instrument cluster JAGUAR XFR 2010 1.G Owners Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1783 of 3039

Published: 11-May-2011

Instrument Cluster - Instrument Cluster - System Operation and Component Description

Description and Operation

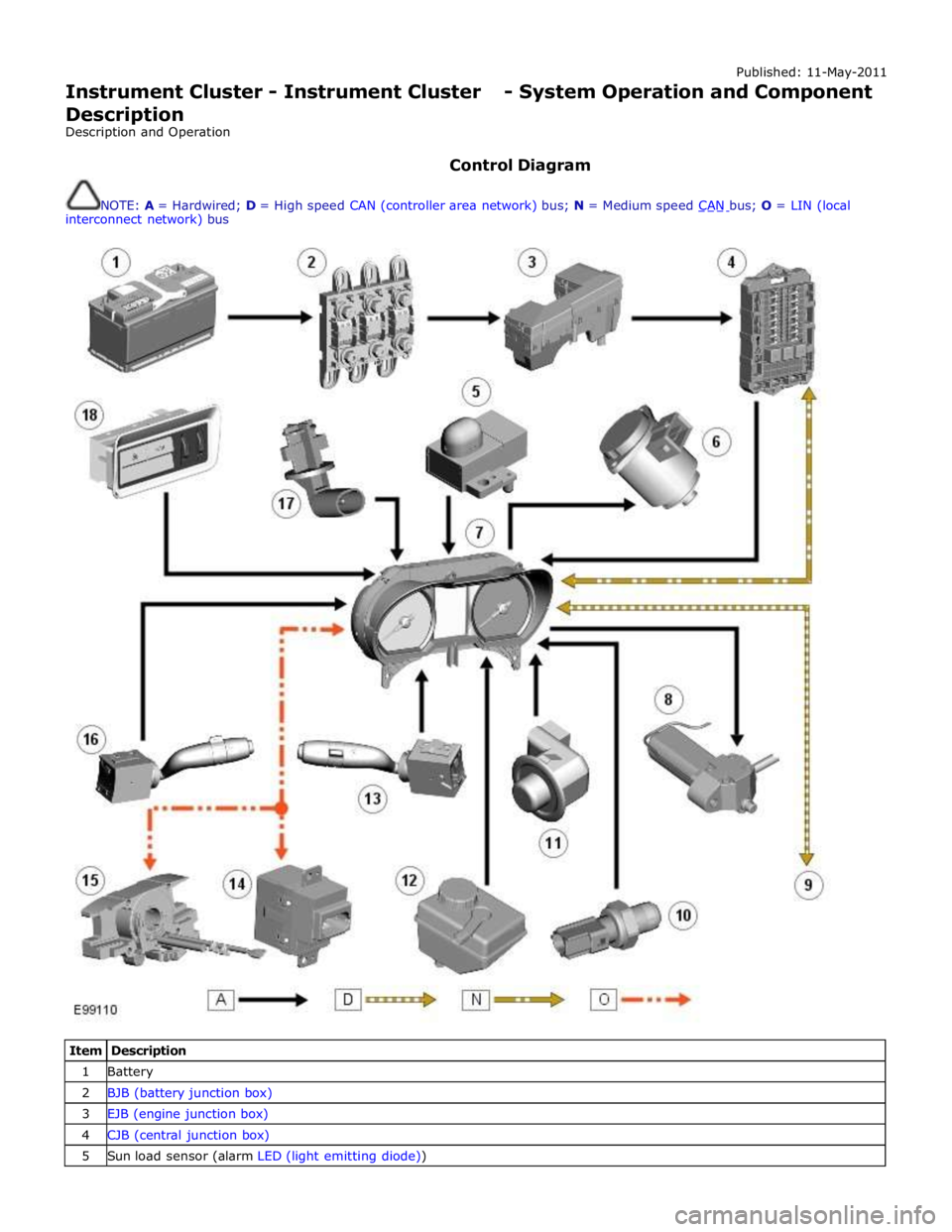

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus; N = Medium speed CAN bus; O = LIN (local interconnect network) bus

Item Description 1 Battery 2 BJB (battery junction box) 3 EJB (engine junction box) 4 CJB (central junction box) 5 Sun load sensor (alarm LED (light emitting diode))

Page 1784 of 3039

7 Instrument cluster 8 Steering column motor 9 High speed CAN bus connection to other vehicle systems 10 Engine oil pressure switch 11 Steering column adjustment switch 12 Brake fluid level switch 13 LH (left-hand) steering column multifunction switch 14 Start control module 15 Clockspring 16 RH (right-hand) steering column multifunction switch 17 Engine coolant level sensor 18 Auxiliary lighting switch

