air condition JAGUAR XF 2009 1.G AJ133 5.0L Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 36, PDF Size: 0.38 MB

Page 17 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-15

Engine Management System

Knock Sensors

KNOCK SENSORS

The ECM uses active knock control, which serves to

prevent engine damaging pre-ignition or detonation

under all operating conditions, enabling the engine to

operate without additional safety margins.

The ECM uses 4 piezo-ceramic knock sensors to determine

the point at which a cylinder is pre-detonating. Two sensors

are mounted on the intake side of each cylinder head.

Each sensor monitors engine knock by converting the

engine block noise into a suitable electrical signal, which

is then transmitted back to the ECM via a twisted-pair

cable. The signal is processed within the ECM to iden-

tify the data that characterizes knocking.

This information is compared to known signal profiles to

determine whether pre-ignition is present. If so, the

closed loop control system retards the ignition on that

cylinder for a number of cycles, after which it gradually

moves back towards its original setting.

Safety Precautions CAUTION: Terminals in sensor and connec-

tor are gold plated for corrosion/temperature

resistance. Do not probe connections.

NOTE:

Accurate orientation of the knock sensors on the

cylinder block is required to ensure correct connection to

the vehicle wiring harness.

Failure Modes

• Sensor open circuit

• Short circuit to vehicle ground or battery voltage

• Faulty component or incorrectly torqued / coming loose

• Noise on vehicle 12V supply could look like knock signal causing knock fault

• Min fault usually due to open circuit

• Max fault short circuit to battery voltage or extreme mechanical engine noise/piston slap

• ECM calculates the default value if one sensor fails on each bank of cylinders

Failure Symptoms

• Knock control is disabled and a default ‘safe ignition map’ is used

• Possible rough running and reduced engine perfor- mance

Failure Mode Behaviors

• The vehicle control system constantly checks open circuit of knock sensor. Therefore, the knock sensor

is connected to the power source via pull-up line of

the ECM.

• When short/open circuit occurs to the knock sensor signal circuit, the system detects it, sets failure flag,

and commences maximum retard control on spark

advance.

• As far as the behavior of knock sensor is concerned, however, the above-mentioned failure modes cannot

cause serious outcomes such as heat generation,

smoke emission and/or fire hazard.

NP10V8100

Specification

Function

Power Source N/A

Wiring Type Twisted Pair

Shunt Resistance 4.8M Ohms

Operating Range 3kHz – 22kHz

Mounting Torque 20Nm +/- 3.8Nm

Page 25 of 36

Technical TrainingNP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine04/14/20093-23

