089

THROTTLE BODY

MANIFOLD ABS

OLUTE PRESSURE S ENSOR

ENGINE

CONTROL MODULE

FUEL INJECTOR

IGNITION COIL

MASS AIR FLOW SENS OR

CAMS HAFT POS ITION

S ENS ORS

VARIABLE CAMS HAFT TIMING

S OLENOIDS

OIL LEVEL / TEMPERATURESENS OR CAMS

HAFT POS ITION

S ENS ORS

VARIABLE CAMSHAFT TIMING

S OLENOIDS MASS AIR FLOW

SENS OR

Page 6 of 36

3-4

04/14/2009 NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine

Technical Training

Overview

Engine Management System

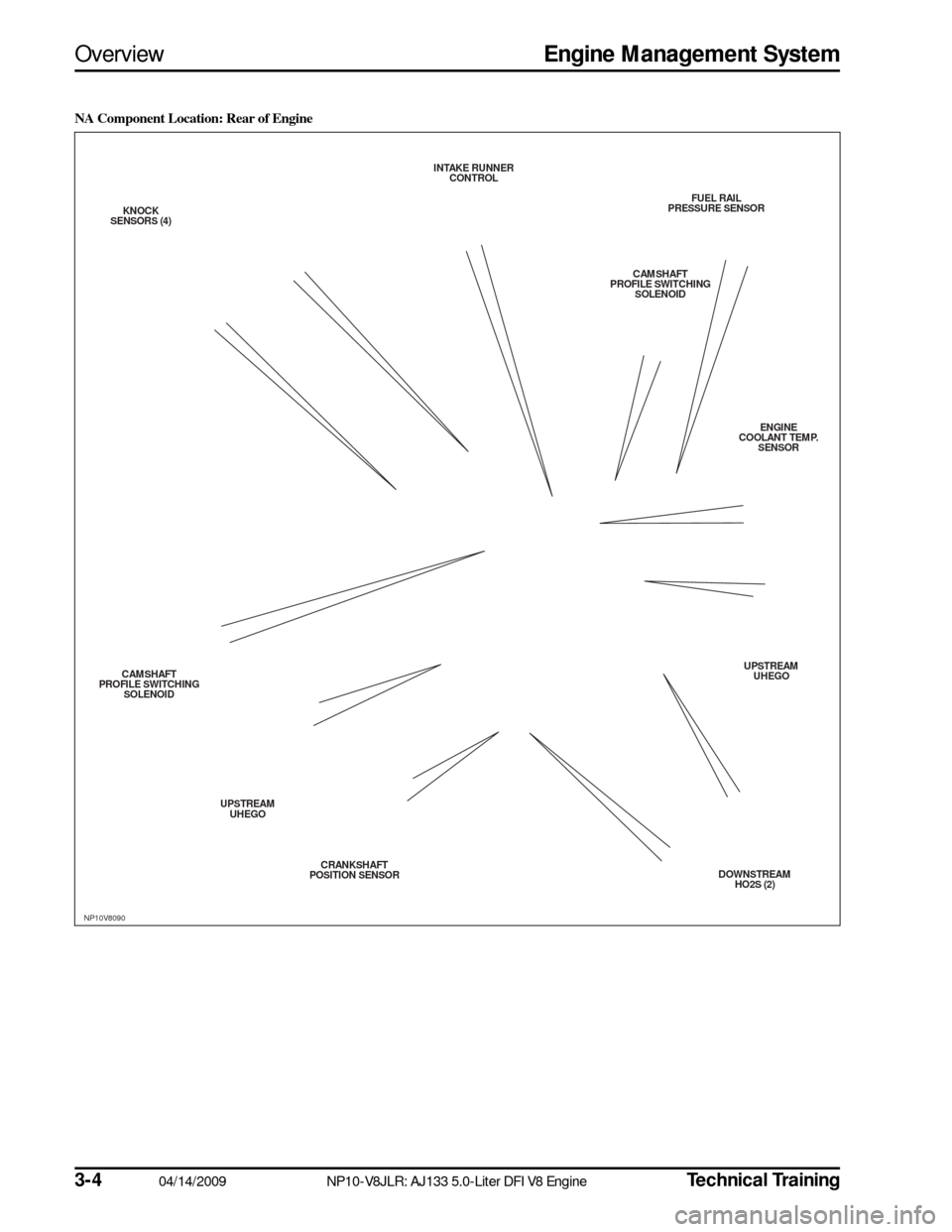

NA Component Location: Rear of Engine

NP10V8090

FUEL RAIL

PRESSURE S ENSOR

CAMS HAFT

PROFILE S WITCHING

S OLENOID

ENGINE

COOLANT TEMP. SENS OR

UPS TREAM

UHEGO

DOWNS TREAM

HO2S (2)