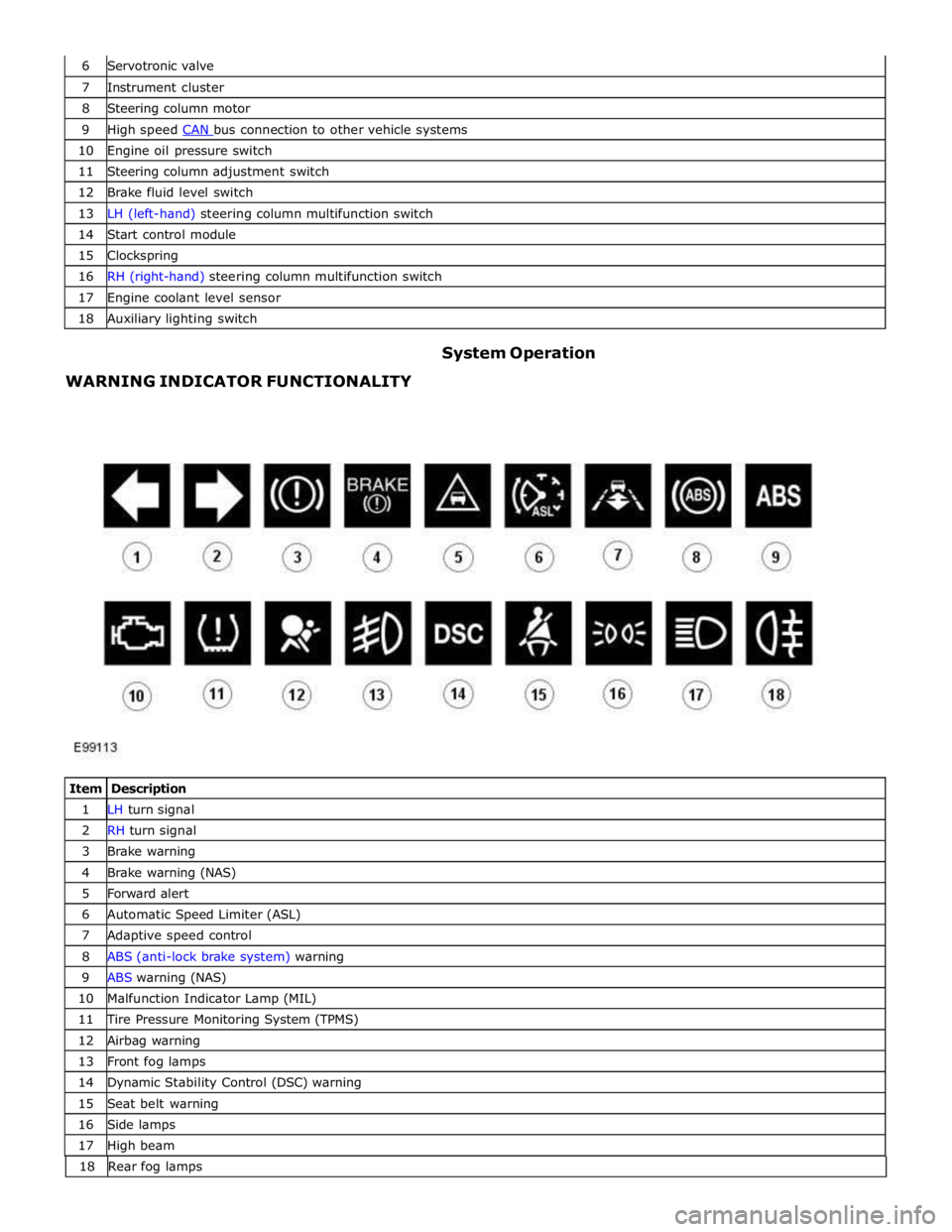

WARNING INDICATOR FUNCTIONALITY System Operation

Item Description 1 LH turn signal 2 RH turn signal 3 Brake warning 4 Brake warning (NAS) 5 Forward alert 6 Automatic Speed Limiter (ASL) 7 Adaptive speed control 8 ABS (anti-lock brake system) warning 9 ABS warning (NAS) 10 Malfunction Indicator Lamp (MIL) 11 Tire Pressure Monitoring System (TPMS) 12 Airbag warning 13 Front fog lamps 14 Dynamic Stability Control (DSC) warning 15 Seat belt warning 16 Side lamps 17 High beam 18 Rearfoglamps

Page 1785 of 3039

The functionality for each of the above warning indicators is described in the following sections:

1 and 2. Turn Signal Indicators

The turn signal indicators are controlled by the CJB on receipt of medium speed CAN bus signals from the instrument cluster.

The instrument cluster outputs a voltage to the turn signal indicator switch. The switch contains resistors of different values.

When the switch is operated in either the LH or RH direction, the voltage is passed to a ground connection in the instrument cluster which detects the reduced voltage supplied via the resistors. When the turn signal indicator switch is operated in the

LH or RH direction, the instrument cluster detects the ground voltage and determines whether a LH or RH selection is made.

The instrument cluster transmits a medium speed CAN message to the CJB for operation of the applicable turn signal indicators. The message can contain a number of states for each possible switch position and also an out of range low and

high state for circuit faults and an initial value for the switch neutral position. The turn signal indicators are not subject to the

3 second indicator check when the ignition is switched on.

The RJB (rear junction box) software controls the flash rate of the warning indicator which sends 'ON' and 'OFF' signals to the

instrument cluster which flashes the indicators in a green color. During normal operation, the warning indicator flashes slowly,

accompanied simultaneously by a sound from the instrument cluster sounder. If a fault exists, the RJB transmits a message to the instrument cluster which responds by displaying an appropriate message in the message center.

