oil pressure JAGUAR XF 2009 1.G AJ133 5.0L Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 36, PDF Size: 0.38 MB

Page 3 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-1

Engine Management System

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Engine Control Module . . . . . . . . . . . . . . . . . . . . . . 8

Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Crankshaft Position Sensor . . . . . . . . . . . . . . . . . . 11

Camshaft Position Sensor . . . . . . . . . . . . . . . . . . . 13

Engine Coolant Temperature Sensor . . . . . . . . . . 14

Knock Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Manifold Absolute Pressure Sensor . . . . . . . . . . . 16

Mass Air Flow Sensor . . . . . . . . . . . . . . . . . . . . . . 17

Temp. / Manifold Absolute Pressure Sensor . . . . 18

Throttle Position Sensor . . . . . . . . . . . . . . . . . . . . 19

Accelerator Pedal Position Sensor . . . . . . . . . . . . 21

Heated Oxygen Sensors . . . . . . . . . . . . . . . . . . . . 22

Ambient Air Temperature Sensor. . . . . . . . . . . . . 26

Ignition Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fuel Tank Canister Purge Valve . . . . . . . . . . . . . . 28

Viscous Fan Control (Land Rover only) . . . . . . . 29

Controller Area Network. . . . . . . . . . . . . . . . . . . . 30

On-Board Diagnostic Monitoring . . . . . . . . . . . . . 31

Crankcase Ventilation System . . . . . . . . . . . . . . . 32

Page 5 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-3

Engine Management System

Overview

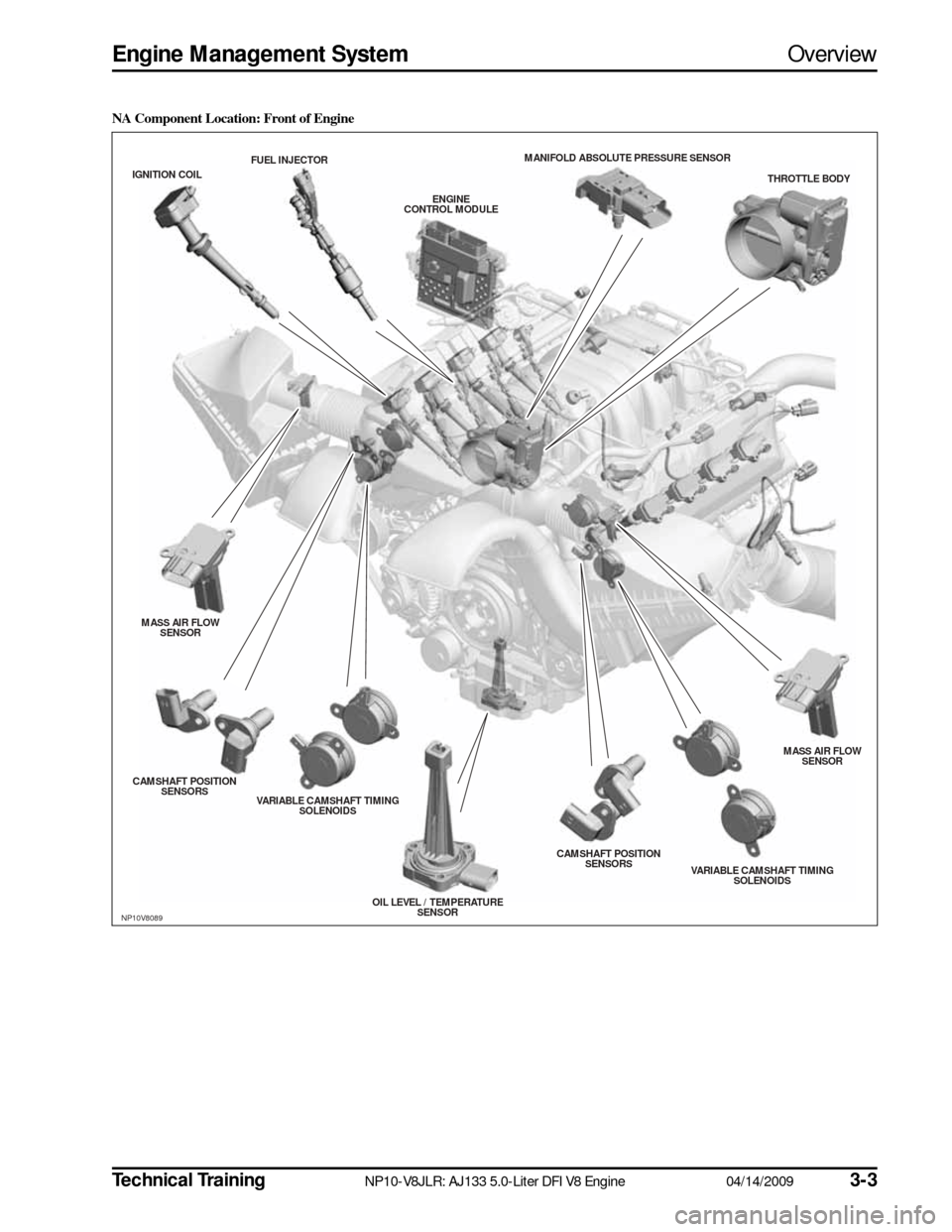

NA Component Location: Front of Engine