Engine Management SystemHeated Oxygen Sensors

Upstream Universal Heated Exhaust Gas Oxygen Sensors

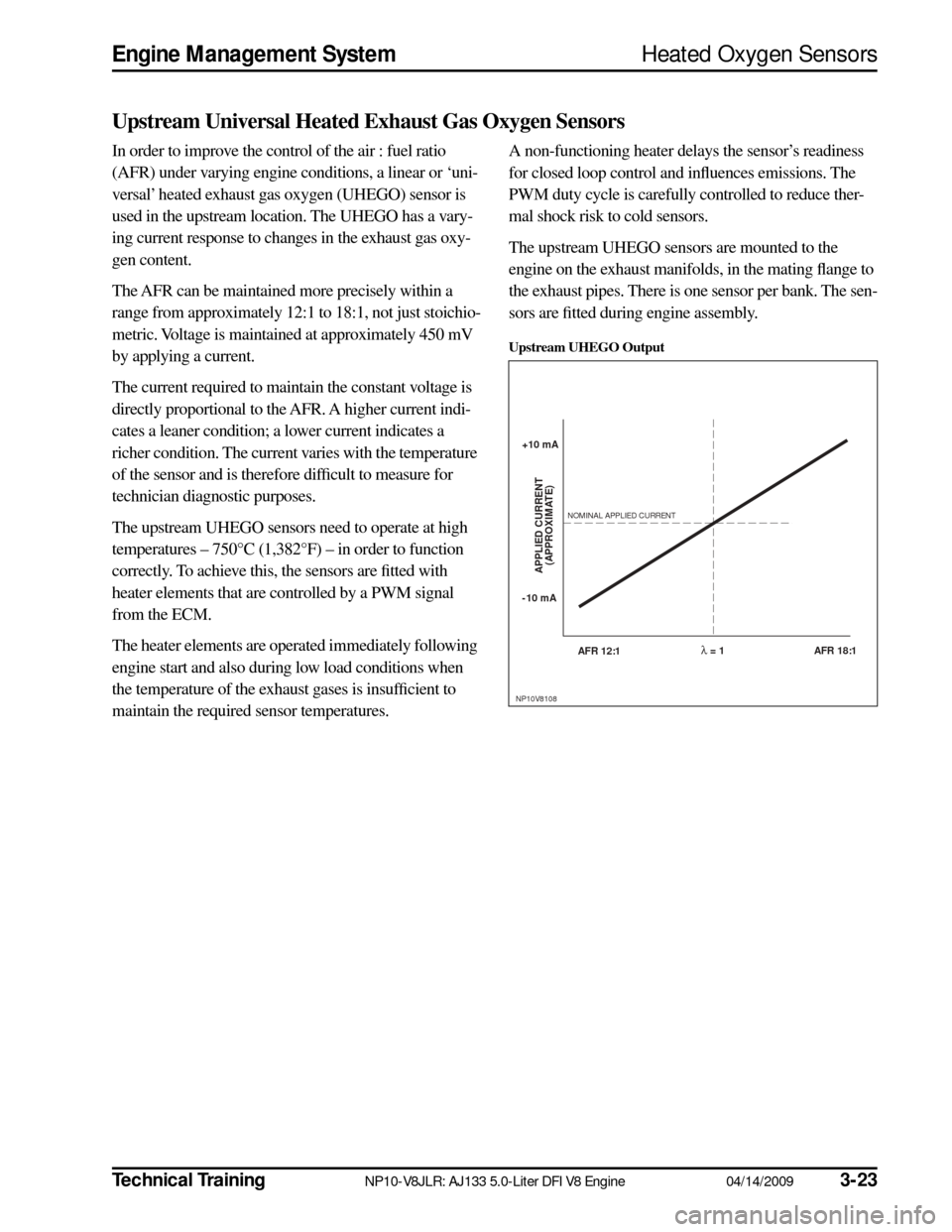

In order to improve the control of the air : fuel ratio

(AFR) under varying engine conditions, a linear or ‘uni-

versal’ heated exhaust gas oxygen (UHEGO) sensor is

used in the upstream location. The UHEGO has a vary-

ing current response to changes in the exhaust gas oxy-

gen content.

The AFR can be maintained more precisely within a

range from approximately 12:1 to 18:1, not just stoichio-

metric. Voltage is maintained at approximately 450 mV

by applying a current.

The current required to maintain the constant voltage is

directly proportional to the AFR. A higher current indi-

cates a leaner condition; a lower current indicates a

richer condition. The current varies with the temperature

of the sensor and is therefore difficult to measure for

technician diagnostic purposes.

The upstream UHEGO sensors need to operate at high

temperatures – 750°C (1,382°F) – in order to function

correctly. To achieve this, the sensors are fitted with

heater elements that are controlled by a PWM signal

from the ECM.

The heater elements are operated immediately following

engine start and also during low load conditions when

the temperature of the exhaust gases is insufficient to

maintain the required sensor temperatures.A non-functioning heater delays the sensor’s readiness

for closed loop control and influences emissions. The

PWM duty cycle is carefully controlled to reduce ther-

mal shock risk to cold sensors.

The upstream UHEGO sensors are mounted to the

engine on the exhaust manifolds, in the mating flange to

the exhaust pipes. There is one sensor per bank. The sen-

sors are fitted during engine assembly.

Upstream UHEGO Output

NP10V8108

+10 mA

NOMINAL APPLIED CURRENT

-10 mA

AFR 12:1

APPLIED CURRENT(APPROXIMATE)

AFR 18:1λ = 1

Page 27 of 36

Technical TrainingNP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine04/14/20093-25

Engine Management SystemHeated Oxygen Sensors

Safety Precautions

WARNINGS:

• Anti-seize compound used on service sensor threads may be a health hazard. Avoid skin

contact.

• Exhaust system components, catalysts in particular, operate at high temperatures and

remain hot for a long time after operation.

CAUTIONS:

• Oxygen sensors must be treated with the utmost care before and during the fitting

process. The sensors have ceramic material

within them that can easily crack if

dropped or over-torqued. They must be

tightened to the specified torque figure with

a calibrated torque wrench. Care should be

taken not to contaminate the sensor tip

when the anti-seize compound is used on

the thread.

• To prevent damage to the sensors, a special tool (box spanner) should be used when

removing.

• If the sensor sticks in the exhaust, apply de- seize product and use a repeating tighten

and loosen strategy.

• Ensure that the sensor harness is robustly secured away from moving or hot parts. Failure Modes

• Mechanical fitting and integrity of the sensor (i.e.

cracked)

• Sensor open circuit/disconnected

• Short circuit to battery voltage or ground.

• Lambda ratio outside operating band

• Crossed sensors (RH bank fitted to LH bank and vice-versa)

• Contamination from leaded fuel or other sources

• Harness damage

• Air leak into exhaust system (cracked pipe/weld or loose fixings)

Failure Symptoms

• Default to open loop fuel metering

• High CO reading

• Strong smell of sulfur (rotten eggs) until default condition

• Excess emissions

• Unstable operation

• Reduced performance

Page 33 of 36

Technical TrainingNP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine04/14/20093-31

Engine Management SystemOn-Board Diagnostic Monitoring

ON-BOARD DIAGNOSTIC MONITORING

Some OBD monitors are continuous, that is they operate

all the time the ignition is on.

Some OBD monitors have conditions that must be met

before the monitor is allowed to operate, such as engine

speed 1000 – 4000 rpm and engine airflow 10 – 100 g/

sec and intake air temperature -10 – +50°C, in order to

ensure the vehicle is operating in such a manner that the

failure may be correctly diagnosed. For this reason it

may be possible for a failure to be present on the vehicle

but remain undetected by the module.

Most OBD monitors use 2-trip detection: if on the first

occasion the failure is detected, a pending DTC is

recorded. If the failure is again detected on the next drive

cycle, then a confirmed DTC is logged and the MIL may

be illuminated.

A few OBD monitors operate on a single-trip basis

where the MIL is illuminated as soon as the failure is

diagnosed.

Detection of a failure may prevent the operation of other

OBD monitors. This is to prevent the logging of multiple

DTCs for a single. However, the system is not infallible,

and a single fault may result in two or more failures

being detected, with two or more DTCs being recorded.