The hazard warning indicators are controlled by the CJB on receipt of a completed ground path from the hazard warning indicator switch. The CJB outputs a medium speed CAN message to the instrument cluster which operates both the LH and RH turn signal indicators simultaneously. The hazard warning indicators can operate with the ignition switched off, therefore the

CAN message from the CJB will also carry a 'wake-up' message for the instrument cluster. 3. Brake Warning Indicator

This warning indicator is displayed in a red or amber color (dependant on market) as a brake symbol in all markets except

United States of America (USA) which have the word 'BRAKE' in place of the symbol. The indicator is controlled by high speed

CAN messages from the ABS module and the parking brake control module. The indicator is illuminated in a red color for a 3 second indicator check when the ignition is switched on.

The instrument cluster monitors the fluid level in the brake fluid reservoir using a hardwired level switch. If the fluid level falls

to below a determined level, the switch contact is broken and the ABS module detects the low fluid level condition. The instrument cluster illuminates the warning indicator and simultaneously displays a 'BRAKE FLUID LOW' message in the

message center.

NOTE: If both the brake warning indicator and the ABS warning indicator illuminate simultaneously, a major fault in the brake system will have occurred.

The warning indicator also displays parking brake status. When the parking brake is applied, the warning indicator will be

illuminated by the instrument cluster and, if the vehicle is moving, the message 'PARK BRAKE APPLIED' will be also displayed

in the message center in response to a CAN message from the parking brake control module.

If a condition exists where the parking brake cannot be applied, the parking brake control module issues a CAN message to the instrument cluster which flashes the warning lamp on and off and is accompanied with a message 'CANNOT APPLY PARK BRAKE'.

If a fault occurs in the parking brake system, the parking brake control module issues a CAN message to the instrument cluster which illuminates the warning indicator and displays the message 'PARK BRAKE FAULT' in the message

center.

4. Forward Alert Indicator

The forward alert system uses the components of the adaptive speed control system to alert the driver of the presence of a

vehicle ahead. The system can be turned on and off using a switch located in the auxiliary lighting switch when the adaptive

speed control system is off. The indicator is illuminated in an amber color for a 3 second indicator check when the ignition is

switched on.

The forward alert system is controlled by the adaptive speed control module. When the switch is pressed, the forward alert

system is activated and the adaptive speed control module issues a forward alert active message on the high speed CAN bus to the instrument cluster. The forward alert icon in the instrument cluster will illuminate in an amber color and a 'FORWARD

ALERT' message will be displayed in the message center. When the button is pressed a second time, the module issues a

forward alert off CAN message. The forward alert system will be deactivated, the forward alert icon will go off and a message 'FORWARD ALERT OFF' will be displayed in the message center.

5. Automatic Speed Limiter (ASL) Indicator

The ASL is controlled by the ECM (engine control module). An ASL switch is located in the floor console, adjacent to the gear

selector lever. When the ASL switch is pressed, this is sensed by the ECM which issues a high speed CAN message to the instrument cluster. The instrument cluster illuminates the ASL warning indicator in an amber color to show the driver that ASL

is active. The driver sets the required speed using the speed control SET +/- switches on the steering wheel. The selected

speed is shown by the message ' LIMITER SET XXX MPH / K/MH' in the message center. The indicator is illuminated in an

amber color for a 3 second indicator check when the ignition is switched on. ASL can be deselected by pressing the ASL switch,

by depressing the throttle pedal initiating kick-down or by pressing the 'cancel' switch on the steering wheel. The ASL indicator

will go off and the message center will display the message 'limiter cancelled' for 4 seconds. If a fault occurs in the ASL

system, the ECM will send a message to the instrument cluster to illuminate the ASL indicator and display the message 'LIMITER NOT AVAILABLE'.

Page 1786 of 3039

6. Adaptive Speed Control Indicator

The adaptive speed control system is controlled by the adaptive speed control module. Operation of the SET +/- switches on

the steering wheel will activate the system. Operation of the switches is detected by the adaptive speed control module. The

module issues a high speed CAN message to the instrument cluster which illuminates the adaptive speed control indicator, when the system is in 'follow mode', in an amber color and displays a 'SETSPEED XXX MPH / KM/H' message in the message

center. The indicator is illuminated in an amber color for a 3 second indicator check when the ignition is switched on.

7. Anti-lock Braking System (ABS) Warning Indicator

The ABS warning indicator is controlled by the ABS module. If a fault in the ABS system is detected by the ABS module, the module issues a high speed CAN message to the instrument cluster to illuminate the ABS warning indicator in an amber color and display the message 'ABS FAULT' in the instrument cluster. The indicator is illuminated in an amber color for a 3 second

indicator check when the ignition is switched on. If a fault is present when the ignition is on, the bulb will remain illuminated

after the 3 second indicator check period.

NOTES:

The 'ABS FAULT' message is not displayed in NAS markets).

If both the ABS warning indicator and the brake warning indicator illuminate simultaneously, a major fault in the brake system will have occurred.

On NAS vehicles, the ABS warning indicator is also used for parking brake operation. The NAS warning indicator does not have 'ABS' on the icon and will function as described previously for the parking brake operation of the brake warning indicator.