NP10V8089

THROTTLE BODY

MANIFOLD ABS

OLUTE PRESSURE S ENSOR

ENGINE

CONTROL MODULE

FUEL INJECTOR

IGNITION COIL

MASS AIR FLOW SENS OR

CAMS HAFT POS ITION

S ENS ORS

VARIABLE CAMS HAFT TIMING

S OLENOIDS

OIL LEVEL / TEMPERATURESENS OR CAMS

HAFT POS ITION

S ENS ORS

VARIABLE CAMSHAFT TIMING

S OLENOIDS MASS AIR FLOW

SENS OR

Page 7 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-5

Engine Management System

Overview

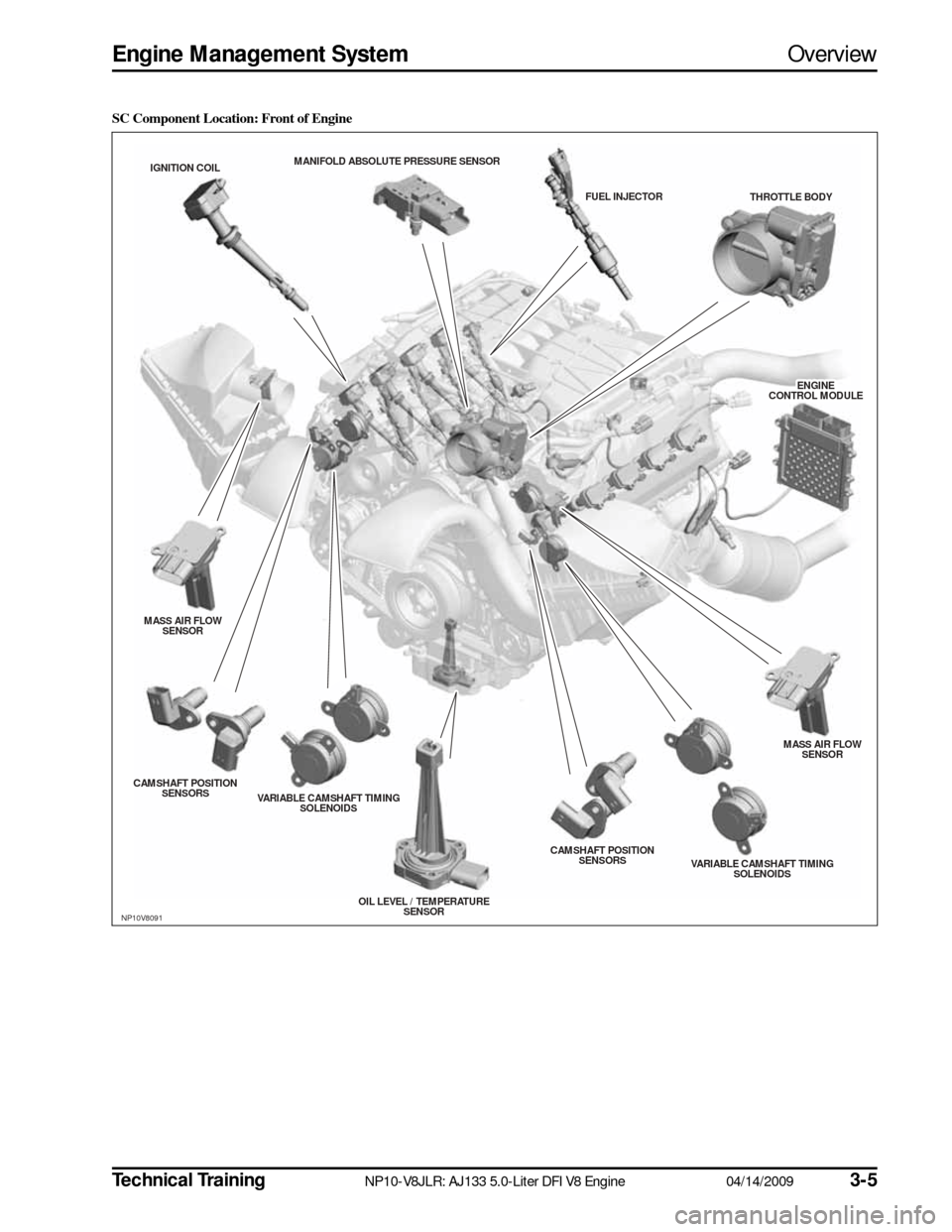

SC Component Location: Front of Engine

NP10V8091

THROTTLE BODY

MANIFOLD ABS

OLUTE PRESSURE S ENSOR

ENGINE

ENGINECONTROL MODULECONTROL MODULEENGINE

CONTROL MODULE

FUEL INJECTOR

IGNITION COIL

MASS AIR FLOW SENS OR

CAMS HAFT POS ITION

S ENS ORS

VARIABLE CAMS HAFT TIMING

S OLENOIDS

OIL LEVEL / TEMPERATURESENS OR CAMS

HAFT POS ITION

S ENS ORS

VARIABLE CAMSHAFT TIMING

S OLENOIDS MASS AIR FLOW

SENS OR

Page 10 of 36

3-8

04/14/2009 NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine

Technical Training

Engine Control Module

Engine Management System

ENGINE CONTROL MODULE

The ECM is supplied with battery voltage from a 5A fuse and an ignition supply from the ECM relays through\

a 15A

fuse, both located in the CJB. A regulator located within the ECM supplies a 5V current to internal compone\

nts such

as the microprocessor unit. Other components or functions requiring full\

battery voltage are controlled by external

relays or internal switching modules.

The microprocessor within the ECM receives signals from different components and control modules and uses a pro-