CRANKS

HAFT

POS ITION S ENSOR

UPS

TREAM

UHEGO

CAMS

HAFT

PROFILE S WITCHING

S OLENOID

KNOCK

S ENS ORS (4) INTAKE RUNNER

CONTROL

Page 7 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-5

Engine Management System

Overview

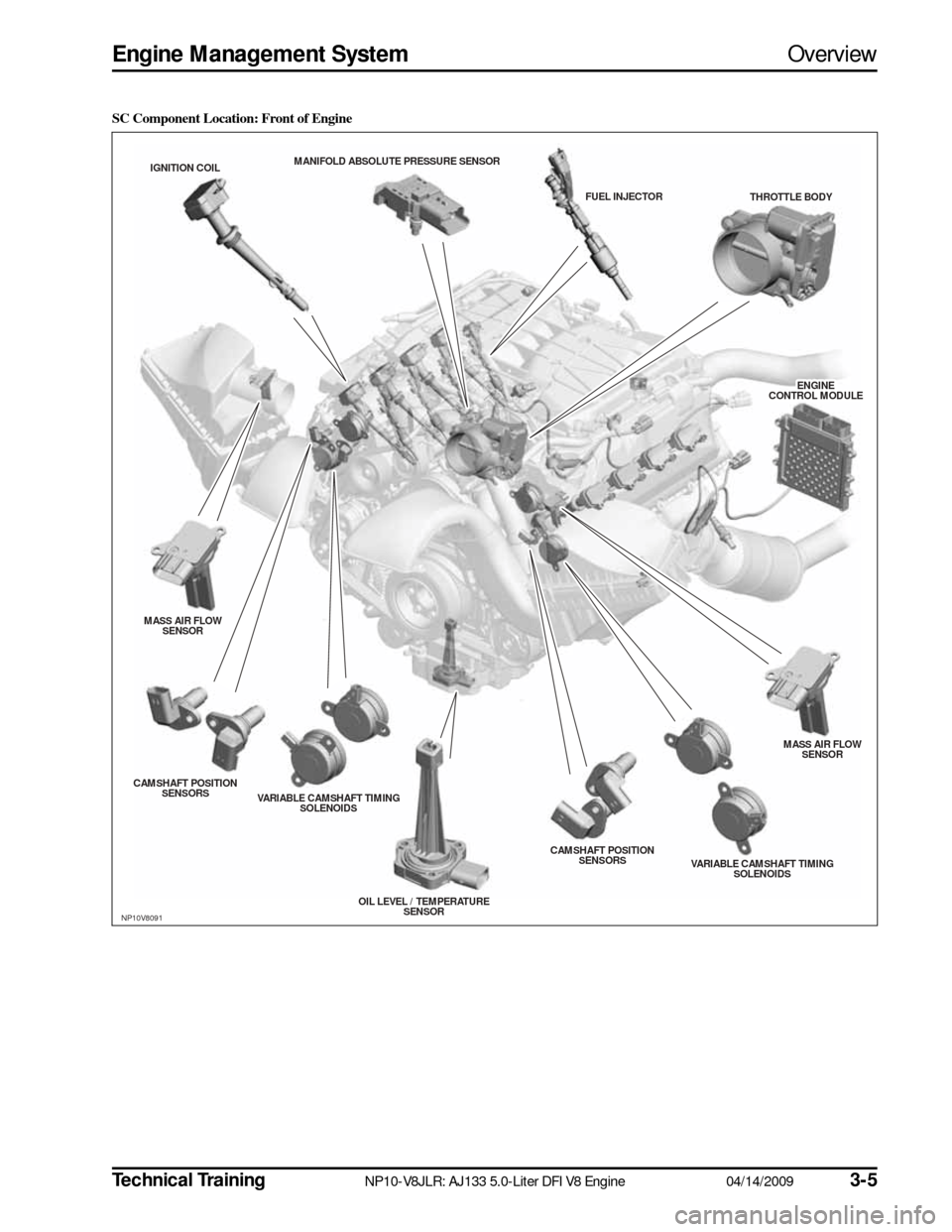

SC Component Location: Front of Engine

NP10V8091

THROTTLE BODY

MANIFOLD ABS

OLUTE PRESSURE S ENSOR

ENGINE

ENGINECONTROL MODULECONTROL MODULEENGINE

CONTROL MODULE

FUEL INJECTOR

IGNITION COIL

MASS AIR FLOW SENS OR

CAMS HAFT POS ITION

S ENS ORS

VARIABLE CAMS HAFT TIMING

S OLENOIDS

OIL LEVEL / TEMPERATURESENS OR CAMS

HAFT POS ITION

S ENS ORS

VARIABLE CAMSHAFT TIMING

S OLENOIDS MASS AIR FLOW

SENS OR

Page 8 of 36

3-6

04/14/2009 NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine

Technical Training

Overview

Engine Management System

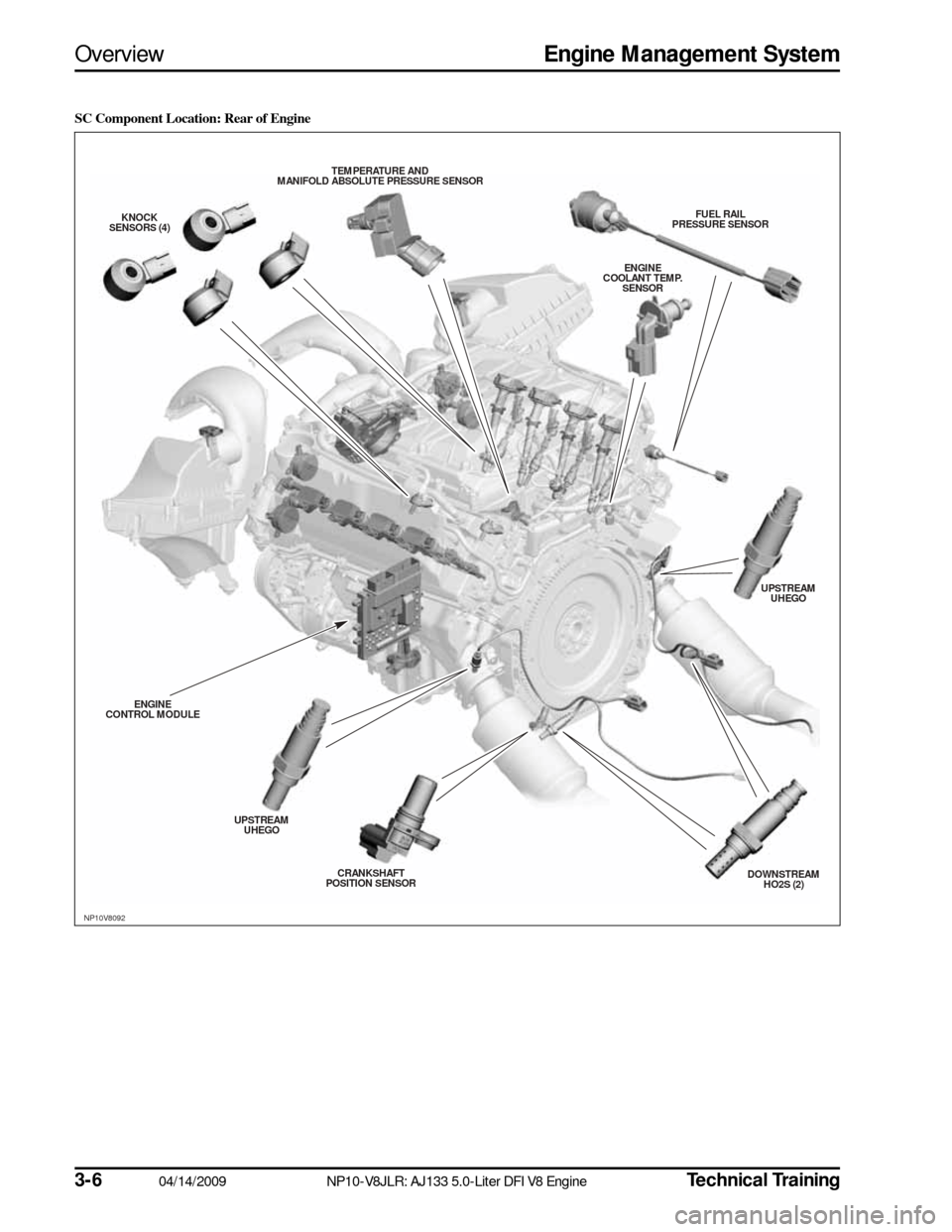

SC Component Location: Rear of Engine

NP10V8092

FUEL RAIL

PRESSURE S ENSOR

ENGINE

COOLANT TEMP. SENS OR

UPSTREAM

UHEGO

DOWNS TREAM

HO2S (2)

CRANKS

HAFT

POS ITION S ENSOR

UPS

TREAM

UHEGO

ENGINE

CONTROL MODULE KNOCK

S ENS ORS (4) TEMPERATURE AND

MANIFOLD ABS OLUTE PRESSURE S ENSOR

Page 9 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-7

Engine Management System

Overview

WARNINGS:

• Direct injection injectors require high booster voltages (65V); special care must be

taken to guarantee proper electrical isola-

tion of the cable harness and all connectors.

The ECM outputs for the injectors are pro-

tected in case of open and short circuit.