8. Engine Malfunction Indicator Lamp (MIL)

The MIL warning indicator is controlled by the ECM and illuminated by the instrument cluster on receipt of a message on the high speed CAN bus from the ECM. The indicator is illuminated in an amber color for a 3 second indicator check when the ignition is switched on.

If the MIL remains illuminated after the engine is started or illuminates when driving, a fault is present and must be

investigated at the earliest opportunity. Illumination of the MIL warning indicator alerts the driver to an OBD (on-board

diagnostic) fault which will cause excessive emissions output. This may relate to either an engine management system fault or

a transmission.

9. Tire Pressure Monitoring System (TPMS) Warning Indicator

The TPMS warning indicator is illuminated by the instrument cluster on receipt of a medium speed CAN message from the TPMS module. The indicator is illuminated in an amber color for a 3 second indicator check when the ignition is switched on.

If the indicator illuminates and is accompanied by the message 'TYRE PRESSURE SYSTEM FAULT' in the message center, then a

TPMS fault has occurred. If the indicator illuminates and accompanied by a different message, then a low tire pressure has

been detected, a spare wheel has been fitted or a TPMS sensor has failed.

10. Airbag Warning Indicator

The airbag warning indicator is controlled by the instrument cluster. The indicator is illuminated in an amber color for the 3

second indicator check when the ignition is switched on. The indicator remains illuminated after the 3 second period has

expired until the instrument cluster receives a turn off message on the high speed CAN bus from the RCM (restraints control module).

11. Front Fog Lamp Indicator

The green colored front fog lamp indicator is controlled by the CJB and illuminated by the instrument cluster on receipt of a front fog lamp on message on the medium speed CAN bus from the CJB. The indicator is illuminated for as long as the front fog lamps are active. The front fog lamp indicator is not subject to the 3 second indicator check when the ignition is switched

on.

12. Dynamic Stability Control (DSC) Indicator

The DSC warning lamp is controlled by the ABS module and illuminated by the instrument cluster in response to messages received on the high speed CAN bus. The indicator is illuminated in an amber color for the 3 second indicator check when the ignition is switched on. The DSC warning indicator, are permanently illuminated in an amber color if the instrument cluster

receives a high speed CAN message from the ABS module relating to one of the following faults:

Traction control fault

Yaw control fault

Engine drag torque control fault

Panic Brake Assist (PBA) fault

Signal missing relating to either traction control active, yaw control active or DSC switch input.

The above faults will also generate an applicable DSC and ABS warning message in the message center. The DSC warning

indicator will flash at 2 Hz for if the traction control or yaw control is active when the DSC system is enabled. If the DSC

system is switched off, the warning indicator will be permanently illuminated until the DSC system is subsequently

re-activated.

13. Safety Belt Warning Indicator

The safety belt warning indicator operates for both the driver and passenger safety belts. The warning indicator is controlled by

Page 1787 of 3039

the RCM and illuminated by the instrument cluster on receipt of high speed CAN bus messages. The safety belt warning indicator is not subject to the 3 second indicator check when the ignition is switched on.

The operation of the passenger seat buckle switch is as described below with the exception that the instrument cluster must

receive a hardwired signal from the belt minder control module to indicate that a passenger is occupying the seat.

The safety belt warning indicator is subject to a timer. The warning indicator is activated when the following conditions exist:

Ignition is switched on

One of the front seat belts is unbuckled

USA market only - 75 seconds has elapsed after ignition on mode is selected

Vehicle is not in reverse gear

Vehicle speed is more than 8 km/h (5 mph).

Once the above parameters are met, the instrument cluster flashes the warning indicator at 2 Hz for 10 seconds accompanied

by a simultaneous chime. After 10 seconds the chime ceases and the warning indicator is permanently illuminated for 20

seconds. This sequence is repeated every 30 seconds until one of the following events occurs:

300 seconds has elapsed

The safety belt of the occupied front seats is fastened

The ignition is switched to off mode

The vehicle speed decreases to below 5 km/h (3 mph).

NOTE: On USA market vehicles, the warning indicator in not permanently illuminated.

The safety belt minder function cannot be disabled. The seat belt minder function can be disabled.

Refer to: Safety Belt System (501-20A Safety Belt System, Description and Operation). 14. Side Lamp Indicator

The instrument cluster controls the green colored side lamp indicator on receipt of a side lamp status message on the medium

speed CAN bus from the CJB and the auxiliary junction box. The lighting switch on the LH steering column multifunction switch is connected to the instrument cluster. Selections using this switch are detected by the cluster which requests the side or

headlamp operation via a message to the CJB and the RJB. The CJB and the RJB responds with a side lamp active message and the cluster illuminates the side lamp indicator. The side lamp indicator is not subject to the 3 second indicator check when

the ignition is switched on.

15. High Beam Indicator

The instrument cluster controls the blue colored high beam indicator on receipt of a high beam status message on the medium

speed CAN bus from the CJB. The lighting switch on the LH steering column multifunction switch is connected to the instrument cluster. High beam or flash selections using this switch are detected by the cluster which requests the light

operation via a CAN message to the CJB. The CJB responds with a high beam active message and the cluster illuminates the high beam indicator. The high beam indicator is not subject to the 3 second indicator check when the ignition is switched on.