gram within the ECM software to interpret the signal information and issue signals which relate t\

o how the engine

components and functions should be controlled. The ECM communicates with other control modules via bidirectional

Controller Area Network (CAN) communication interfaces.

The ECM uses the following inputs and outputs:

Inputs

• Camshaft position (CMP) sensor

• Crankshaft position (CKP) sensor

• Fuel rail high-pressure sensor

• Mass air flow (MAF) sensors (2)

• Knock sensors (4)

• Engine coolant temperature (ECT) sensor

• Manifold absolute pressure (MAP) sensor

• Electronic throttle position sensor

• Accelerator pedal position (APP) sensor

• Cooling fan speed

• Upstream Universal Heated Exhaust Gas Oxygen (UHEGO) sensors (2)

• Brake switch

• Speed control cancel/suspend switch

• Intake air temperature (IAT) sensor (integrated into the MAF) (2)

• Ambient air temperature (AAT) sensor

• Engine oil level and temperature sensor

• Temperature and manifold absolute pressure (TMAP) sensor (SC only)

Outputs

• Throttle Actuator

• Coil-on-plug (COP) ignition coils (8)

• Upstream Universal Heated Exhaust Gas Oxygen (UHEGO) sensors (2)

• Downstream Heated Oxygen Sensors (HO2S) (2)

• Direct injection fuel injectors (8)

• Variable camshaft timing (VCT) solenoids (4)

• Camshaft profile switching (CPS) solenoids (2)

• Intake manifold tuning solenoid

• Carbon canister purge valve

• Fuel pump relay

• Starter relay

• A/C condenser fan relay

• ECM main relay viscous fan control

• Generator control

• Air flap solenoid (SC only)

• Pump control diagnostics

• Diagnostic Monitoring of Tank Leakage (DMTL)