• Due to the high currents in the injectors, strong magnetic fields are created. An influ-

ence within a distance of up to 0.2m from

the wiring harness or control unit is to be

expected. Each vehicle type must therefore

be checked to ensure that this distance is

maintained. In particular, the interference-

free function of pacemakers cannot be

guaranteed.

CAUTIONS:

• DO NOT connect test probes connected to battery positive supply to any ground pins,

as this will DESTROY the ECM.

• Use care when probing connectors for wir- ing checks. The gold plating used on low

current signal connector terminals is easy

to damage by inserting a probe.

• Do not use probes that pierce wiring insula- tion since they damage/sever wiring, leav-

ing it vulnerable to corrosion.

Page 10 of 36

3-8

04/14/2009 NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine

Technical Training

Engine Control Module

Engine Management System

ENGINE CONTROL MODULE

The ECM is supplied with battery voltage from a 5A fuse and an ignition supply from the ECM relays through\

a 15A

fuse, both located in the CJB. A regulator located within the ECM supplies a 5V current to internal compone\

nts such

as the microprocessor unit. Other components or functions requiring full\

battery voltage are controlled by external

relays or internal switching modules.

The microprocessor within the ECM receives signals from different components and control modules and uses a pro-

gram within the ECM software to interpret the signal information and issue signals which relate t\