16. Rear Fog Lamp Indicator

The amber colored rear fog lamp indicator is controlled by the auxiliary junction box and illuminated by the instrument cluster

on receipt of a rear fog lamp on message on the medium speed CAN bus from the RJB. The indicator is illuminated for as long as the rear fog lamps are active. The rear fog lamp indicator is not subject to the 3 second indicator check when the ignition is

switched on.

SPEEDOMETER

The speedometer is driven by high speed CAN signals transmitted by the ABS module. The wheel speeds are measured by sensors reading the rotational speed of the rear wheels from toothed targets on the hubs. An average of the two wheel speeds

are passed from the sensors to the ABS module in the form of pulsed signals. The ABS module converts these signals into a speed output on the high speed CAN to the instrument cluster. The same speed outputs from the wheel speed sensors are also used to calculate the distance the vehicle has travelled.

TACHOMETER

The tachometer is driven by an engine speed signal transmitted on the high speed CAN from the ECM. The signal is derived from the CKP (crankshaft position) sensor. The signal is received by the instrument cluster microprocessor and the output from

the microprocessor drives the tachometer.

FUEL GAGE

The fuel gage is controlled by CAN messages from the RJB. The RJB reads the values output by the fuel level sensors every 131 ms and transmits a fuel tank contents value, corrected for battery voltage, in a CAN message to the instrument cluster. A fuel pump symbol is displayed to the left of the linear gage. An arrow above the symbol shows the driver on which side of the

vehicle the fuel filler cap is located. Above the linear fuel gage, is a LCD (liquid crystal display) area which displays odometer

and trip readouts. When a trip computer function is selected, these are replaced by a trip computer display for the trip function

selected.

LIQUID CRYSTAL DISPLAY

In the area above and below the message center is a LCD display. The area below the message center displays a linear fuel www.JagDocs.com

Page 1788 of 3039

gage, odometer, trip distance and trip computer readouts. The trip distance and trip computer information is derived from

information supplied on the high speed CAN bus to the instrument cluster from the ABS module and the ECM.

The area above the message center displays the transmission gear position information and speed control related information.

The transmission information is supplied on the high speed CAN bus from the TCM (transmission control module).

NOTE: There is no engine coolant temperature gage displayed. If the engine coolant temperature increases to above a

predetermined threshold, a warning message is displayed in the message center. The message is sent from the ECM in a high speed CAN message to the instrument cluster.

TRANSMISSION GEAR SELECTION POSITION

The gear position display shows JaguarDrive selector position or selected gear when using the Jaguar Sequential Shift. The gear

selector module transmits a CAN message to the instrument cluster for gear selector lever position. The module also outputs a 'not in park' signal to the instrument cluster. The TCM transmits a high speed CAN message to the instrument cluster with data containing the selected gear when in Jaguar Sequential Shift mode.