Page 34 of 36

3-3204/14/2009NP10-V8JLR: AJ133 5.0-Liter DFI V8 EngineTechnical Training

Crankcase Ventilation System Engine Management System

CRANKCASE VENTILATION SYSTEM

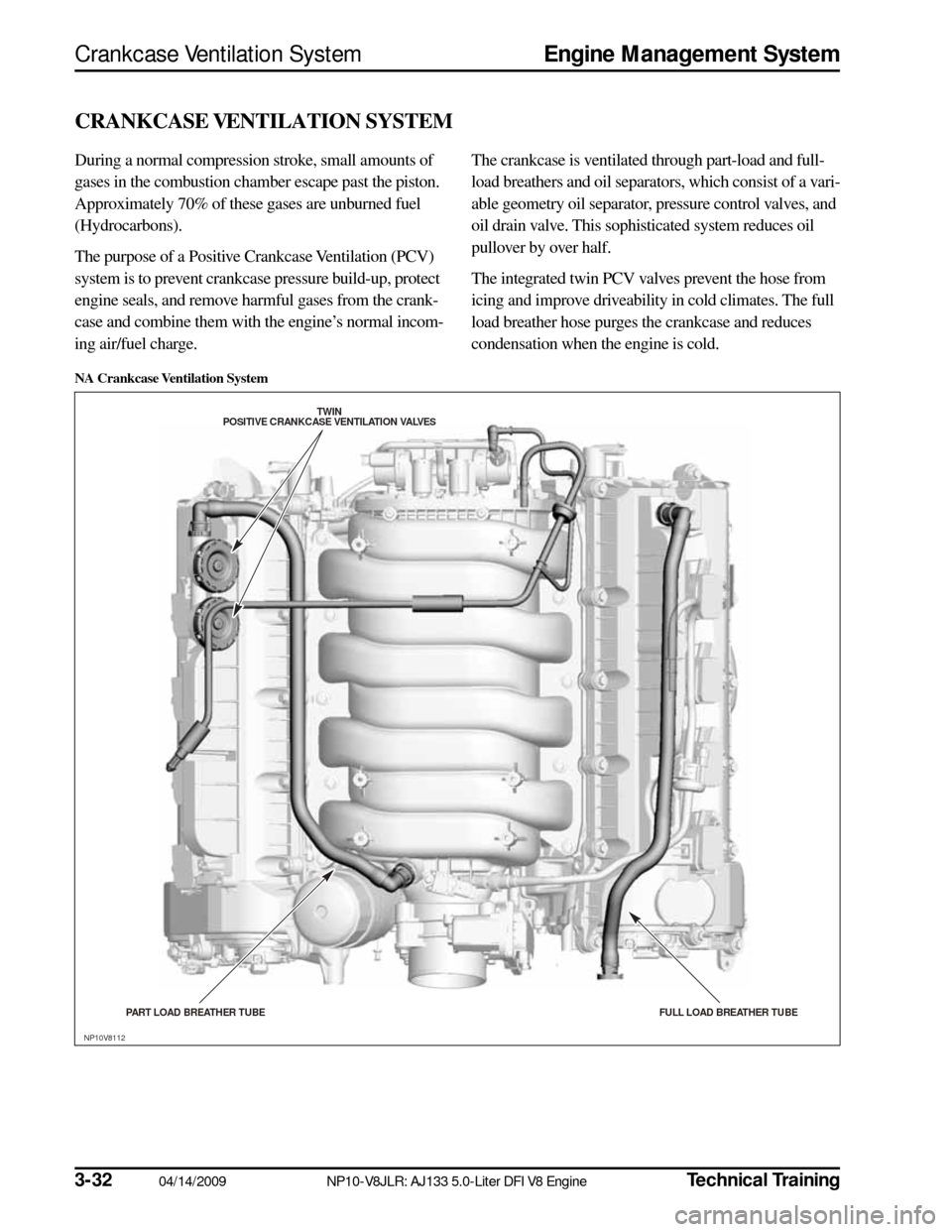

During a normal compression stroke, small amounts of

gases in the combustion chamber escape past the piston.

Approximately 70% of these gases are unburned fuel

(Hydrocarbons).

The purpose of a Positive Crankcase Ventilation (PCV)

system is to prevent crankcase pressure build-up, protect

engine seals, and remove harmful gases from the crank-

case and combine them with the engine’s normal incom-

ing air/fuel charge. The crankcase is ventilated through part-load and full-

load breathers and oil separators, which consist of a vari-

able geometry oil separator, pressure control valves, and

oil drain valve. This sophisticated system reduces oil

pullover by over half.

The integrated twin PCV valves prevent the hose from

icing and improve driveability in cold climates. The full

load breather hose purges the crankcase and reduces

condensation when the engine is cold.

NA Crankcase Ventilation System

TWIN

POS ITIVE CRANKCAS E VENTILATION VALVES

PART LOAD BREATHER TUBE FULL LOAD BREATHER TUBE

NP10V8112