o how the engine

components and functions should be controlled. The ECM communicates with other control modules via bidirectional

Controller Area Network (CAN) communication interfaces.

The ECM uses the following inputs and outputs:

Inputs

• Camshaft position (CMP) sensor

• Crankshaft position (CKP) sensor

• Fuel rail high-pressure sensor

• Mass air flow (MAF) sensors (2)

• Knock sensors (4)

• Engine coolant temperature (ECT) sensor

• Manifold absolute pressure (MAP) sensor

• Electronic throttle position sensor

• Accelerator pedal position (APP) sensor

• Cooling fan speed

• Upstream Universal Heated Exhaust Gas Oxygen (UHEGO) sensors (2)

• Brake switch

• Speed control cancel/suspend switch

• Intake air temperature (IAT) sensor (integrated into the MAF) (2)

• Ambient air temperature (AAT) sensor

• Engine oil level and temperature sensor

• Temperature and manifold absolute pressure (TMAP) sensor (SC only)

Outputs

• Throttle Actuator

• Coil-on-plug (COP) ignition coils (8)

• Upstream Universal Heated Exhaust Gas Oxygen (UHEGO) sensors (2)

• Downstream Heated Oxygen Sensors (HO2S) (2)

• Direct injection fuel injectors (8)

• Variable camshaft timing (VCT) solenoids (4)

• Camshaft profile switching (CPS) solenoids (2)

• Intake manifold tuning solenoid

• Carbon canister purge valve

• Fuel pump relay

• Starter relay

• A/C condenser fan relay

• ECM main relay viscous fan control

• Generator control

• Air flap solenoid (SC only)

• Pump control diagnostics

• Diagnostic Monitoring of Tank Leakage (DMTL)