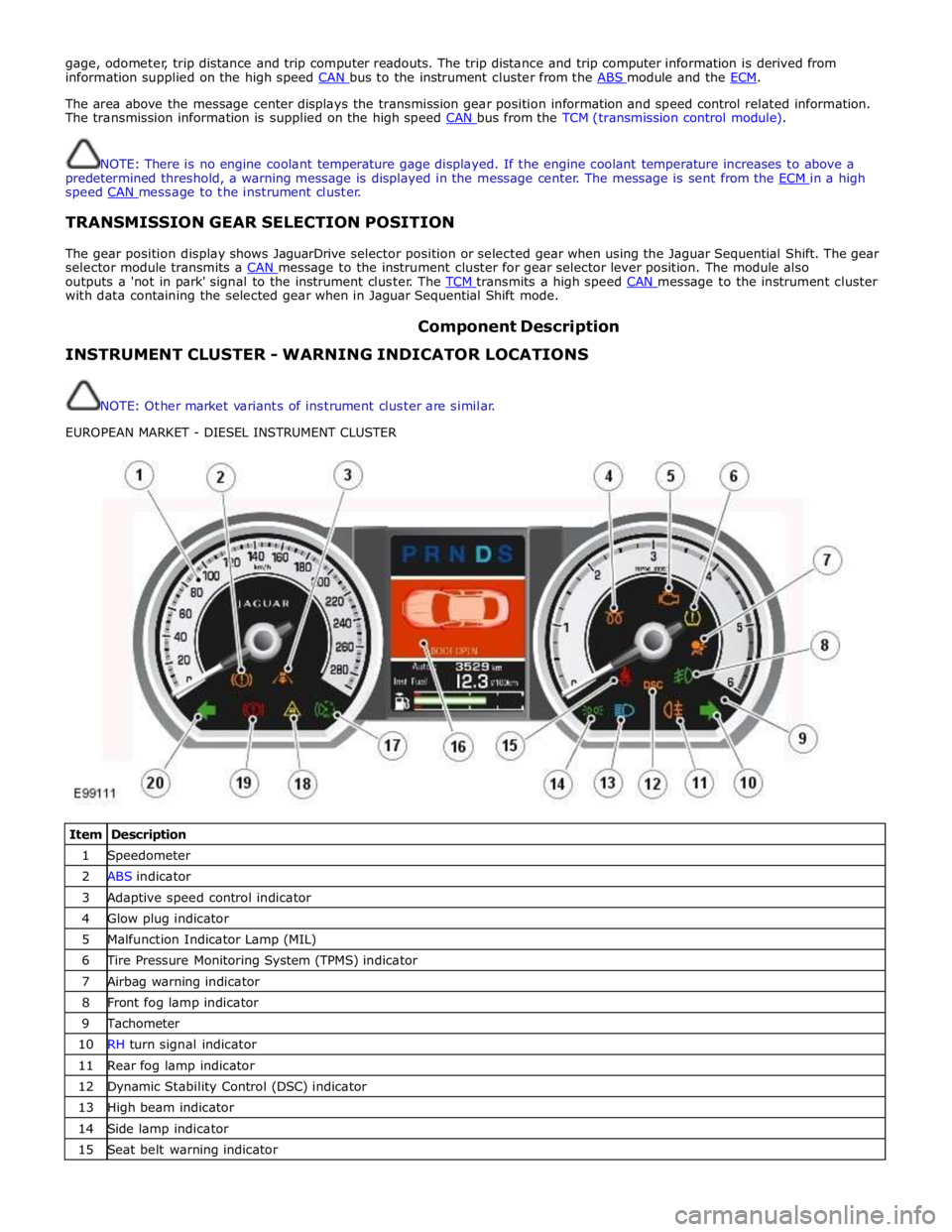

Component Description INSTRUMENT CLUSTER - WARNING INDICATOR LOCATIONS

NOTE: Other market variants of instrument cluster are similar.

EUROPEAN MARKET - DIESEL INSTRUMENT CLUSTER

Item Description 1 Speedometer 2 ABS indicator 3 Adaptive speed control indicator 4 Glow plug indicator 5 Malfunction Indicator Lamp (MIL) 6 Tire Pressure Monitoring System (TPMS) indicator 7 Airbag warning indicator 8 Front fog lamp indicator 9 Tachometer 10 RH turn signal indicator 11 Rear fog lamp indicator 12 Dynamic Stability Control (DSC) indicator 13 High beam indicator 14 Side lamp indicator 15 Seat belt warning indicator

Page 1789 of 3039

17 Automatic Speed Limiter (ASL) indicator 18 Forward alert indicator 19 Brake warning indicator 20 LH turn signal indicator NAS MARKET - V8 NORMALLY ASPIRATED INSTRUMENT CLUSTER

Item Description 1 Speedometer 2 ABS indicator (NAS) 3 ABS indicator (ROW) 4 Adaptive speed control indicator 5 Tachometer 6 Malfunction Indicator Lamp (MIL) 7 Tire Pressure Monitoring System (TPMS) indicator 8 Airbag warning indicator 9 Front fog lamp indicator 10 RH turn signal indicator 11 Rear fog lamp indicator 12 Dynamic Stability Control (DSC) indicator 13 High beam indicator 14 Seat belt warning indicator 15 Side lamp indicator 16 Message center 17 Automatic Speed Limiter (ASL) indicator 18 Forward alert indicator 19 Brake warning indicator (NAS) 20 Brake warning indicator (ROW) 21 LH turn signal indicator The warning indicators are located in various positions in the instrument cluster. The indicators can be split into two groups;

instrument cluster controlled and externally controlled.

Instrument cluster controlled warning indicators are dependent on software logic within the instrument cluster for activation.

The cluster software controls the indicator illumination check at ignition on (power mode 6).

Externally controlled indicators are supplied with current from another vehicle system control module or illuminated by the

instrument cluster software on receipt of a bus message from another vehicle sub-system. The indicator illumination check at

ignition on (powermode 6) is also controlled by the sub-system module for these indicators.

Page 1790 of 3039

MESSAGE CENTER

The message center is a LCD located in a central position in the cluster. The message center displays system status information.

Refer to: Information and Message Center (413-08 Information and Message Center, Description and Operation).

ANALOGUE GAGES

Speedometer

The analogue speedometer is located on the LH side of the instrument cluster and is available in 4 market variants: Major scale Miles Per Hour (MPH), minor scale kilometers per hour (km/h) (ROW)

Major scale MPH, minor scale km/h (NAS)

Major scale km/h, minor scale MPH

Major scale km/h only.

Tachometer

The analogue tachometer is located on the RH side of the instrument cluster. The tachometer has different Revolutions Per Minute (RPM) scales depending on the engine variant fitted to the vehicle as follows:

4.2L V8 Naturally aspirated 8000 RPM (NAS Only)

5.0L V8 Naturally aspirated 8000 RPM

5.0L V8 Supercharger 8000 RPM

3.0L V6 Naturally aspirated 8000 RPM

3.0 V6 Diesel 6000 RPM.

ELECTRONIC GAGES

Fuel Gage

The linear fuel gage has a colored bar which moves left or right depending on the tank contents. As the bar moves to the left

the fuel tank contents displayed is decreasing. A warning message is displayed in the message center when the fuel tank

contents fall to below the reserve level.

Transmission Gear Position Display

The gear position display shows the JaguarDrive selector position or the selected gear when using the Jaguar Sequential Shift.

The applicable drive letter is highlighted to show that a selection has been made using the JaguarDrive selector.

When Jaguar Sequential Shift is selected, the letters change to numbers; 1 - 6, and the selected gear is highlighted to

emphasize the selection to the driver.

Page 1791 of 3039

Instrument Cluster - Instrument Cluster

Diagnosis and Testing

Principles of Operation Published: 22-Mar-2013

For a detailed description of the Instrument Cluster, refer to the relevant Description and Operation sections in the workshop

manual. REFER to: (413-01 Instrument Cluster)

Instrument Cluster (Description and Operation), Instrument Cluster (Description and Operation), Instrument Cluster (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Fluid level(s)

Accessory installations

Fuse(s)

Wiring harness

Electrical connector(s)

Instrument cluster

Central Junction Box (CJB)

Engine Junction Box (EJB)

Driver Door Module (DDM)

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

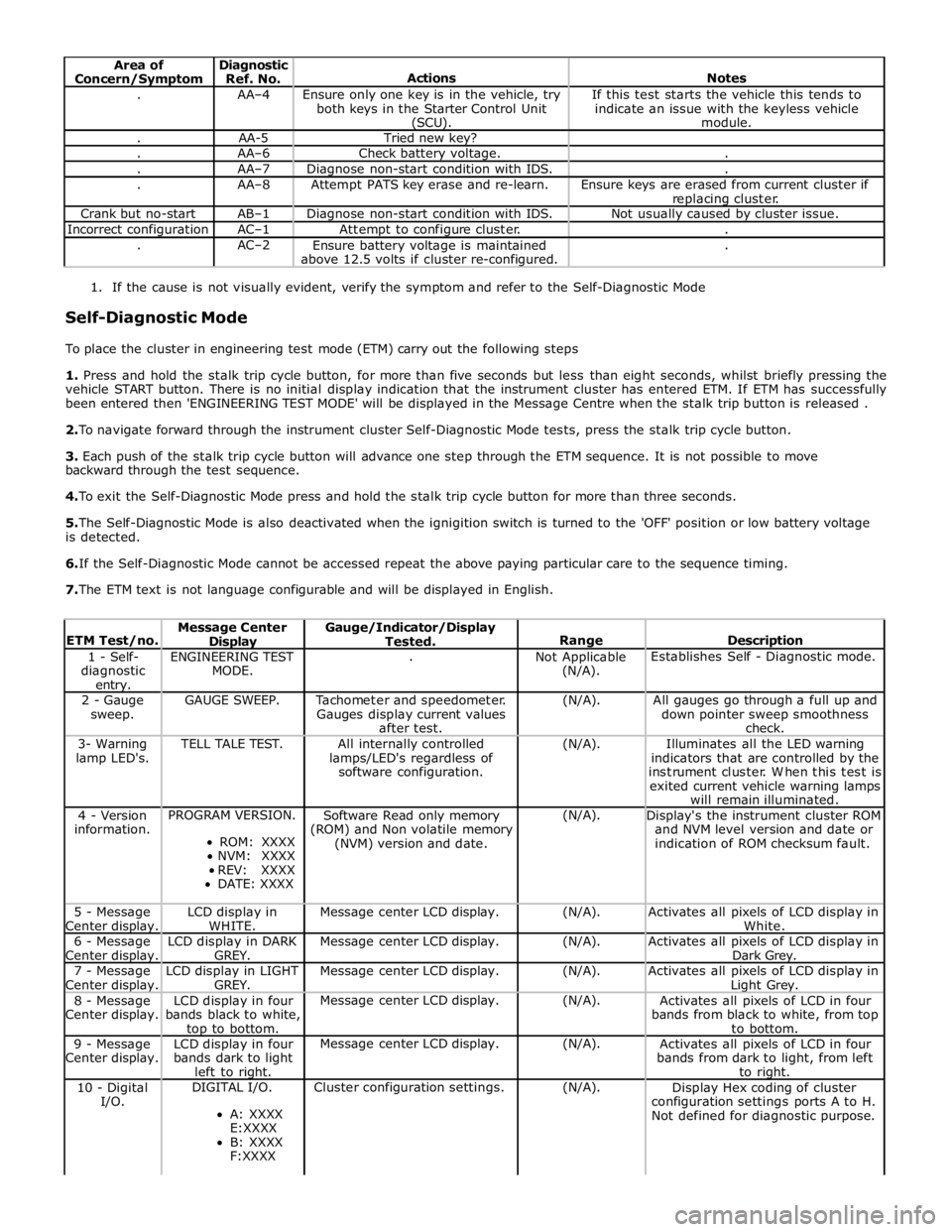

Symptom Chart

The instrument cluster contains a self-diagnostic mode known as engineering test mode (ETM). This can be used to show the

status of the instrument cluster inputs as well as a number of other useful features.

When in the ETM, the Message Centre displays internal data that can be cycled through. All functions except the message

centre display will continue to operate normally unless otherwise noted.

This document is to be used in conjunction with the instrument cluster ETM (see relevant section within this document) and

the Integrated Diagnostic System (IDS) facility; this does not supersede or replace the IDS facility.

Go directly to the 'Area of Concern/Symptom' that indicates the customer concern(s) and perform the actions described within

the relevant section(s):

Area of Concern/Symptom Diagnostic

Ref. No.

Actions

Notes Warning lights A-1

Perform instrument cluster Self-Diagnostic

Mode/ETM test 3. When this test is ended the warning lamps

currently required to be 'ON' will remain

illuminated. Multiple warning lights

'ON' B–1

Check with IDS for DTCs related to

identified vehicle system(s). . . B–2

Check instrument cluster battery and

ignition wiring - refer to circuit diagrams. Specifically check continuity of Standard

Corporate Protocol (SCP) and Controller Area

Network (CAN) lines. . B–3 Check instrument cluster grounds. . . B–4 Check fuses in battery junction box. . . B–5 Check for harness traps in facia. . . B–6

Perform instrument cluster Self-Diagnostic

Mode/ETM test 3. Frost/ice warning illuminated in mixed red and

amber; therefore colour differs from other

warning lamps. When this test is ended,

warning lamps currently required to be 'ON' will

remain illuminated. . B–7

Check for open circuit/shorts in wiring to

related warning lamp trigger (module,

sensor, switch). .

Page 1794 of 3039

Area of

Concern/Symptom Diagnostic

Ref. No.

Actions

Notes . AA–4

Ensure only one key is in the vehicle, try

both keys in the Starter Control Unit (SCU). If this test starts the vehicle this tends to

indicate an issue with the keyless vehicle

module. . AA-5 Tried new key? . AA–6 Check battery voltage. . . AA–7 Diagnose non-start condition with IDS. . . AA–8 Attempt PATS key erase and re-learn.

Ensure keys are erased from current cluster if

replacing cluster. Crank but no-start AB–1 Diagnose non-start condition with IDS. Not usually caused by cluster issue. Incorrect configuration AC–1 Attempt to configure cluster. . . AC–2

Ensure battery voltage is maintained

above 12.5 volts if cluster re-configured. .

1. If the cause is not visually evident, verify the symptom and refer to the Self-Diagnostic Mode

Self-Diagnostic Mode

To place the cluster in engineering test mode (ETM) carry out the following steps

1. Press and hold the stalk trip cycle button, for more than five seconds but less than eight seconds, whilst briefly pressing the

vehicle START button. There is no initial display indication that the instrument cluster has entered ETM. If ETM has successfully

been entered then 'ENGINEERING TEST MODE' will be displayed in the Message Centre when the stalk trip button is released .

2. To navigate forward through the instrument cluster Self-Diagnostic Mode tests, press the stalk trip cycle button.

3. Each push of the stalk trip cycle button will advance one step through the ETM sequence. It is not possible to move

backward through the test sequence.

4. To exit the Self-Diagnostic Mode press and hold the stalk trip cycle button for more than three seconds.

5. The Self-Diagnostic Mode is also deactivated when the ignigition switch is turned to the 'OFF' position or low battery voltage

is detected.

6. If the Self-Diagnostic Mode cannot be accessed repeat the above paying particular care to the sequence timing.

7. The ETM text is not language configurable and will be displayed in English.

ETM Test/no. Message Center Display Gauge/Indicator/Display

Tested.

Range

Description 1 - Self-

diagnostic entry. ENGINEERING TEST

MODE. .

Not Applicable

(N/A). Establishes Self - Diagnostic mode. 2 - Gauge

sweep. GAUGE SWEEP.

Tachometer and speedometer.

Gauges display current values

after test. (N/A).

All gauges go through a full up and

down pointer sweep smoothness

check. 3- Warning

lamp LED's. TELL TALE TEST.

All internally controlled

lamps/LED's regardless of

software configuration. (N/A).

Illuminates all the LED warning

indicators that are controlled by the

instrument cluster. When this test is

exited current vehicle warning lamps

will remain illuminated. 4 - Version

information. PROGRAM VERSION.

ROM: XXXX

NVM: XXXX

REV: XXXX

DATE: XXXX Software Read only memory

(ROM) and Non volatile memory

(NVM) version and date. (N/A).

Display's the instrument cluster ROM

and NVM level version and date or

indication of ROM checksum fault. 5 - Message

Center display. LCD display in

WHITE. Message center LCD display. (N/A).

Activates all pixels of LCD display in

White. 6 - Message

Center display. LCD display in DARK

GREY. Message center LCD display. (N/A).

Activates all pixels of LCD display in

Dark Grey. 7 - Message

Center display. LCD display in LIGHT

GREY. Message center LCD display. (N/A).

Activates all pixels of LCD display in Light Grey. 8 - Message

Center display. LCD display in four

bands black to white, top to bottom. Message center LCD display. (N/A).

Activates all pixels of LCD in four

bands from black to white, from top

to bottom. 9 - Message

Center display. LCD display in four

bands dark to light

left to right. Message center LCD display. (N/A).

Activates all pixels of LCD in four

bands from dark to light, from left

to right. 10 - Digital

I/O. DIGITAL I/O.

A: XXXX

E:XXXX

B: XXXX

F:XXXX Cluster configuration settings. (N/A).

Display Hex coding of cluster

configuration settings ports A to H.

Not defined for diagnostic purpose.